Rick01

Members-

Posts

652 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rick01

-

Don't despair - I'm on to my fourth model and still can't get the planking correct. I've butchered this kit myself turning it into something resembling the real Lady Nelson and would suggest that once you start on the second planking you get a nice timber in .6 x 5 (or 4) rather than the 1 x 4 walnut supplied. I found the supplied timber quite hard to work with whereas the .6 was much easier to soak and bend in the three dimensions needed particularly round the bow and stern area. Rick

- 69 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Advice on Billing Boats Endeavour and/or shrimp cutter

Rick01 replied to innkeeper's topic in Wood ship model kits

I'm only just out of training wheels as a model builder and would suggest that you grab something like the Artisania Latina "Endeavour's Longboat" as a practice/starter kit then go on to whatever you've selected as your main model. There are a number of builds on the forum for this kit and it will give you that first taste of planking without breaking the budget. Rick -

SCHOONER ENTERPRIZE by GConiglio - POF

Rick01 replied to GConiglio's topic in - Build logs for subjects built 1801 - 1850

Just noticed this log yesterday. Funny coincidence as I was on the replica Enterprize last weekend! Rick -

Check this log http://modelshipworld.com/index.php/topic/5618-bounty-launch-by-captainsteve-finished-model-shipways-116-scale-small/page-1?hl=%20bounty%20%20jolly%20%20boat Rick

-

Check this out for an experience. http://www.drakenexpeditionamerica.com/ The video makes a trip on the Endeavour replica look like a sail on a duck pond! Rick

-

looking at ships, what's the best boat for a newby?

Rick01 replied to shutter's topic in Wood ship model kits

My first build was Endeavour's longboat. Simple kit, fairly reasonable instructions and makes up into a nice model. There are a couple of builds on here if you like to search for them. Rick -

Don't fix any sails/running rigging until you've completed the standing rigging. It's a pig trying to do it any other way! Rick

-

First bulkhead compares with my kit but the second does look like a bit of fill may be called for and three also doesn't look too bad. Rick

- 69 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Looks as if you've a bit of a curve on the fill you've done. Once you've packed the bow section you need to get a nice smooth sweep from the bow on through to that second bulkhead - takes time and isn't easy but you do need it to get the final planking right. I used a flexible sanding stick to finish that area. This was made by pinching one of my wife's flexible nail buffers and double sided sticky taping fine sand paper to it - made life so much easier. Rick

- 69 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

You may find planking easier if you completely fill the bow section with balsa and sand/file to shape. It gives the first layer of planks something solid to grip in that first important curve. Rick

- 69 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

I'd expect it to go to the back - then the lift for the gaff would be hooked/lashed to it. Also note that there should be a similar set up on the fore mast so the cap with only two eye bolts sits above the cap with three one each mast. Search some of the cutters for an illustration of the rigging around this area. Rick

-

If I remember correctly the rings remain on the masts at all times. The sail has a rope that runs down the leading edge looped through a ring then through a hole in the sail then back through the next ring and so on. At a guess the spare hole is for the tail end of the rope running down the sail to be secured through. Sorry but I've no idea what the nautical terms are for these actions. :-( Rick

-

Yes she's only a 50ft brig - I had thought about a straight pull and was only contemplating a lead block to provide better leverage. I've searched for brigs of similar size and era but not been able to find one with a really clear indication of its running rigging. Having said that those I have seen would appear to end on the mast at cleats. I'll do a few more searches and see how I go. Thanks again for your help - it's really appreciated. Rick

-

Put in a complete stern filler - I've worked on this model and it makes planking that area so much easier if you've got a solid surface in that area. Rick

- 69 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Thanks very much for that - as a rank amateur most of this is still a mystery to me! One last question then - would halyards and sheets then be run through blocks hooked to ring bolts at the foot of the mast then back up to cleats fixed on the mast, thus saving valuable deck space otherwise taken up by fife rails? Rick

-

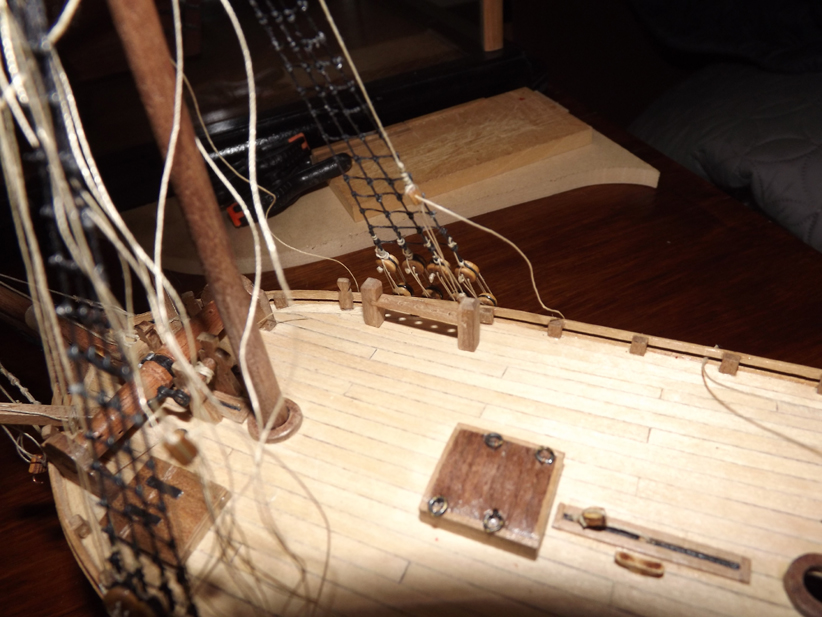

I'm starting rigging my interpretation of HM Brig Lady Nelson http://collections.rmg.co.uk/collections/objects/66562.html andas there are no gunwales it leaves me with a problem re belaying pin locations. The ship is a 1799 built 60 ton brig, thus quite small. I've searched on line for a definitive answer but so far nothing, I have however seen three variations and wonder which would be more correct. 1/ A free standing fife rail as per this photo of one I've mocked up. 2/ Cleats lashed to the shrouds. 3/ Cluelines etc. tied directly to a lanyard strip. Any assistance would be greatfully received. Rick

-

How about a series devoted to Australian exploratory ships. HM Brig Lady Nelson, top sail schooner Enterprize, HM Cutter Mermaid (slightly more accurate version) all come to mind. Scale at 1:48 Price range $200.00 ~ $350.00 With the number of Aussies on this forum alone I'm sure there's a market for models celebrating our history in addition to those "First Fleet" vessels already available. Rick

-

Metric vs English

Rick01 replied to jdiven's topic in Building, Framing, Planking and plating a ships hull and deck

But the old system certainly made your mental arithmetic better - coal is £3, 7s , 6p per hundredweight what is the price of 4 and three quarter tons . Ahhh the good old age of 11+ exams !! 20 cwt = 1 ton 12 pence = 1 shilling 20 shillings = 1 pound. so [(20 x 4) + 15] x 3 pound 7s 6d = ? Quite simple really. Rick -

Recommendations for essential tools for a beginner?

Rick01 replied to Cindyp's topic in Modeling tools and Workshop Equipment

No 3 scalpel handle plus at least 25 number 11 blades, lots of rubber bands, mini clamps, assorted grades of sandpaper, mini vice/drill with drill bits from .25mm up to 1.00mm, water based wood glue (don't know what's available in SA), Helping hand http://www.ebay.com/itm/Helping-3Th-Hand-Soldering-Stand-Magnifier-Glass-Clamps-Modelling-Stand-US-stock-/141503727975, tweezers nicked form someone's makeup kit, likewise a nail buffer ( double sided sticky tape will fix fine sandpaper to it for sanding curves.) The ability to improvise tools from bent bits of wire also helps. Don't go mad buying stuff until you find you really need it - you can end up with expensive tools that you only use once that way!! Rick -

Have you done a trial fit on the stand? My model just wobbled around so I ended up making a cradle stand instead. Rick

- 32 replies

-

- longboat

- artesania latina

-

(and 1 more)

Tagged with:

-

http://www.dailymail.co.uk/news/article-3568740/Captain-Cook-s-HMS-Endeavour-United-States.html Rick

-

Nice oars - I dumped the metal thole pins in favour of double pins in line with Chuck's 18th century longboat build. Rick

- 32 replies

-

- longboat

- artesania latina

-

(and 1 more)

Tagged with:

-

In the plans no mention is made of planking the bulkheads fore and aft. I don't think I mentioned this in my build but it's just a little detail that is worth adding before the seating is installed and the interior is finished. Rick

- 32 replies

-

- longboat

- artesania latina

-

(and 1 more)

Tagged with:

-

Help in Identifying an Unknown Tool

Rick01 replied to BANYAN's topic in Modeling tools and Workshop Equipment

Should have a nice brass butterfly or slotted screw - I'm pretty sure the steel item isn't original. Rick

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.