-

Posts

5,453 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

www.pssm.club

-

Welcome to MSW StebbinsTim, there are quite a few people from PNW joining in the past. Yes, there is PSSM (Puget Sound Ship Modelers) meeting up every month. Again, Welcome to MSW

-

Alan, use hardened steel nozzle they are better and long lasting.

- 460 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

Alan, this is looking very nice. How did you create the davits?

- 460 replies

-

- Finished

- Flower-class

-

(and 1 more)

Tagged with:

-

HSwMS Äran by Nirvana

Nirvana replied to Nirvana's topic in - Build logs for subjects built 1901 - Present Day

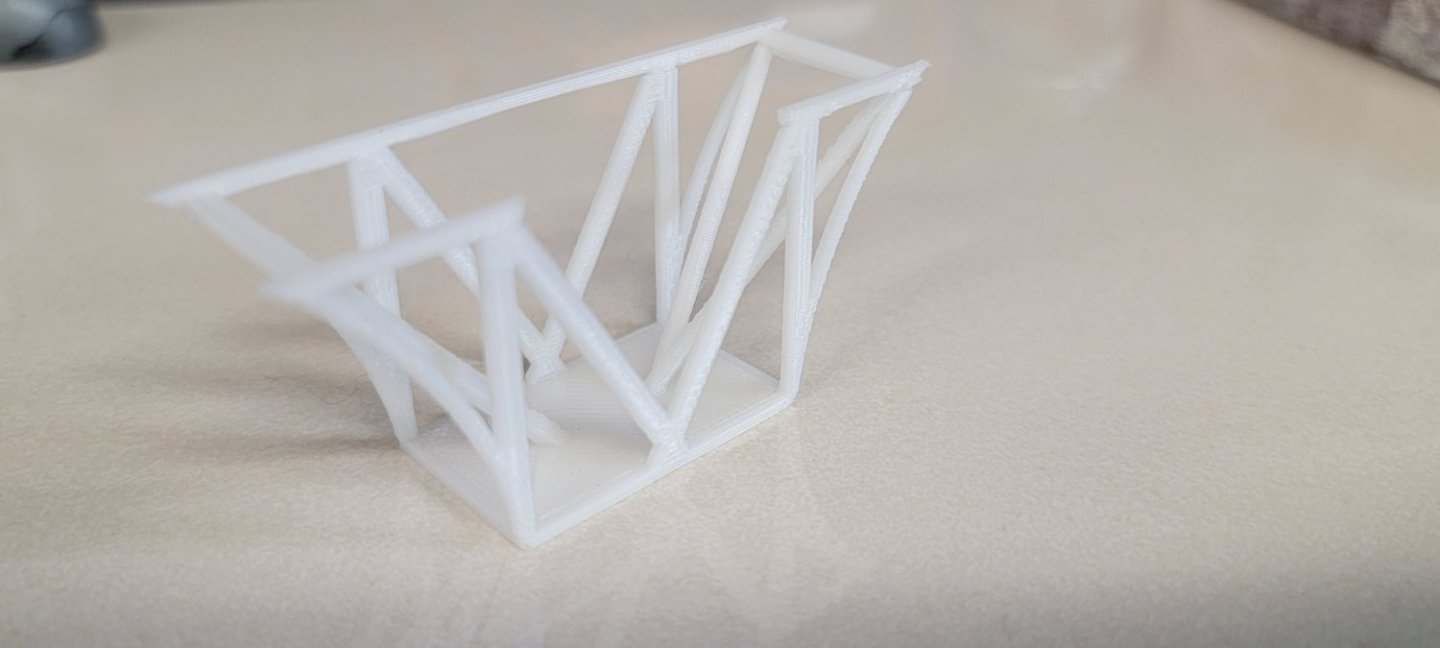

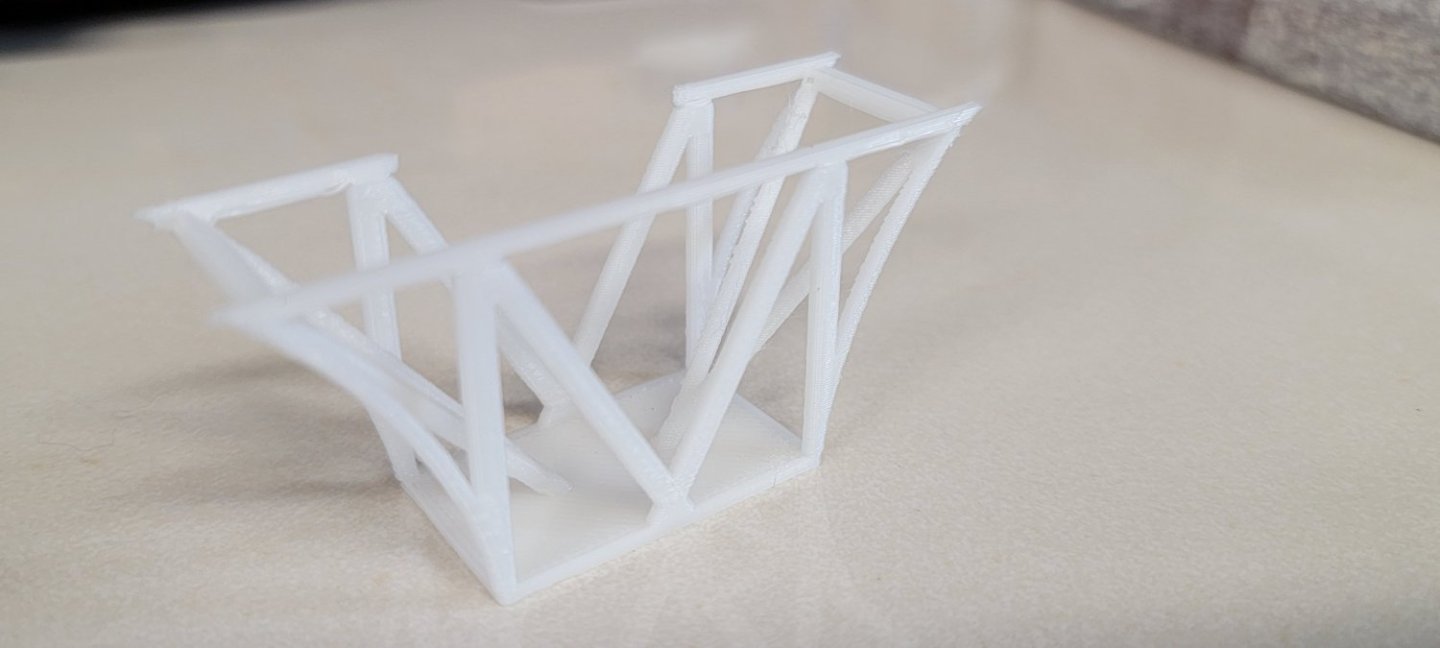

So I got the 3d printer built and tuned. Did my first serious print of the searchlight superstructure. No support needed! -

I am done with power tools; I have what I need as my arsenal was completed last weekend when my Admiral picked up a Craftsman 9 bandsaw for 50 dollars at a nearby estate sale. Bandsaw Byrnes Table saw Byrnes Thickness sander Byrnes Disc sander Generic scroll saw Dremel corded and re-chargable drill Dremel Lathe Ender 3 V2 3d printer Airbrush And yes, I do use all of them.

-

Rich, I hope you have a window, because I didn't have any cooling in garage until lately. The two windows I have in the garage is facing south and west, in my building corner. And made it unbearable to be in during summer time. There are various brands out there, so do your research. Then I got this and it works wonder.

-

I will definitely try this as well. Good for cramped spaces.

-

Air Compresser

Nirvana replied to Guyuti's topic in Painting, finishing and weathering products and techniques

Guy, I would recommend a small hobby compressor with tank, like this There are so many various brand names of these units, most important is the airbrushes themselves. The more you pay - the higher quality. Good luck. -

Chris, warm Welcome to MSW and yes I like to second what steamschooner wrote. Contact us at Puget Sound Ship Modelers, PSSM. You can also contact me as I am the editor for the news letter. Twice a year we are meeting at Foss Waterway Museum.

-

Ange, I truly like the build log of yours, very nice done and having Atlantic as a comparison model for size. I have Constructos America on hold, hoping to give her the same love and attention you have done to yours.

- 37 replies

-

- BlueJacket Shipcrafters

- America

-

(and 1 more)

Tagged with:

-

Radek at HiSModel.com and the decks seems to be superior to the deck I got. Besides he also offer so much more of aftermarket items for the ship.

- 446 replies

-

- Revell

- Constitution

-

(and 1 more)

Tagged with:

-

Bill, here is the link from AL with the plans for download. There are four of them. You need to download the jpg's and save to a thumb drive, then take it to a print shop. They will be able to print them at 100% as the pre-view are at approx. 30% Good luck with the build.

-

Greeting from Pennsylvania

Nirvana replied to New England Captain's topic in New member Introductions

Andrew, my best welcome greeting to you.... trying to outshine the other greetings....😆 Don't know if I did so, but now you are one of us. Hope to see your build log soon. -

Coming into ship modelling from a unusual angle

Nirvana replied to von_bednar's topic in New member Introductions

Witam, warm welcome to Model Ship World. The 3d printed steam ship SS Venture seems like a fun project. Did you have to scale it up? And yes, even I have ordered Paper card models from Poland. Mine are from JSC, got the Swedish fleet. -

Hello from Canton Ticino, the Italian Land of Switzerland

Nirvana replied to Piero52's topic in New member Introductions

Piero, is that a version of Peter? Anyway, a warm . I am glad you have your ship (or part of a ship) narrowed down. And it's never too late to fall in love again. Since I didn't know exactly where you are located, I looked it up...... and I have to give to you. It's just stunning beautiful! I am in awe. (For all other members look up this location, I could spend a lot of time there) -

Ed, just stunning! So, I take you will get going with Rattlesnake soon.

- 96 replies

-

- model shipways

- bluenose

-

(and 1 more)

Tagged with:

-

Very well done! Congrats to the final! Now what is remaining is a case!

- 96 replies

-

- model shipways

- bluenose

-

(and 1 more)

Tagged with:

-

New to modeling - wish I found this site earlier

Nirvana replied to flutlo6180's topic in New member Introductions

Ken, a warm -

HSwMS Äran by Nirvana

Nirvana replied to Nirvana's topic in - Build logs for subjects built 1901 - Present Day

Paint job is much of a guess work with little history of ships of the time era. Thank you, Andrew, for the encouraging words. -

HSwMS Äran by Nirvana

Nirvana replied to Nirvana's topic in - Build logs for subjects built 1901 - Present Day

-

HSwMS Äran by Nirvana

Nirvana replied to Nirvana's topic in - Build logs for subjects built 1901 - Present Day

New ESC's was ordered yesterday. New computer TX to be ordered today. Sadly, I have had such a great experience with the Spektrum brand (yes, it's expensive) but that's what I am going again. -

HSwMS Äran by Nirvana

Nirvana replied to Nirvana's topic in - Build logs for subjects built 1901 - Present Day

Working with ESC and not checking polarity can be hazardous, as I experienced. Burned out one of them. And I also learned the motors has a tremendous torque. Today I am working more on the details, painting and assembling of turrets. Outdoor temperature makes the curing time very short. Each turret and cannon consist of 8 parts.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.