-

Posts

2,841 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AON

-

To mark this special occasion I've updated my profile photo with a younger me. Today I took a trip to Exotic Wood in Burlington (1 hour drive north) and purchased three pieces of Castello Boxwood 2-1/2" x 5-1/2 to 6" x 51" at $11.50 bd foot. They have two pieces 2-1/2" x 8" x 51" left. When these are sold the price increases 30% higher. Luckily I can cut this down, plane and sand it to my required thickness. I also made my scales (rulers)..... used my Eastern Hemlock fir strapping for this. I can measure to 1" at 1:64 accurately I glued the paper scales to the wood with Rubber Cement and then sealed the whole piece with spray sealer. Funny story... since my first use in grade school I have always used the Rubber Cement incorrectly. I always bushed it to both pieces and placed them together immediately then waited (im)patiently for it to dry. I was recently shown it is to be applied to both pieces, let them dry and then place the one piece over the other and press. I think I'll use the Hemlock for the False Keel among other choice locations for colour variation. So the build begins!

-

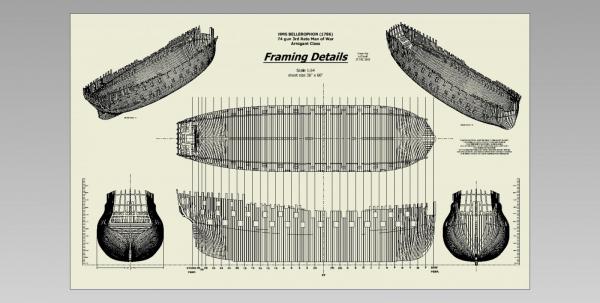

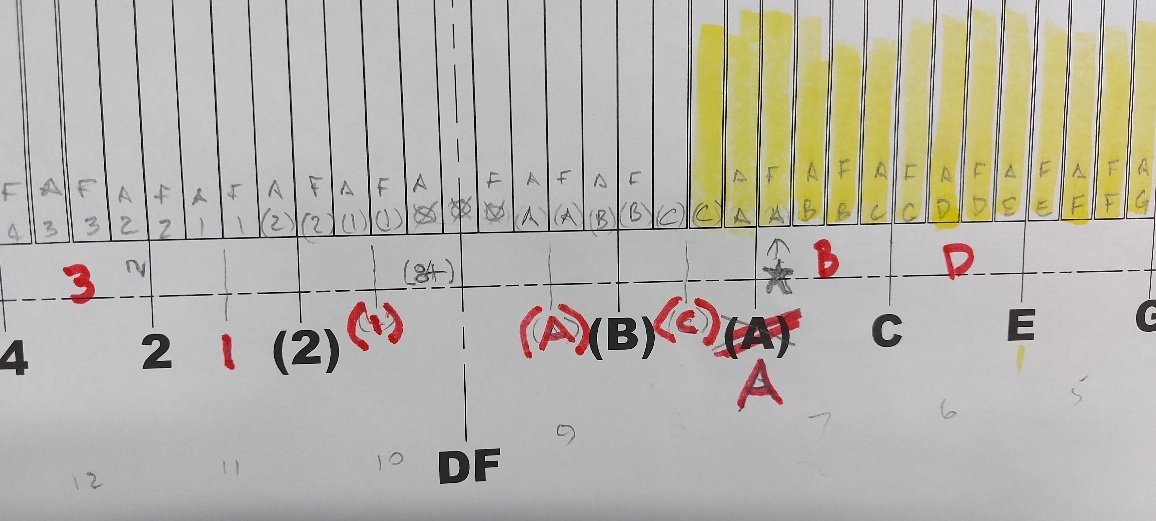

PDF Templates Print to size indicated in title and on image The first file as a 36" x 60" PDF sheet is a 4.5Mb file I tried compressing it but cannot get it below 3.5Mb which is still tool large for uploading So I've uploaded a JPG file. If anyone prefers the PDF please PM me with your personal e-mail address and I'll send it to you. You still need to purchase the original HMS Elephant documents from NMM image J2930 (lines), J2934 (framing) , J2938 (decks) and the Bellerophon build contract ADT009 for details. EDITED: note the correction to be made to the station labels near the deadflat in this image below (Alan 16 AUG 2021) (2) 36x48 STEM_STERN POST + KEEL.pdf (3) 36x60 Stn H-AFT to Stemhead sh 1 of 2.pdf (4) 36x60 Stn H-AFT to Stemhead sh 2 of 2.pdf (5) 36x60 Stn 2-AFT to G-FWD sh 1 of 2.pdf (6) 36x48 Stn 2-AFT to G-FWD sh 2 of 2.pdf (7) 36x60 Stn 3 to 17 sh 1 of 2.pdf (8) 36x60 Stn 3 to 17 sh 2 of 2.pdf (9) 36x60 Stn 18 to STERN sh 1 of 3.pdf (10) 36x60 Stn 18 to STERN sh 2 of 3.pdf (11) 24X36 Stn 18 to Stern sh 3 of 3.pdf

-

14 February 2016 is a date worth marking on my calender. The templates are done, checked, rechecked and checked again. (I am sure errors will poke their ugly heads up at some unforgiving time) They will be printed this week and the build begins (again). There are 11 sheets (PDFs to be converted to smaller files and uploaded shortly). The first thing to be made (next weekend) are two wooden combination 1:64 measuring scales or rulers if you prefer (see sheet 6 of 11 bottom left corner). One is 64 feet (12 inches real life) and the other 32 feet (6 inches real life). One side will be a standard scale layout where as the other side will be a centre measuring scale. While measuring off the NMM drawings at 1/4 scale my old drafting scales were invaluable so these should become very helpful in the build. So what have I learnt starting from a blank sheet, working though computer crashes and file losses, corrupted files and basically things that would make a real sailor swear up a storm? I've learnt to realize what 1:64 scale means as opposed to drawing in CAD at full scale (1:1); I've learnt to relax measurements and thoughts; I've learnt patience (a most unnatural state for me); and I've reinforced my "never quit" attitude (Irish stubbornness?). Of course I've also learnt there were many different ways to approach making the templates... but in the end "I did it my way". I've also learnt that all the free eastern hemlock (fir) strapping I've collected from my son's home renovation to use in my build may not be the very best choice of wood for many parts of my build. It is quite grainy and can be an concern. This will be dealt with at a cost I hoped to avoid. A good friend (I hope to have earned the privilege to refer to them as such) has given me a tremendous helping hand to start dealing with this concern. ... and so we begin.

-

I read the message in my e-mail program and didn't fully understand; then I opened the forum and saw your drawing.... and the light turned on!

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

What a wonderful weekend I have had. I am a firm believer in paying it forward and always try to do the right thing but due to my human failures I sometimes do not succeed. The big guy upstairs knows I try and as I understand it Saint Nick is keeping a score card. Possibly it was karma but someone did a wonderfully unselfish thing for me yesterday which due to their nature I have taken a vow of secrecy but it has restored my belief in the possible goodness of mankind.... and in return I vow to "pay it forward". Thank you. Now, back to my build, or lack thereof. I have completed my templates... twice now. I blame my CDO (or OCD for those that do not suffer from it) but every time I take another good look at it there is something I should tweak or believe could be done better. I swear I am very near a point where even I have to say enough is enough. I imagine it will be in the next few weeks. I have 11 drawings in all and my cost to have reproduced 2 copies of each has been quoted at approx. $80 Cdn (that's about 1 quadrillion US with the way the Canadian dollar is performing) I have removed my earlier PDF's of templates and will be reposting the full set. Then I once again restart cutting wood.

-

We didn't bundle them but then again we weren't flopping about on the deck of a warship! I can imagine things being kept tiddly (tidy / organized) by lashing them together. We also kept all blades in one direction, forward.

-

Back in the 70's we use to store the sweeps (oars) of the 27' whaler's and 32' cutter's under the thwarts on the floor boards. Not sure if you can manage to slide them in but we could.

-

I find matching one side to the other to be very exhausting working. Knowing when to stop is always the biggest challenge because you cannot afford to go too far. I imagine the transoms will be the biggest challenge yet! Can't wait to see you master it!

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Very nicely done Mike! Have you finished working on the port side transoms? Alan

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

might as well grab a couple bottles while you're out there!

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

I apologize for my somewhat cryptic message above and hope the info I sent you is of some value. I will be following and learning how such a small wonder is performed! Alan

- 28 replies

-

- bellerophon

- 74 gun

-

(and 1 more)

Tagged with:

-

Interesting method! May I ask which ship the plans belong to?

- 28 replies

-

- bellerophon

- 74 gun

-

(and 1 more)

Tagged with:

-

that is an excellent question that I hope to see an answer to (unfortunately I don't know)

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

WOW (AND THANK YOU) I'M GOING TO BE STUCK HERE AWHILE!

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Good morning Druxey Because? I imagined other more substantial reasons! I have purposefully left minute gaps to help me with the breaks between pieces when making the templates My breaks are between full scale 1/2" and 1" (depending on the location) which will not amount to anything in the build (0.016" max) There are also other painful errors, for example there is a ripple in the outer surface of the stealer timbers at the stern below the lower transom pieces but the ripple is outwards and so will sand away if I should happen to be oversize a wee bit. I've tried and tried and it just gets worse so, I've thought it through and have my plan. (I am also sometimes calling Waldo a stealer timber as I haven't found the proper term as yet) There are also a few irregularities in the lower transom pieces that I can fix (blend) easier in the 2D drawing I also left the radii out of the corners of the wing transom as my gut tells me I should gentle do this by eye sanding the pieces I've had to make decisions along the way, and will live and learn by them. Lord knows there is likely something I haven't noticed... seeing the forest for the trees kind of thing. Alan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.