-

Posts

2,867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

I completed my mast calculations and came to the conclusion that, once again, Mr. Steel and his rules do not agree with his plates of tables and scaled diagrams. Knowing no one will be taking a measuring rule to my build the yard will likely be applying the "good enough" rule. PDFs of my calculations and a summary spreadsheet are attached for those interested. My mast, trees and tops drawings are in progress and will be posted later. AND... one of our local club members agreed to 3D Resin print my swivel guns from my model! (fingers crossed that they turn out wonderfully) Hope everyone had a safe Christmas holiday.... and have a safe New Years celebration. mast dims summary - spreadsheet.pdf Lower Mast Calculation.pdf

-

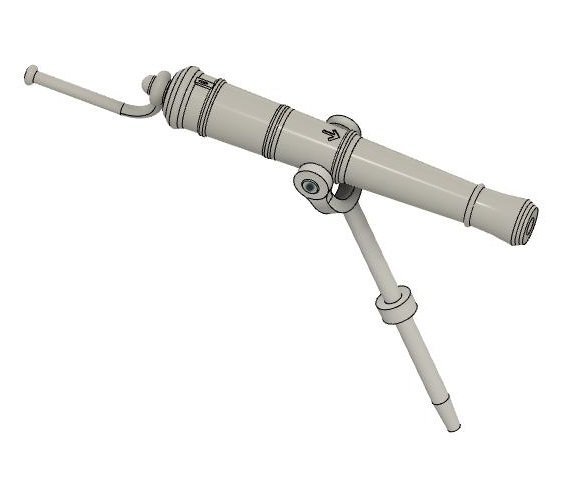

As I am staining the leaves for the Library display I cannot afford to stir up any sawdust from my shop so I decided to go back to my computer and work on my made fore and mizzen masts.... but before I start that I modelled my 1/2 pound (1-1/2" bore) swivel gun for my fore and main tops (platform). Originally I saw these as 16 inches long but that was from one reference, a Battlefield 18th century swivel gun manual printed in 2016. Lewis and Clark had a 1-3/4" bore 22" long barrel swivel gun in 1804. It's just that everyone I talk to suggests naval guns we scaled down in size so my 1/2 pdr would be 27 to 30 inches long following that train of thought. At 1:64 scale that makes it just under a 1/2" long! Now to see if they can be resin printed as my other cannons were done.

-

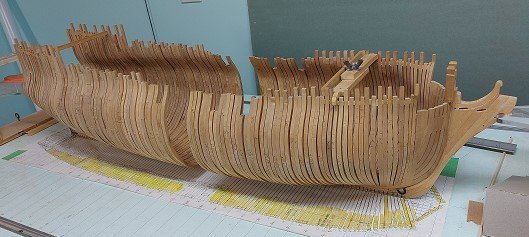

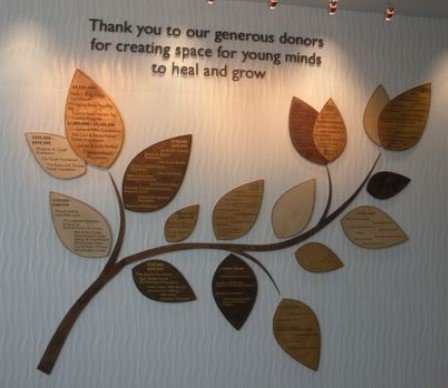

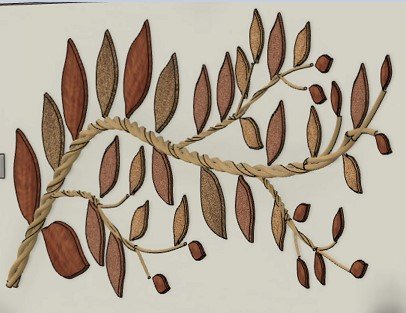

Year end update? My build progress to date: Only a few frames to go. If you've been following you know I've also worked on the figurehead, bowsprit, jib boom and associated yards, the rudder and the main mast and tree. But I am again distracted. I volunteered my time to make a donor wall display for our local library. They wanted something like this. But I proposed this. And I am presently sanding the leaves (yuk). The edges have been bevelled (45°). They will be stained (3 different stains for variety) and sealed. I made card stock templates to locate the hangers so they each dangle at their proper angle. 2" synthetic manila rope for the main branch, 1" for the off shoots to be spliced in. 2 ounce waxed whipping will be used for the sailmaker's whipping to finish the one base end and common whipping for everything else to keep things tiddly!

-

Really enjoyed watching you win that battle! Jazz... I couldn't help but focus on the birds in the background. It is -3°C here in the Niagara Falls area (-35°C a bit northwest of us - Thunderbay, Ontario, Canada) All our birds are hunkered down waiting for the sun to pop out.

- 1,129 replies

-

a ready made rolling table! waste not, want not.

- 1,129 replies

-

It's like building an igloo (with dirty snow)!

-

Good afternoon "Flyer". I am very interested in following and understanding your rigging of this ship. I appreciate your comment about the Preventer Stay rigging changing in 1793. This will be very helpful to me. I presently have one question: what do you mean by the statement of "The futtock shrouds have a strength of 1 mm"? Did you mean diameter?

- 366 replies

-

- bellerophon

- victory models

-

(and 2 more)

Tagged with:

-

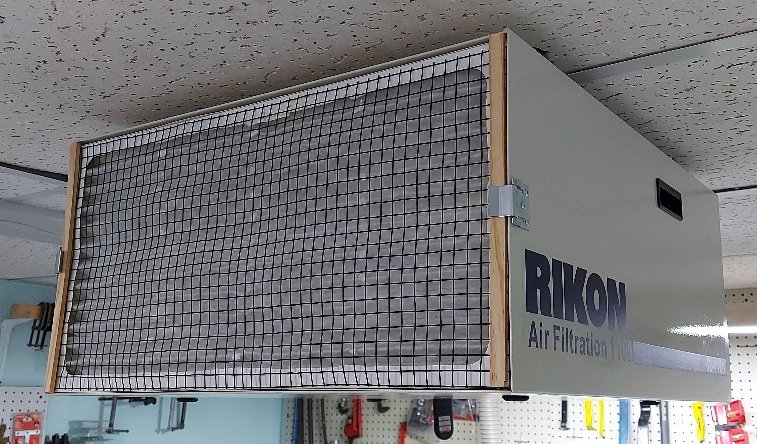

I don't like to waste money replacing perfectly good filters. But the design of these pleated filters with crossing cardboard retainers makes it difficult to vacuum the filter clean even with a crevice tool. So I modified it. Removing the cardboard cross pieces and replacing with a removable thin wire screen (to assure the pleated filter doesn't fall out) increased the open area by 19% (increasing filter efficiency) and makes access for cleaning much easier. Quite an improvement if I do say so myself.

-

McMaster-Carr https://www.mcmaster.com/number-drill-bits/

-

Just finished cutting the last of the square frame pieces moments ago. Now to fit, and assemble, and install, and move on to .... sanding. Also got a few new items for the shop. The ceiling mounted air filtration unit has be up for a couple days and it has caught quite a bit of the mess that use to migrated throughout my basement (and probably the whole darned house). The thickness sander, table saw and accessories came in early last week. They haven't been used yet, but very soon! The fees getting them across the boarder were outrageous... more than half the costs were Canadian taxes!

-

Archaeology of a 19th century Great Lakes shipyard

AON replied to JKC27's topic in Nautical/Naval History

Practically in my back yard. The site is next to the fire fighters training centre and the old sea cadet hall. -

Cheers from Port Hope, Ontario, Canada

AON replied to Peter Rumgay's topic in New member Introductions

Welcome to MSW Peter. If you're looking for a monthly live connection with other modellers there is the Model Shipwrights of Niagara (Niagara Region) presently conducting Zoom meetings. Next one is being held on Nov 21, at 1:30 PM. -

Welcome to MSW Paul. I understand there is a great modelling club in the Hamilton area (Confederation Marine Modellers) and then ours down in the Niagara Region (Model Shipwrights of Niagara) if your looking for a monthly connection!

-

Welcome to MSW from near Niagara Falls, Ontario, Canada. We were all new once.... and some of us still don't know what we are doing! (that would be me more than half the time)

-

Try a black permanent marker. Check that it doesn't rub off with your finger.

-

I've found that LOS does not seem to react with brass. Bill wrote that it takes a long time. If so it takes much longer than I am willing to wait. It works extremely well with copper.

-

Very impressive work Derek. Can't wait for the day I can come over and see it, or we get back to club face to face meetings and your bring it in to show! The one schooner I rigged (my first and only involved rigging to date) was quite relaxing work.... although I found the ratlines to become a bit tedious after a short while.

-

I make a scrapper and scrape the rabbet groove in. I was told to use an old metal saw blade. Heat it cherry red with a torch to soften (anneal) it (quench in cold water), and then file the desired shape into it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.