-

Posts

1,303 -

Joined

-

Last visited

-

Steef66 reacted to a post in a topic:

Does cherry carve well?

Steef66 reacted to a post in a topic:

Does cherry carve well?

-

Canute reacted to a post in a topic:

Does cherry carve well?

Canute reacted to a post in a topic:

Does cherry carve well?

-

allanyed reacted to a post in a topic:

Does cherry carve well?

allanyed reacted to a post in a topic:

Does cherry carve well?

-

CiscoH reacted to a post in a topic:

Does cherry carve well?

CiscoH reacted to a post in a topic:

Does cherry carve well?

-

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74 gun, as designed

Mike Y reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74 gun, as designed

-

mtaylor reacted to a post in a topic:

Does cherry carve well?

mtaylor reacted to a post in a topic:

Does cherry carve well?

-

GrandpaPhil reacted to a post in a topic:

Does cherry carve well?

GrandpaPhil reacted to a post in a topic:

Does cherry carve well?

-

IWHARPER reacted to a post in a topic:

74 gun ship by Gaetan Bordeleau - 1:24

IWHARPER reacted to a post in a topic:

74 gun ship by Gaetan Bordeleau - 1:24

-

After I built the last cabinet, all the small tools fitted 1 cabinet, so I gave all the other wood cabinets. Storage for these is incredible for metal tools. You can customize each drawer and each drawer they can support 300 pounds. I have another series of chest. they were used by a lens fabricator. They had cardoard little boxes that I also used int he small wood chest.The global idea is I guess when you have few tools, you need drawers.

-

Antique wood dental chest are very nice. We could say it is like a Gerstner chest with more drawers. With the years, I did some tool chest in this style. The last one I did include over 1000 tool and accessories. The main difference and also the main reason it can have so many tools is because of the height and the depth of the drawers.

-

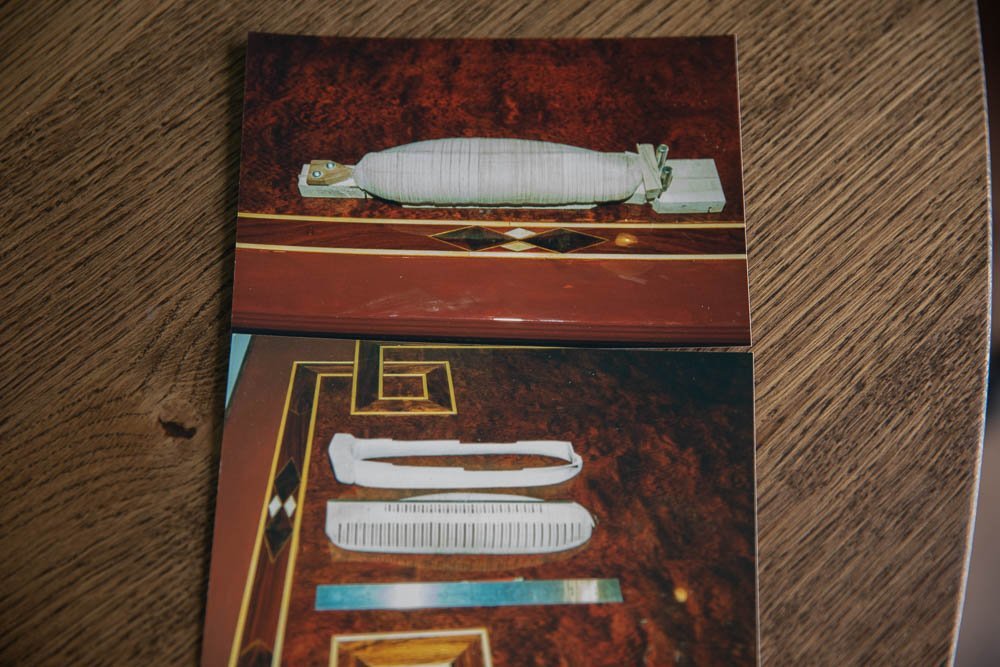

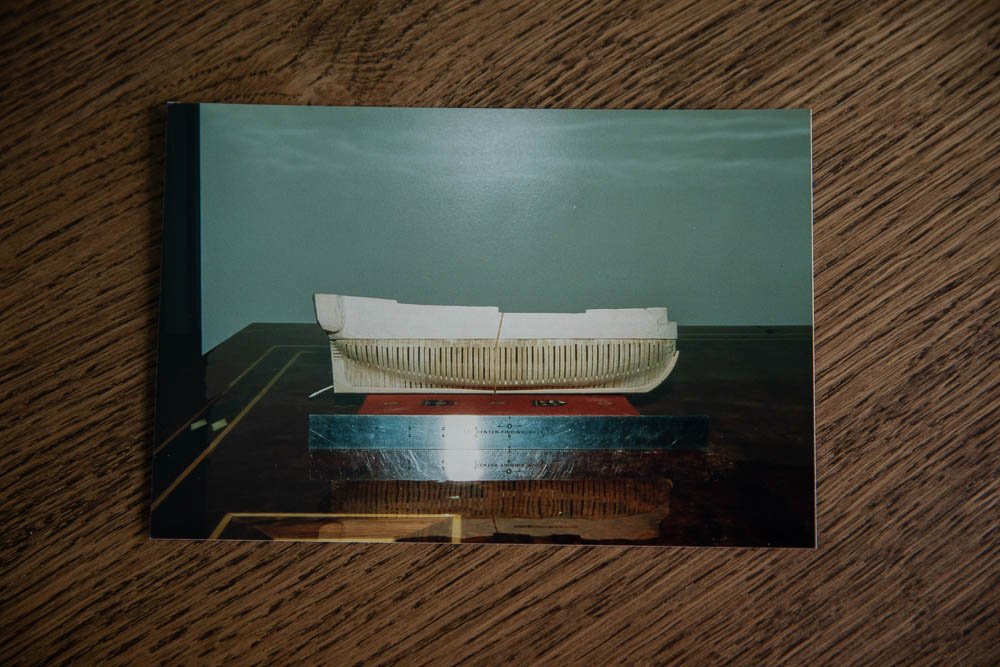

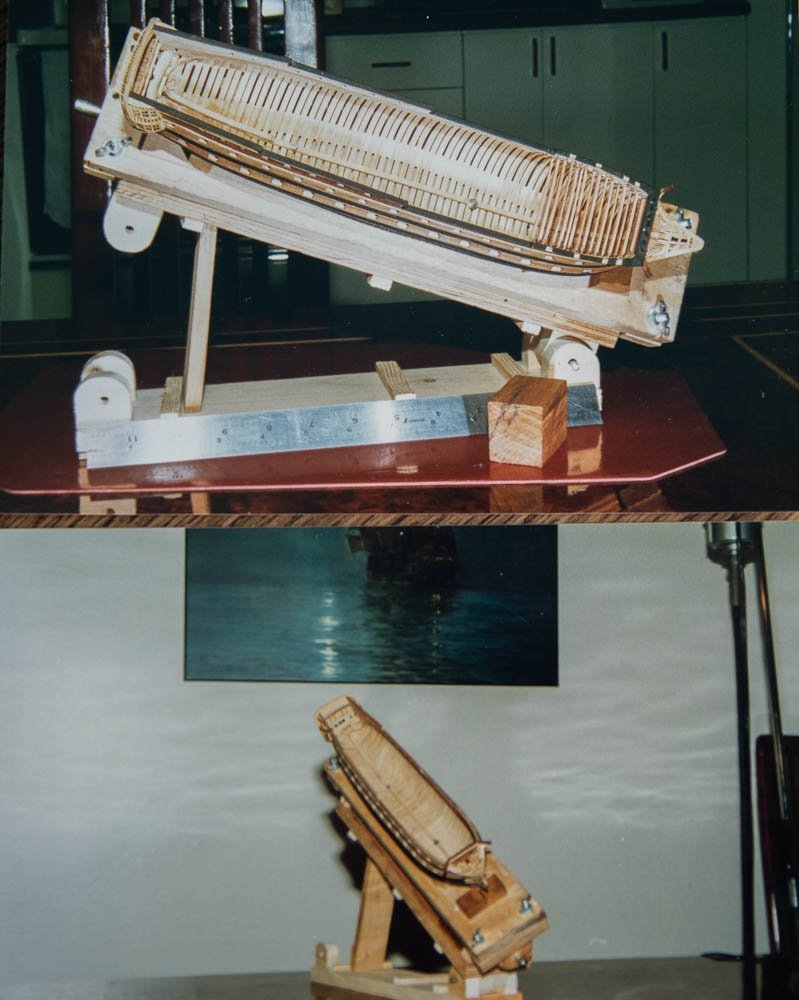

I have seen a lot of rope making machine over the years from the most simple to the most exotics. There are a lot of ways to turn ropes and the quality of the turned ropes can cover a wide area of quality. Here are 2 example of rope machine, similar in their principle: The rope machine from the Musée de la Marine The rope machine I use One of the greatest advantage of this type of rope machine is that it can control the rigidity or the flexibility of the rope. The more weight, the more rigid will be the rope and also the swivel is a regulator for the tension and the number of turns. There are a lot of tools on the market and some do the job the best way possible...

-

Chisel hone guide question

Gaetan Bordeleau replied to CPDDET's topic in Modeling tools and Workshop Equipment

-

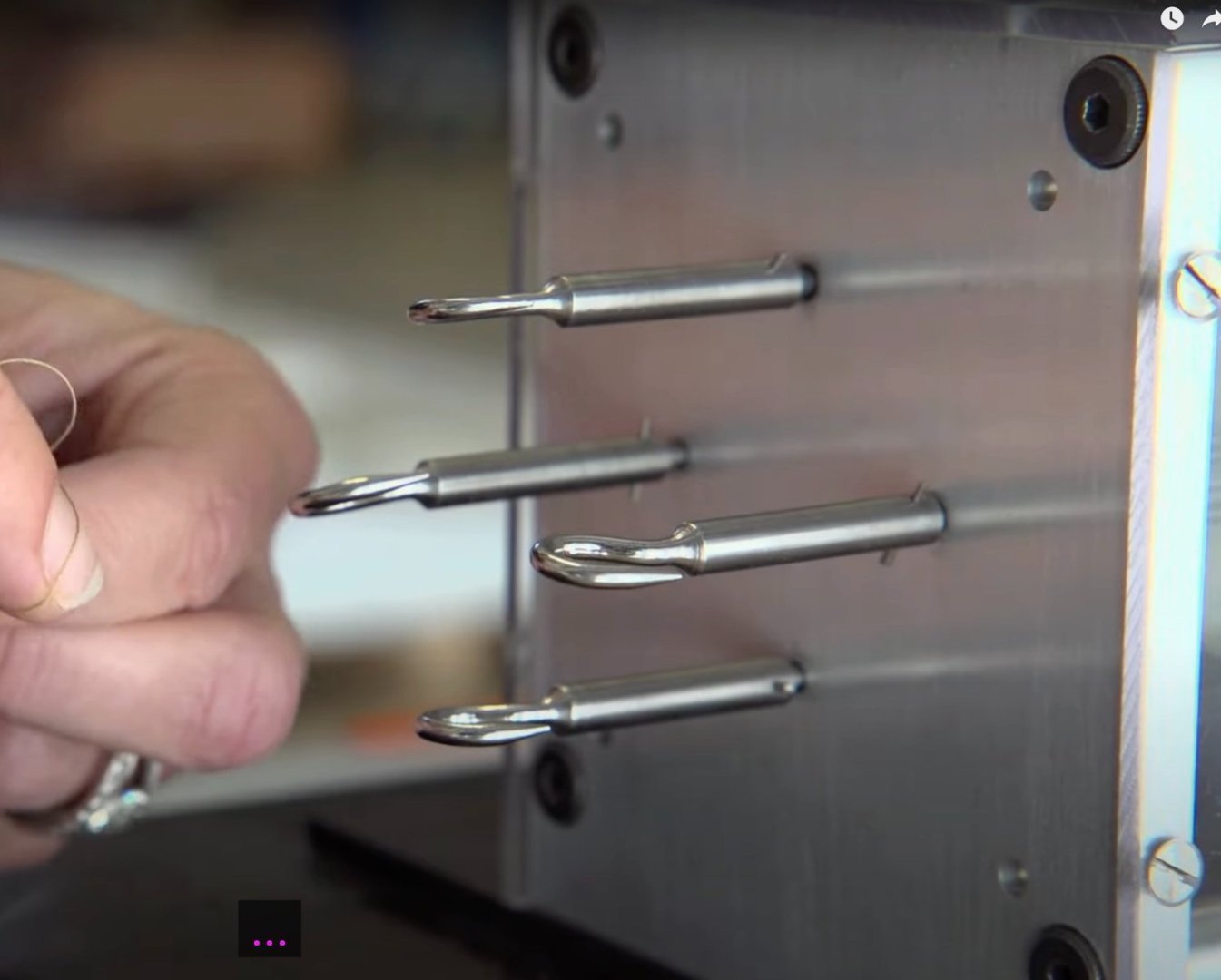

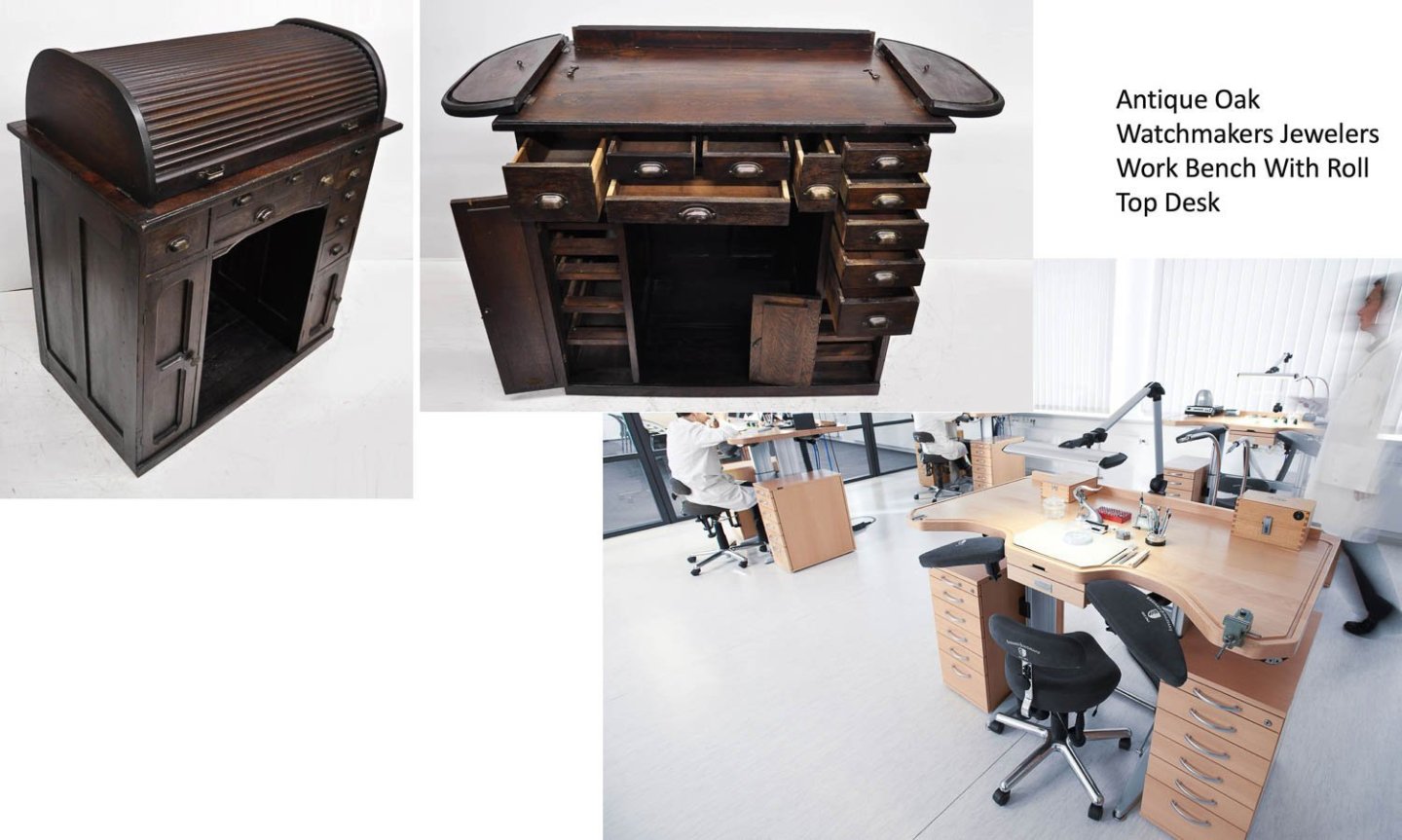

Jewelry is a good source of inspiration for tools, Here is an example of the classical workbench 100 years apart. Electric height adjustable desk is probably the best tool we can use for many reasons. I have seen many declinations of armrest, the first one I remember was a felt donut recovered with leather for the elbow. In a way, all these resting tools offers the same thing: allowing to rest a part of the arm to have a better control of the hand.

-

I would say that the main difference working small vs larger is the concentration level is very much more demanding, especially in carving to control your hands moves which are much more smaller. The magnifier style you use is a personal choice. I like to work with Optivisor and for smaller scale I like to use a surgical loupe and occasionally for quality control a microscope.

-

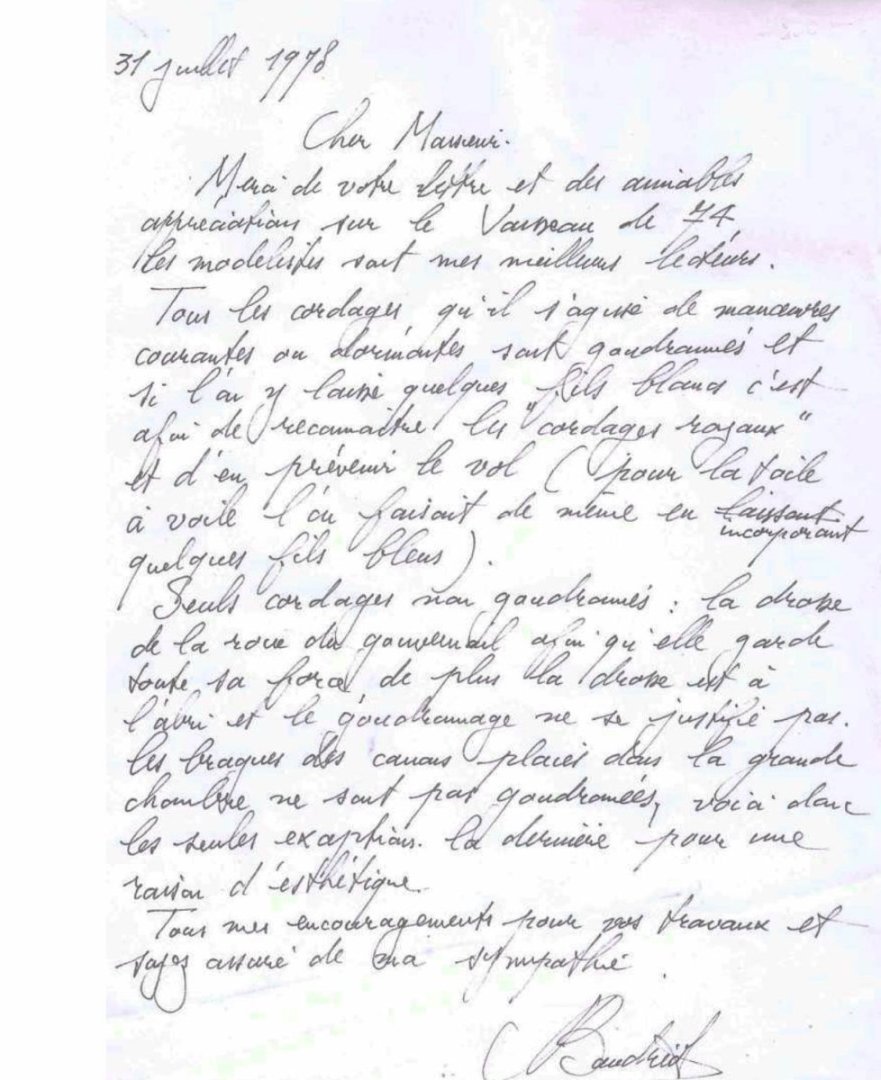

Why nobody in the books talk about this subject? I think, we highly underestimate the enemy: the aggressiveness of the salt. Why would a line be tarred and the next one untarred? Inevitably, by cross contamination, both lines would finish tarred. Jean Boudriot wrote a letter about which lines are tarred. One sentence is interesting: The rope for the ship rudder wheel is not expose to the salt, so tarring this line is unjustified. Does that mean that the idea is very simple: If a line is expose to the salt, tar the line.

-

Every tool yo will choose will always be a personal choice. Here is what I would use especially to be comfortable while working: height adjustable table, omnidirectional vise, micro motor, magnifying lens and at least 2 LED light adjustable in intensity and position.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.