-

Posts

6,402 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Canute

-

Nicely done Sal. I'll file that change of wood for my builds.

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Nicely done, Brian. Your Niagara is coming along quite nicely.

- 287 replies

-

- niagara

- Model Shipways

-

(and 1 more)

Tagged with:

-

Ah, my little chickadee - with apologies to W.C. Fields. (I'll go quietly now)

- 203 replies

-

- artesania latina

- marie jeanne

-

(and 1 more)

Tagged with:

-

Paul, I'll add my well done, too.

- 37 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

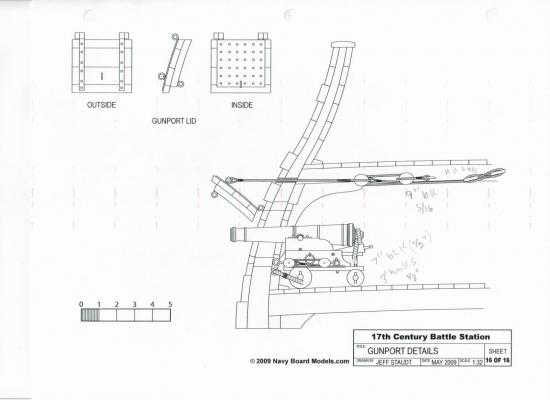

Here you go, Jesse: The notes are mine, sizing the blocks. This plan is part of a practicum over on the MSB site as a Battle Station practicum. It's done in 1/32 scale.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Wise man, Mark. As somebody said "Happy wife, happy life"!

- 203 replies

-

- artesania latina

- marie jeanne

-

(and 1 more)

Tagged with:

-

I'd like to follow along, too. Gonna hang with Mark, Grant and the rest of the gang.

- 129 replies

-

- armed launch

- panart

-

(and 1 more)

Tagged with:

-

I used to paint brass model railroad engines with a brand called Scale-Coat. The metal had to be clean; even had to strip the clear coat from some engines, since they had bubbles in the clear coating. The Scale-coat worked great, since it was a lacquer and dried glossy. Easier to decal over than flat paints. It didn't need a primer, but if you're painting yellows or reds, you better prime first.

- 222 replies

-

- 18th century longboat

- model shipways

-

(and 2 more)

Tagged with:

-

They may have had some tackle and a tie off cleat in the overhead, between the deck beams and carlines. I have battle station plans and that's where the gunport door operating mechanism "resides". A couple of single sheave blocks is all.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

You should clean and prep the metal (brass?), either dunk it in some vinegar for brass or apply a primer paint for other metals. The vinegar is acid, so it etches the brass and gives some tooth to the part for the paint to stick to. Let the primer, then paint your color.

- 222 replies

-

- 18th century longboat

- model shipways

-

(and 2 more)

Tagged with:

-

Looks good, Jack. Transom is blended in nicely. The hull planking looks smooth. Since this is double planked, the second layer will lay down nicely.

- 203 replies

-

- artesania latina

- marie jeanne

-

(and 1 more)

Tagged with:

-

Well done Dave! The good doctor was suitably wowed.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Great way to recharge the batteries, Jay.

- 572 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

Grant, I'll join you in the front row. Looking forward to another build by Clare.

- 51 replies

-

- wasen

- thermal studio

-

(and 1 more)

Tagged with:

-

1/10-scale Japanese Fishing Boat kit from Thermal Studios

Canute replied to catopower's topic in Wood ship model kits

Very interesting boat, Clare. Will be following your build. The masking tape looks like the same tape Tamiya sells. Excellent masking tape!. -

How will you keep it level? Guess you could pin the wheels and put one under the trunnion point.

- 572 replies

-

- constitution

- frigate

-

(and 1 more)

Tagged with:

-

Mick, the first few and the ones showing the overall acrylic supports for the cant frames on top of your build board. Wasn't visualizing the supports until I looked at the overall ones. Takes a while to get stuff drilled into this Irish-Sicilian skull.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Click! Light bulb on now. One picture (or in this case a series) does the trick. Thanks, Mick!

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

That boat's a beauty, Sal. As are the sweeps and oars.

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Sharp blades and a cutting mat work well. But, balsa is a very soft wood; really only useful as filler for a hull, between the bulkheads. Trying to shape items, like deck furniture, is difficult because the wood is so soft. The edges don't hold up if much pressure is applied, so fine detail is hard to achieve. You may want to try some basswood. It's still soft, but it doesn't have the issues of balsa.

-

Very work on the gun carriages, Grant. Worth a bookmark!

- 456 replies

-

- finished

- bomb ketch

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.