-

Posts

5,452 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

Scratches on plexiglass can be buffed out, using fine compound for cars. Well depending on the depth of it.

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

The instructions tells me it is time to consider type of pedestals and base. Considering the size of the longboat, I am making the base small, and using brass as pedestal. Pictures will follow. Picked up the material from Hobby-Lobby.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Chris, Those bulkheads has very little space between them. Looking good!

- 54 replies

-

- glad tidings

- model shipways

-

(and 1 more)

Tagged with:

-

So true!I am using the ropes from Syren for my longboat.

- 54 replies

-

- glad tidings

- model shipways

-

(and 1 more)

Tagged with:

-

Downside with acrylic, not so scratch resistant. Downside with glass, can break and shatter.

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

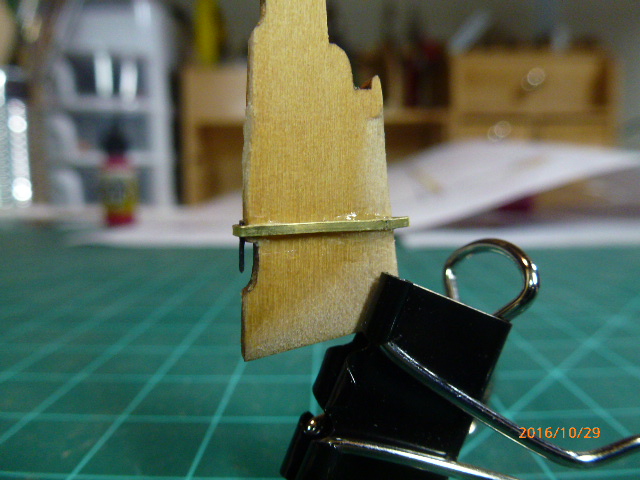

Well, it's called trial and error. I'm currently working on set three of rings and bands. It's the drilling that destroys some of them. Getting there anyway.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Mr. Pucko Two words. Great work. Now we want more.

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

That's a very nice rudder installation. Well done and it gave the idea of using that system.

- 245 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Well, I used my five minutes this day (turned out to be fifteen but still), and made the iron rings for the top blocks. Another step forward.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Jerry, It would be a shame installing false keel, but maybe the only option. Or are you able to fill the hull with lead ballast enough to prevent any "maiden voyage accident".

- 97 replies

-

- macedonian

- frigate

-

(and 2 more)

Tagged with:

-

This is like waiting for a good Jack-in-a-box, and I am not talking about food.

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

HKC, Is the whole unit 7mm (that including the eye at the end)? If so, you can get 6mm blocks from Syren and make the end eye yourself with wire. Anyway, this is probably the best way for you to get blocks, just my two cents. Good luck.

-

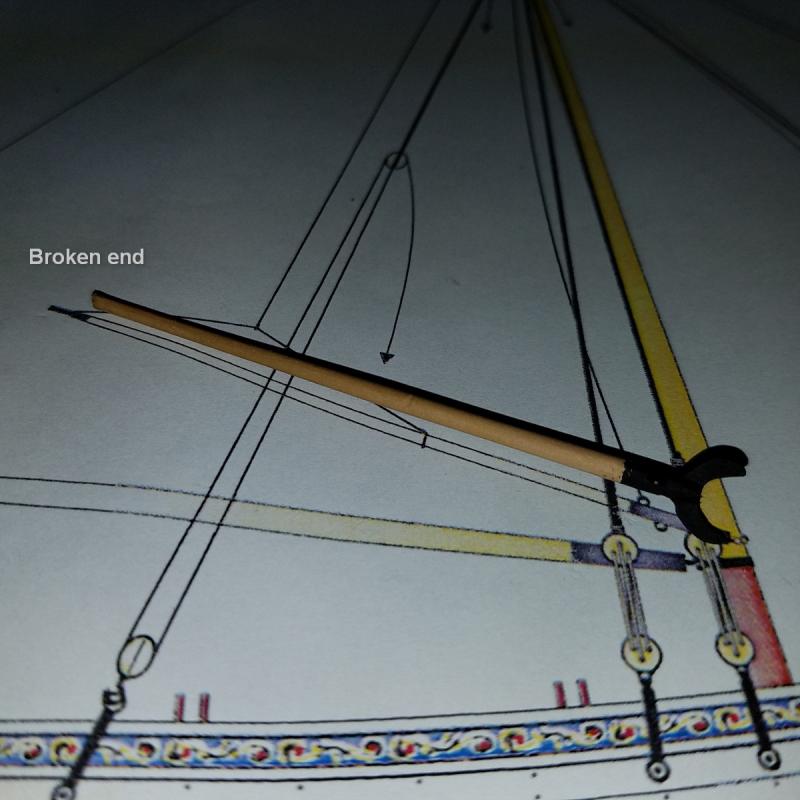

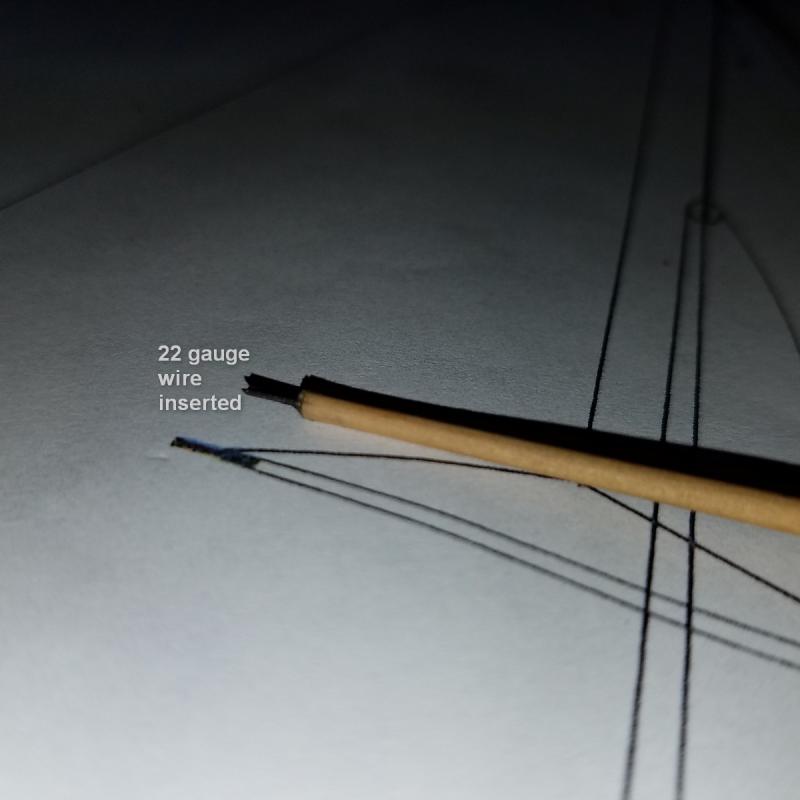

Even though I don't have much of pictures to present at the moment, I have been working on the longboat. One thing that happened was the tip of the gaff got broken. It was an easy surgery.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Greg, When I planked the AL 1851 America, should had been double planked I used nails, that I inserted half way to keep the plank in place while the glue was drying. Once dried, I cut them off at the plank area, a little tap on top of that and the nails were as good as invisable. Specially with paint job on top of it. To conclude my input, when I started building America, I didn't have any CA glue which helps tremendously when it comes to planking. And I didn't add on with a second layer. Carl said, "Will you start a build log?" I would suggest " You start a build log, if you running into problems - just highlight them and you will get helped. Oh, I forgot the most important part, A warm

-

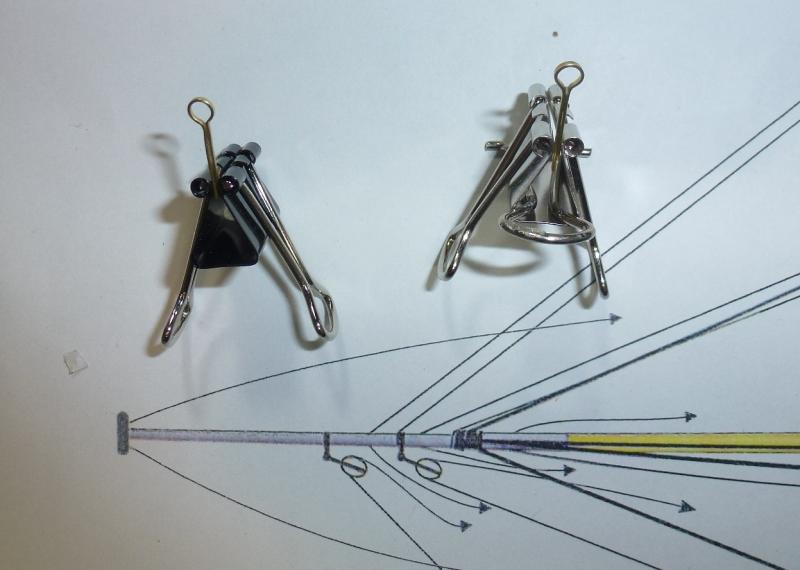

Maury, and you have evidence with pictures that it's there. Love those clamps too. Just like your Emma C this looks amazing.

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

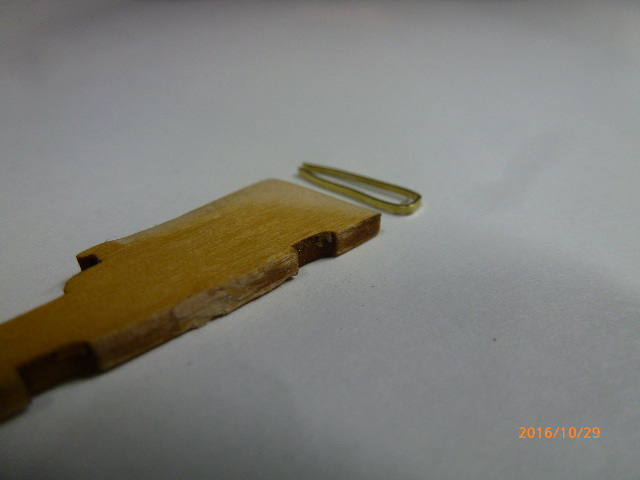

Lots of progress today. Rudder is ready for painting, It was tricky to get the pintles and gudgeons right, but after some work I got it right. But getting the eyebolt done was a pain.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

The rudder is now shaped and so is the tiller. I predrilled the whole for the tiller and then used a flat pointed file to open up for the insert.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

I am cursing myself, because I have lost plan one along with a box with material for the longboat. Have no idea where it all is, so I am working from plan two and the instructions.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.