-

Posts

2,863 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

What about using these replacement erasers on the end of a dowel? Integra Pencil Cap Eraser for Standard Pencils, 144 per Box, Pink (ITA36523) https://www.amazon.ca/Integra-Pencil-Standard-Pencils-ITA36523/dp/B00181LCHU/ref=sr_1_6?crid=47MKFGNSI70S&keywords=eraser+tips+for+pencil&qid=1647134226&sprefix=eraser+tips+for+pencil%2Caps%2C167&sr=8-6

-

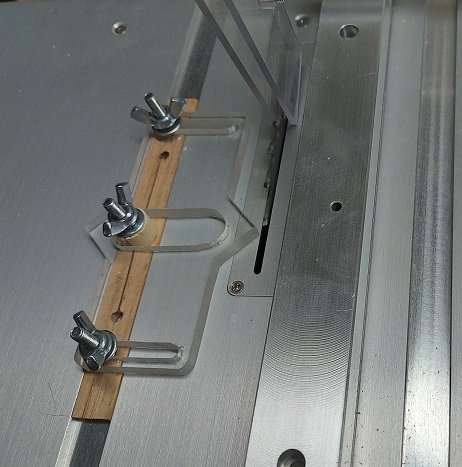

Does the thumb screw on the end of the post move at all with the passing of multiple strips over time? Your and Michael's design has some merit to it. My posting #1277 (8 JAN 22) in my build log shows an image with drawings I made. I'd be happy to send you a PDF copy. Kurt says the NRG are looking at selling a simplified version (mine was a combination of his and John's versions) sometime soon.... he is getting pricing for the bits and pieces. If I were to do mine again I'd likely make it at least 1/4" wider.

-

I will post the one image showing the sheave in use later this morning when the noise of the scanner will not wake up Her Majesty. Also, I just sent you a PM regarding the other information. Alan

-

Sorry, I assumed most vessels from the late 1700's through the 1800's would be rigged somewhat similarly so all sailors would be familiar with it regardless what ship they transferred to. I am probably wrong. I did not expect you to have the books I mentioned in your library, hence I asked if any information I had mentioned was of any interest to you. I understand it is not. I hope someone knowledgeable steps up and you find what you are looking for! Good luck Commander.

-

The Fully Framed Model by David Antscherl (Swan class Sloop) has these sheaves. Modelling the Brig-of-war "Irene" by E W Petrejus does not show any. The Brig Niagara (on Lake Erie) does not have these.

-

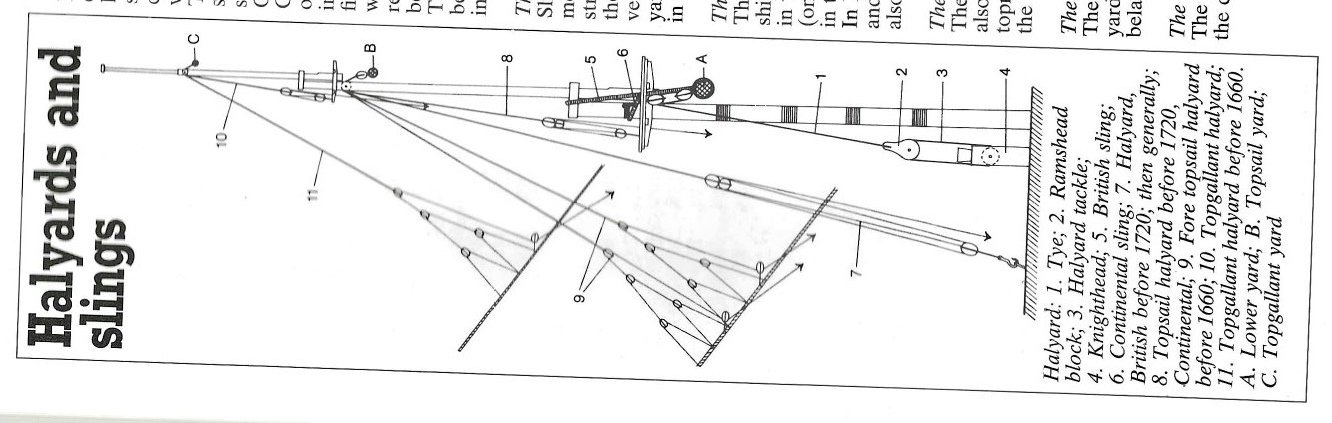

Have you Harold Underhill's "Masting and Rigging the Clipper Ship & Ocean Carrier" ? Fold out Plate 51 (pages 281 through 290) show all 135 belaying points for all lines. But I have not noticed any details on fife rail sheaves. Edward Hobbs' " How to make Clipper Ship Models" has very informative fold out standing and running rigging plates (III & IV) But once again nothing noticed regarding fife rail sheaves. Wolfram zu Mondfeld's "Historic Ship Models" pg 310 has a figure showing the lowest heaviest yard halyard running down to a ramshead block where it and the sheave in the fife rail act as a block and tackle system to provide additional mechanical advantage to raise/lower the yard. Are an of these of interest to you?

-

Thank you for posting these. Very interesting. I never knew they were soaked, heated and widened.

-

Ropewalk: A Cordage Engineer's Journey Through History

AON replied to BenD's topic in Nautical/Naval History

It is interesting for the purist to note that none of the ropes are BLACK or WHITE. Even the 4 strand tarred rope is not BLACK. -

The Fully Framed Model (6th Rate), vol 4, pg 44 - served all over The Anatomy of Nelson's Ships (1st Rate), pg 226 - seized at the bight at the heart and another at the foreside of the hole at the in the knee and a third at half span between the other two. Historic Ship Models, pg 276 - the two parts were seized together in several places

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.