-

Posts

804 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mark Pearse

-

Hi Samson thank you for posting it, the model looks lovely & captures the beautiful aesthetic balance of the design. I have never seen a Junior Folkboat but have admired them since I became aware of the design. There's quite a few International FBs in Sydney, but I doubt there are any 'Juniors', we race against the Internationals quite often. Mark

- 39 replies

-

- kdy 15 juniorbad

- yacht

-

(and 2 more)

Tagged with:

-

Keith that is a long hull, & what you can see of the lines are interesting. The rig is going to be dramatic indeed.

-

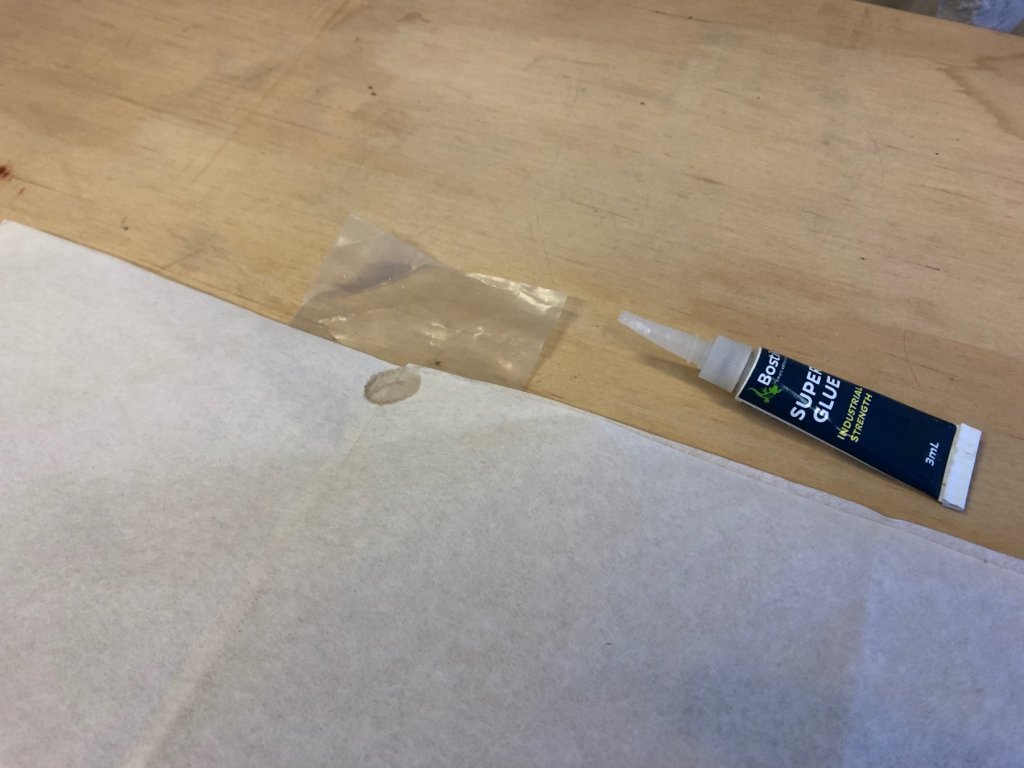

Hi Druxey - yes, staggering the joints is what I was thinking of, just thinking with some degree of trepidation. handling wet silkspan makes me feel like a 3 year old trying to handle household plastic wrap - you just know disaster is lurking. The Silkspan obviously has some ability to do compound curves, but not as much as I thought. The work area - I prep sanded lumps etc off the ply. The overlaps were done on opposite ends & a spot of CA glue to help sheet alignment. Once two sheets of Silkspan are painted & against each other it's quite difficult to move one without making a mess of it. I mixed acrylic paint plus about 10-15% plain PVA, painted this on one side of the first sheet in strips & quickly laid the second sheet on it before it had started to dry (it's been warm here). Then painted the top of the second sheet, & after about 5 mins I could turn it over & do the same on the other side. Then hung it up to dry. The colour is whiter than the previous sample, a creamy white with just a tiny dot of black to stop it being yellow. Then the other one (jib). I'm happy with the effect: the colour, texture, weight & feel are all good. This is one of the joints, not bad. I even like the wrinkles - they look like the wrinkles in dacron. It's not what I was imagining 3 weeks ago, but I'm pleased. Next is string up the sail sea, adding reinforcing latches, cringles, sail numbers.

-

thanks, that's better: it's interesting to see the rig changes in between the 1926 & 1933 designs - the headsail is very small initially

- 39 replies

-

- kdy 15 juniorbad

- yacht

-

(and 2 more)

Tagged with:

-

the curved roach of the mainsail balances the curves of the hull beautifully; such a good looking boat would you be able to post a link to the website that has the original drawings?

- 39 replies

-

- kdy 15 juniorbad

- yacht

-

(and 2 more)

Tagged with:

-

The curved form is great but I should have experimented with the Silkspan first. It really doesn't want to form a 2-way curved shape, or at least not one as curved as this is - but it does look & feel good. The process was: I painted some small sheets using flat acrylic paint in an off white colour, & after they had dried I laminated 3 layers using standard PVA diluted with about 20% water - with a small roller to apply the glue. It's quite difficult to laminate a second or third sheet when it's all on a curved surface, the wrinkles form because the curves are too great. The wrinkles aren't bad at all, a real dacron sail is quite wrinkled if it's had some work, but it remains flexible enough to not retain the curved shape. As an experiment I also gave both sides a couple of coats of a matt spray polyurethane based clear varnish, each time laying it back on the form to dry...no good. It yellowed a bit & didn't stiffen it up. One useful conclusion is that 3 layers of Silkspan is probably too thick, but 2 layers feels good, you can see a corner where I pulled the outer layer back. The videos I watched were for 1:48 models & this is 1:12, so really that's 16x the size. Good news is the 6H pencil lines are nice, & I think that if I tone some glue with grey paint I can do sail cringles by putting a blob on the sail & drilling or punching the centre out. So, I'll likely use a double thickness of Silkspan, laid flat. If it doesn't go well or if it's just too big to have up, then I can still furl the sails - the mainsail is a little taller than a 36" Silkspan sheet. The family might have something to say about it.....

-

The dynel & fibreglass went well. At the time it appeared to be going very badly, the dynel needs a lot more edge support than the poly/cotton does. At the time it appeared that only the parts bounded by the timber sticks were going to work out, but I used pieces of string & lots of clothes pegs to pull the loose edge (the sail's leech in this case). The brown is beach sand, & it appears that the Dynel kept sagging a bit after I'd done it, the bagginess is just a little too much, so I'll adjust in the way the jib is shaped. Good news is that I reckon I can use this form for the jib as well. The photos don't fully show the shape, it's more even that it appears. I'm now doing a test of Silkspan as a sail - the Tom Lauria videos on youtube were extremely helpful. I emailed Tom via his website & he was kind enough to answer & give guidance. The videos show a 1:48 sail, using a single thickness of Silkspan. I am testing doing a triple thickness: the outside face of the outside sheets being painted, seams drawn in pencil, reinforcing patches & battens etc. Then lay them up on the form using diluted PVA as a bonding & stiffening agent. It will also tell me if the minor irregularities that are still visible on the form will matter or not. thanks

-

Hi GL that's very nice. Are you planning to finish the hull? Mark

- 219 replies

-

- smack

- cross-section

-

(and 2 more)

Tagged with:

-

Hi Keith, looks lovely already Do you know how they manoeuvred the top staysail & topsail when going about?

-

Hi Roger initially I did do that, but it was still very flexible. If the cloth was to be the actual sail that might be fine, but the plan is to build up a Silkspan sail over a curved form. It looks that the Silkspan part won't be as difficult as making the form. I think the reason it wasn't stiffer is that polyester/cotton mix of the fabric has poor tensile rigidity - my guess is that resin & fibreglass is rigid because the components are fairly rigid in compression & tension. The Dynel is a quite an open weave, so a test will see how well it holds the thicker epoxy. As part of the test I'll probably do part of it with a piece of fibreglass cloth on top & see both how rigid that is & how well the two together hold the resin.

-

thanks for the assistance & suggestions. Keith, you'll be horrified that I had to use the www to find out what splicing the mainbrace means. Not always helpful, but a timely glass can help with thinking sometimes. I saturated the fabric with Everdure epoxy & laid on top some fibreglass tape that I had, then added more epoxy. Initially I was disappointed with the results, but in separating what worked from what hasn't I think I can get it to work. These things didn't go to plan: Everdure is too thin for this job, a more standard thickness epoxy would work better; the fabric is rippled on the underside (the face side of the form), I think because the cotton blend fabric stretched & the glass fabric doesn't. The Everdure has soaked right through the fabrics & didn't get held in the fibreglass, so the layer of fibreglass didn't't really bond too the fabric below. What I'm thinking is to use Dynel fabric for the lower layer & a sheet of fibreglass on top, then some thicker runny epoxy, applied with a brush. Possibly I'll do a small test to see if I need to put a sheet of plastic film below the Dynel. The good side is: the sail shape is very nice, this view is as if looking up at the sail & the twist at about the throat height looks good to my eye. You can see how the fibreglass hasn't bonded. thanks

-

thanks everyone; Druxey, yes it is, but perhaps stab in the dark is better - I might market a technical book "sailmaking by the assisted gravity technique".

-

Hi Jens, lovely project & a very pretty boat indeed. I think I've hear them called Junior Folkboats - the similarity is there but I think they pre-date the Folkboat design....?

- 39 replies

-

- kdy 15 juniorbad

- yacht

-

(and 2 more)

Tagged with:

-

some progress on the sail mould, & Heath Robinson would be pleased...lots of string with knots, pegs & dodgy fixings Below shows the fabric suspended & tensioned here & there, the grey blotches are from water spray to soften the fabric, & hopefully will reshape a little as it dries; a hefty bucket of Bronte sand awaits. The good news is that the shape is about right - aerofoil shape towards the mast & gaff, & flatter towards the leech; with maximum belly in the upper part of the sail (in the photo the close timber is the gaff, next is the mast & the loose one below a timber strip furthest away is the boom). as it turns out, only a very small amount of sand was required; the shape looks quite good & my earlier estimate of the difference angle between boom & gaff was quite a lot more than here, but I will probably ease than suspension line a little more so the gaff lays out a little more After it's all dry the next step is to put some mixed Everdure epoxy resin into a spray bottle & spray it all, make small adjustments to the tension, add sand etc. When that's hardened a bit I'll lay some more fabric on the top with more epoxy, perhaps even 3 or 4 layers.

-

Minwax stains in Australia

Mark Pearse replied to vossy's topic in Painting, finishing and weathering products and techniques

Hi Chris I got a Minwax product (polyshades black stain/polyurethane) shipped to Oz through buy.com, & the approx 300ml tin cost $57, incl $21 shipping & customs. It's an excellent product, very black & thin, but I opened the tin & did 3 coats within 4 days & the 3rd coat had flecks of hardened polyurethane in it - so to salvage the work I had to strain it carefully & use it immediately. I was restoring a coffee table & the finish was to replicate the original black 1960s finish. Paint has much more 'build', & this product allowed a certain amount of visible wood grain texture to be visible. It's a great product but the problem above was a concern. Mark -

thanks Bob I have some clear shellac. I actually used the orange/brown quite a bit in the model on the timberwork, with a finishing wipe with satin polyurethane.

-

Hi Steven your sculptural skills are excellent, it's interesting to see the viking emerging.

-

thanks Bob, that's very helpful & a lovely model. It does change my thinking on cotton, but for now I'll press on as is. If I'm not happy, I have a 1940's cotton sail that's no good as a sail any longer, the fabric has a very tight weave & might work ok. Did you use glue to stabilise the rope rigging?

-

Hi Carl, yes that's what I was thinking, & in addition using sand to weight it as required. I think the hard part will be to be the balance between baggy shaped curves in one area & a flat curve in another - hence using sand, almost like being able to locally increase gravity.

-

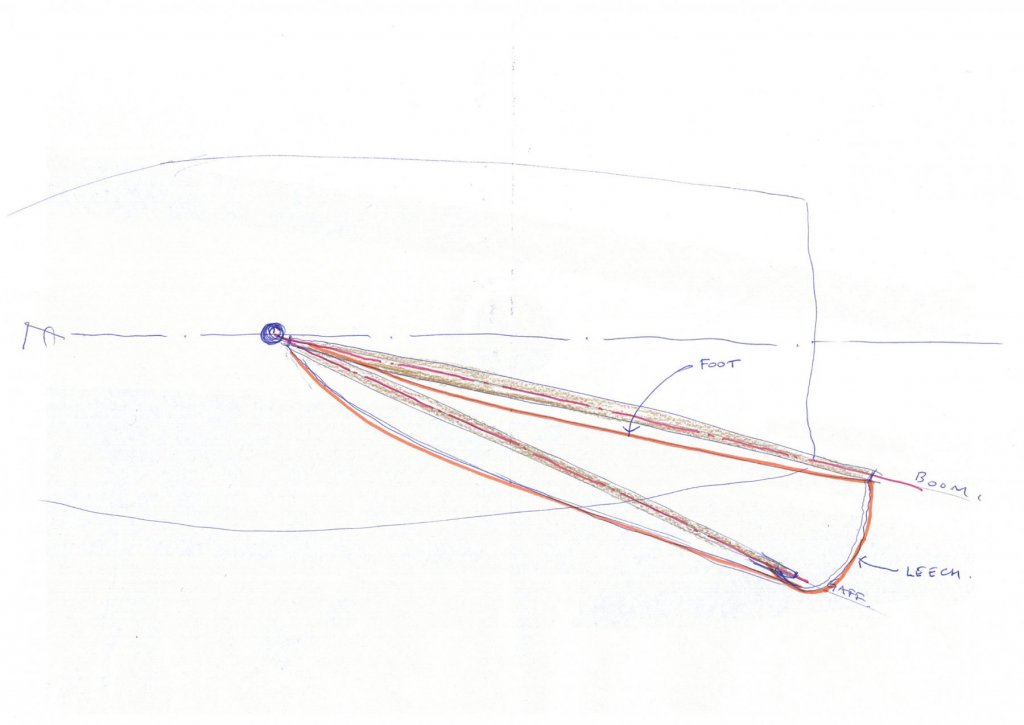

Thanks for the comments, all discussion will help me. PVA is strong but the form is large at around 800-900mm tall so I think it's going to be soft at that scale, & there's the problem of wet Silkspan on a PVA based form. You can dilute epoxy with acetone, but I'll use the one that's already mixed thinner, as it might be stronger than a home-made version - called Evidure here, I think it's International Paints (Azko Nobel). If I do get a good shape, I'll just keep laying in sheets with epoxy until I'm sure it'll be stiff. All thoughts would be very welcome. Below is a plan view of the curvatures I'm trying to get. The leech line isn't quite right but gives a fair impression.

-

15' Dinghy by Bedford - FINISHED - 1:1 scale

Mark Pearse replied to Bedford's topic in Non-ship/categorised builds

g'day bedford looks lovely - how do the sails fix to the spars in this boat?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.