-

Posts

5,453 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

I have been trying to find some sort of a chart with several manufacturer of paint for matching. Then I stumbled over this website, where you can enter one manufacturer and get a comparison of another brand. Hopefully this would make it easier when finding paint for our kits. Vallejo color chart Any comparison is possible. Upload a picture and use it for reference is also possible. Enjoy!

-

Micro Combo Saw, from Unique Master Models

Nirvana replied to Mahuna's topic in Modeling tools and Workshop Equipment

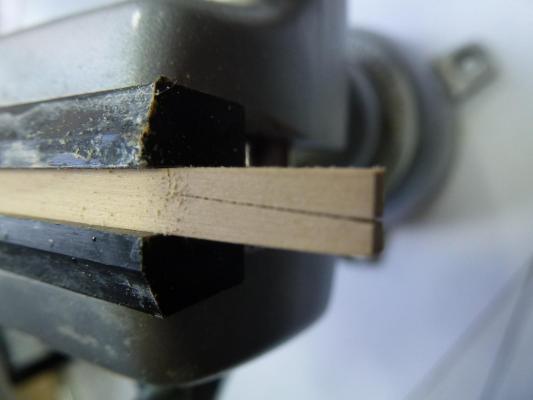

This micro saw is an amazing little tool, bought it about 10 month ago. Have used it when cutting the keel for the longboat. At 16 dollars for the big set from UMM (when I got it) you can't go wrong. Buy extra blade when you get it! This pictures is from my building of the longboat and the new keel, material from Jeff at HobbyMill. The first one, showing the extreme fine cut it makes, second the scarf. -

Matti, Happy Birthday or we say in Sweden, Grattis på födelsedagen. Don't let a birthday stop you from continuing to work on Vasa unless you have a big party.

-

Matti, Vasa is coming together amazingly, your eye and skill for the products makes her justice. I am surprised you haven't been approached by Billings at this time for creating better instructions. I think their representative for the US/Canadian market is viewing and scanning NRG's MSW, as I were approached regarding my upcoming build of Danmark. This is when BB also is Beautiful Built

-

Augie, Another admirer to that decking. That's amazing shine. Enjoy your vacation and your Confederacy will be waiting.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

General Scroll Saw use

Nirvana replied to jdbradford's topic in Modeling tools and Workshop Equipment

kurtvd19, Thanks for the plexi info. -

Just Beautiful! What a wonderful job you have done so far.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Pete, Very impressive! Both the build log and pictures from the races.

- 220 replies

-

- finished

- volvo open 70

-

(and 1 more)

Tagged with:

-

Sorry to change the subject for a short time, I had a Red Maple 4 shell 8-piece 1976 Ludwig Classic while living in Sweden. Miss it tremendously... Hailing from your starboard (Cheney, WA) Enjoy the gig tonight. My son lives in Seattle and also have a friend there. Visiting Seattle from time to time.

- 308 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

Steve, That's an interesting ship I have an eye on as well, however I am in a non-buy situation. The admiral has stipulated no more kits until I have some done. And yes there are some waiting in the yard. Btw, from the other side of the Cascades, A warm welcome to NRG's MSW. Is that a DW set?

- 308 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

Pete, I wonder if it may be a spring-loaded feature as it goes in very quick. I don't see the purpose of using servo in this matter. Would be too slow. But that's just my two cents.....

- 220 replies

-

- finished

- volvo open 70

-

(and 1 more)

Tagged with:

-

Pete, I also checked the stockmaritime and their boats, however the price tag was on the higher end, starting at 2000 Euros.

- 220 replies

-

- finished

- volvo open 70

-

(and 1 more)

Tagged with:

-

Michael, 1.5m! I like that idea. Just imaging a race with ten of them! Powerful!

- 220 replies

-

- finished

- volvo open 70

-

(and 1 more)

Tagged with:

-

Pete, WOW! The real pictures along with your build log. Like it, Like it and Like it! Now I wonder how to convince you to share the plans as I like to build one, for RC purpose. There is one boat available from Kyosho or ThunderTiger but I prefer to make to one meter length.

- 220 replies

-

- finished

- volvo open 70

-

(and 1 more)

Tagged with:

-

Remco, I think you got us all with this one...... Improving!?? What and where, think none of us has found any area that needs improvement. Stunning!

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.