-

Posts

840 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mark Pearse

-

I've made the gaff jaws & gaff spar, but not done the final finishing & assembly yet. The jaws are what I am guessing would have been modern at the time of the yacht design, the mid 1960's. The part that would once have been a timber jaws piece is here a curved piece of metal, probably 6mm aluminium sheet or similar with cleats welded to the aft face, & the mast face clad in leather - which I probably won't try to replicate to scale. This photo shows it approximately in its working angle - mocked up with a scrape dowel to replace the mast. The gaff angle in Australia seems to have been usually a high peak & the gaff spar length was usually almost as long as the boom. The angle means that the resolution of the parts is a bit tighter to fit in.

-

HI Steven I have one comment & one question: The spar wouldn't be particularly heavy but the sail would be very heavy, but considering the ready labour on board I reckon they'd be ok about a 1:1 halyard with half a dozen hefty Mediterranean types. There's also the mechanical advantage you get by 'sweating' the halyard, where you lock the tail of the halyard (usually around a cleat) & then above the locked point you pull the halyard horizontally away from the mast (it has a leverage action) - which pulls the halyard up a little bit - & then you quickly take up that slack on the downhaul part, & it inches upwards. Sorry if that's not clear. How would a double sheave in the mast actually work to get greater than 1:1? Mark

-

Bravo! And thank you for patiently showing the methods used Michael, Mark

- 749 replies

-

- albertic

- ocean liner

-

(and 2 more)

Tagged with:

-

I fitted the running backstays chainplates, after avoiding them for some time because two thin & shaped timber pieces were required, which were tricky to get accurate. But done now, as below. This will require a tackle system for the backstays so that the resultant loading on the chainplates is more or less vertical, rather than pulling them off - which would be the case if the backstays were 1:1. The angle between the backstay to the mast & the tail to the winch is such that if you bisect it (1:1 backstay), the angle would be pulling the chainplates aft by quite a lot. Likewise, they lean inboard to the same angle as the run of the backstays to the top of the mast. before: after: I have also done a mast track for the mainsail. A yacht rigged in the mid-late 1960s would have had a track for the luff, which I replicated using an off the shelf brass C channel. It's oversized for tracks of the time, but doesn't look wrong & there seems to be only limited sizes available for the C section in brass. The gap at the top to the spreaders is because the gaff throat would sit just above the top of the track when there was a reef in the main. thanks, Mark

-

We changed the rig on our boat, partly to lower the CoE. Without calculating it I would guess it was lowered between 5 & 10%, & the difference was noticeable. 30% higher would be a large difference, & if my geometry/physics is good, the same force higher up would have more effect on a hull because of it's distance from the pivot point. What are your thoughts on the role of the sails on these vessels - were they a pleasant respite from the oars or the preferred way of getting around?

-

Hi Steven is the CoE for the 2 sail rig much lower than the single sail rig? The single sail looks to be significantly taller.

-

Very interesting. Also noted is the quite large lateen sails on hulls that don't look to have much righting moment - or even freeboard - & the wind isn't light (black & white photos at the start). On the rig balance question, I would have thought it's adjustable by changing the spar angle. More horizontal & there is more sail forward, more vertical & the sail is further aft. It would mean multiple sheeting positions so the sail could set well at a range of spar angles, perhaps a line of cleats or pegs along the rail.

-

thanks Steven. Have you seen this video of a replica longship at sea? No doubt there are differences, but the hull righting moments might be similar to your craft. The incredible work done in Denmark & Norway on these craft have shown we previously greatly underestimated their abilities, & I might add the hulls seem much stiffer to heel than I would have guessed. A low square sail would be somewhat comparable to low triangular sails. Hope it helps. all the best, Mark

-

Hi Steven the setup you've drawn would allow disassembly - the fixing block could be removed by a hefty thwack from the side. I am guessing that with the loads & movement of the boat, the difficulty is having a mast step that is both strong & also reliably easy to take down.

-

Frank, thanks for the enjoyable & informative posts - a great model to watch come together. That's a really thin boom for the length, but obviously it works Mark

-

agree, that's a very good idea for marking the waterline I like the way you can still see the planking lines, the model looks all the more real for that

-

Hi Steven, yes you'd probably be correct on that....but perhaps the mast rotating isn't a problem - if the force stays in the same direction as the hook it would reduce twist loading on the mast. Could the shaped end be to help the lateen spar clear the mast as they go about?

-

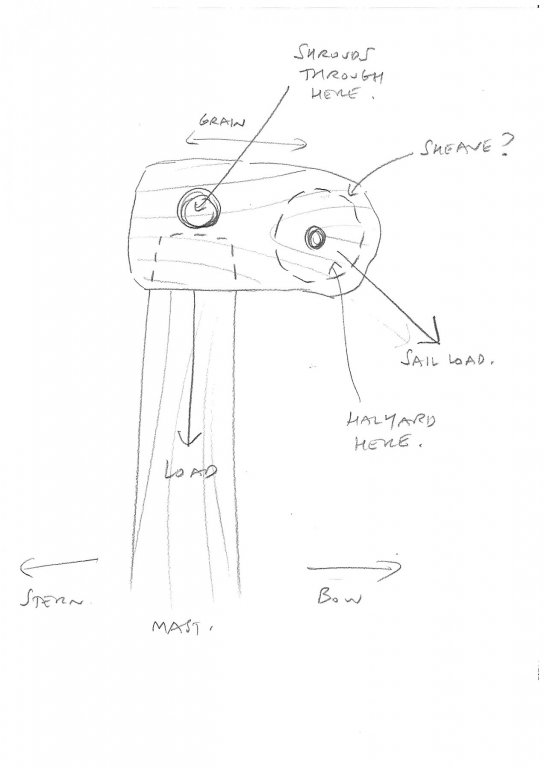

Hi Steven an interesting & difficult problem. Ideally you would put the shrouds & halyards converging at the same point, we can do that now because of our metalwork. If you take away that technology then bringing all these lines together to one point is much more difficult. Unpicking the reasoning behind that I think is the key. I think that you are correct to assume the hockey stick end is the halyard: the shroud loads will be balanced by the mast & should connect directly to the mast, or in line with it. I feel the mast cap piece has to be a second piece of timber, & probably some sort of tough, strong timber. A good choice of timber for a mast wouldn't be a good choice for the cap timber. The sketch below might work, the grain is at 90º to the mast & it held in place by the shrouds load, & mast housed into the cap. The closer boat in the Homilies picture has a line that might indicate a separate piece of timber, & it looks to show the shrouds going into a hole above the top of the mast. The shrouds could be fixed to the mast by wrapping around the top or back of the cap a couple of times & then back down the other side, so the shrouds are continuous. It's hard to say how the halyards are connected, but maybe it was just a loop of metal & the halyard ran through it. Alternatively, could it have had a single sheave? The sheave probably in some really tough timber & lubricated with fat.

-

Hello Maury those lines do look quick, the run aft underwater is very clean. Was the need for speed something to do with the economics of the oyster trade? Is there any similarity with Slocum's Spray? (albeit longer & larger....) Mark

-

The sail tracks are now completed. As they were left from the last posting the plain surface looked a bit blank, so I got some decent quality 1mm bits & drilled some part-depth holes to replicate the car locating points down the tracks, & also scribed a centreline - to help locate the drill bit plus I thought it would look right for some reason that I can't explain. I drilled some through holes to peg the tracks down & they are shown below pegged in their position but not glued down, the deck might need some more paint & there's no guarantee the colour will still match, or indeed even be usable so another full coat of deck paint is a definite maybe. The track holes didn't look very good or convincing, so I put a dot of darkening solution in each plus in the scribed centreline. I'm happy with the result, & I must say it's much faster to drill brass using a good bit than some piece of cheap rubbish that I bought in sets.... A longer track for overlapping headsails, plus a short one forwards for #3 & #4 headsails. thanks all, Mark

-

thanks, I made the forward sail tracks tonight & they were surprisingly easy - a classic T track from a wider piece of brass soldered on top of a narrower piece, in this case the narrower is from two very small squares - as that's what I had & the size is good. Full size for the track is about the standard size 32mm or I guess that's 1 1/4" imperial. There will be longer tracks further aft on the deck, a #1 headsail on this boat would probably have the clew about 2' or 600mm from the edge of the raised deck. I'd like to drill some shallow holes along to give some texture & replicate the car stop holes, but it seems that the drill bits I have get blunt very quickly. I'll see if I can get a tungsten tip one from the local hardware store, anywhere from 0.5mm to 0.8mm or so would do, about 6-10mm diameter full size. In the photos they tracks are in the approx position, just sitting there. I'll colour them also.

-

Hi Vaddoc more nice work. Could you explain a bit about the comment below? thanks Also, you might already know - but esp on a yacht it's important that the waterline isn't painted dead horizontal, whether just a change in colour or a boot top line. A shipwright explained it: lowest point aft of the centre of the hull about 40%/60% of the hull length, raising towards the bow & stern, & finishing higher at the bow. If it's a boot top line it should also get a bit thicker in the same way. For a yacht that's 30 foot long it's around 2 to 3" difference between the lowest & highest point. You don't actually notice it, but I'm told that you notice it if you don't do it, it appears to curve downwards towards each end. Just when you thought it was complex enough.... maybe the advice is wrong though,

-

thanks, I made the forward sail tracks tonight & they were surprisingly easy - a classic T track from a wider piece of brass soldered on top of a narrower piece, in this case the narrower is from two very small squares - as that's what I had & the size is good. Full size for the track is about the standard size 32mm or I guess that's 1 1/4" imperial. There will be longer tracks further aft on the deck, a #1 headsail on this boat would probably have the clew about 2' or 600mm from the edge of the raised deck. I'd like to drill some shallow holes along to give some texture & replicate the car stop holes, but it seems that the drill bits I have get blunt very quickly. I'll see if I can get a tungsten tip one from the local hardware store, anywhere from 0.5mm to 0.8mm or so would do, about 6-10mm diameter full size. In the photos they tracks are in the approx position, just sitting there. I'll colour them also.

-

I haven't been working enough on the model yacht, but some recent progress: the boom is done with thumb cleats each side & the gooseneck fitted, plus the fitting on the cap iron on the end of the boom is done also. The boom really sets the hull lines off. Some other minor bits: the running backstay chainplates are done. They will be mounted on the sides at the step in the deck. I refined the shape of the cutwaters, they now taper down in height as they go further aft. (they are angled boards on the deck). And I've been looking at some fairly cheap brass blocks, as below, & wondering how they can be improved.... I sanded off the knurled edges of the riveted axle (which wouldn't look great on a scale model), & good news is that the block didn't fall apart .... so ... the plan is to glue thin pieces of timber each side of the block to replicate tufnol, or timber. If I can sand the sides very flat I might be able to turn them into double blocks by gluing or soldering two side-by-side. thanks all ,

-

thanks, yes that is helpful & it's clearer now - a Lateener is new to me also. I just noticed the lateen spar is in two parts (in the sculpture), joined near the mast; which would account for some of the ropes shown around where they join.

-

Hi Steven could you explain for my benefit what you believe the rigging on the mast & sail would be for one of these craft? The bas relief sculpture shows quite a few lines (& furthermore - are they showing the mast being raised or lowered?). thanks

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.