-

Posts

9,725 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

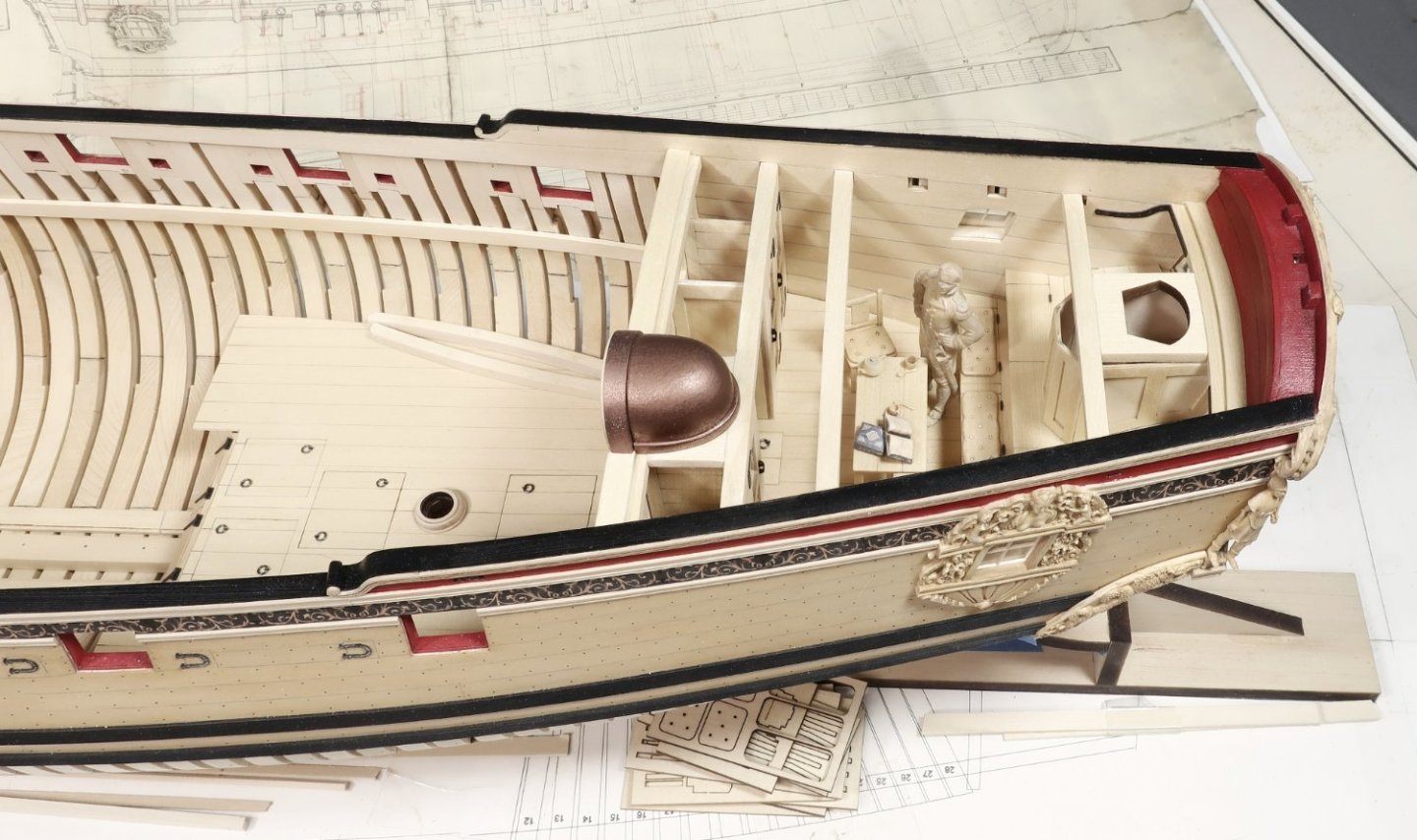

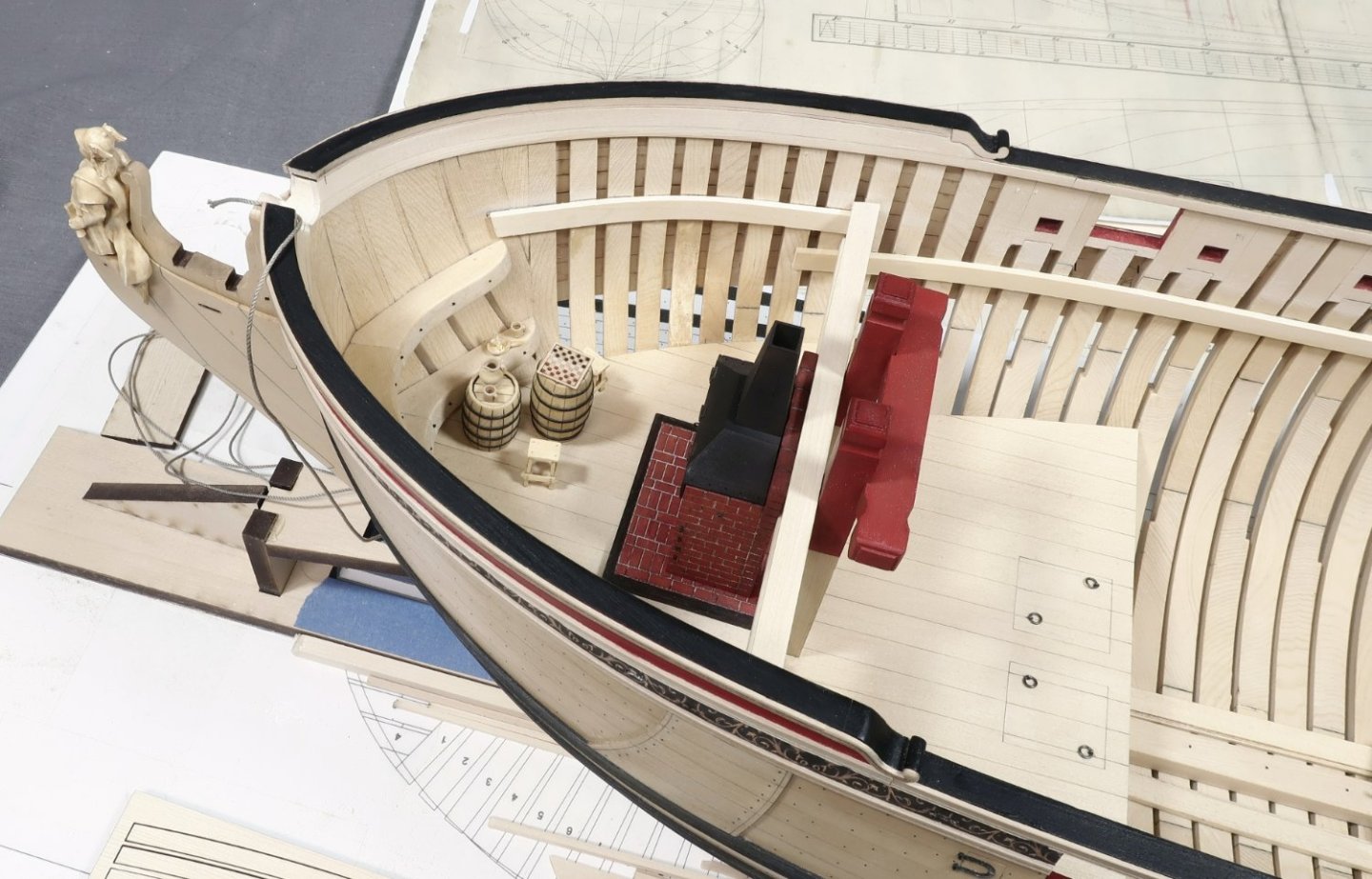

The fcastle deck beams were glued into position . The knees, carlings and ledges for the hatches were added as per the usual. The knees are laser cut and just need some sanding to get a tight fit against the frames. The ledges and hatch framing is completed with 1/8 x 1/8 strips. Cut them to length and follow the framing plan. To finish off the fcastle for now...the ladder was made for the companionway on the starboard side. You can just make that out in the photo. This is as far as I will take the fcastle which matches where I left off on the poop deck. So this completes chapter six believe it or not. Chapter seven begins with the few cabins and sail room on the forward lower platform. More to come on that soon I hope. But I have to start laser cutting some more chapter sets and making more rope. Having a real job stinks....what I wouldn give to hit the numbers tonight, LOL. Chuck

-

Its up to you. I found it easier to add them as I go. As long as you have a frame on either side you can add the shorter frames. I also added the port fillers as I went but that is something you can wait to do until you have three or 4 ports to make. This way you can use the template to make sure they are all at the same height and spaced accordingly. But its up to you.

-

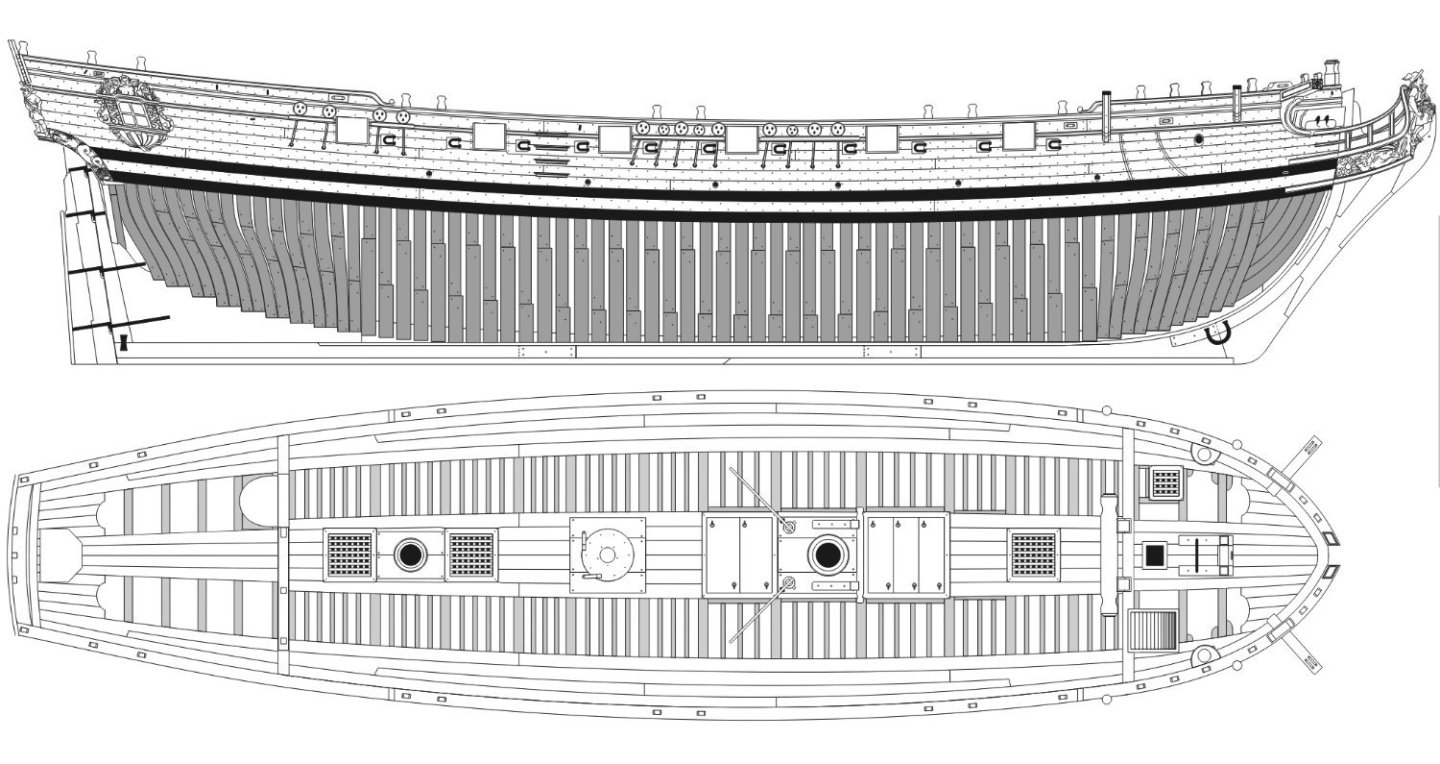

Just a heads up...I have decided to make the plan sheets for this project available electronically. Many have asked for an additional set so they can cut them up or so they can have a clean extra set. Although I am printing them and including them with each appropriate laser cut installment, some folks may be worried about stretching and or shrinking of the folded paper plans provided as well. So to ensure there are no issues they are available electronically and can be printed on your own for a spare set to cut up as well. I routinely cut them up myself to use for templates and such. Since no framing parts are included there really isnt a concern that this will lead to copying of my kit design. Not all laser cut parts are shown on the plans...for good reason. So here are the first three....plan sheets completed. The remaining will be added to my website once I am sure they are OK, after I build those areas of my prototype. They are also available on my website speedwellsheetone.pdf speedwellsheettwo.pdf speedwellsheetthree.pdf

-

Just a heads up for those building the kit. Jim Rogers caught a error on the labeling of parts. It is now corrected. But you will find that there are two sets of frame parts AF.....The taller set is actually AF. The shorter set is mislabeled. Those are actually 10A. Good catch Jim....thank you. The parts are actually fine. The one set is just mislabeled. So grab your parts and correct the label on the shorter set before you get that far. Label them as parts 10a. You will find them on sheet "M" of laser cut parts. Those need to be relabeled. Chuck

-

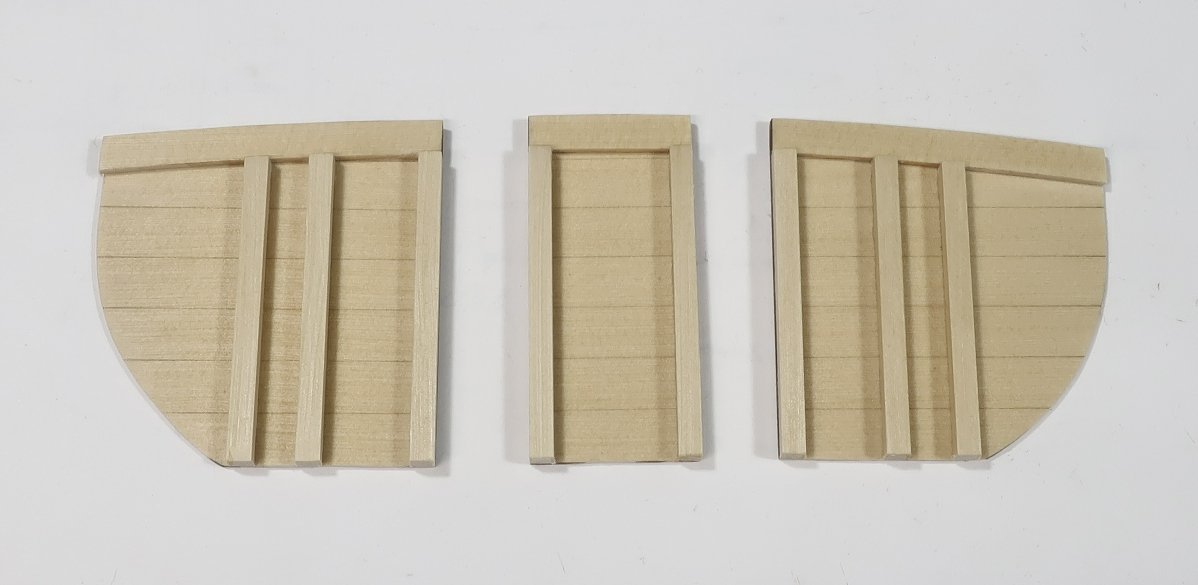

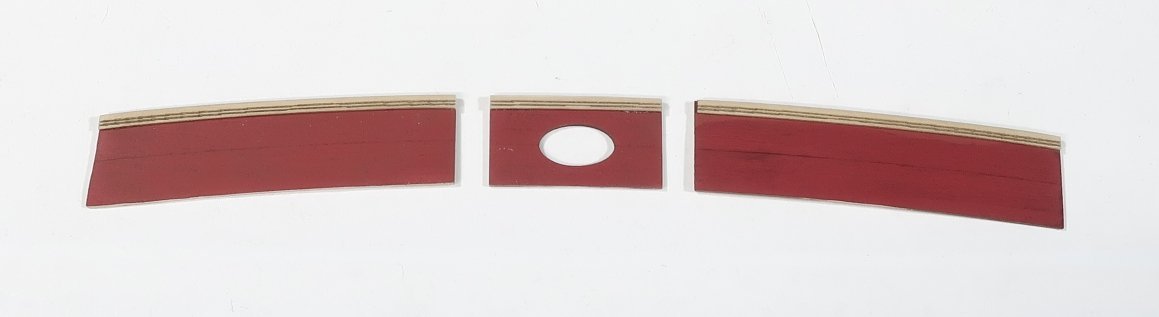

Work continues on the forecastle area. With those first two beams in position I can now start working on the bulkhead that sits against them. In this first picture, I am just test fitting the three sections of laser cut bulkhead. These (like all others) are laser cut slightly wider and taller than needed. First...work on getting a nice fit on the center section between the riding bits. Only worry about the width on both sides...dont worry about the height of these yet. The two pieces on either side are next...sand the outboard side ONLY to reduce the width and get a tight fit against the riding bitts. There will be a space between the frames and the bulkhead where the inboard planking would have been. Try and make it a consistent width. Again dont worry about the height. Only after you get the widths taken care of should you then sand the top of each bulkhead section down so the height is flush with the top of the lower beam. The photo shows the three sections with a proper fit all around...now its time to detail them. Remove the three sections so you can add the uprights and simulated deck beam. First up...sand the char from the laser cut beam pieces. These are glued to the top edge of each bulkhead flush. They are laser cut longer than needed so you can sand the sides flush as well. Then the uprights go in position. These are the uprights for the cabins on the lower platform. We will be adding them a little later. But it is easier to add these now. They are just 1/8" x 1/8" strips cut to length and glued in place. There are laser etched lines that show you exactly where they should go. Then glue the three sections in position permanently on the model. Note the riding bitts will not be glued on permanently yet. They will just get in the way when we are doing so many other things in this chapter. So make sure you can remove it after the three sections are glued in place. Riding bitts removed. Now for the next layer above that. this is handled in the exact same way. I could have just included these on the first three section only a bit taller, but I wanted to be able to paint them cleanly and get a crisp edge. But the same principle applies here. Sand the widths of each first....then get the heights done. These are flush with the top of the fcastle deck beam. Then remove them..... Paint them red. Then add the laser cut and etched molding along the top edge. The molding was rounded off on top and bottom. You could also scrape your own if you want to. Then sit this on top of the lower sections of bulkhead as shown below. The riding bitts are still removable but you must use them to get a good fit. Glue these bulkhead sections in position now as well. Top this off with the margin plank along the beam. Cut a 1/4" x 3/64" strip for this. Basically, just like you added for the quarter deck margin plank. It hangs over the bulkhead a little bit. The aft edge hanging over is rounded off a bit to your liking. The forward side will leave a nice ledge or rabbet for the fcastle deck planking. The only difference here is that you must notch out this plank for the riding bitts. see below. Also the riding bitts are not yet glued in position...I will let you know when its best to glue that in position. BUT I did finally glue the fire hearth in place permanently. Just remember to do so without its stack. That will just break off later without a doubt. And if you want to add anything else to the galley...do it now. We are about to close her up for good with deck beams and knees, etc. The three fcastle deck beams were cut to length and are just resting on the deck clamps. I must locate their exact positions using the plans. Thats it for now...BUT I did get a chance to cut the plan sheet up to see how my planking design will look. Its always tricky deciding how much planking to add or leave off the model. I think I am liking this particular cut-away with some planking removed. You can still see quite a bit of stuff down there... The hearth stack was just placed on top for giggles and a test. I also did the same for the quarter deck...once again plenty of detail is still viewable down there. I will live with these templates for a while and mull over some other possible planking schemes. But so far I think these will do just nicely. What do you think?

-

Glad to see a build log. Yes…i actually have a photo of that. Which you posted. The circled areas (on one end or the other of a given joint) need to be sanded to close the gaps. The gaps are intentional and yes you will need to sand the end of the scarph on the opposite side to close the gaps. This will be especially true with each frame segment as the thick wood when laser cut leaves a curved and bevelled edge that wasnt easily remedied by just flipping the pieces on the laser cutter. So each piece will have one end that needs just a hair of sanding. See the page of the 1st chapter that explains this. Just a few swipes should do the trick. Chuck

-

Ship Ribbing with CAD?

Chuck replied to Sanjith_D's topic in CAD and 3D Modelling/Drafting Plans with Software

While most folks here are concentrating on the software I would first find out the capabilities of that Library laser cutter. You will want to cut wood ….depending on species that can get pretty thick. My guess is this laser cutter wont be of high enough power to cut anything more than 3/32” thick basswood. And certainly not ply unless its very thin. So check the specs before you start. you would certainly need a 60 watt laser at a minimum but that is pushing it. its far better to use 80 to 100 watt laser. Otherwise it wont cut the thicker stuff at all. Smaller machines for paper and light crafts are useless for ship model work. -

Thank You. There is really no trick here. Its just sanding mainly. I use a coarser grit first to get the main stuff off. Most often 220 0r even 100 grit. I throw the paper away as soon as it gets loaded with char. Otherwise it just makes the wood dirty. Then I switch to a finer grit of about 320. There are occasions where I also initially scrape the char off with a straight razor or #11 blade carefully without damaging the wood. Then follow up with 320 grit. A few passes and then blow the dirty char dust away so you dont push it around the wood making it dirty again. That it really. The real trick is that I design every piece knowing that you and I have to remove the char and so it is very slightly larger than the sanded size. Otherwise like most other kit mfgs the part becomes too small. Hence the hesitancy of folks to sand so much. But not with the parts for this model or any other I have designed. If the part is too fragile however I may just go with a few passes of 320 or finer and then just paint the piece to look like wood.

-

I am not sure if I will add those details yet. I am still mulling it over. The reason why we builders add those fun details is to set our models apart from the many that will end up being made. It also means I have to build another set of every table and chair again so I can write the instructions for them...LOL. But the Speedwell project moves forward at any rate. Now working on fcastle details.

-

See my post above.....cheaper and premium quality. You just cant beat the quality for the money. If you are building Syren I recommend you get 3/64" thick strips. Although I dont remember what actual thickness I used when I designed that prototype. It was such a long time ago. That was my first kit design which I sold to Model Shipways. I believe I recieved a $500 gift certificate for Model Expo products for that design. I think they got a good deal on it, LOL. So best to check out the materials list in your kit and just replace with whatever you prefer from Joe. Cedar or Boxwood. And fun fact...this is why I started my own company and it is named for this very first ship I ever designed a kit for.

-

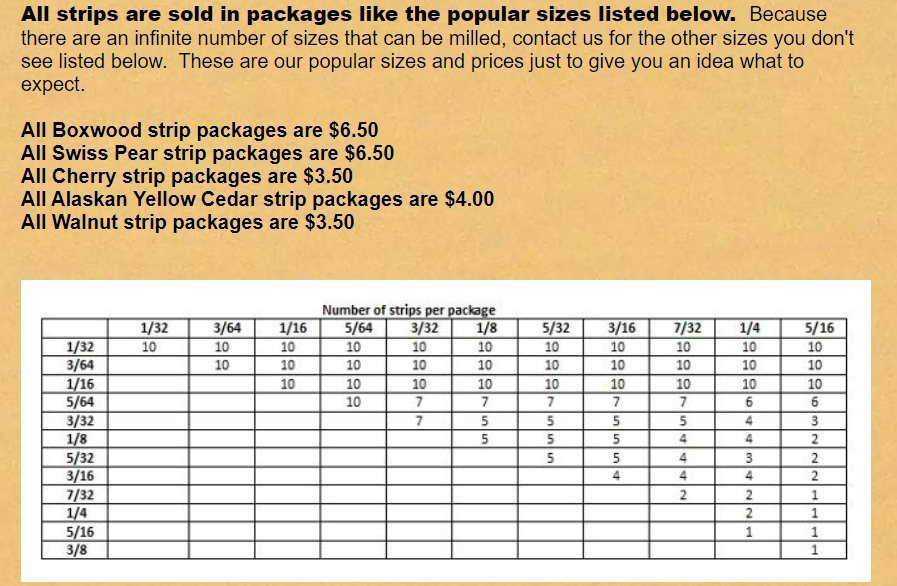

Thats not boxwood from ME....Its dyed yellow and a common lesser wood veneer that is very rough and stringy. It is very common and cut into strips by ME. Its a bit unethical to say the least but they fool a lot of people with those. Just do a google search for yellow dyed veneer. Its why they only carry 1mm thicknesses. A sheet will cost you about $4 retail and you can cut about 25 or 30 strips from each sheet. Maybe even more depending on the widths you want. You paid $8 for 12 strips. That is a lot of profit and I doubt they paid retail...sorry but you got snookered. It would be challenging to find a strip in your pile with a nice crisp flat edge that can be butt against another for a tight seam when planking. They do sell yellow dyed veneer of better quality wood which would hold a nice edge and be suitable for planking...but your pile of strips is not that. You paid $8 for about .80 worth of wood strips. You would have been better served to buy the same number of Yellow Cedar strips from Modelers Sawmill... $4 for 10 strips and beautiful yellow color that doesnt look artificial. Plus so many other sizes. See below. A nice hard edge as well. About 1/2 what you paid... OR better yet....buy actual Boxwood from Joe (south american) and its still cheaper than what you paid for that stuff. Ship model with yellow cedar...

-

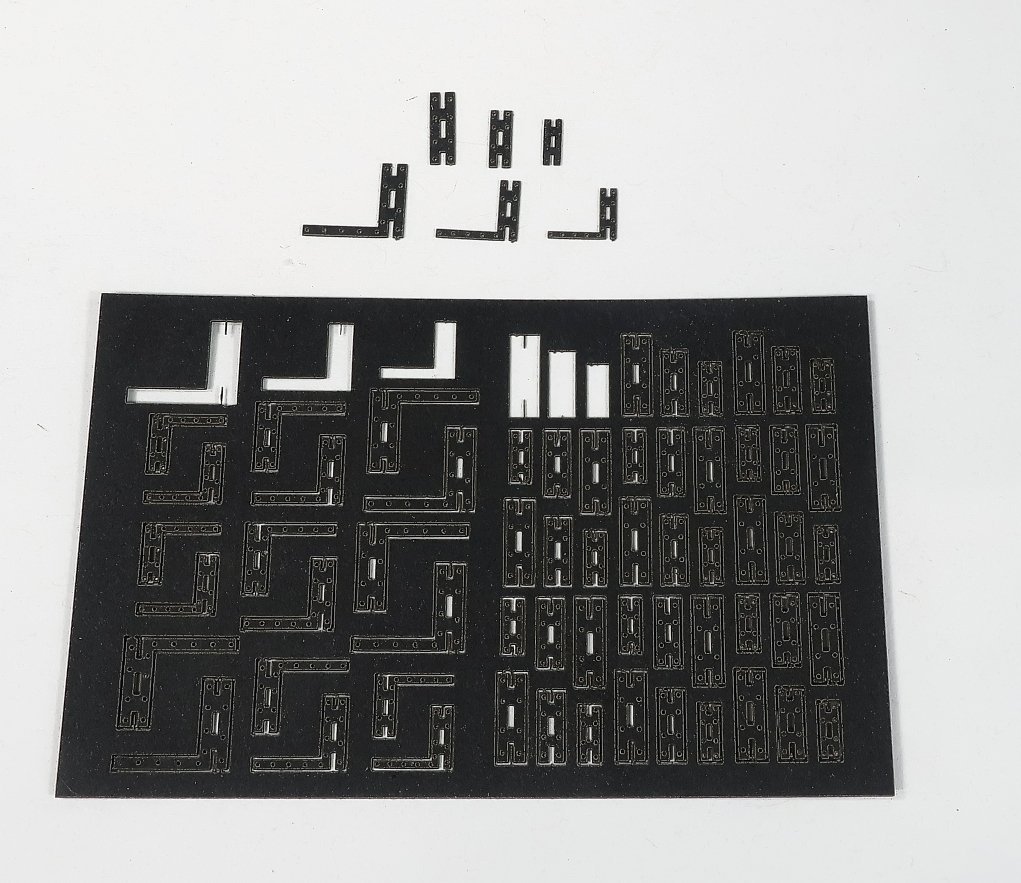

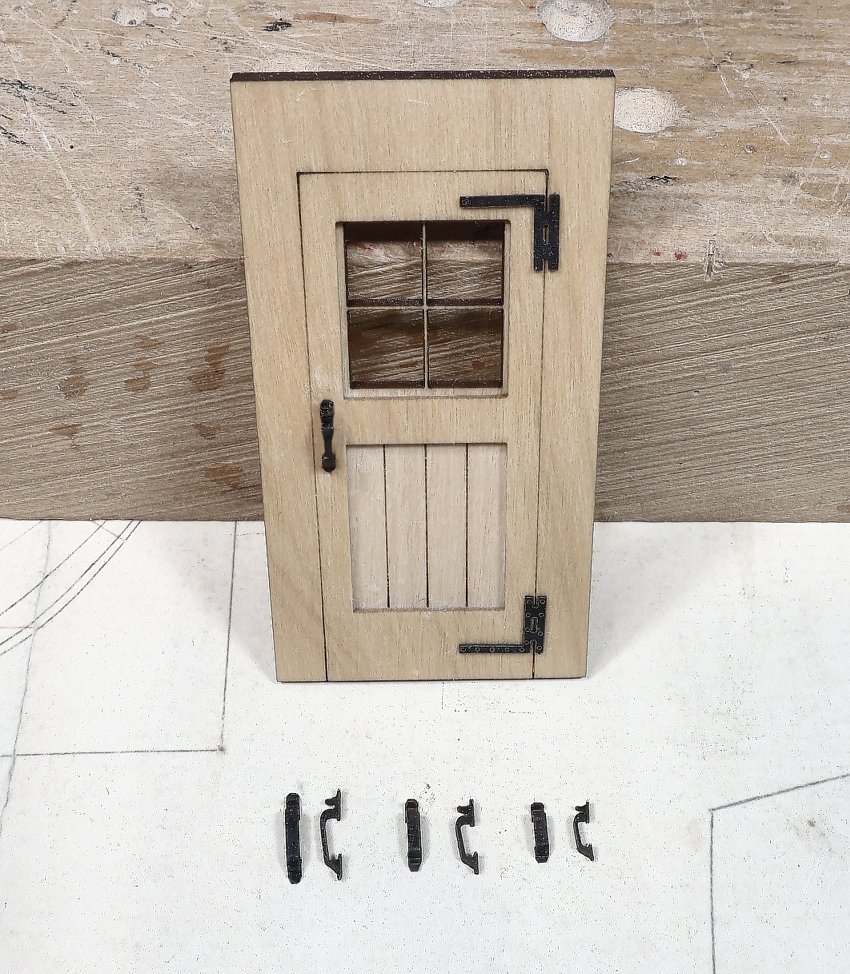

Based on popular demand and multiple requests, a package of smaller door handles is now available. This multi-pack gives you 30 each of the 3/16" tall handles and now 1/8" tall handles. In addition ....a multi pack of smaller door hinges is also available. You get 16 each of 1/8" and 3/16" tall Hinges. In both styles....

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.