-

Posts

2,812 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

Thank you Druxey. The long 's' and I are very good friendf prefently.. When I sat down to start I made a decision on exactly how I would approach it and I was committed to correct each long 's' and so I have. Then there was 'rabbit' and 'fastned' and.... the list goes on. I am very happy I have done this otherwise the darn contract would still be a myftery. I found reading it was like reading The Last of the Mohicians... the longer I stuck with it the easier the language prose became. I will admit to being a bit hesitant to start gluing and pining parts.... but I can see myself starting very soon... visualizing. My son claims he found some thicker lath in his pile late yesterday so I will be remaking the parts I must in the knee of the head and stem pieces as I start gluing and pining them. Thank you all for following... it's going to get scary really soon. Alan

-

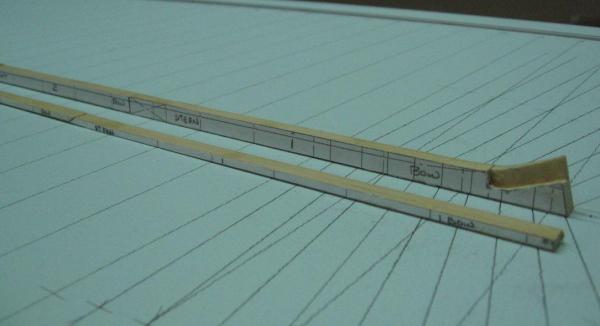

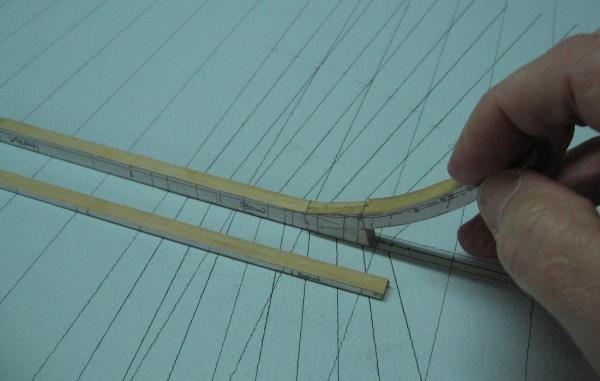

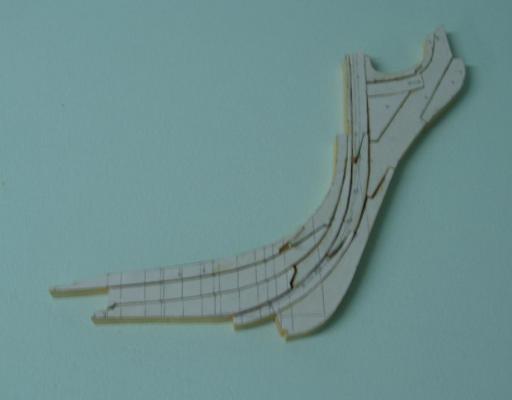

Today I cut and dry fitted the last two pieces of the stern deadwood and keelson (template items marked 9 and 10) I also cut two strips 8" thick (1/8" to scale) x 22" wide (0.3438" to scale) for the rising wood that sits on top of the keel. Actually my pieces are ever so slightly larger (approximately 0.01" in both thickness and width). They would need to be cut to short lengths with scarph joints. I will not do that until I am ready to glue and pin it together on the keel assembly. Today, I also remade my boxing joint piece. This would be the third time. I had trimmed too much on the upper scarph joint. I have also been busy doing something very constructive over the last two weeks. Never having been able to sit down and read nor understand the complete build contract I decided to transcribe it (type it out)... only the first 21 pages as the last few pages are payment schedule details that will not affect my build. I've added some spelling corrections for today in brackets next to the questionable words; below each paragraph I've added explanations and descriptions for unknown words or phrases and I've added reference books, pages, image information so when I am at the point in the near/far future I can find it again quickly. Presently I am transcribing page 20 of 21... this would be typed page 57 for me. I've attached a PDF of the first 3 typed pages to give a better sense of what I mean. Making Sense of the Contract.pdf

-

Joshua I typed in - Free Google E-Book and the following website popped up https://www.google.com/cse/home?cx=000661023013169144559:a1-kkiboeco I typed in a book name I wanted (example: Anatomy of the ship Bellona) and there it was about third from the top listed as free and downloadable Some books are not PDF but there are You Tube videos explaining how to convert the file to PDF Some books are not free but they offer viewing of pages... when I stumble on some pages that are useful I take take a screen snapshot and save it for reference. If the whole book seems really good and no free e-book version is available I will try inter-library loan (books are loaned to individuals from libraries across the nation (not sure if you have this available with you library system). It may take a few weeks but then I can view the whole book and decide if I it is indeed that good and I should purchase a copy. Presently the best real purchased books in my library are the 4 volume set of The Fully Framed Model. My copies are quite new but to look at them today you might think I've had them awhile. Alan

-

Good luck! let us know how your test run goes. Alan

-

Good morning Josua I use Draftsight every day and the free version is quite good but not perfect. I've been draughting in pencil since 1970 then switched to AutoCAD R12 in the early 90's, then Solidworks 3D and Inventor 3D. Had to take courses for all of them to be productive. Now as I said using Draftsight for straight 2D stuff. There are many other free programs out there and you will hear the same about them. I am sure some are better than others. I'd suggest you upload them and try them out. I imagine that if you have any level of experience in CAD draughting (drafting) you will be able to tell which you prefer fairly quick. If this is your first attempt at drawing in 2D with a CAD program, it is easier then it might appear at first, you will need a good tutorial to learn the commands. Apparently draftsight offers them, I've never looked at them. Alan

-

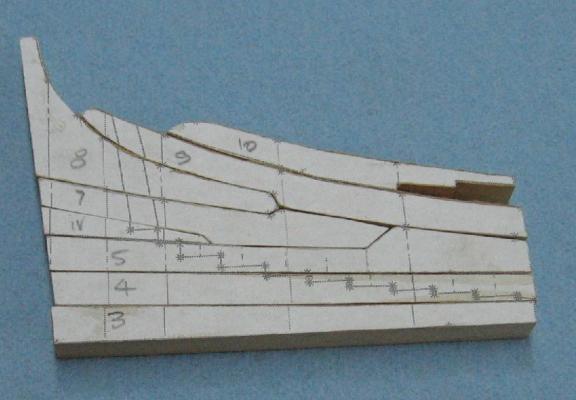

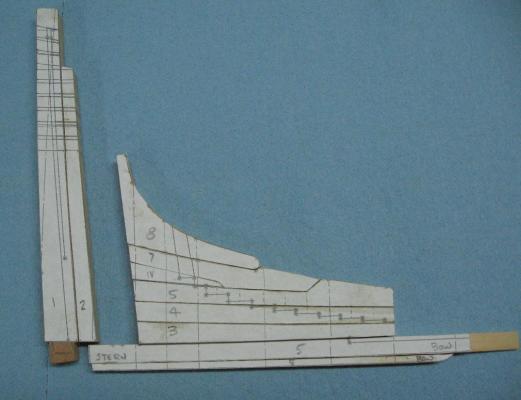

Below is the photo of last weekends Stern Post (1) and False Stern Post (2) along with the earlier Keel and False Keel Today I made the Deadwood pieces and the Deadwood Knee (8) with one piece left to fit above it. Hope to have it done tomorrow. You will note the one piece marked with the roman numeral (IV)... that's because I made this piece three times before it fit proper. That little wedge piece was a tough one to fit. I've to remake the Keelson pieces... yet to make the Rising Wood.... and taking a good long look at the Stem assembly pieces which were the very first parts made. I think I may take another shot at them as I've been doing a slightly better job lately. Milled down more hemlock lath but cannot seem to find another ceiling piece in the pile. Those are thicker (1/2") and will mill down to the necessary 26 inches (0.4063" to scale). Presently I am getting 24.8 inches (0.3875" thick). The ceiling pieces must be at the bottom of the pile, under the tarp, covered with snow in my son's yard. Somehow I don't think 1-1/8" inches (0.0188" = 0.46 mm) will make much difference in the end, but it would be nice to be a wee bit closer. Possibly I can keep the inboard pieces. I'll have to sleep on it. Oh yeah... the monofilament line came it and it looks good! Have to keep reminding myself to slow down as I am itching to glue something together.

-

You`re young yet wait when you get older and you`ll appreciate the magnification so much more!!!

- 962 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

I just cut and sanded the stern post and false (inner) stern post. Left some material at the bottom of the stern post for the tenon into the keel. The fit of these two pieces are perfect! (photos to be posted later) I have not tapered them as yet. I will wait until I have the stern post pieces together and then taper them as one. The stern post assembly is 1'-11" square at the head down to the deck transom, and then tapers to 12-1/2" on the keel The keel is 12-1/2" athwartships at the stern tapering from some "x" distance from the original 16" athwartships at midships. As this is a mere 1-3/4 inches of tapering of the keel per side, which equals 0.027 inches at 1:64 scale I am not too worried about where to start any taper as no one will likely notice it.

-

Short report of progress. Cut out the stern post, false stern post. deadwood at the stern and keelson pieces. By the time I was done a good portion is IMO no better than scrap. I should feel bad about it but I don't.... because I feel I can do a whole lot better. I learned a great lesson by it and am reminded of something I read here on another log: 'that you should treat each piece like a model'... so I will try a new approach. This morning I re-cut ALL the paper templates If time allows, as a good portion of Sunday is family day, I will mill a new piece of lath to the max width of the stern post. Then I will cut and finish one piece at a time. Concentrating on the one piece as there is no feeling of being rushed to get more than that one piece done.

-

Bob I would have responded earlier but I just saw your post. Up here in Canada you have to be a registered student to get a free copy When I was laid off a few years back for 18 months I had an in with the local representative and after explaining my situation and that I was trying to teach myself they mailed me a free copy. Alan

-

Ordered 30 lb black monofilament from E-bay as suggested by a follower earlier. (thank you!!) Even after adding in shipping and $US exchange it was cheaper than the big box stores up here! The smaller stores I frequent do not carry black. I decided on 30 versus 40 lb because it was listed on the website as being 0.023" diameter which scales exactly 1-1/2" diameter at 1:64 According to charts 30 lb should be 0.018 to 0.022" and 40 lb is 0.022 to 0.026" Having checked the contract I have from 7/8" and 1-3/4" bolts so I think the 30 lb will look reasonable for any of these sizes. Also picked up black tissue paper at Michael's at lunch today to simulate the tar covered flannel or horse hair where used. Getting closer to assembly!

-

Completed the remake of the stern keel piece and the lower stem post piece.... and I got the joint correct this time. I also sealed (three spray coats) the top of my table so I will not smudge the pencil layout marks I made. Below are a few pics. Everything still dry fitted. I will work on the stern post and aft deadwood pieces next weekend.

-

Hello Mark, Thank you for visiting and for the suggestions. I have the set of the three draughts of HMS Elephant and one of Goliath. I also have copies of the build contracts for HMS Bellerophon and Elephant. Being an old time draughtsman in this new age computer drafting world I've chosen to draw a 3D image to create a model of the hull and then 2D templates to start my build. I finally get to use my old instruments again, but down in my workshop. I hope you will visit again and include a link to your build as I should like to see how you come along! Alan

-

Two weeks have passed and not a lot to show. I managed 3D modelling and 2D drawing up quite a few frames only to realize I had a compounding error in them as the lower scarph joints rise in elevation on the real Elephant's plans but not in my version. Made corrections over last weekend and then caught some bug Monday that had me down for the rest of the week. Head ache, muscle aches, chills, unbelievable fatigue but none of the more nasty possibilities. I cannot recall the last time I was sick on work days. I normally get sick on Friday at about 6 PM and am miraculously cured by Monday in the wee hours of the morning. Feeling considerably better today so I went downstairs and cut the keel and false keel pieces and then the scarph joints in the keel pieces. Immediately buggered the first attempt ... and after all those practice runs a few weeks ago! Then I began cutting the boxing joint in the forward most keel piece and was quite happy with the result. Began to cut the mating joint in the lowest stem post section... checked, double checked, triple checked, marked the waste half with with an "X"... and yes I then cut it wrong. So now I have two pieces that without question need a "do over". Templates cut and glued to some drops from earlier cuts.

-

I prefer to support the local mom and pop stores while they still exist, so like E-Bay, the Pro Bass Shop would be a last resort. I am also not a fan of the automatic check (yourself) out stands in some stores as I believe the more people use these the more other people will be out of work. I miss the days when the pump attendant filled'er up, washed the windows and checked your oil... I also miss the $0.35 admission to a movie when the rest of my 50 cents bought me a pop (or soda) and small bag of pop corn.... those were simpler days... of course I was 13 then.

-

I also worked on the remaining pieces of the Stem Post assembly. Glued up, cut out and sanded. Then dry fitted them all together. Then I glued up the Keel and False Keel templates to wood read to cut. I had thought I'd need an oscillating drum sander to make sure I managed square curved surface sanding but I noticed one member posted his using his drill press... so I did a similar rig on mine

-

Did my glue test with the 40 lb test fishing monofilament line (0.0235" diameter) to be used as faux 1-1/2" diameter bolts in my assembly I took a scrap piece of hemlock and drilled 4 holes using a #70 drill (0.0280" diameter) I cut off 4 pieces of line and scuffed up the length of two of them, leaving the other two naturally smooth #1 was the un-scuffed line coated with wood glue, inserted in the hole and worked up and down a few times (as EdT discribed in his build log of Young American) #2 was wood glue on a scuffed line #3 was 10 second Gorilla Super Glue on a scuffed line #4 was the Gorilla glue on a smooth line I let them set for 5 hours I then tried to pull them out with a pair of pliers.... they all held there place. I clipped off the lines close to the surface of the wood and sanded both sides of the wood. Only #1 could be pushed out meaning the glue did not penetrate any appreciable distance along the length of the hole so sanding removed the glue. I am not a fan of the Gorilla Glue and am happy the wood glue work well on the scuffed surface of line. I also noted the end of the line in the sanded version didn't look all that bad. I will continue to call around to see if I can get this line locally in BLACK as opposed to the translucent GREEN before I resort to E-Bay.

-

I personally like the natural look (changes in colour and grain) of the wood! Just as the Big Guy upstairs intended.

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

So the new question since yesterday (via PM) has been whether to continue on as I have been with the upper scarph joints in the futtocks or use chocks throughout with the frames being "scarphed" to receive the chocks? (Notice the twist in the usage of the term scarph joint) The decision process… gathering of facts. 1. The contract reads as I had posted earlier. 2. My NRG mentor suggests they would likely have followed the contract… but had two weeks earlier recommended a book of ship construction that will explain the wood shortage and effect on ship building. I have ordered it but it is at the very least a six week delivery and unfortunately it will not arrive for at least another four more weeks. 3. Another very respectable and experienced modeler has mentioned via PM that there was a shortage of compass timber at the time and so scarph joint construction in the upper frames were being replaced with chocks so the timbers would be slightly shorter in overall length. 4. Construction of the English Man of War 1650-1850 by Peter Goodwin states on page 16, 17, 18 that chocks were used (c. 1710-1811) up to but not including the fourth futtock to top timber joint due to the wood supply problem. 5. The Bellona, the forerunner of the Arrogant Class ship seems to have been built with chocks per “Bellona - Conway - Anatomy of the Ship - The 74-gun Ship” (although depicted incorrectly) 6. If the Bellona was ordered on 28 DEC 1757 and was possibly/likely chocked and the first of the arrogant class ships, HMS Arrogant, was ordered on 13 DEC 1758, it would stand to reason that they would be of a similar construction. Therefore HMS Bellerophon (ordered 11 JAN 1782) a full 25 years later (during even more of a wood supply problem) would not likely be built in an older style. At this very early time in my build I intend to leave one half uncovered (deck and hull) with a portion of frames removed to expose the interior and lower decks. So all the frames on one half of the build will be exposed to some extent for viewing of chocks or alternatively scarph toes from above. The decision seems obvious when viewing the facts. I need to revise/redraw my station joints made to date to be chocks below the top timber / fourth futtock joint which will be a scarph joint. Luckily I love to draw and in this day and age (and particular endeavor) it does not include erasing.

-

One more small item to share... the HMS Bellerophon Ship's Crest (from the last ship of that name and as assigned to the Sea Cadet Corps before they decided to add the three maple leafs to the bottom to differentiate the cadet corp from the real thing in the early 80's). I do not believe the earlier ship's had crests as they had figure heads (?) I'm cleaning out my hard drive and back up and found a really nice clear image.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.