-

Posts

9,639 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Ok Guys.....put your thinking caps on. What if any type of flag (1742) should we fly on the mast? Lets see some images... Chuck

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I ship almost anywhere in the world. Except for China, LOL

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nope....you will always need to buy at least the starter package and the plans will NOT have any drawings for the bulkheads and other parts. This is being done to prevent folks from stealing the design and pirating the project. You wont need those templates on the plans because you will have the laser cut parts. It also prevents people from posting the plans on their websites and forums as a download which is unfortunately all too common. It has happened with my Cheerful and I only need that to happen once before I find a way to prevent it. Chuck

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

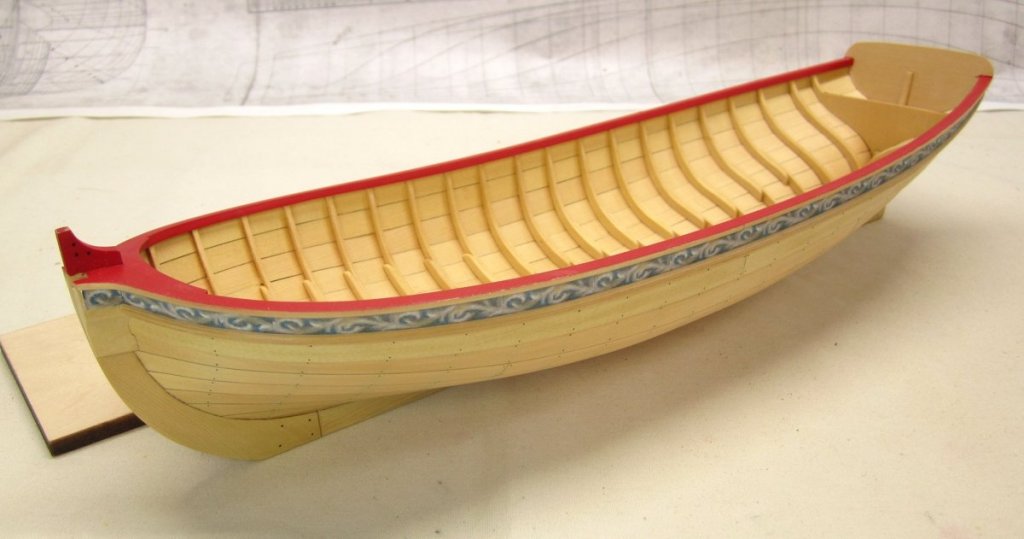

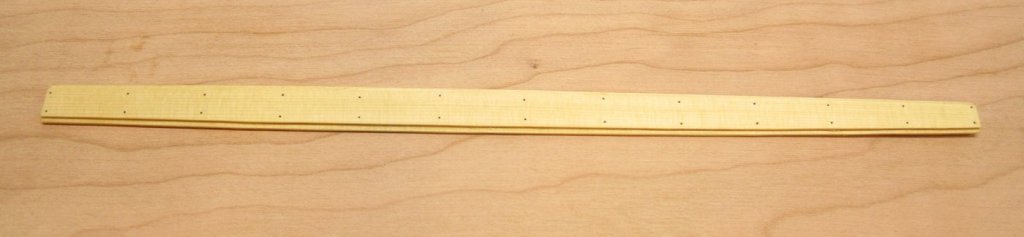

I currently offer milled sheets and strips at Syren. I dont know many other who do. But most exotic lumber places stock it in larger billets. The Medway longboat posted below is made entirely from AYC except for the molding strip which is boxwood. https://www.syrenshipmodelcompany.com/milled-lumber.php#!/Alaskan-Yellow-Cedar-Ship-Model-Wood-from-the-Syren-Woodshed/c/28580529/offset=0&sort=normal

-

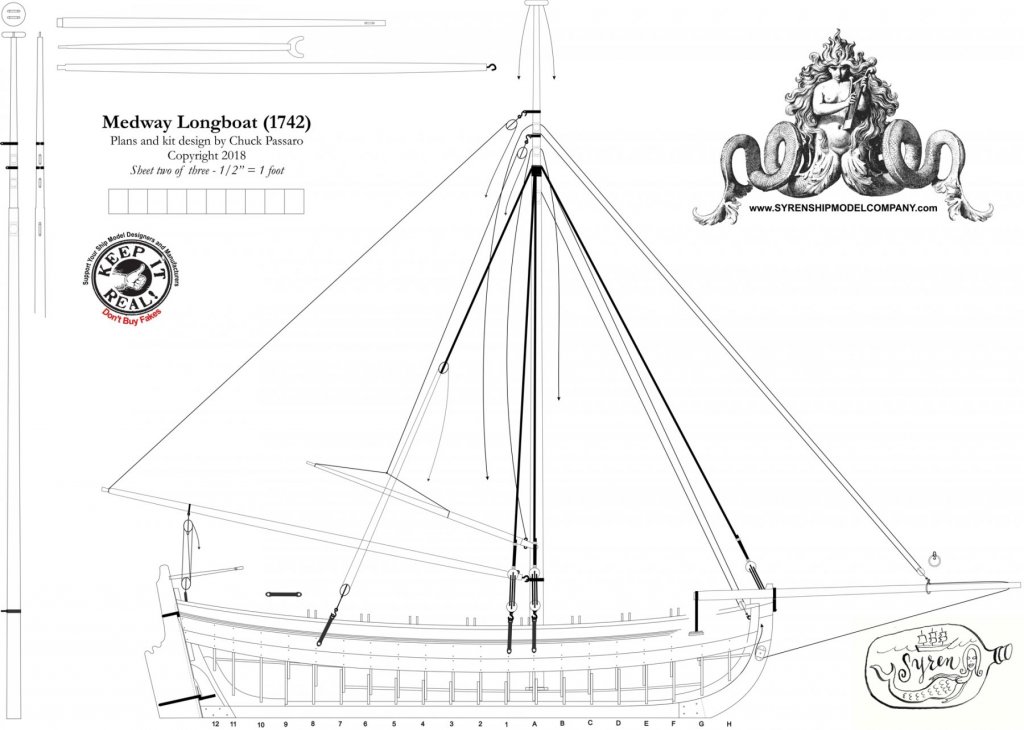

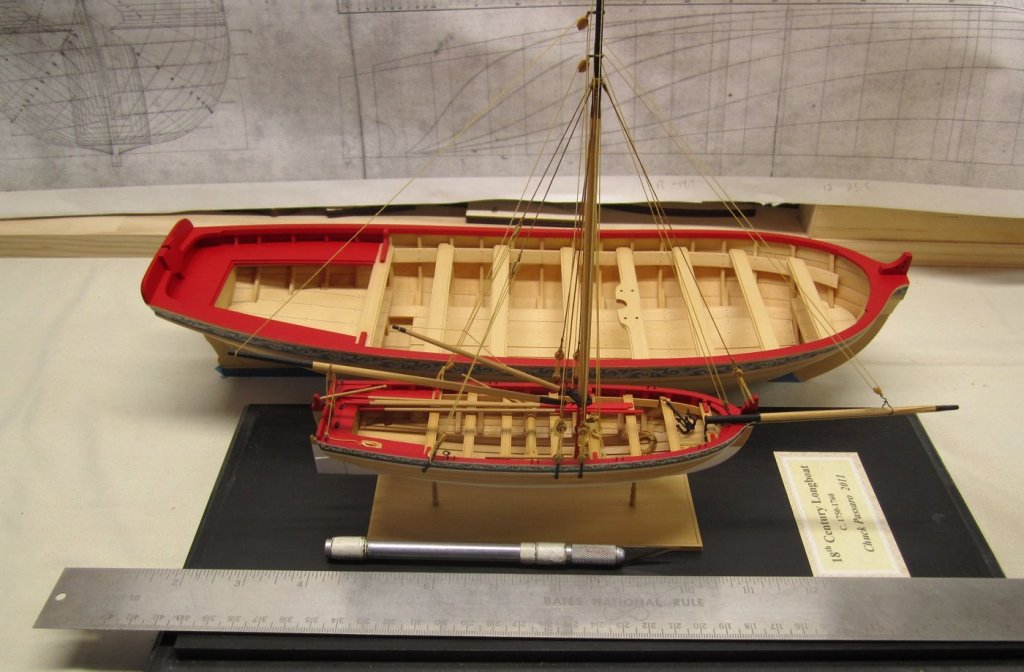

FYI.....as some have asked for dimensions of rigged model. Rigged, this model will 23 1/2" long and 18 1/4" tall. 😊 This is the rigging plan for those that wont want to add sails...

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Allan. Anyone can join in. I will say once more though, this is not a beginner model project. It is very challenging. But its hard for me to judge because I designed the thing. Having said that, I am sure that within a group environment there will be much encouragement and many ideas and suggestions to help you problem solve. That is the power of a group project. I learn things every day from folks and many of those tricks and tips were used while I built the prototype. Chuck

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

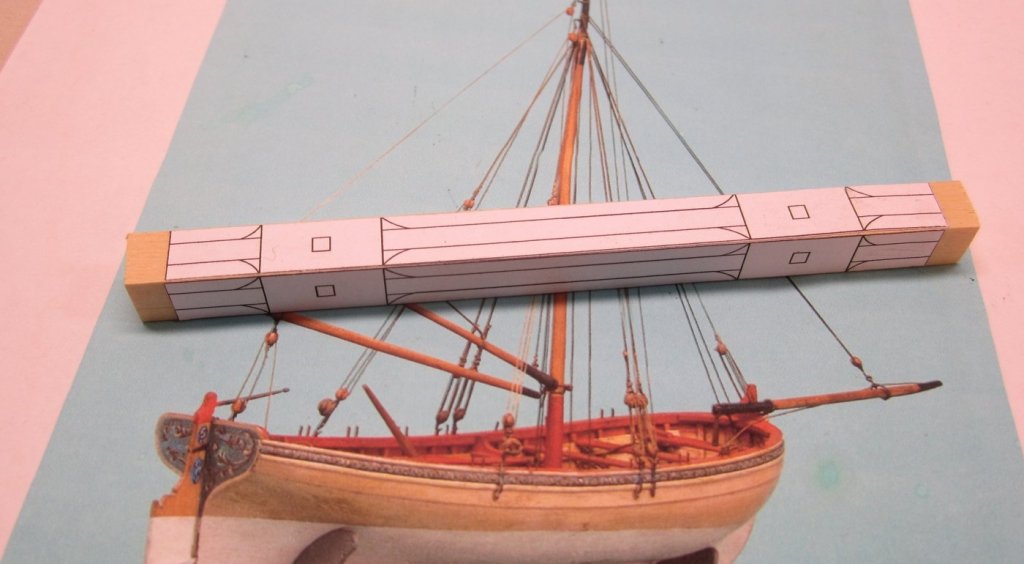

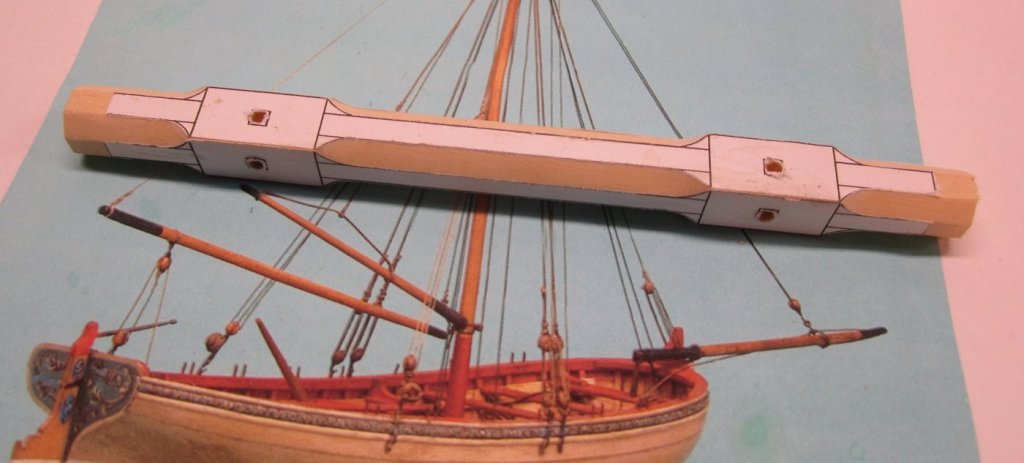

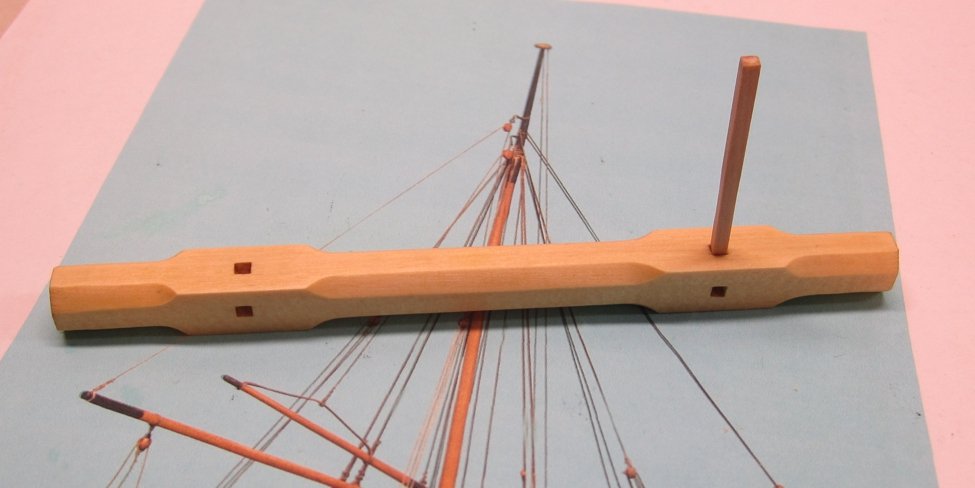

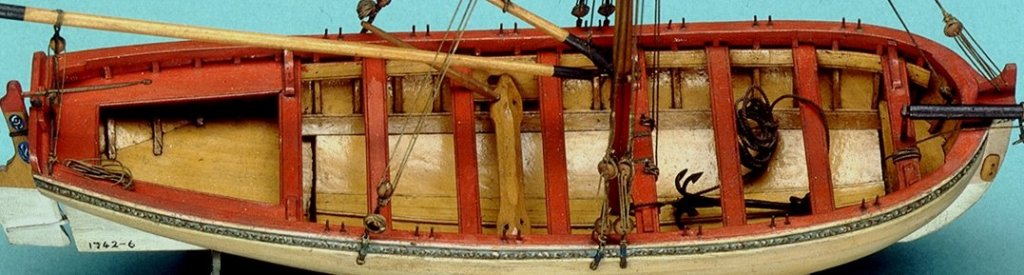

Thanks guys. Its time to make the windlass. Some people may get nervous about shaping a piece of wood like this. But if you just take your time and go slow it will go well. I created templates that will be glued to all four sides of a 3/8 x 3/8" stick of cedar. I used a glue stick to attach the templates. Note how the stick is left a bit longer than the templates. The ends will be rounded eventually to a cone shape. I will wait to check its fit before I do that and trim each end to fit the space. Then the corners were removed and sanded down to match the template as shown below. I used a sharp #11 blade initially to remove the material quicker. I shaved off the corners carefully and stopped just short of the line ob the templates. Then I finished it up with 320 grit sandpaper. I also drilled the holes for the windlass bars. I used a #40 drill bit. The templates were removed easy enough by wetting them down and then they come right off. I cleaned up the edges a bit by sanding and tweaking the edges until it looked nice and crisp. Then I used my #11 blade again to carefully square up those holes. The finished windlass up to this point is below. Remember that I still have to reduce the ends to a cone shape so the windlass fits inside the brackets along the risers inboard. That isnt a finished handle for the windlass. That is just a 3/32" x 3/32" strip test fit in each hole. I used a boxwood strip which is a hard wood. It helped to make the square holes nice and crisp. Just push them into the holes gently. You can use any square strip this size even a brass strip which I didnt have handy. You can see the windlass in the contemporary model below.....next I will be shaping the ends and adding the brackets so it can be installed.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That will just be a PDF to download like every other kit monograph/instructions I write. It keeps costs down. Chuck

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes......more or less. For a complete kit of all of the parts you will need to complete the hull (including friezes) it would cost $170 - $175. That is all cedar with boxwood accents. I am not sure what the starter package will cost which I originally stated would include the keel parts and frames along with the plans and base board. That was originally going to come in at around $110. But then folks wanting to scratch the remaining parts including the planking would still need to buy the cedar sheets to complete the hull. It doesnt make economical sense to have a starter package because after you buy the additional wood sheets you will need, it would end up costing about the same anyway. But if you guys still want it, I will provide one. I thought most would see that it doesnt make economical sense and instead would rather have all the laser cut parts anyway. I am not pricing this kit to far beyond the materials and laser costs. I want to see more people join the group and build the kit together. The kit has about 25 laser cut sheets and additional strip wood, brass strip, wire and fishing line etc.....and the printed friezes. What do guys think? I think its quite affordable considering the new 1/2" scale MS kit which is basswood will cost you about $125. I think its well worth an additional $50 considering the differences in the two kits. The rigging package will follow but in all honesty you guys can get that stuff anywhere....I am thinking another $30 - $35 or so but it depends on the sail materials or silkspan. But you guys can pick that stuff up anywhere. Rope, blocks, wire, brass strips, Deadeyes and sail material with a flag. The original hull kit will come with the rigging and sail plans. Chuck

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

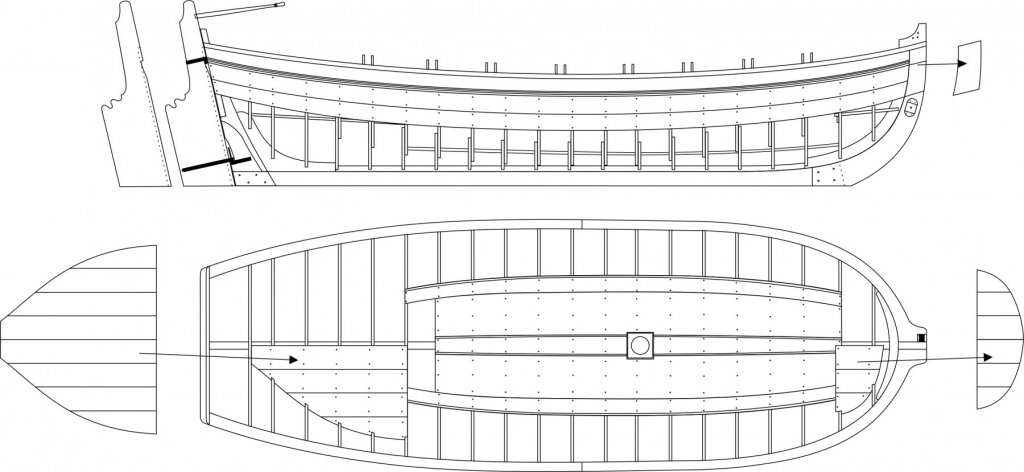

Erik....Does this help? You should join the group. What would be better to get your ship model juices flowing again. The new model is abut 15 -16" long for the hull. Then you have to of course add the mast ...yards and rigging. 😊

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

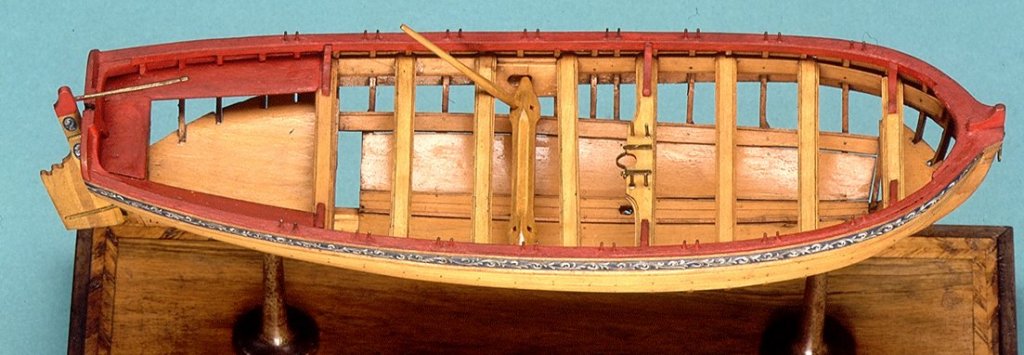

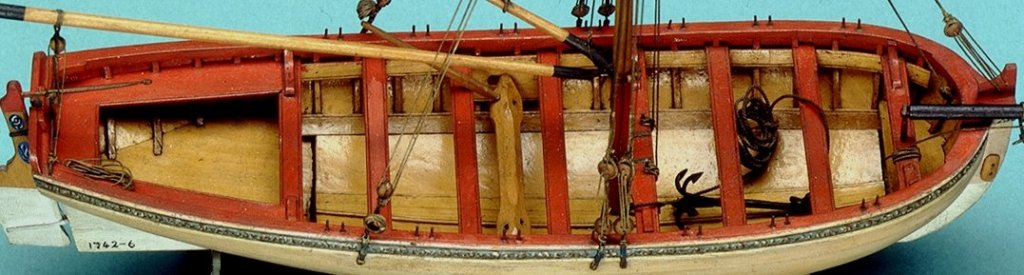

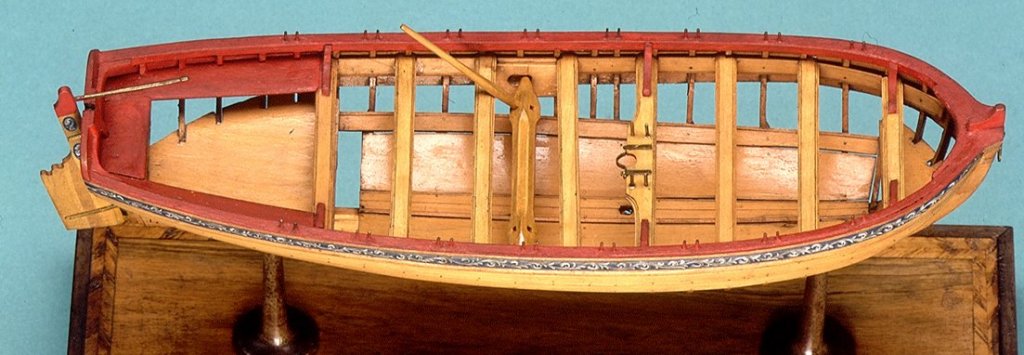

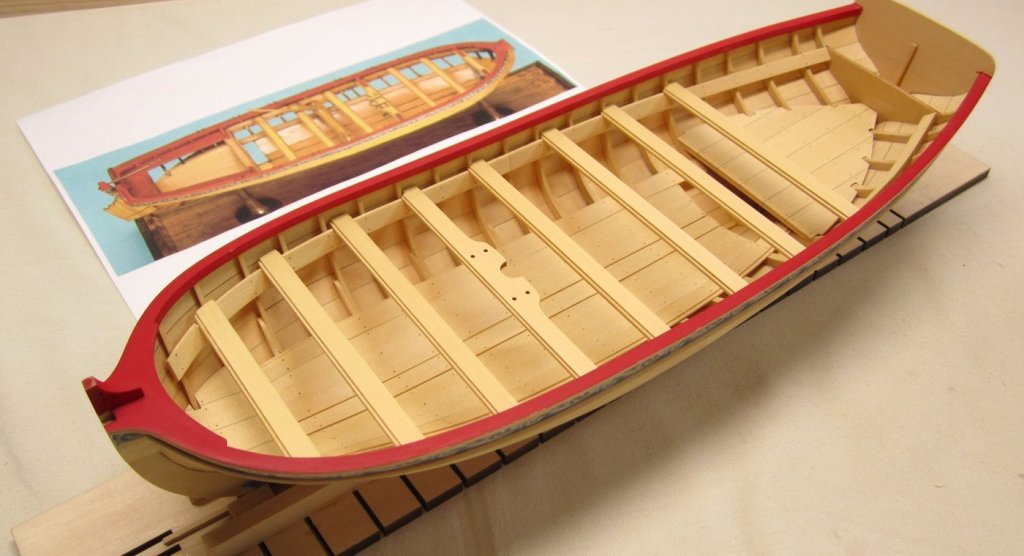

Thank You gentlemen!! Just a quick comparison as the new larger and improved longboat is far enough along. You can see how different and more elegant the shape is on the newer version. It has a much fuller bow and as you proceed to the stern the newer version has a more pleasing curve. You can see many other differences as well. The floorboards and other features are more detailed and true to the Medway contemporary model.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks guys. Nothing has changed. There will be a full hull kit (everything you need in one box) followed by a smaller mini kit with all of the rigging and masting stuff. Just like the barge, virtually every part of this hull you saw me build so far is made of laser cut parts. In fact, I already have 10 kits already made up. But those are reserved for the guys in my local club. I literally just finished cutting the last sheets today. I am awaiting a new batch of milled cedar which should come in a couple of weeks. I will make 10 more right away. Each kit has about 25 sheets of laser cut parts. Thats just for the hull. As soon as the hull is finished and I finalize the plans, I will be ready to get this group started if there is still any interest. Once I get to that point I will ask again for a comitment in the online group before I start setting up a new forum area. All I really have left to make on the hull is the windlass, some metal work on the mast thwart, the thole pins, the roller at the bow....rudder and tiller. Thats really it. Then its time to rig it....first without sails.....then with sails. We need a minimum of 8 to start a group....but ten would be a real nice round number to start with.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

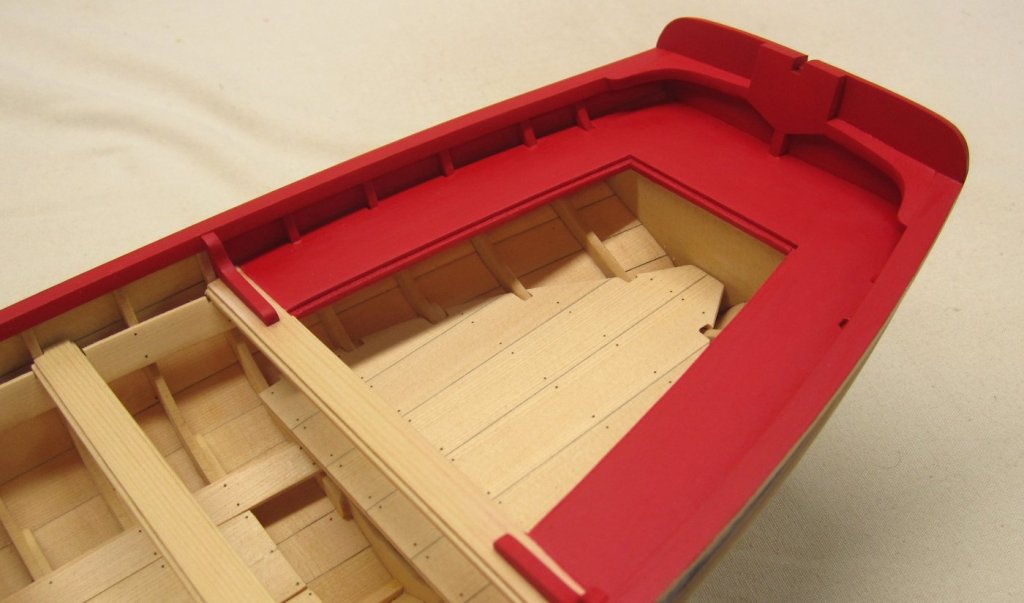

I finished painting the cockpit seats. I also added the knees atop the last thwart and the knees and bracket along the inside of the transom. The knees on the transom were tricky but not too bad. They need to be beveled along the sides and back to fit the angles of the bulwarks and transom. Also note that the center bracket or panel on the transom was added to the top of the stern post and sanded flush. But before doing so, the stern post was reduced in height about 1/16" first. This allowed the top of the panel to sit flush with the top of the transom. Once this was glued into position and the knees added on either side, they were all sanded flush with each other so you couldnt see any seams. I used some wood filler for this too. Once painted it looks nice and clean. The notch on the center of that panel is used as a guide to file that same notch through the transom as well. You can see that in the photos. I hope that makes sense. Next up working my way forward will be the windlass.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Moving right along.....I will be working my way forward on the interior. None of the thwarts are glued into position just yet. There will be some things that need to be done to many of them as I work my way forward. For example, the seats in the cockpit need to be notched into the aft thwart. The seats are what I did next. The seats are laser cut in two layers just like the thwarts. The laser char was removed from their edges and then they were glued up so there was a decorative edge on one side like shown in the photos and on the plans. The two side seats were "tweaked" for the best fit first. They are laser cut a bit long on purpose to give everyone some wiggle room with this. You will be shaping and sanding and test fitting many times over until these fit properly. Everyone's model will very slightly so the notches for the frames will need to be filed in. BUT ..... -first, I beveled the aft edge of the seats so they sit flush against the transom which is angled. -then I held the seat in position against the frames so I could mark their locations on the seat. -I filed the notches for the frames a little at a time constantly testing the fit and adjusting. The edge of the seat against the frames also must be beveled to sit properly against the inside planking. -When the slots for the frame were acceptable, I laid the seat in position to cut its forward edge to length knowing that it will be notched into the last thwart. You can see the notch I filed into the thwarts below. Basically you must file away the lower layer of the thwart. In the next photo you can see how it looks after test fitting. Once they were glued into place, the center seat was treated the same way and adjusted to fit. This is how the whole model looks at this point. Its getting close now with only a few more details to add. The seats in the cockpit area will be painted red like one of the contemporary models. The two contemporary models are painted differently but I think I will follow the scheme shown below in the unrigged contemporary version. I also posted a photo of the rigged contemp. model to show you guys the difference.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That is not boxwood at all. They shouldnt sell it as such. It is clearly a dyed wood to imitate (very poorly) boxwood. They used a yellow dye and my guess is that in spots you will find that the yellow doesnt go all the way through the strip. The wood texture being all stringy and fuzzy is indicative of submergence and cooking in a dye bath for long periods of time and the same thing would happen to any soft wood when submerged like that. Good dyed veneers dont have that texture. Take a sharp blade and slice a shaving off of the top of a strip and see what the color looks like deeper and if you even stand a chance of getting a smooth finish on that wood. I doubt it. Its basically a cheap dyed wood veneer which is common and that is why you will only find MS offering it in 1mm thickness. Cheap yellow wood veneer ripped into strips. These veneers are usually dyed very bright primary colors like this example of yellow veneer sold for marquetry enthusiasts. This is what the store writes about it but its a good quality dyed veneer and actually pretty expensive. "All of the dyed veneers that we work with have been bleached first and then pressure cooked with dye to saturate completely through every wood fiber. This is done to reduce fading and any ability to sand through the color. This dying process is done in Italy. These dyed veneers could be any of the following: Maple, Birch, Poplar, Tay, Koto or any American white wood."

-

Not that I am aware of...but they were removable to allow drainage and pumping of the water that lie beneath it.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ouch!! I guess I shouldnt have nailed the center floorboard. 😏

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That was my initial thought as well. But both contemporary models have the bottom boards nailed so I followed suit since this is a model of a model. Its easy enough for folks to decide otherwise though. Chuck

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

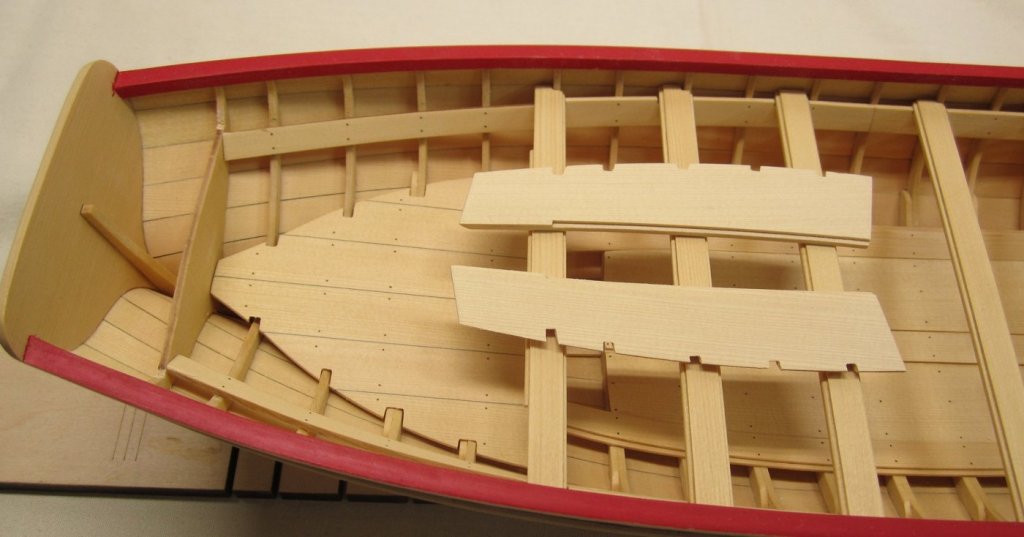

Installing the risers was up next. They are designed in two pieces for each side. They are laser cut with notches in them for the thwarts. This means that the placement of these is crucial. The very first thing I did was measure off the plan the distance from the top of the caprail down to the top edge of the riser. I did this at every frame on both sides of the model so I was sure these would be placed at the same level port to starboard. The aft piece is the first to be glued into position. But I did add the nails ahead of time because I think it would be easier. So I clamped it in position temporarily to mark the frame along the riser and then after unclamping, I drilled and inserted the fishing line for the nails. This first piece is left a bit long just like I did with the planking. So you need to mark the forward end in the middle of the frame and cut off the excess. This is very important because the next section will butt against it and the thwart notches need to line up. Its easy enough to do but you must be careful. Then it was glued into position making sure that the top of aft end was level with the top of the bulkhead frame it sits against. The cockpit seats will sit on top of this so they need to be level with each other. You could see the forward section waiting to be glued into position. No trimming needed. This just needs to be butt against the aft section tightly. Here you can see both sections of the risers in position. Then I made up the thwarts. Like the floorboards these have a fancy edge. Since scraping Cedar is problematic, I made each thwart in two layers glued together. I just cleaned the char of the edges and glued the layers together creating an even fancy edge on both sides. These are laser cut extra long as well. You will need to cut them to length so they fit in the notches nicely. You may have some that require some notching around the frames. But its pretty straight forward stuff. These are not glued in yet. I will wait until I make the cockpit seats next and after some detailing on those which I will describe, they will be glued unto position. The center thwart with the cut away for the mast also needs detailing before it can be glued into position. Its finally moving along and actually looks like a boat!!! It wont be long now!!! Feel free to ask me any questions. This model really shows the beauty of the yellow cedar which I am really liking the more I use it.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Not to many actually. Thank you for the kind words. I wish I had more time during the week to build. I am only spending about 4 hours a week on this project as far as build time goes. The platforms and floorboards took me a couple of hours. If I had to guess actual build time (not development time for the plans and design) I would say I have spent maybe 25 hours give or take actually constructing the model up to this point.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

You could but its tough to see where the frames are Mike. So I held it up to the light because the hull is translucent and marked the locations for the frames on the outside of the hull. Chuck

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I did finally finish the nailing of the external planks. That took a long time. My advice would be to really consider how long it takes to drill all of those holes and insert the 10 pound black fishing line. I think its quite worthwhile but once you commit to it you have to follow through and do it to the entire model. So think it over first. Once that was done, I could work on the inside...finally. The photos below show the floorboards and platforms in position. The floorboards are a bit different than you might be used to. This is the way they are made on the contemporary model and I actually found some original drafts of longboats that show them this way as well. Its very interesting and I think its a nice detail to add to make this longboat model a bit unique and different from other kits of the same subject matter. It may be hard to tell from my photos but the center plank and two outside planks of the floorboards have a rabbet along their edges. Normally I would scrape these details into the planks but Yellow Cedar doesnt scrape well. So instead I made these three floorboards in two layers. They are all pre-spiled and laser cut. The finished thickness for the floorboards is 1/16". So two 1/32" layers were used. They were glued together to leave the rabbet on both sides although the outside planks of the floorboards only have a rabbet on one side. You guys will see this on the plans. Once completed I marked the locations where the frames would be so I could add the simulated nails before I glued the floorboards on the model. See below. The thinner floorboards were easy enough to glue into position. Its the wider boards that were a bit tricky. These are 1/16" thick as mentioned and because they are quite wide it was more difficult to pre-bend and glue into position. Should anyone have trouble with this there are other solutions. You could make these out of two layers of 1/32" stock like the other floorboards and glue each layer into position separately. They would bend more easily that way. You could also convert the wider floorboards into two thinner strips too. The platforms were pretty straight forward. Each of the pieces are laser cut and after gluing them together edgewise they are ready for test fitting. I also ran some 1/16 x 3/16" strips across the bottom of the platforms to give it strength. Probably just like they do in real life. I also added one of these across the flat edge of each platform which will show so take your time with this. The platforms were nailed off the model as well. A look at the bottom of the aft platform...it aint pretty, but it doesnt have to be. One feature not laser cut into the platforms are the notches for each frame. Everyone's model will be slightly different as they may shift. So you must mark there locations and file the notches before final placement can be finished. Its not hard to do. You may want to trace each platform on some card stock first and locate the notches that way as an alternative. Then transfer them to your cedar versions. The bow platform is a bit trickier because of its location. So I recommend that you do make a card templete first and transfer it to your glued up version. I made the pieces for the bow platform over-sized to compensate for the wide variety of bow shapes everyone will have. But you can see how mine look ad are shaped. Note how the notches are also beveled so they sit nicely against the frames. This is something you will need to do as well. The bow platform is done exactly the same way. A look at the contemporary model.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you very much. If we could only go back in time and ask them!!! But as model builders of boats from this era we can only guess. Sometimes more questions than answers. I do not know the answer to that question, but it must have seemed practical at the time. That set up was copied from two contemporary models one of which is known for its original rigging. I wondered the same thing when I saw that the first time.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.