-

Posts

5,453 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

Arthur, don't stress and push to get things done. Here is very example to stop,don't glue anything into place. Take pictures for us to look at so we can help.

- 11 replies

-

-

-

Home depot of all the placed....😀

-

The dowels I am working with are oak.

-

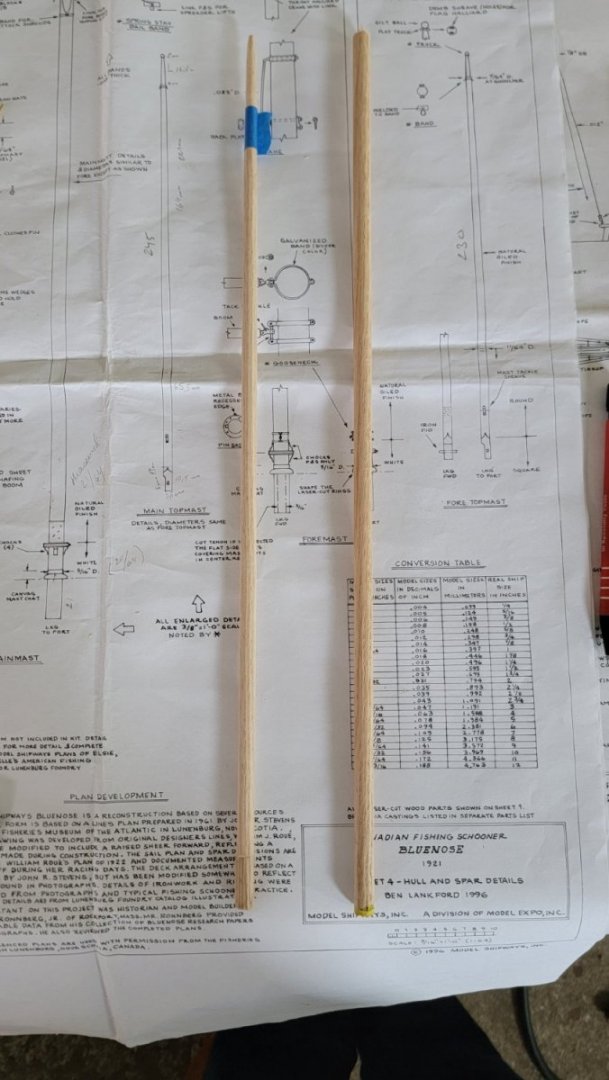

I headed over to one of the local hardware store to get new dowels for the masts of Bluenose, I went with round dowels from start. I had to go through some 26 dowels to find myself 4 usable straight once. I placed them on the floor and if they could roll without any major effort they were fine. Sighting from one end to another didn't show any warp at all. These dowels are larger than what plans says so there was a lot of sanding to get the proper shape. And yes, I put the dowel in my power drill and sanded it by hand. I use a leather glow that holds the sandpaper, this to avoid the heat build up from the turning.

-

Arthur, first of all - A Warm Welcome to MSW! I am glad you got the Bluenose as a starter. Yes the dowels for the mast and booms are a disaster in the kit. Mine was badly warped as well - and today again - I went to my hardware store and got some straight dowels. This to start all over again with the masts. As for the Bluenose herself, I would suggest to get going with her before attacking the dories. This will give you the skills to handle the smaller and more delicate items in the kit. However I am looking forward to see your progress, and if you have questions - don't hesitate to ask!

- 11 replies

-

Ed, I wish I could and a wow to the like. This is so much better than the instructions provided from MS. I might go back to the table and redo everything regarding the rigging.

- 96 replies

-

- model shipways

- bluenose

-

(and 1 more)

Tagged with:

-

Bluenose II copyright infringement lawsuit

Nirvana replied to Nirvana's topic in Nautical/Naval History

Allan, the amount to the family was 300000 dollars! -

When the Bluenose II was built back in 1963, the family of the original Bluenose saw it was a direct copy of the original ship. This led to a lawsuit started in 2012. So it's not only our models that becomes victims of IP theft. I haven't found any records that the case is close, but considering the timeline I guess it has been closed.

-

Kevin, that's an incredible picture. The angle makes the ship to look much much bigger than it is, specially with your house in the background. If you wouldn't had the towel in the picture it would had been even harder to tell.

-

And with Heller's HMS Victory there are a lot of aftermarket parts available. Like better cannons, wood deck etc. Look at this website. Once I am embarking the journey of building Revell's Constitution many items will be come from that place.

-

Ed, your building documentation will certainly help me and future builder of Bluenose. I am working on my masts.

- 96 replies

-

- model shipways

- bluenose

-

(and 1 more)

Tagged with:

-

Jim, I planked the lower deck and used 2b pencil for caulking. However, 2b pencil do smudge badly if not careful. Looking good and it brings back memories of my build.

- 15 replies

-

- Artesania Latina

- Marie Jeanne

-

(and 1 more)

Tagged with:

-

That's why I bought some lego squares, rectangulars. It has helped me.

- 15 replies

-

- Artesania Latina

- Marie Jeanne

-

(and 1 more)

Tagged with:

-

Air brush vs paint & brush

Nirvana replied to jefferyt's topic in Painting, finishing and weathering products and techniques

In the latest issue of the Nautical Research Journal, Kurt Van Dahm has a very nice article when it comes to maintaining your airbrush, sure this is written with his experience of the Badger brand. But what he writes is applicable to any brand. Well worth reading. Thank you Kurt, this will help me. -

Amalio, what is the finest grit of sandpaper you use in order to keep the material so "fuss-free"? This is art not shipmodeling at my level. Beautiful done!

-

Zeno, One method used by many of us when it comes to bulkheads ( and yes, the less "play", the better) is using lego bricks to get perfect 90 angle between bulkhead and false keel. This can also help to straighten up a lightly warped keel. You will find out that clamps are a very good friend to get items secured while waiting for glue to dry.

- 15 replies

-

- Artesania Latina

- Marie Jeanne

-

(and 1 more)

Tagged with:

-

Maybe a sherline mill isn't so expensive after all, take a look at this unit!

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

My bowsprit is all done by hand, lots of sanding and manual carving with knife. Not as beautiful done as yours but I think it will pass for a less picky eye than mine.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.