-

Posts

2,646 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

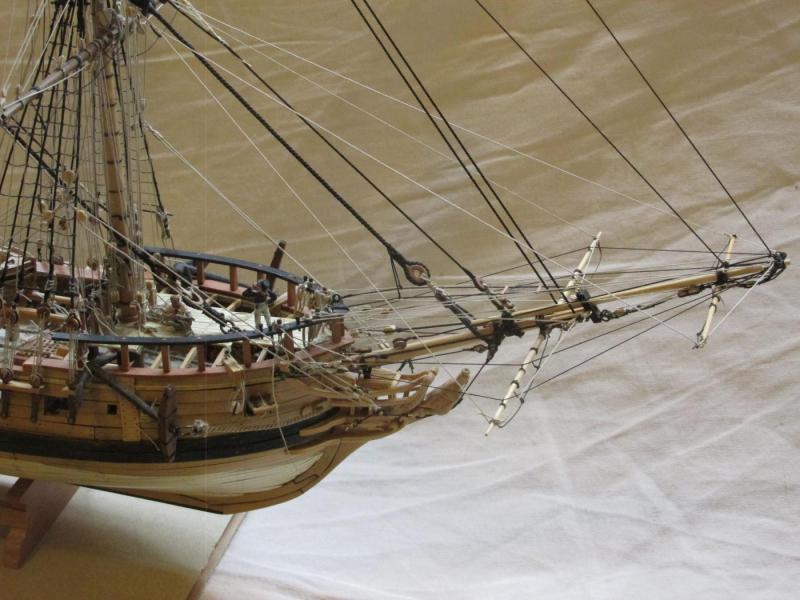

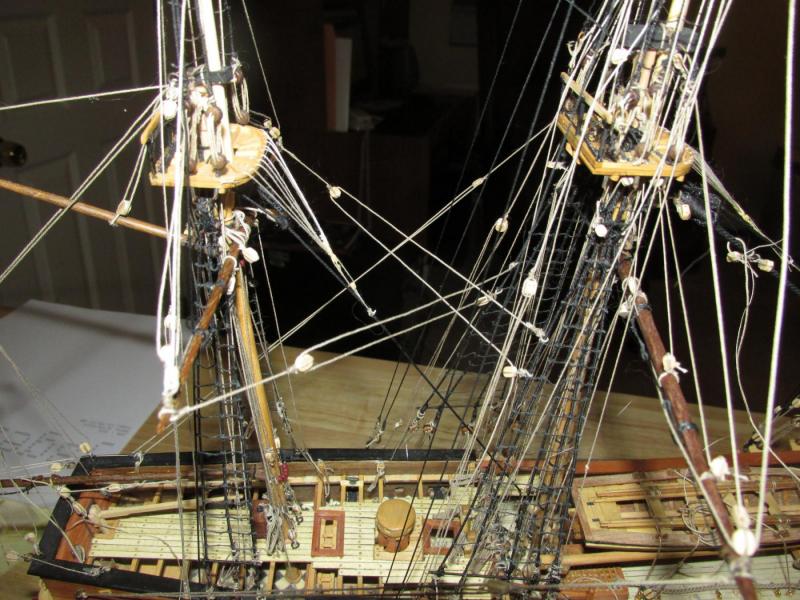

FINISHED Well here they are, the last planned official images of my Rattlesnake, safe and snug in her case. For those who followed my loooonnnnnng and s l o w build over the past seven years, once again, thank you for being so patient and thank you for all the “likes.”

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

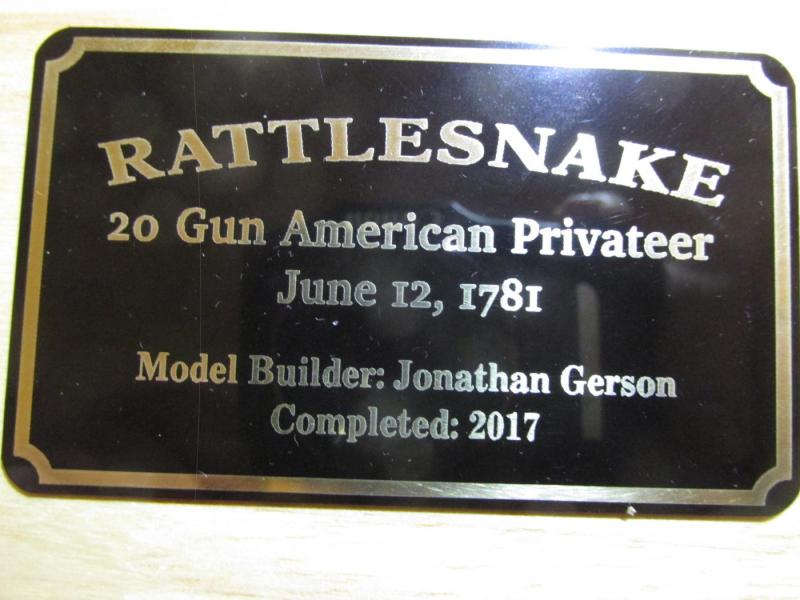

Name Plate I had a name plate made from a local trophy shop. I gave them a mock-up I created in Powerpoint, and they reproduced it beautifully.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

KenW - I got the 1/8" plexiglass at my local glass shop (auto and other repair). I initially tried Lowe's but they were all out. The I went up the street to Home Depot (they always seen to come in pairs, don't know why) and they did have it but they would not custom cut it like Lowe's would have. The third try was a charm; the glass shop had it and custom cut for me. They even re-cut it again (no charge) when I realized my dimensions were a little off and it needed a minor trim. I had to get 1/8" thickness because that is what the case required. Once the wooden frame was around the plastic, the panels were very sturdy. The case (No. GM7W) I got from Model Expo as I mentioned in post #949 above Hope this helps To all - Thank very much for your "likes" and following me on this long slow journey. Once I've buttoned up the model in the display, configured and customized my new computer, and taken a small breather, stay tuned and I will start the next journey on the USS Constitution Jon

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

The last pictures will be posted when the case is finalized, the model cradle is tweaked, and the model is inside.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

The height of the case can be shortened by slicing off the appropriate amount from the vertical frames. I cut 4” off. The frames have a 1/8” square groove on two adjacent sides for glass or in my case plexiglass. I didn’t relish the thought that the case could conceivable break and the glass shards do irretrievable damage. The only real problem I had was that the case assembly instructions stated that the vertical posts needed to be predrilled to accept the wood screws so that the post would not split. I made the mistake of assuming that the drilled holes were to be dead center of the cross section of the posts; it was not. I should have marked the drill point from the predrilled hole in the top frame the post connected to. So the holes did not line up properly and I will have to fill with plastic wood and re-drill. I have no woodworking background, so live and learn.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

The flag on the Mizzenmast is not belayed on the model as it is being “hauled” by a sailor figure. The Foremast flag is belayed to the bitt rail. That’s it. The model is complete and it only took me 7 years! Display Case I also worked on the display case and table. I purchased a Rosewood table from HandcraftedModelShips.com and case I got from Model Expo three years ago during a sale. They don’t make the cases but contract out to White's Woodworking in Osceola IA. The case was made from Red Oak without any finish which meant I could/had to stain it the obvious color, Rosewood. I couldn’t find any Rosewood stain locally and had to order it on the web. It took three coats to get it as dark as the table. The shade is close enough although not perfect, but it will have to do. The first picture shows the table in a temporary location with the base board and one case frame pillar before any stain

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

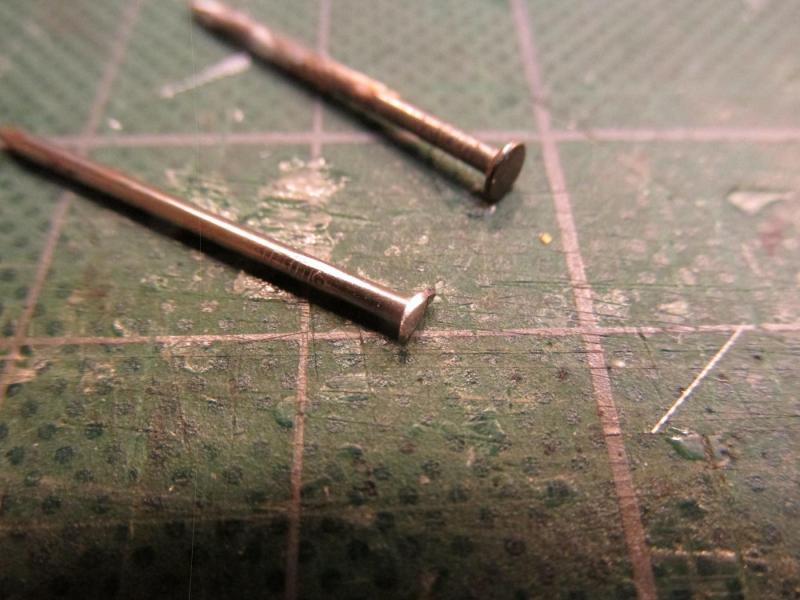

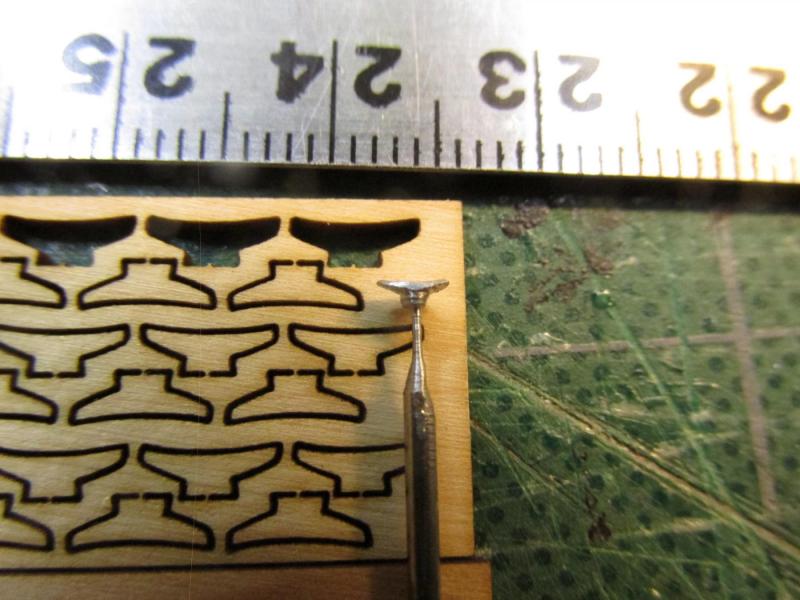

Gaff Flag Cleat Then there was the old question I posed some time back when I was rigging the gaff. Where does the Gaff flag halyard belay? My initial though was to a cleat on the boom and as it turns out, the Mamoli plans show just that. However, at the last NRG convention in San Diego, a two-masted schooner ride was offered to the members which I partook. I noticed that when the sails were lowered, they covered the booms and any cleat that would have been there would have been buried under hundreds of pounds of sail canvas. Also, my research indicated that flag halyards are belayed at any convenient point on the deck. So, I decided to add a cleat to the aft railing. Flag halyards are probably the smallest diameter rope used on the ship and I figured that any of the cleats I had were too big including Syren’s 5mm. Using a technique I developed when I was building the Mini-Mamoli solid hull schooner Evergreen, I made a 2mm metal cleat. Using a nail intended for a picture hook, I filed off the opposites of the nail head. By shaping with the file the remailing head and bending them slightly upwards, these would become the horns of the cleat. I also filed the shaft just under the horns to make the nail shaft a bit oval. This was the cleat. I needed a way to fasten the cleat to the rail so I formed a pin by putting the nail into a Dremel drill and very gently ground the shaft to the thickness of a #75 drill bit (0.021”) using the edge of a small file. The cleat was cut off the shaft and then blackened. I wanted to place the cleat on the inside edge of the rail, but at this stage of the build, there was no way I could do that. It was placed on top. I documented the rudiments of this technique (excluding the pin) some time back on The Kit-Basher's Guide To The Galaxy blog.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

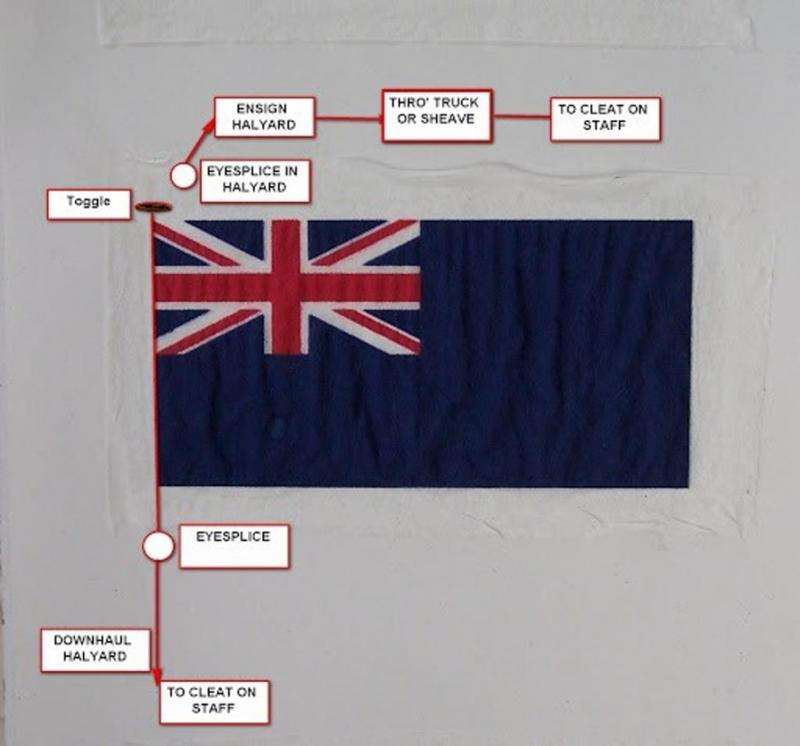

Flags The kit flags were made of a stiff material and should hold their shape. I soaked them for a few minutes and they softened up a bit and added the wind contours. The kit instructed me to fold the side border material over the halyard line to fasten flag. I didn’t do that. After a bit of research I came upon a number of posts on this site which showed a flag diagram originally posted by Blue Ensign explaining how a flag is attached to the halyard. I followed his lead.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

It’s been a while since my last post and believe it or not, some things were accomplished. I think I have belayed the remaining lines (you never know where a loose one may be), and repaired the anchor tie down and the gunport doors. Sailor Figures In addition to the list of things to do posted above, I forgot to mention I wanted to add some “scale” to the model so a while back I purchase some sailor figures to add to the final display. Taking a guess that the average height of a typical seaman, was 5’6” or 66”, at 1/64 scale that comes out to just a tiny fraction over 1 inch (25.4 mm). So, I purchased some Amati 25mm sailor figures. I had some 1¼” figures but that worked out to a sailor being 6’ 8”. I imagine there were seamen of that size, but not a whole crew. I found some images of typical sailor attire of the period and proceeded to do my best at painting them onto the metal figures. I prepared the figures by dipping them in the acid solution I used for silver soldering to clean them of any oils and impurities and to my surprise, they blackened (yes, I did check to see if I used the right bottle). The darkened metal did not affect the painting process. Using flat paints, a fine brush, and my magnifiers (eye loupes and headset) I proceeded on. When I saw the photographs I am posting, I noticed my fingers left some smudges giving them the appearance of being a bit grubby, not spit and polished. That work fine for me. These guys are supposed to be privateers, not regular navy

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

All my power tools are miniature: Brynes saw, Brynes thickness sander, rotary drill, and a 40 year old Dremel scroll saw that vibrates like crazy. I'd loved to get a milling machine and lathe, but as I have learned through school...the school of hard knocks, you don't buy a tool until you need it. I can't tell how many doohickys and thing-a-mabobs I've bought and never used. So I'm always window shopping and asking questions. Thanks for the prompt reply. Jon

- 742 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

Just found your log and will join all the others to follow you as you complete this arduous but satisfying journey. I hope to start building my Conny soon if I can ever finish my Rattlesnake. A quick question: You mention earlier using small router bits. What kind of router are you using? I have jury-rigged a pseudo router thingy in the past but using the proper tool for the job is always best. Any other power tools you intend to use i.e., lathe, milling, etc.? Jon

- 742 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

Been quietly following you from afar. Your work bench looks familiar, hmmm, seems like I've seen it before. I know, I have one exactly like it! I got mine from Harbor Freight last year. It not a bad deal for the price. I've always been told that to do a job right, you need the right tool and it this case I think you're going to have to bite the bullet and get a scroll saw. It will make your model building a whole lot more pleasant and more productive. As for the wood, I try to avoid Basswood altogether if I can, it doesn't sand smooth (gets "fuzzys") and it doesn't hold an edge well. I prefer boxwood. Its a nice hard wood and a pleasure to work with. Jon

- 108 replies

-

- mamoli

- constitution

-

(and 2 more)

Tagged with:

-

I believe you have the correct idea: "center out". I tried using that philosophy when I did my rigging which I started only after I completed all my woodwork and I did run into space problems especially near the main mast. You've expanded the idea to include the deck furniture which gives you initially more room to work with. Just be careful to keep dry fitting the furniture pieces as you add stuff. Small shifts in position placements can add up so you don't have the proper location space for other stuff. For example, those deck eye bolts and their subsequent rigging around the masts can mess you up placing the spare masts in position even if they are off by only a few millimeters. Jon

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Your model is coming along very nicely. I like its clean look. I am curious though; I don't see any ladders or gang planks to the quarter deck nor the spare masts and ship's boat. Are you planning on adding them soon? It's going to get quite crowded soon on that deck to add any construction. Jon

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

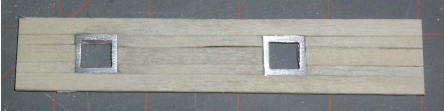

As I mentioned in my response to you on my build log, I followed Robert Hunt's practicum for kit bashing, but he also provided detailed instructions for creating the model straight out of the box. In this particular case with the gun ports, he suggested using a full plank in the middle and modified strips on either side. He provided this image:

-

JustBlowingInThe Wind - My kit was in fact exactly like yours... in the box. However, I bought Robert Hunt's practicum which showed me how to kit bash it. Without his instructions, I would never have attempted even to buy, let alone build such a kit. In order to follow along, I had to invest in a new wood package, new tools, books, and lots and lots of time. As it ended up, I would say that my build was at least 90 - 95% scratch built. The only thing I used from the kit were the excellent plans, keel framework, bulkheads, deadeyes, and maybe a few other odds and ends. I used Syren's rope and blocks for the most part. As an example of the kit bashing, the keel, as you noted, as well as the stem were replaced to make it more realistic.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Just discovered your build log. I am just putting the finishing touches on my Mamoli Rattlesnake model. This is my first build and I jumped in with both feet and kit bashed it following Bob Hunt's practicum. Because it was my first build and I didn't know what I was doing at the start and I didn't know what I didn't know, I moved slower than molasses on a cold day, like 7 years. Hopefully you'll take a look at my log to avoid the pitfalls I fell into. Maybe it can can help you along. Jon

-

Just got caught up having been out of town for 10 days. She's looking real good. As my log documents I too ran into a lot of conflicts between books and the various plans I had accumulated. Not only did the Captain of the Rattlesnake not have to follow British rules, I believe he had the right to modify the rigging as he saw fit. The rigging he started out with on a voyage may not have been the rigging he ended up with when the ship returned to port. Jon

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Ken, I like your optimism. Based on my past "speed," I'm guessing a least another month to say "done". As it is, nothing will be accomplished till after Xmas due to other commitments. Hopefully things will go smooth and I won't break anything. 8-) To all who have endured my snail pace following me, thank you. The adventure is nearing its end, but is not quite over...yet. Jon

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

This is a big milestone: All of the rigging is installed. That being said, there still some work to be done: · Belay all the remaining lines · Repair: o Rudder straps – some of the original paper ones came off o Anchor tie down line – replace snapped line o Gunport doors – glue back on · Add the flags with their associated blocks and halyards · Rework the model stand – the model wobbles too much · Buy the cut Plexiglas for the case · Stain and assemble the model case · Obtain a table for the case to sit on

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

The 8 tack lines were then installed. Six of them originated from an eyebolt on the outside of the hull through a 4 mm block in the cluster and back through a hull sheave to be belayed on a bulwark cleat. The other two originated from a 4 mm block on the boomkin, through the 4mm cluster block, back to the originating boomkin block, and then to be belayed at the bow pinrail.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Clew Garnets Next came the four clew garnets and their associate tack block clusters (I think I got those terms right). They’re supposed to be attached to the bottom corners of the main sails if I were to install them. Sorry, no sails on this model. The block clusters are made up of 2 10” (4.0 mm) and 1 12” (5.0 mm) blocks

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Braces Again working stern to stem, bottom to top, the braces were installed. The Crossjack braces were unique in that they originated on the Main backstay on one side, went through a block hung from the tip of the Crossjack yard on the opposite side, back through a block on the original backstay, and belayed to the deadeye below.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Before I tackled the braces, I needed to add the rope coils to the various belay pins and cleats. If I didn’t, getting access to the inner areas of the deck would become more difficult than it already was.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.