-

Posts

1,867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Chuck Seiler

-

-

-

You don't indicate whether the bulwark will be planked or not. I would be inclined to NOT use the bulwark provided but instead use 1/16" basswood (using the old bulwarks as templates) then plank over it, inside and out. This would reinforce the basswood in the same manner as 2 ply lamination as suggested by James. If the kit does not supply planking material, 1/32" basswood strips (if planking interior and exterior) or 1/16" BW strips will work. That should be available from hobby shops like Michaels.

Another alternative is Alaskan Yellow Cedar. It is soft like basswood but I find it much better as a planking wood. Hobby Mill EU (Europe) and Modelers Sawmill (US) bother carry AYC. Both are MSW sponsors.

-

It needs to be done by mid May for entry into the Fair. Photos are submitted by April, but your PdN is far enough along that current pics are good.

Delivery to the Fair is in mid May, I believe. Model must be completed by then...although the glue doesn't need to be completely dried.

Delivery to the Fair is in mid May, I believe. Model must be completed by then...although the glue doesn't need to be completely dried.

- Coyote_6 and Glen McGuire

-

1

1

-

1

1

-

I have never used Vallejo. As mentioned above, I like Windsor and Newton. It mixes well with water and I can vary the consistency. Because I paint small areas, I have come to like the "carriage process" outlined by Chuck Passaro in one of his builds. Winchelsea, I believe. I am told it is so named because that is how they painted fine carriages in days of old. The paint is thinned to sightly thicker than water. The paint is applied and allowed to dry, then buffed between coats. I have found the first 2 coats go on without buffing in between. At first it is very transparent/translucent, but it gets better. Six to eight coats. Its marvelous!!!

I have been searching for 'the perfect red' for years. I sometimes will see a great 'barn red' barn while driving. I will stop and take a pic. Cadmium Red Deep and Red Ochre (or sometimes a mix of the two) are what I have settled on.

- BenD, Ryland Craze, catopower and 1 other

-

4

4

-

I really like W&N red ochre. It may or may not be available from MICHEAL'S or HOBBY LOBBY. It definitely IS available at DICK BLICK'S, if you have one near you. If not, you can order online. A tube will last you forever.

I normally stain, but when I paint I use watered down artist acrylics.

-

Steve,

The shrouds and stays are where you will want to try your serving techniques. Get with OtherSteve regarding his rigging project. He did a good job in serving IIRC.

- Coyote_6 and Glen McGuire

-

1

1

-

1

1

-

Steve,

The gammoning looks great. I am glad you chose NOT to serve it. I agree with Phil, detail is great, but there comes a time when 'close enough' is good enough. If you worry about absolute authenticity, you will never finish.

What's a pirate's favourite letter?

- Glen McGuire, Jolly Jo and Coyote_6

-

2

2

-

1

1

-

-

What blades did you get?

-

PS-Thanks for reminding me. I just ordered 5 x CT303012000

-

Martindale acquired Malco a few months back. As a Malco customer I got notification. Malco is becoming 'part of the team' so Greg and company are still players. Since it will take awhile to incorporate Malco stock into their catalogue, I was told to continue to order thru Malco.

-

-

-

FYI, MALCO has recently been acquired by Martindale Electric Company. I received that info in an email a few days ago. If you are doing business with MALCO you will probably get the same.

-

-

Patina and Stain: Did you get those from Pavel or a local source?

-

I have the Ultimation hand disk sander as well. In general, I don't like it as much as my Byrnes disk sander, but it is far more portable...and quite useful. I find, however, it must be clamped to the workbench or it slides all over the place.

-

I remember seeing a model in a museum in the LA area where the 'pot metal' parts had all disintegrated into piles of grayish-white dust. I was told they were the lead fitting used a loooong time ago. I think the newer mystery metals such as Britannia don't do that (at least in my lifetime).

-

Those rope seizings look really good.

- Glen McGuire and Coyote_6

-

1

1

-

1

1

-

Siggi,

Amazing work! What are you using for nails/rivets?

- Siggi52 and Keith Black

-

2

2

-

I have the V2 version and have gotten as far as making the frames (while I work on another model). I have thought about using copper wire, with the end treated with a cupping burr. Once the nails/rivets are in place, they can be darkened using Liver of Sulpher...at least that is my theory. I am told LoS does not stain the wood. Alot of work, though.

-

-

On 3/22/2025 at 5:34 PM, palmerit said:

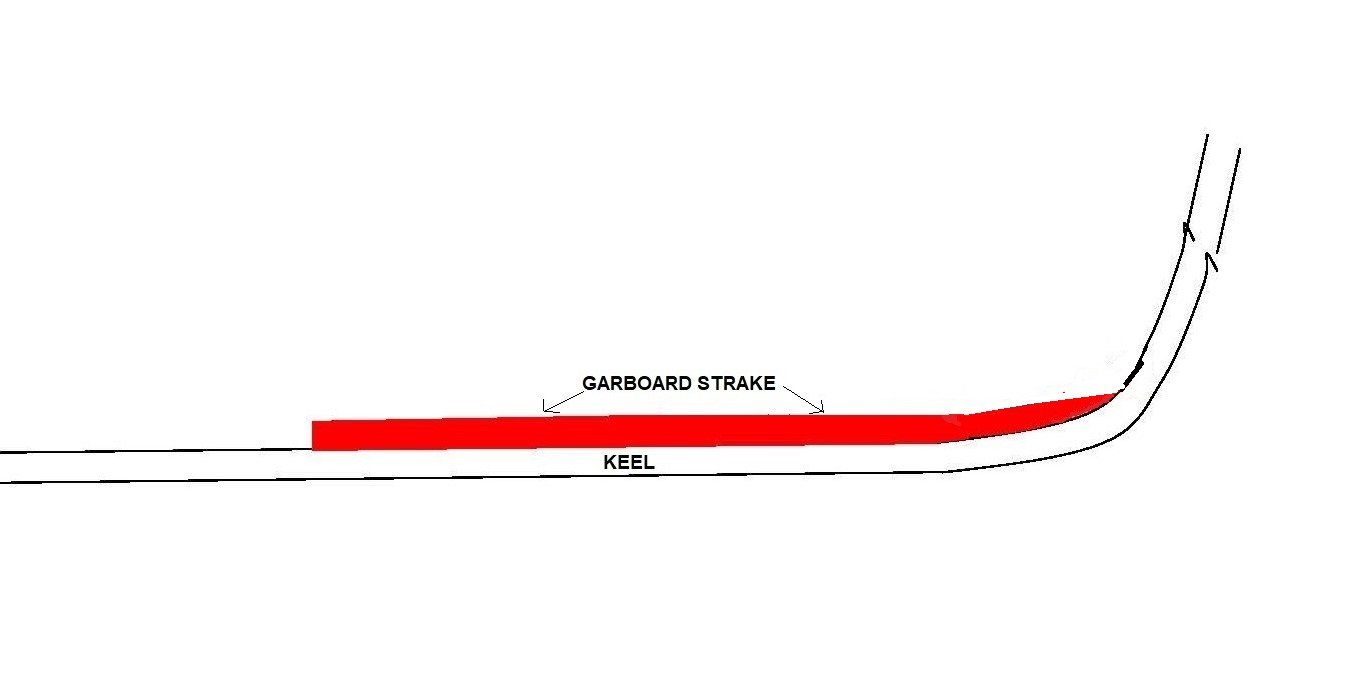

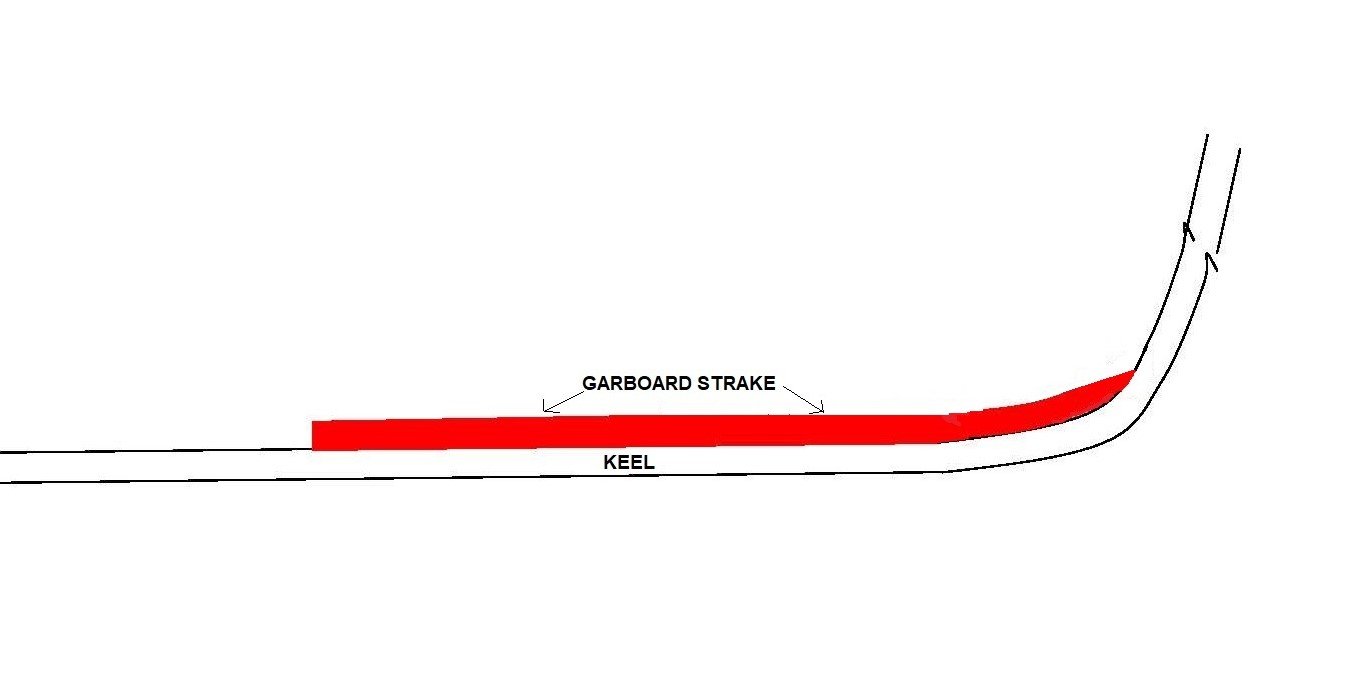

'm still a novice. I thought the garboard strake should not make a "smiley face" (curving up) but be flat with the keel. Not true?

You are correct. That was a poor representation of what I was trying to get at. The updated drawing is probably better. The key is dry fitting a plank or cardboard template so that it snugs into the curve of the stem. As you say, the upper edge should be straight. It will be a natural fit.

- palmerit, JacquesCousteau, robert952 and 1 other

-

4

4

-

2 hours ago, acaron41120 said:

Still having difficulty in figuring out how to cut the garboard strake curve at the bow.

I had that problem as well. I read alot about it and followed many build logs. The light finally came on when I took what I had learned and started experimenting. By taking a test plank and sanding the bow end as I go, I test fit the plank. At one point, the plank fit snug with little or no problem This was normally right at the curve of the keel up to the stem. Working it out just from plans never worked. Test plank or cardboard template in conjunction with the model ended up working for me.

Planking precision and wood filler

in Building, Framing, Planking and plating a ships hull and deck

Posted

Tapered or beveled? I find it is both, for different reasons.