-

Posts

722 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gak1965

-

Yeah, I followed the Daily Atlas description, used gold paint and highlighted the centerline and eyes with blue green paint. Once you gild the thing, my guess is that anatomic accuracy goes out the window, and at this scale I'm disinclined to do anything more.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Okay. Once the first coat of paint dries, I will fill the gap slightly, but I think that this is going to be the final form of the stem. Thanks for the suggestions @ClipperFan

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

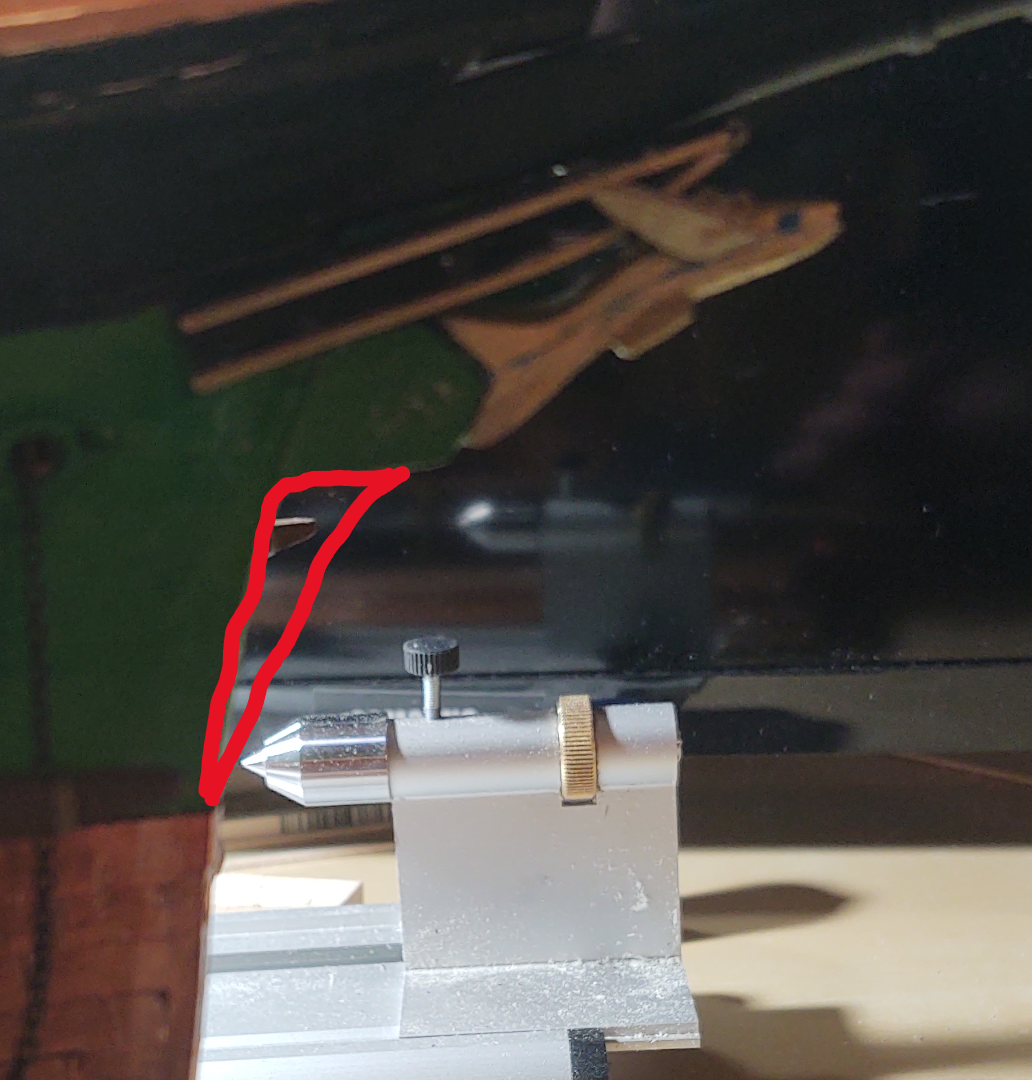

To be clearer. I trimmed the fish and moved him. But are you suggesting I extend the stem into the region shown in the red below:

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

I understand the first part of that suggestion, but do you mean extend the stem further forward as if it is wider (longer?) than it is on the kit? To do the former, I'll need to trim down or move the dorsal fin on the fish itself (no tragedy) and actually it's not glued in place yet, so that's no big deal, but I want to make sure I'm understanding what you are suggesting.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

I was thinking of adding the 'planks' as in one of the prior posts and then covering the boat, so I don't have to do anything to the interior. That resolves the problem with the thickness of the shells and I don't have to make 1:96 knees on the thwarts 😀.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

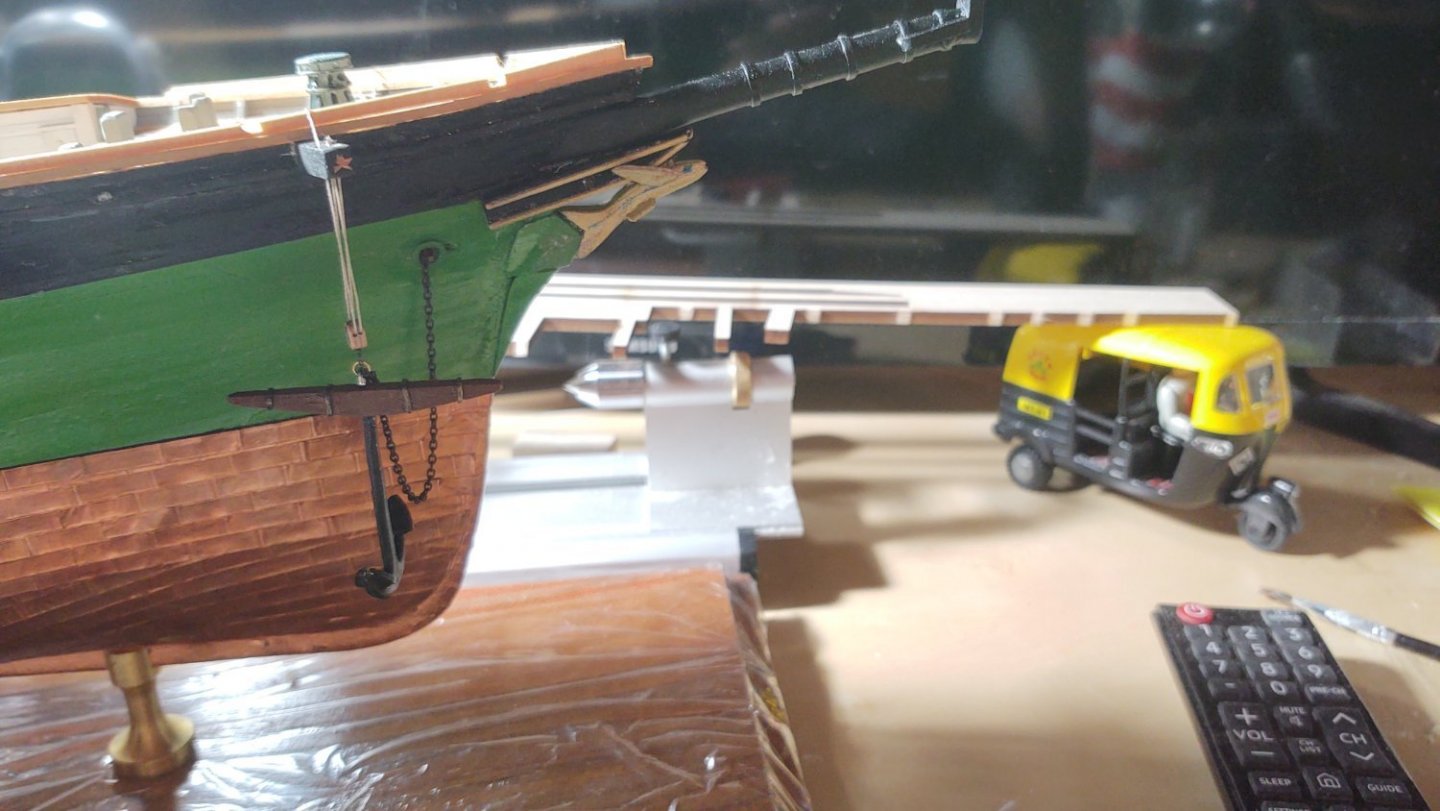

Well, in the last week or so, rather than turning masts, I've been working on a few of the items that still need to be added to the hull, although, in a sense a did turn the first spar, in this case, the bowsprit. I used brass for the iron hoops, and painted the whole thing white (as per the instructions, but it looked really odd, and the Butterworth painting shows it black, so, I repainted it black as per the two photos below: Next onto the naval hoods, cutwater and the figurehead. I used the diagrams that @ClipperFan made (both for the hoods and the figurehead) and then also examined @rwiederrich and @ClipperFan's photos of the Glory of the Seas to try to make something consistent with a McKay clipper. The results are below: Perhaps not perfect, but I think that the cutwater looks like the one in the picture of Glory and the figurehead, even with my carving skills is much better than the one that is supplied with the kit. In any case, the ship now looks like this overall: I've started on the channels (they are cut to shape and sanded, but I need to locate where the chain plates are going to on both the upper and lower channels, cover the ends and paint them before installation. At that point, the only remaining hull piece that I am aware of is the taffrail. After that, there is no excuse to not get those lower masts built and start making the ship grow vertically. As always, thanks for looking in, and for the likes. For those of us in the way of the winter storm, please stay safe and warm. Regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

That's great! The spars that need the most shaping should be of a diameter greater than 1/8 of an inch over most of their length. I shaped my Niagara and PoBII the same way you described, using a dowel held in my drill and sand paper. What a colossal pain that was, I had a bunch of redos driven by snapped dowels and am looking forward to shaping with the lathe, particularly as I think I can make much cleaner ends this way.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

I bought a Proxxon wood turning lathe (https://www.proxxon.com/us/micromot/37020.php) from ModelExpo. Not particularly expensive and the limitation is the length it can expand to, but it should be enough for this project. I may shell out the $40 for a 4 jaw chuck. For longer pieces less than about 10 mm in diameter you can fit the excess through the chuck and the drive motor, so max length for dowels less than or equal to 10 mm is about twice the listed dimensions. I've seen people buy a spare base and create a version that can handle closer to 20" pieces but I am not there.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Those seem pretty clear. Good to know!

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Yep, I got the idea from your post. As for the color scheme, I was planning on painting the lower masts white (including the chapels). The Butterworth painting shows white bands, not sure, I might use blackened brass bands to provide a bit of contrast. I've already stepped into the realm of McKay's dreams by painting the hull green, so... A question for you or ClipperFan (or anyone else) regarding the chain plates. Do you know if McKay clippers used solid iron plates (i.e. an iron bar connected to a separate iron strop (hopefully that's the right word) around the deadeye), or if they were built like the plates in the photo of the Charles W. Morgan below (i.e. a band of iron wrapped around the deadeye that has two segments running in parallel? Regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

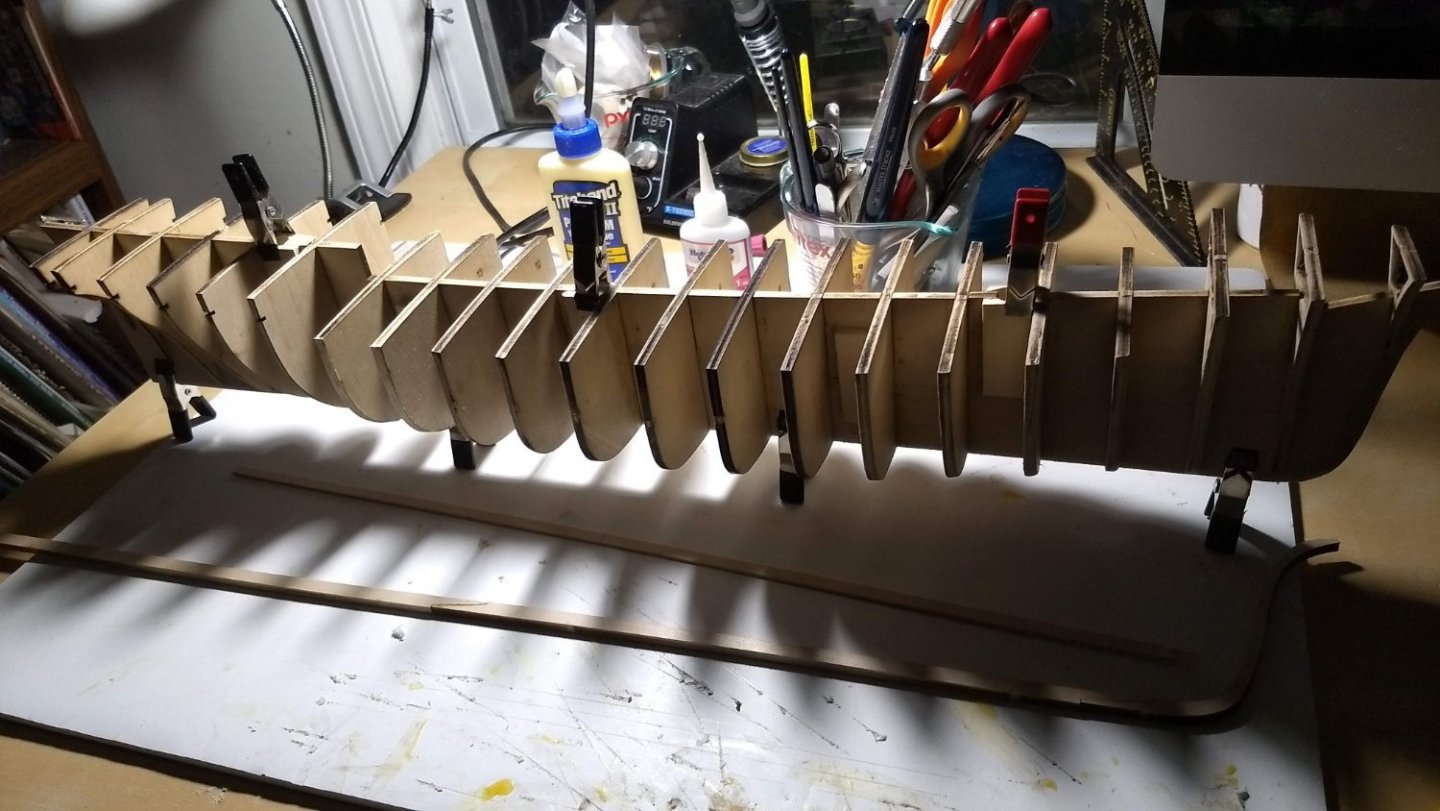

I made a first pass at the built lower mast, in this case, sized for the main mast. It suggests that my method is likely to work, but will require some refinement. I built the mast out of a couple of pieces as shown in the diagram below. The core of the mast is 1/4" square and includes the square portion of the lower mast. It is surrounded by 4 3/16" by 1/4" strips that cover what is going to be round portions of the mast. In the left diagram, which is looking down the long axis, these are the white elements. The built mast has chocks that are placed where the iron hoops are wrapped; these are made with (mostly) 3/16" by 3/16" by 3/16" square blocks and are shown in blue. This is a bit clearer in the right hand diagram which shows the construction viewed from the side. I put this on my wood lathe. The square is 5/8" wide at the start, and needs to be 7/16" at the base and 3/8 at the transition point to the square part of the mast. As can be seen in the picture below, it generally worked. However, as can be seen from the pictures below, my centering was not good enough, so that the other three areas with the gaps were either too large or too small. Part of the problem is that I think I centered on the whole structure when I should have defined the center of the square core and not worried about variations in the size of the four 1/4 by 3/16" pieces. I also have determined that it's going to be pretty sensitive to any misalignment between the square and rectangular segments. Still, for a first try this is encouraging and I suspect that I will be able to make the mast this way. Thanks again for looking in and for the likes. Regards, George K PS: The plans refer to the mast as being "fished" which is odd. As Rob points out and I recall now, "fishing" a mast is usually a repair technique. So - for this entry and beyond I'll be using the term "built"

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Yep. I was planning to use your method, suitably adapted to my tool arrangements.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

First build update of 2022 (and it is really weird to be typing this. First Blade Runner taking place in 2019, and now we are in the year of Soylent Green - yikes). Anyways, a bunch of mostly small additions that nonetheless consumed way more time than I expected. First up, as planned I mounted the starboard pinrail. I then spent the next several days making the carriage house skylight, which consumed a vast amount of time. The skylight is hollow (I built up 4 sides, then put two hollow rectangular frames and a central beam that make up the top of the skylight. I cut sections of clear glass that fit into the frame, and then added pre-painted muntin bars to create the four individual lights. Finally, I set three 24 gauge brass wires to represent the protective bars over the window panes, edged the base in stained decking, and mounted it on the carriage house. I also made and installed the eight bitts and the four mooring chocks on the main deck. On the forecastle, I added the nails that support the catheads, the spray rail, and the four pads that protect the deck from the anchor flukes when the anchors are stowed. Less visible are the three pinrails on the forecastle, one at the bow, and the other two flush with the deck between the forecastle and the WCs. I decided to mount the anchors as if they are being recovered which I think shows them off a little more interestingly than if they were simply lashed to the deck. I connected the anchor chains to the archor using a brass loop, stropped a double block with a hook and rigged the blocks on the catheads. Seen from the bow, the anchors look thus: The ship as a whole now looks thus: Pretty soon it will be time to fabricate the taffrail and start on the chains and deadeyes, marking the transition from hull to rigging. I mentioned before that I was doing some experiments with the ship's boats. Here is the painted boat. The left side has the detail made with Tamiya tape, the right with copper tape. My personal view is that I like the less "in your face" version with the Tamiya tape, and that the Tamiya XF-1 "flat" white is not nearly flat enough. The final version needs to be a lot less glossy. But, I think that with Tamiya taped details, better white paint, and a gunwale painted some contrasting color (likely some brown) the castings will be just fine when turned upside down. The two boats that are right side up will probably also need to have a canvas cover to hide their deficiencies, but I think that will be fine. As always, thanks for the likes and for looking in. Soylent Green is People! I mean Happy New Year 2022. Stay safe out there. George

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Yep, I saw Rob's post and am going to do pretty much the same thing, subject to variations in our shop tools and success or failure with said tools. I don't plan on doing red iron bands, but it does work on his Glory of the Seas @rwiederrich

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

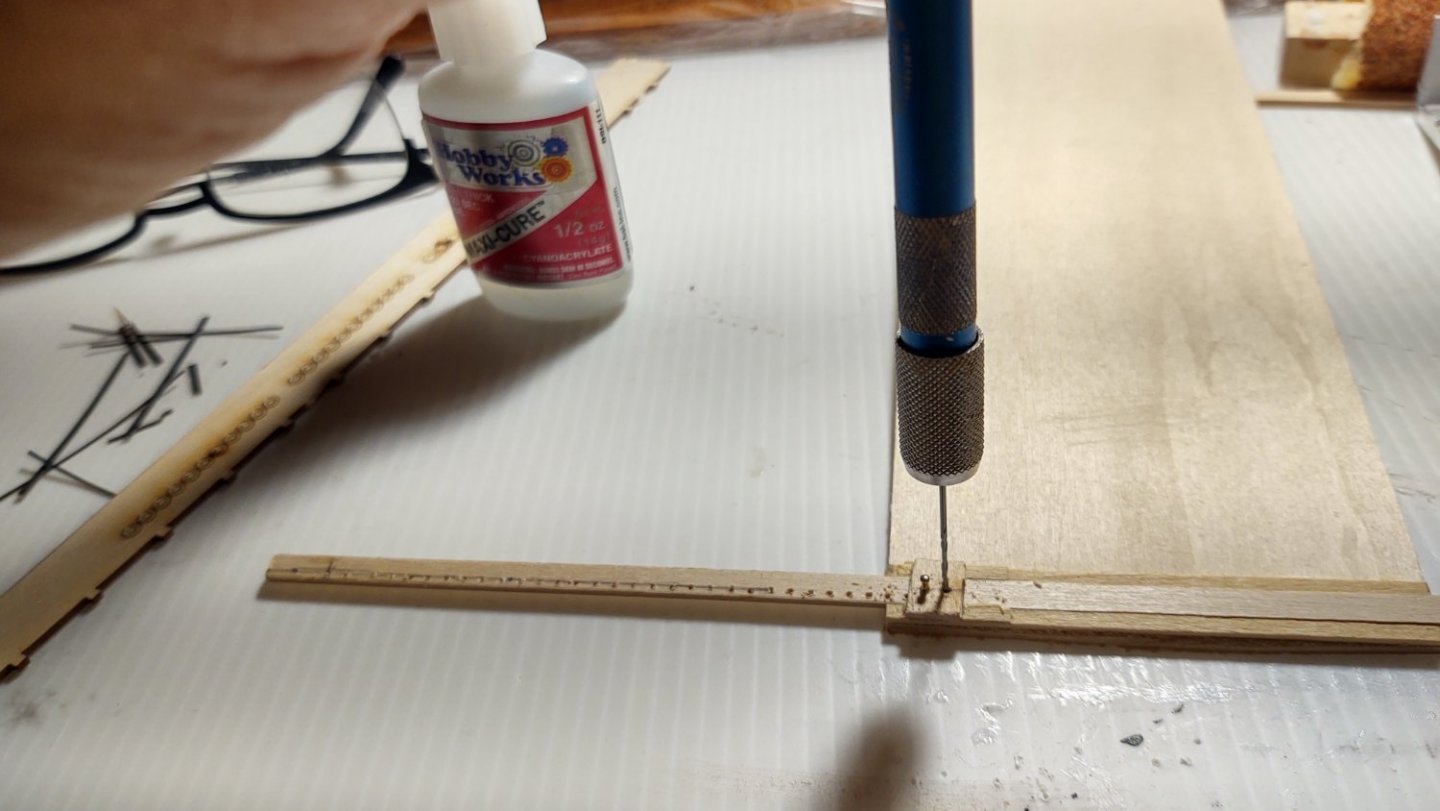

If I do it again for more than about 50 holes, I think I'd make two or three of the hole patterns, as the "drill" hole gets larger over time and you get some more variation. Alternatively, I might line the drill hole with some brass tubing which I think I can get at the right size. A better way, of course, would be a drill press with a compound worktable with precision x and y translation 😃. Not likely to happen anytime soon, however.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Actually, I think you are ahead of me. My next big items (other than the naval hood, cutwater and figurehead) is the taffrail, which you've already installed. While I'm doing that, I've ordered a small wood turning lathe, and I'm going to start experimenting on the fore and main mast lowers since they were fished on the Fish and I've never made anything like them. Happy New Year! George

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

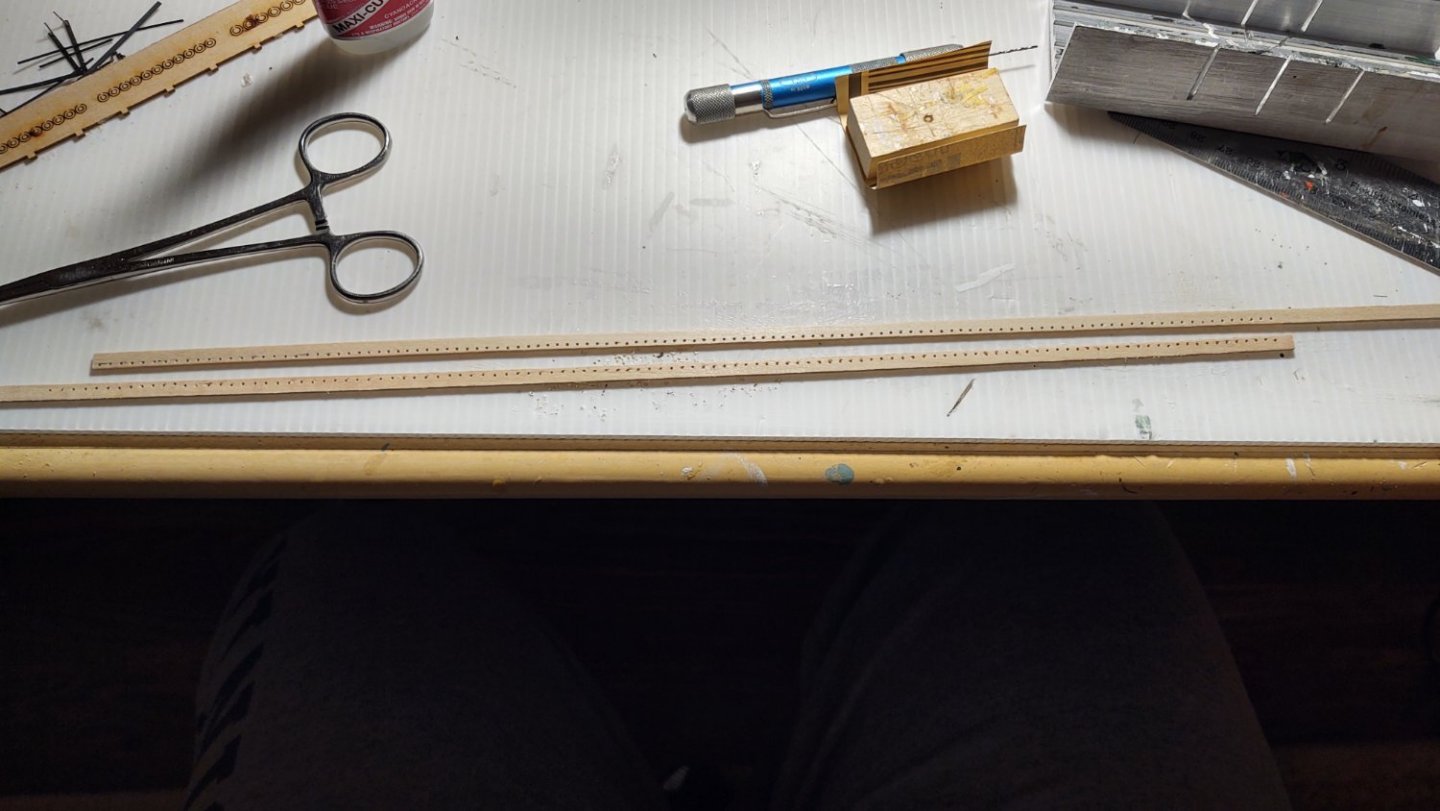

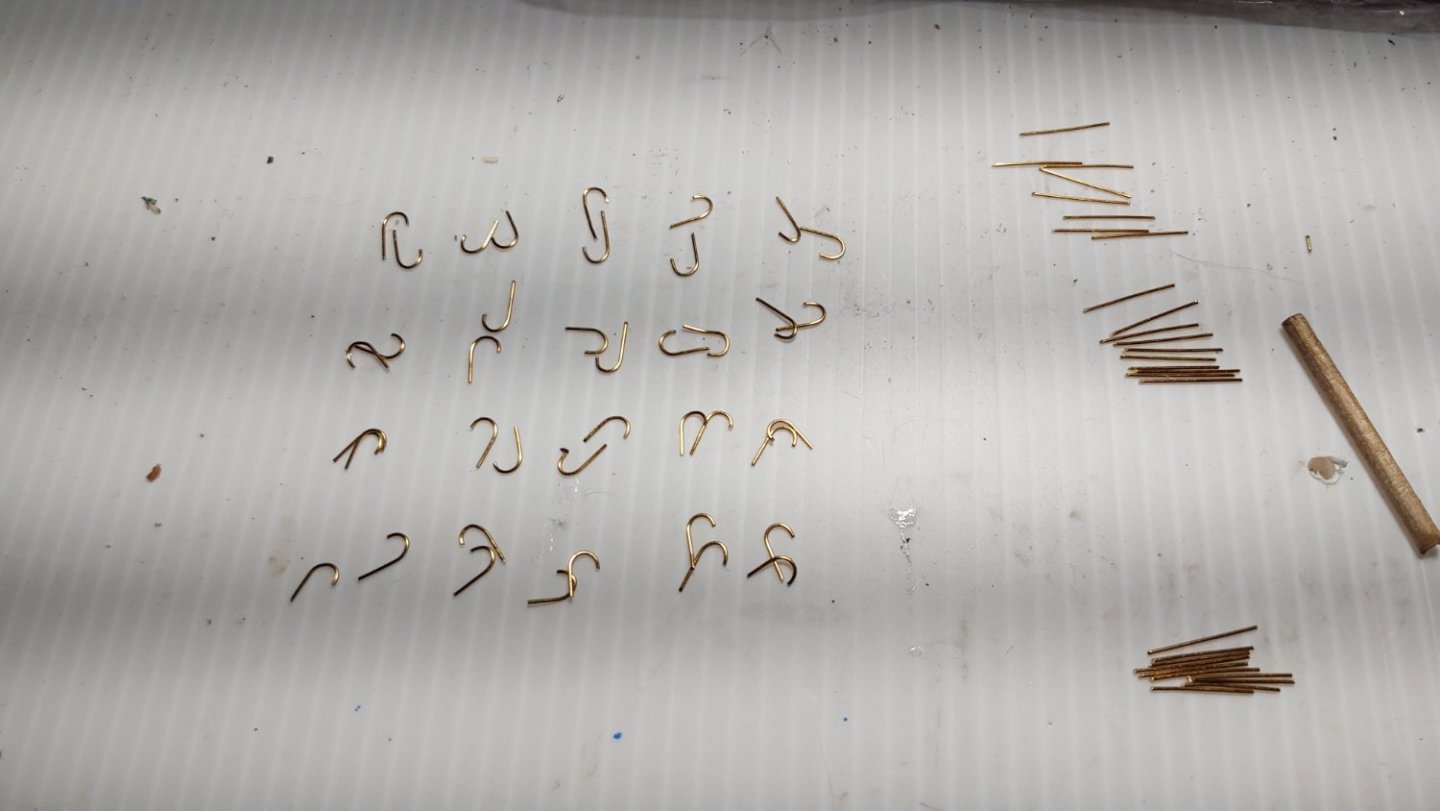

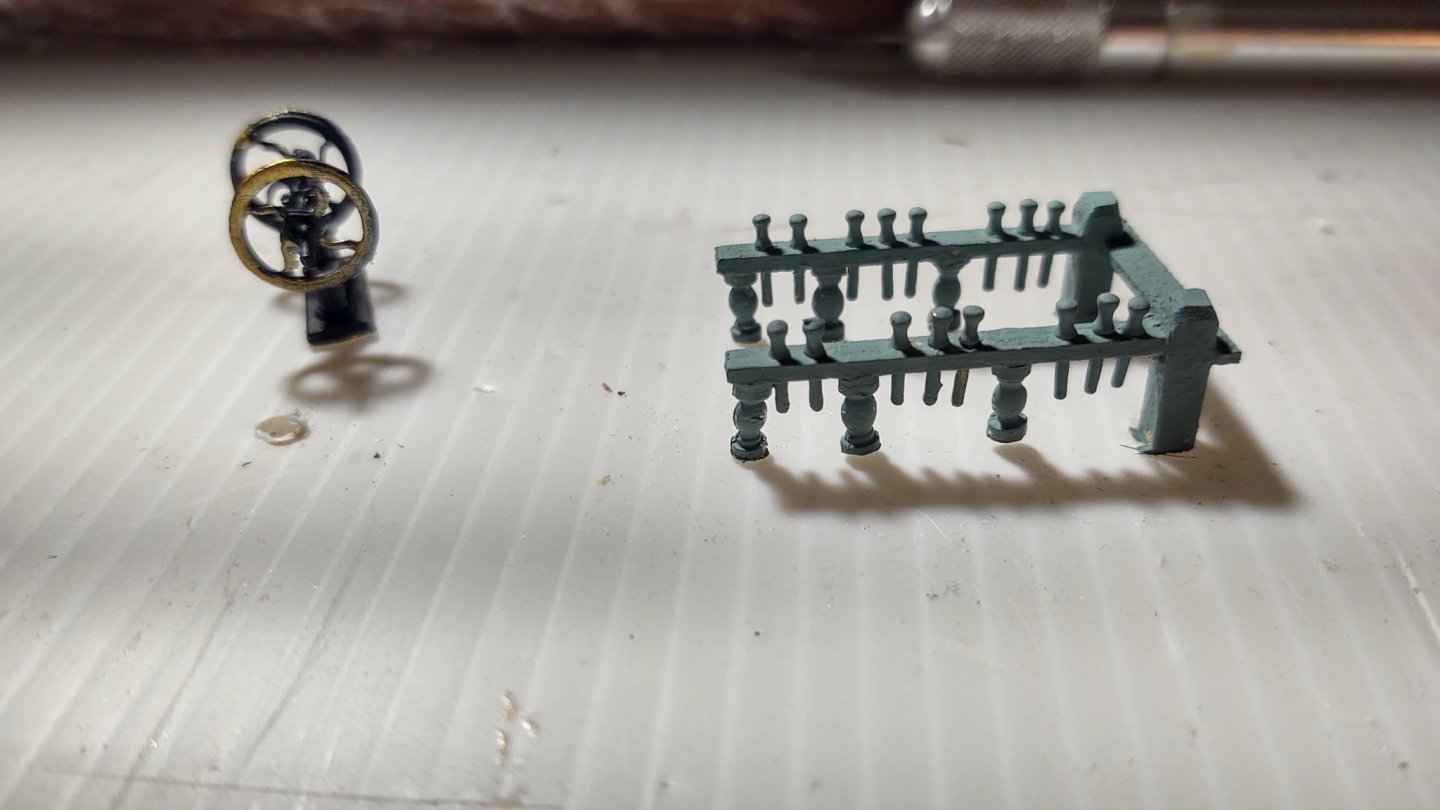

Hello all, Well, the end of the year is upon us, and I hope that the new year treats everyone better than 2021. A final update before the calendar ticks over. I made and installed the gooseneck vents. You can see the pieces that I cut to turn into the vents and the subset that are made in the photo below I made a small jig to ensure that the holes were properly spaced, and after drilling them with my pin vise, I glued them in. Next are the pinrails, which are approximately 14 inches long and made out of 3/16 by 1/16 boxwood. I made a jig for this too, so that as I drilled there would be pressure to keep the wood from splitting. In order to ensure that the spacing stayed the same I glued a piece of wood on top of the space that the pin rail was fed through with two holes 1/8 of an inch apart, aligned so that the holes were parallel to a l is me 1/16 of an inch from the outer edge. I drilled the right hole, slid it to the left and inserted a belaying pin in the left hole, drilled in the right, letter the pin, slid the wood to the left, reinserted the pin, etc. That generated two pinrails. After staining, I installed the port side pin rail, the starboard will need to wait until tomorrow. I don't plan to put in the pins in until after the chain plates are installed, and I can align the locations better. Finally, I've started an experiment. I don't love the ship's boat castings, so I am trying two ways to improve their appearance. In both cases, I'm trying to make it look more like a lap straked hull. On one side I've used Tamiya tape, on the other 5mm copper tape. They are being painted with a couple of layers of white paint. Both already look better than the casting after 1 coat. I will show an example when they are done. Lately, it doesn't feel like a lot of progress is being made, because I've been putting in details that don't change the overall look all that much, but here is a picture of the ship as of last New Year's, and progress has definitely been made. Have a safe and happy New Year! George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

It could be as simple as how steep and wide the ladder is and the need for easy access. The destroyer I was on had pretty steeply angled ladders (it was more like climbing a ladder than a staircase) and you needed the rail to move quickly up or down. Otherwise you'd need to put your hand on the sides or the next rung and risk getting stamped on. Merry Christmas all, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Nice! I know this is going to sound a bit strange, but I love the details on the chain navels, particularly how you went to the trouble of including the chain that ties it to the deck. Sometimes it's the small details like that that really make a model pop!

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Thanks! I scratch built the ones up to the poop, and I'm still trying to decide what to do about the gangway, carriage house and forecastle ladder, all of which are narrower than the poop ladders. The available castings are actually moderately okay, but I wonder if they are going to look out of place in comparison to the two wooden ones I've already built. A Merry Christmas to you and everyone else looking in. George K.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

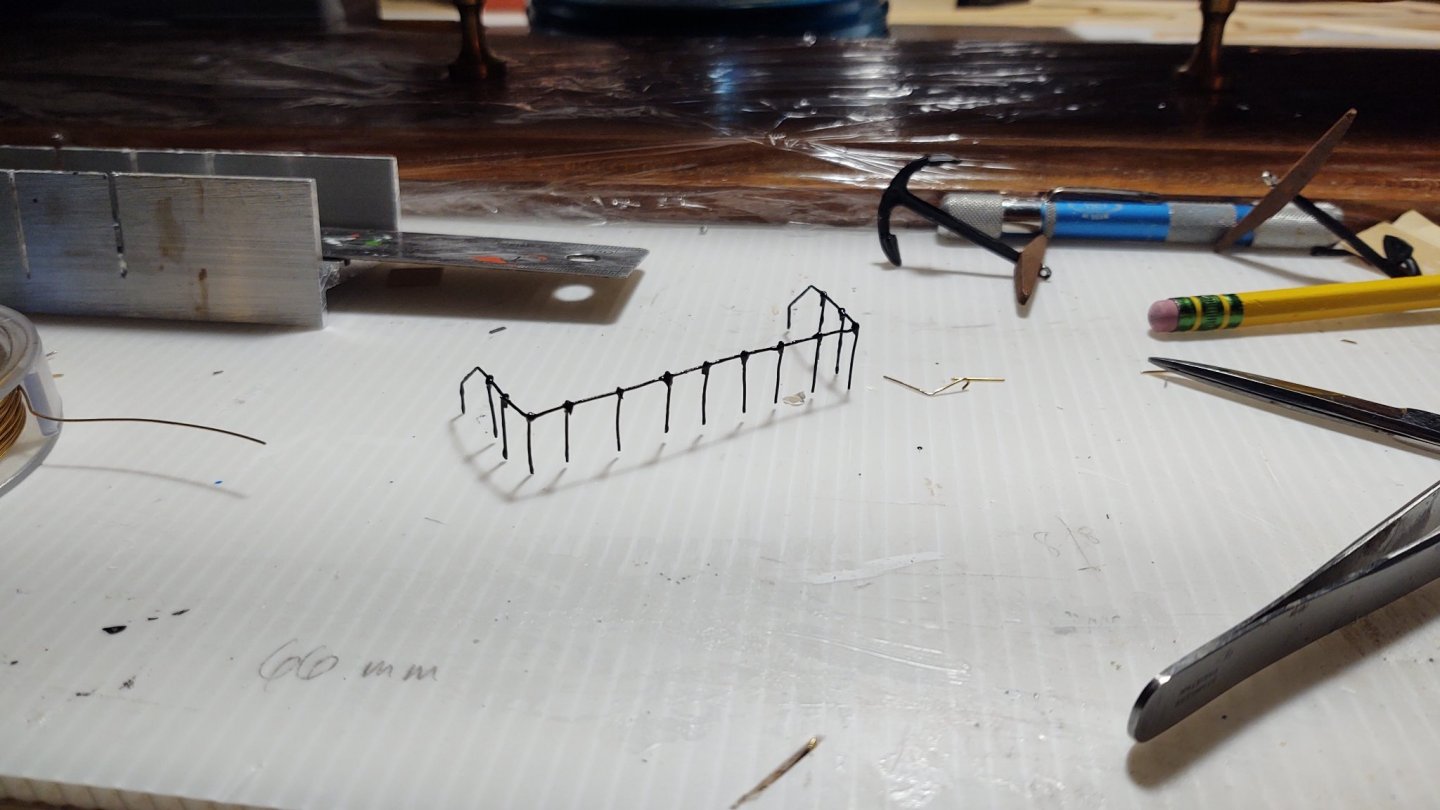

It's been a busy week, so I haven't had a ton of time to work on the ship. However, I've done a few things that are vaguely interesting, so a brief update. First, I built the railing that goes on the carriage house. It's built of 24 gauge brass wire. The stanchions have a loop made at the top that I threaded onto the railing and then soldered in place, giving the joints the appearance of a ball joint, which is what I was trying to do. It was then painted, trimmed and glued into place I didn't like the anchor stock castings, so I scratch built wooden ones, with blackened brass strips to represent the iron work. Finally, I worked on the area around the foremast. Step 1 was blackening some chain that I purchased from Bluejacket that is a more reasonable scale for the anchor chains. I then used the wire that I put in the place to route the chain through the hawse holes, the chain keepers and over the windlass. Before I did that, I made the guides into the chain lockers by wrapping blackened brass strip into an almost complete circle. This was mounted in front of the main house, leaving a small opening for the chain, and I drilled a hole inside the circle made by the strip. Once I had the chain over the windlass, I put some of it in the drilled hole, glued it in place, and made the cover with a circular section of copper tape, which sat on the port like the metal lid it is. Finally, as with the main fife rail, I cut the stanchions off the Britannia castings and scratch built a new fife rail which is painted to match the main fife rail. You can see all of this in the photo below: A couple of questions for the cognoscenti. I've assumed that the belaying pins in the 1850s would have been of wood. Am I correct? The pinrail is coming up soon, and the plans say it should be bright. So far, all of the pins on this ship and the Niagara have been on painted pinrails, but if the wood is bright, I need to paint all of those brass pins some color that isn't completely out of whack with the bright color. Alternatively, I suppose that I could paint the pinrail some sort of brown color and color the brass pins at the same time. Another question is the spacing. It's not clear from the plans if the pinrail had holes unformly across it's entire length, and only filled the ones that were needed, or if there is a set of holes/pins that follow the (approximate) pattern shown on the belaying plan (i.e. the main pinrail has two sections around the main and foremast with closely spaced pins, and a couple of pins in specific locations. Has anyone who has gotten further figured that out? As always thanks for looking in and the likes! I realize I've been at this slightly more than a year, and this is post number 201. Hopefully, by this time next year it will be complete. Regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

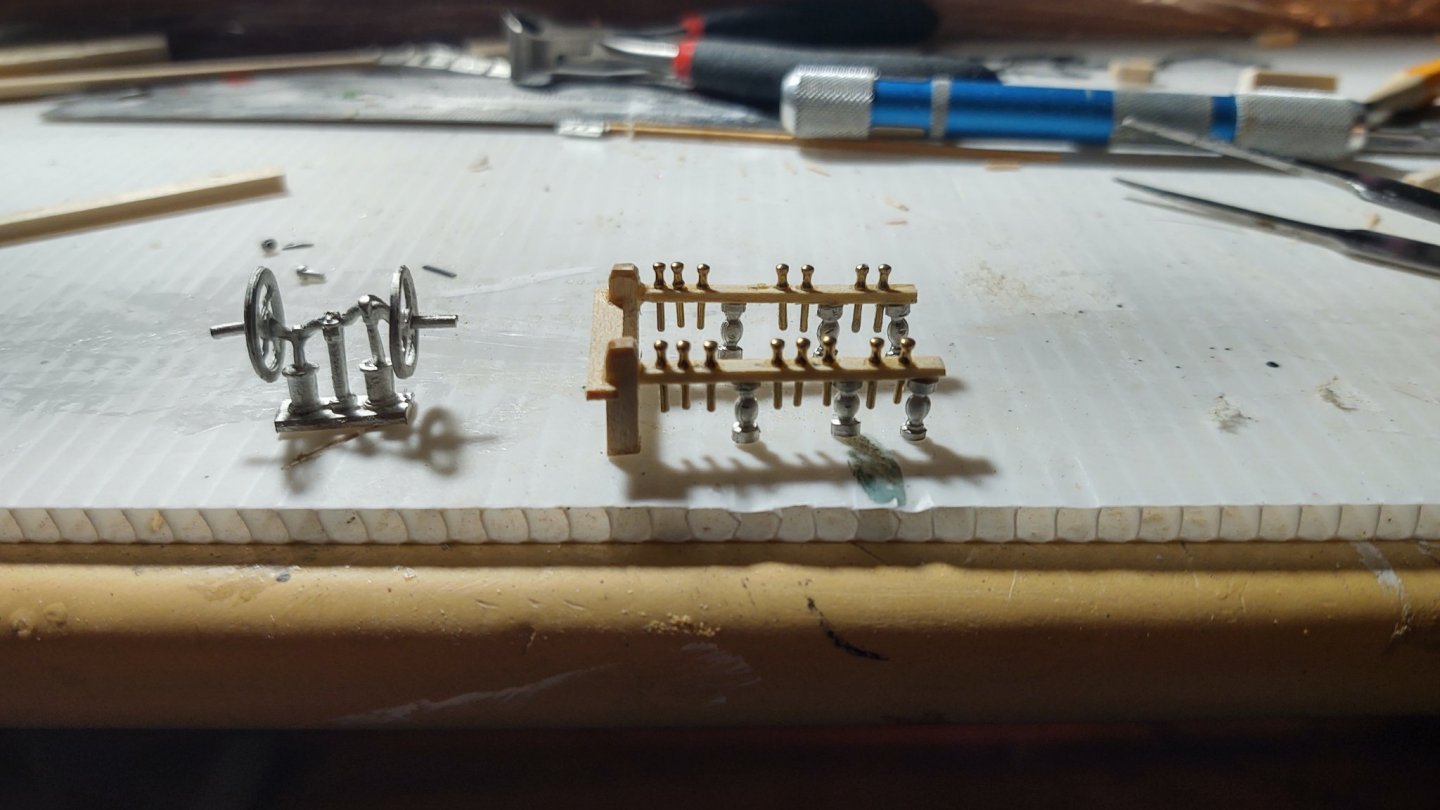

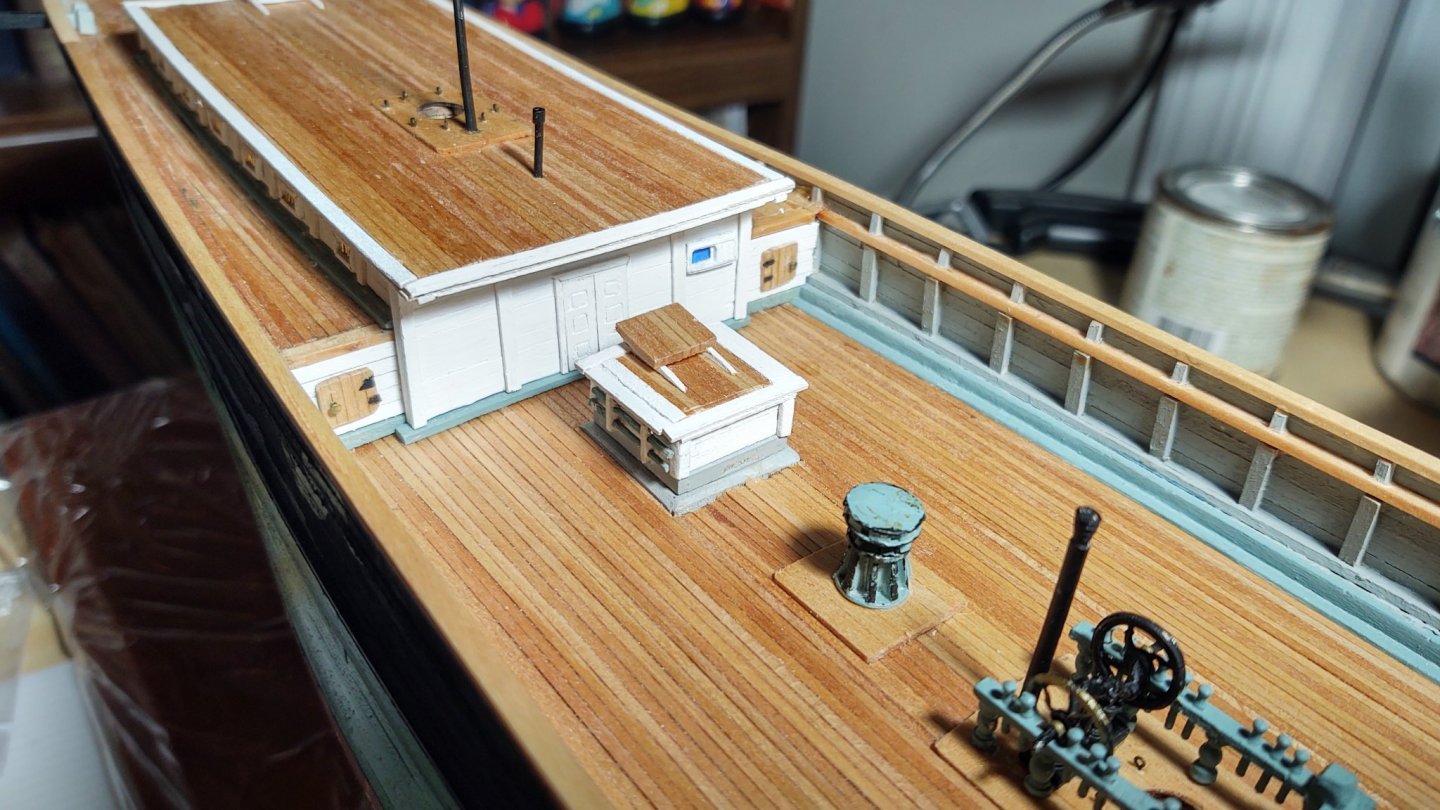

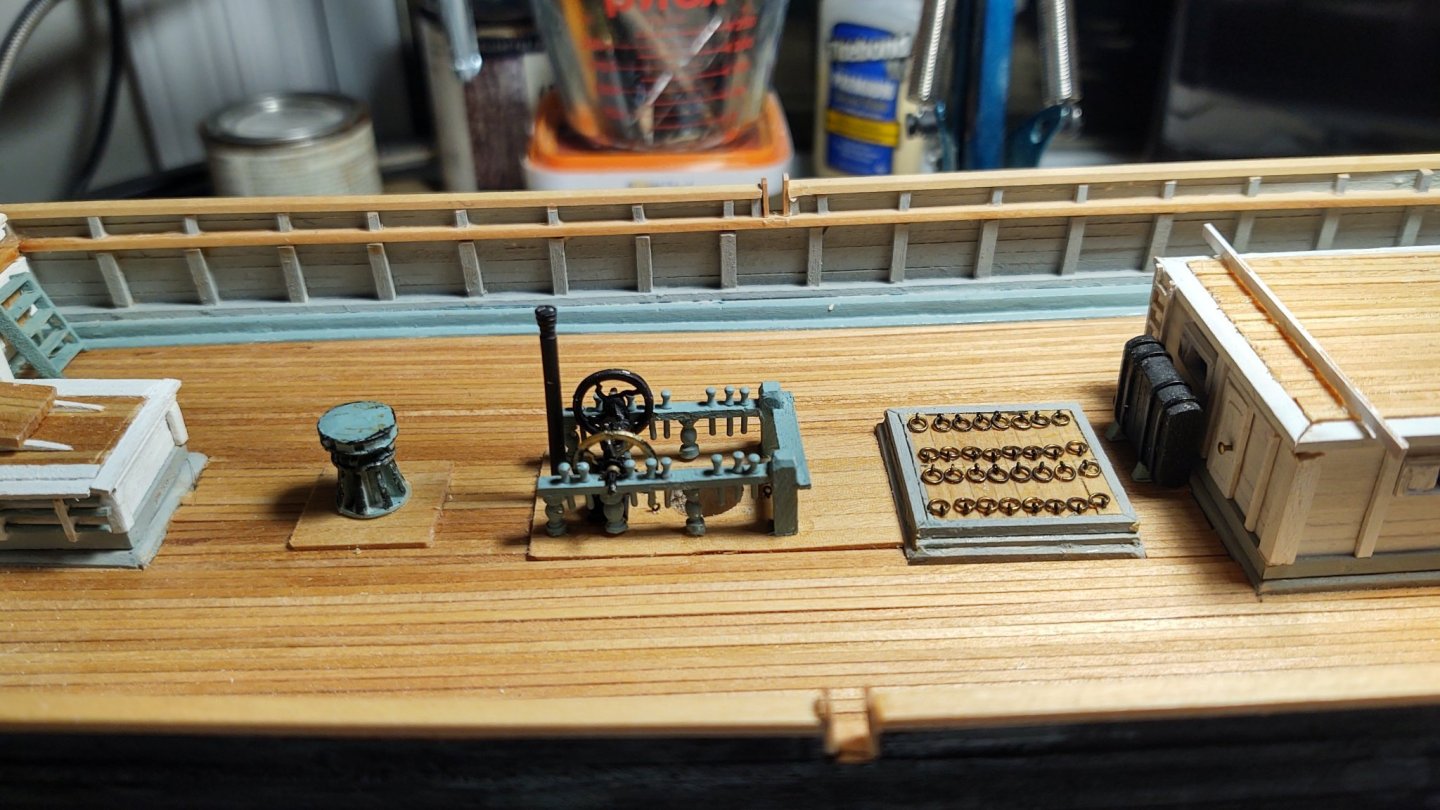

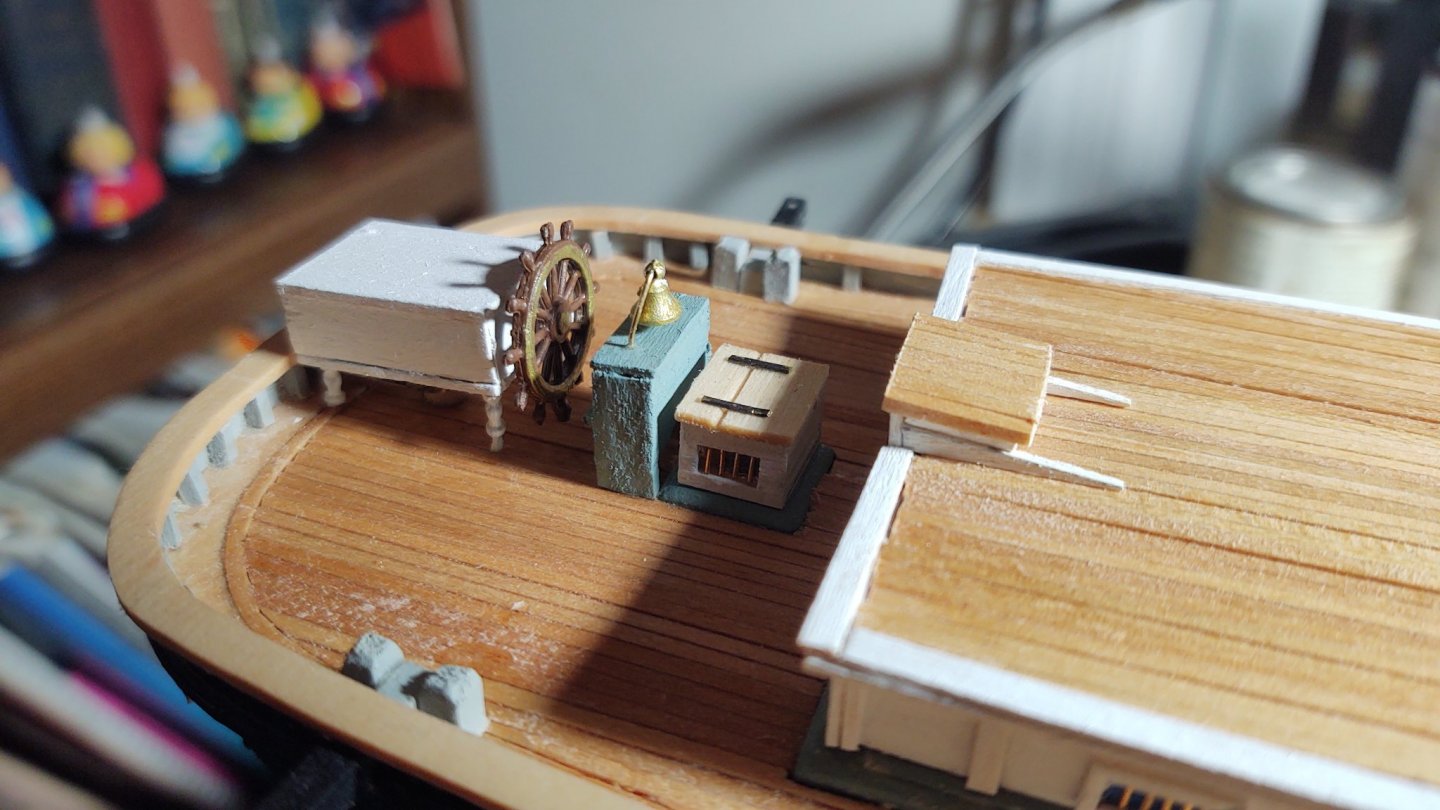

More deck furniture. First, the patent steering gear. Not particularly visible, but I did put the emergency tiller and the connection to rudder post in. Next, a couple of additional items on the carriage house. I mounted the doors to the storage areas, and then promptly covered up the doors with ladders. Didn't love the castings and while the ladders are not exactly perfect, they are better and in place. Finally, the main mast fife rails, pump and vent around the main mast. The fife rail castings were a mess (and needed to be drilled for the pins) so I cut the stanchions off the casting, made a wooden fife rail and painted the whole thing. The pump casting was surprisingly okay, painted it black with some gold on the outer edges of the pump wheel for some contrast, and mounted the whole thing on the main mast pad, with a bit of blacked brass strip to simulate the mounting points for the pump axles. Working on replacing the anchor stocks and planning out how I'm going to carve a 3/4 inch flying fish! As always thanks for the likes and for looking in! Regards, George K.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Three of them will be upside down, so at least their deficiencies will be less visible. I need to see what a BlueJacket one looks like before deciding. Maybe the boats in the davits will be off doing something and not around...😀

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

They look very nice which, much better than the casts from MSW. Looks like some more purchases from BlueJacket or scratch building some replacements. Thanks! George K

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Rob, I've looked through the log to try to find the if you mentioned it, but haven't found it. Are the ship's boats scratch, kits from Model Shipways, castings from BlueJacket or something else? She is looking fabulous! George K

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.ae840989b6daa8451c123c43d6ec3861.jpg)

.thumb.jpg.1ad9a8e3922bfc5e4490d1477f42e977.jpg)