-

Posts

5,457 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

A Lorch Micro-Mill that never was ...

Nirvana replied to wefalck's topic in Modeling tools and Workshop Equipment

Now, that makes the mill even more impressive! -

A Lorch Micro-Mill that never was ...

Nirvana replied to wefalck's topic in Modeling tools and Workshop Equipment

Weflack, Are you creating this little mill from plans or is this just all from plans in your head? I am so impressed! -

Hi Sarah and welcome back along with your Longboat build. That frame support you added will keep the longboat strong while fairing the frames. It is well needed. I beveled the planks lengthwise for a tighter fit to avoid light coming through. I went along with Chuck's additional separate instruction using a hair-dryer or light heat-gun for bending and CA when it came to planking. Worked out really nice. However, your longboat is coming together very nicely and quick as well. We missed you at the annual PSSM BBQ in August. And that applies to you Harvey as well.

-

Herr Pucko, I am very pleased that the instructions are in Swedish as well. The detailing is amazing! Thank you for sharing.

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

Aydin, That looks so amazing. Very nice job!

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

Gråsäl (grey seal), I just found your restoration of Bluenose (jag såg din restauration av Bluenose) And as to me it seems to be an old AL version (för mig ser det ut som en gammal version of AL) However, the ship doesn't seem to be to damaged so it should be a fairly simply fix (däremot verkar det som att modellen är i ganska gott skick, så det borde inte vara så svårt att ordna henne) There are so many build logs of Bluenose, so you shouldn't have to many problems (Det finns så många olika byggnationer av Bluenose (både orginal och version II) så det borde inte vara några problem för dig. If you have any sort of question in with Bluenose, this is the site! (Om du skulle hava någon fråga beträffande Bluenose, så har du hittat rätt!) Good luck to you work - looking forward seeing more!

- 30 replies

-

- bluenose

- billing boats

-

(and 1 more)

Tagged with:

-

Mr. Pucko, I hope you didn't choke on the chocolate drink when you realized it. I wonder if there is an error in the laser cutting?

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

Bill, There are ship parts in the pictures. Guess you got caught by the "surprise"

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

Very nice! Looking forward to seeing what is next in the building line.

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

Thank you Chuck, I appreciate your fast answer. I was suspected the 24 but wanted to be sure.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Can anyone shed some light regarding the oar locks as these are supposed to be made out of 26 gauge black wire. The material list only shows 24 and 28 gauge. Which size has been used on others longboat?

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

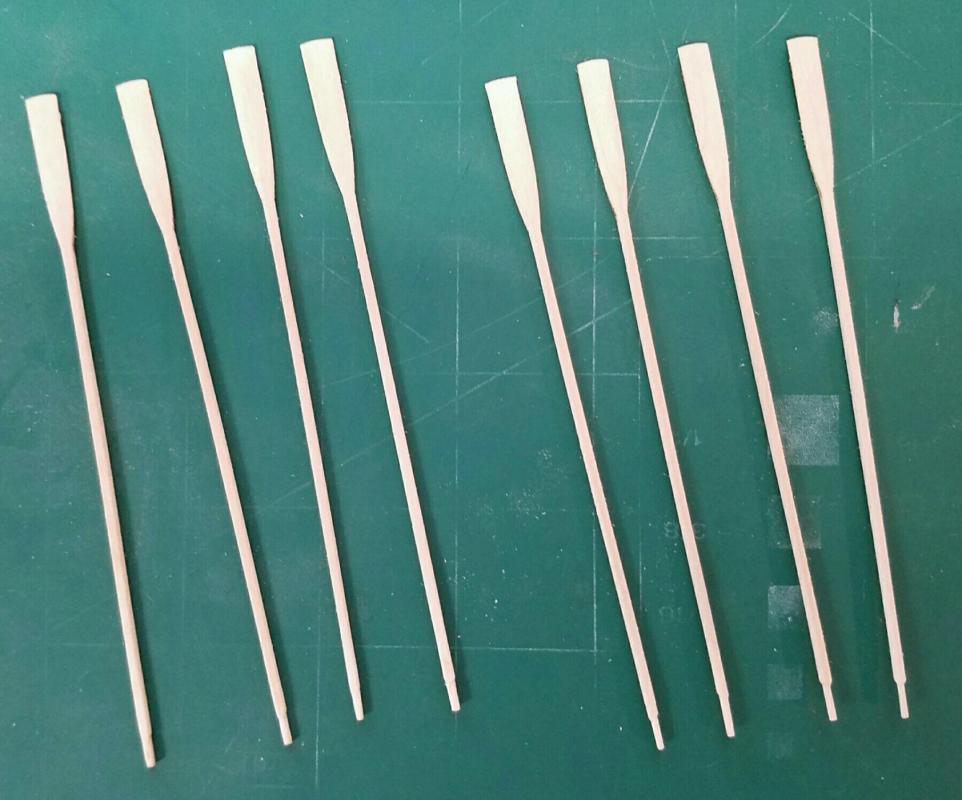

As I stayed Sunday with intention of heading home Monday morning, this allowed me and Floyd to work on our longboats. So, yes I made the oars for both of us. A set of for each.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Tools and Supplies for My "Shipyard"

Nirvana replied to daveward's topic in Modeling tools and Workshop Equipment

Toni, Somewhere in our forum there is a topic regarding "Bondo" with the recommendation to stay away from it. Elmer's Wood putty do work. -

Tools and Supplies for My "Shipyard"

Nirvana replied to daveward's topic in Modeling tools and Workshop Equipment

Kurt and Dave, Many times when it comes using the optical visor of some kind we will experience a light issue. This to illuminate the work we are doing using the visors. For the mentioned visor there is something to consider and that is the led attachment. I have another type of visor that I am not happy with so, I thank you for this lead. -

Aydin, That decking is looking fantastic, I hope you used epoxy for laying the strips. Or are you to cover the deck with fiber-glass as well? I am concerned you will have issues with the water otherwise. It would be such a shame if you get problems. Have you done any interior water protection at all? I hope you have as you have put down the deck already. Everything needs to be protected, sadly to say but necessary since you are to RC her.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

Aydin, Applauses for a wonderful build. Looking so good.

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

Question not related to the Bluenose but the dremel scroll saw. One local second hand store has the old one at 80 dollars plus tax. Should I pick it up? For the Bluenose build, I like it it very much. One step plus one and then it will be more than two.....

-

Model Machines Disc Sander for sale

Nirvana replied to Byrnes Model Machines's topic in Modeling tools and Workshop Equipment

Wow that was fast, Less than two hours - too bad I was engaged with vacuuming the house otherwise I would have had it! Congrats Pete!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.