-

Posts

726 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gak1965

-

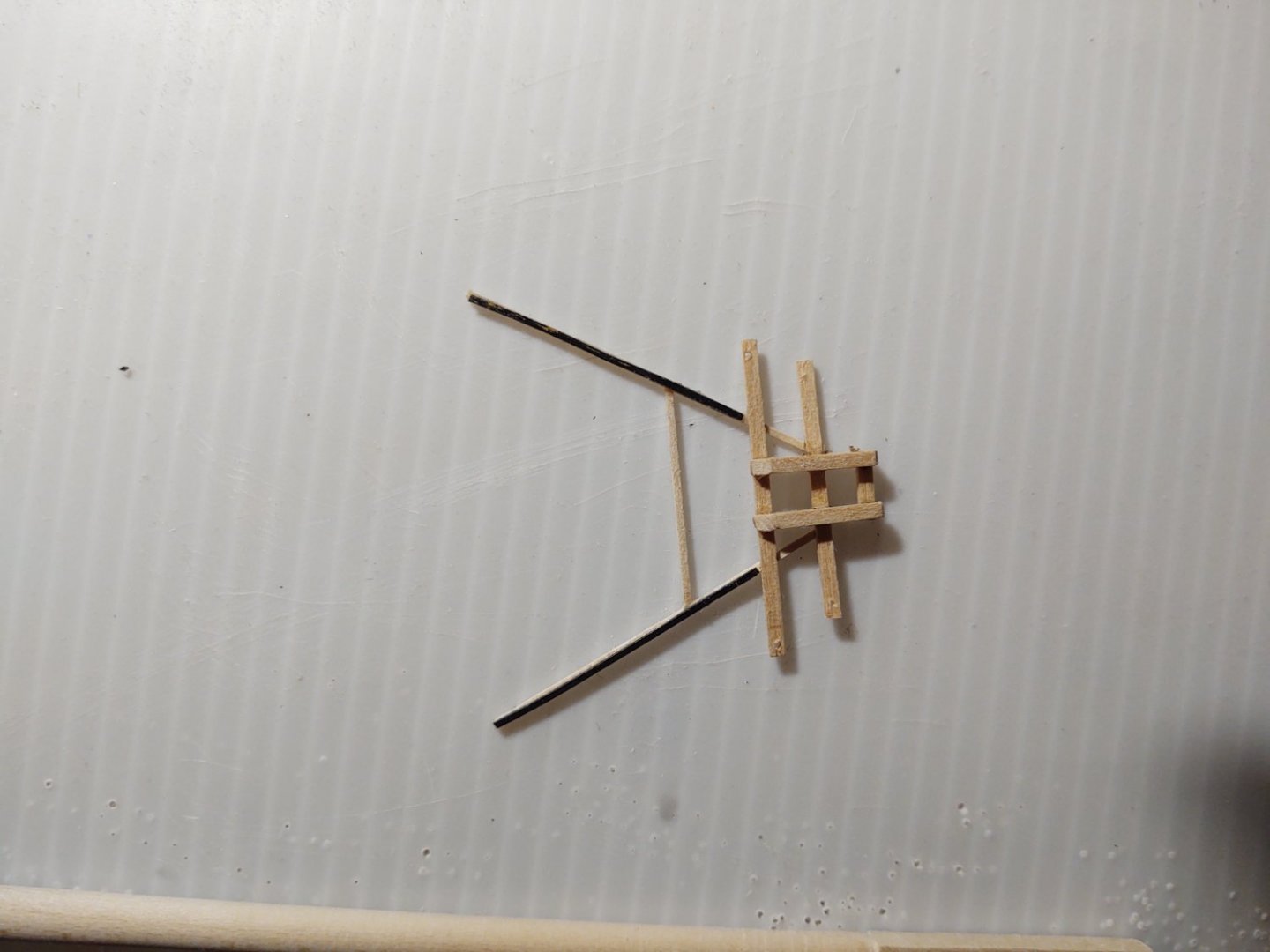

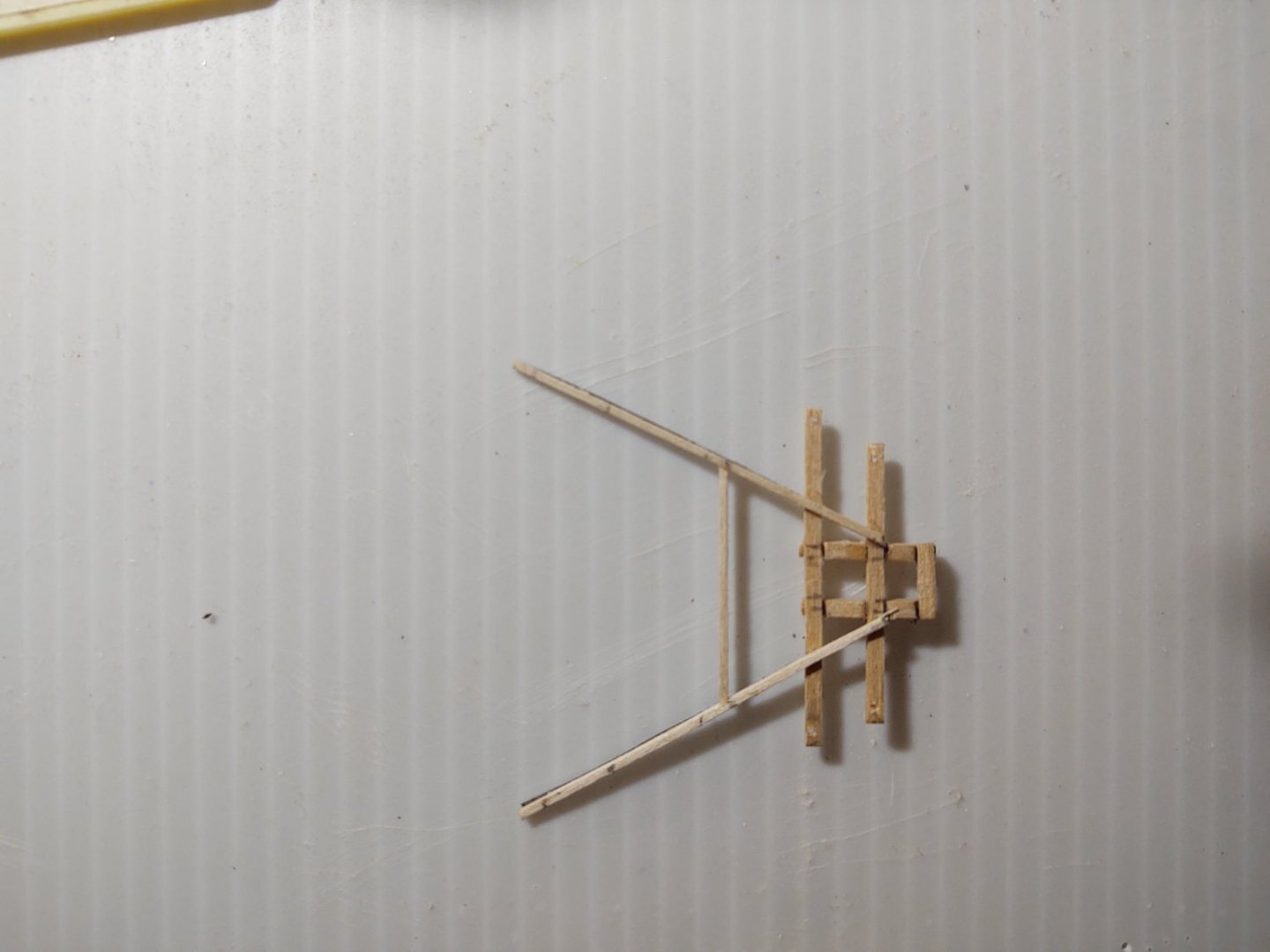

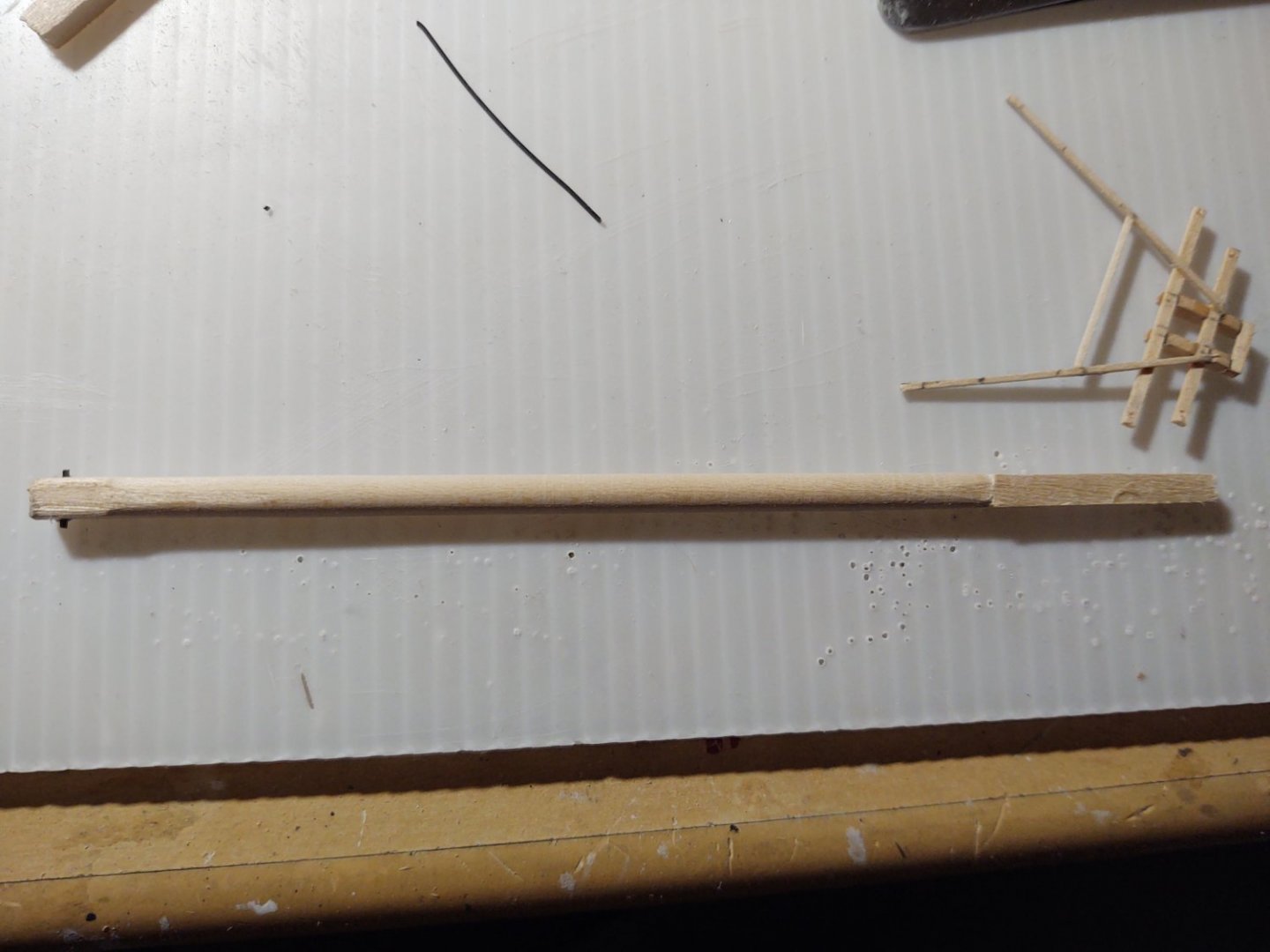

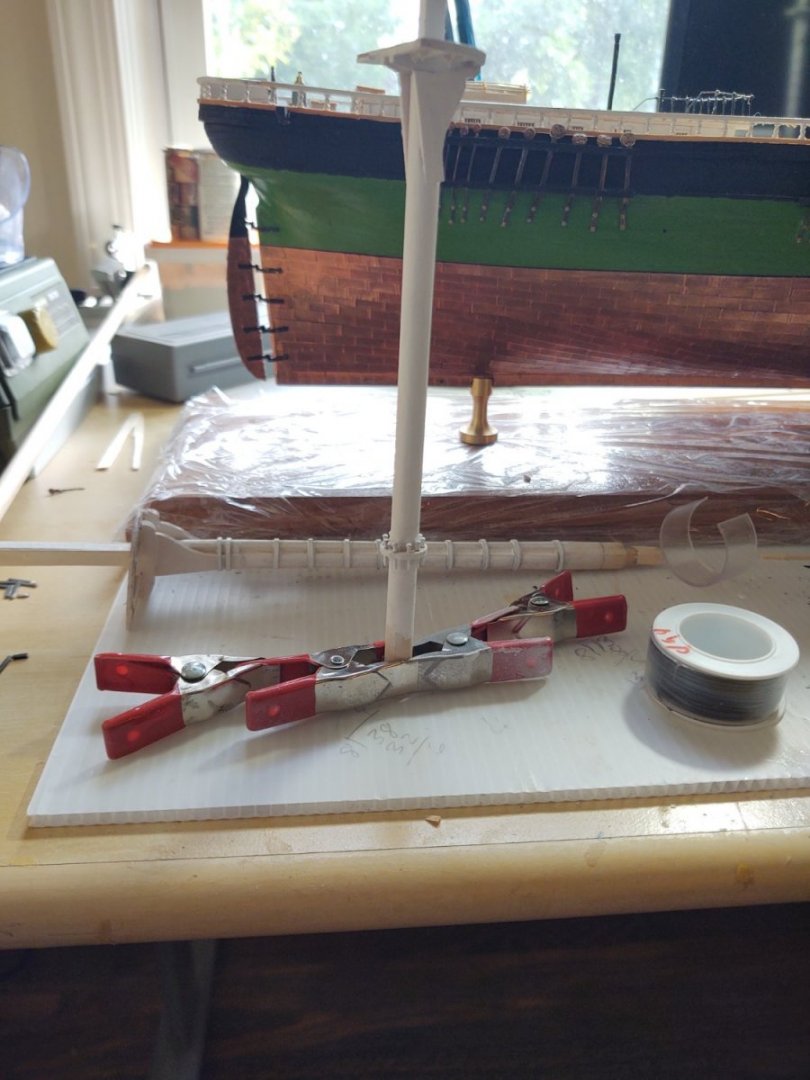

I've started making the topmasts, beginning with the main. Rather than use the kit supplied dowels, I'm starting with larger square stock. For the main that means 3/8 square basswood which I am going to turn and then trim to size. So, the stock on my lathe, marked up to show (left to right) the bottom of square portion of the mast, the end of the round segment, and the end of the square segment. I added a mark (after this picture was taken for the beginning of the round section of the mast. Here is the mast after turning. You will note that the square ends are way too big, as the lower part of the mast should be about 1/4" square and the upper about 3/16" square. This was the expected outcome of this step. Next I took some 100 grit sandpaper and narrowed the square segments so that they were correctly sized, drilled holes for the fid, and made it from two sections of 1/32 x 1/64" blackened brass. The mast is shown below. Once I'v built all three, I'm going to stain it so that it is a little darker. Next the trestletrees, crosstrees, and spreaders. These were made out of boxwood stock. In order to get the the crosstrees to be properly aligned on the trestletrees, I dremeled the cutouts with a cutting blade while the two trestletrees were clamped together. The crosstrees themselves are made from 1/16" x 1/32" stock, and quite flimsy before they were mounted. The spreaders are only 3" square in real life (1/32" at scale), and I was very worried about the loads that they were going to be under. So, I took some blackened 1/64" x 1/32" brass and glued it to the bottom of spreaders. You can see the this in the next two photos of the trees and spreaders from above and below (the marks are where I need to put the cleats and will be removed). The brass is barely visible, and I may put some on the brace as well. As with the mast, once all three are made I'm going to remove all the pencil marks and stain them. I haven't decided yet if I am going to make the six cleats out of wood (they would be really small and fragile) or put an opened jackstay eyebolt or perhaps a bit of very fine wire. They are going to be sufficiently hidden by rigging that I'm inclined to simplicity. I wanted to get an idea what the whole assembly will look like on the model, so I slipped them onto the mast, and I have to say I am reasonably pleased. Thanks again for looking in! Regards, George K.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

1/200 Trumpeter IJN YAMATO - issued by MRC/Gallery Models

gak1965 replied to yvesvidal's topic in REVIEWS: Model kits

When I was a boy, my grandfather built the 1:200 Nichimo version with the lights, working props, etc. I don't know what happened to it ( it got lost sometime in the intervening 52 years) but I've scanned ebay more than once for one of them. May need to make the investment, although goodness knows where I'd display it. at least it wouldn't be as tall as the sailboats so, lower case height.- 104 replies

-

- MRC/Gallery

- Yamato

-

(and 1 more)

Tagged with:

-

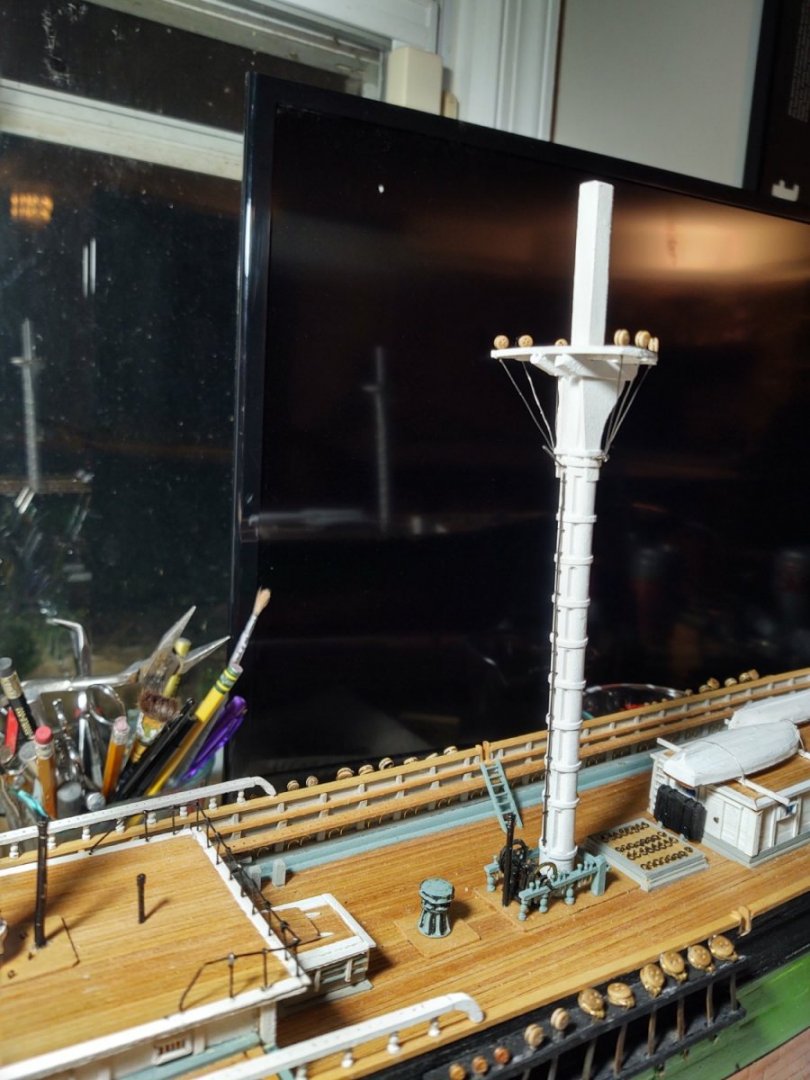

Well, an update. I've been working on the lower masts while I finish odds and ends on the deck. Lots of photos for me (well 6) but we are in a period where many things get done but the ship doesn't change much in overall appearance. With additional paint, the main was painted, and it is time to start adding additional details, including the iron reinforcing on the tops and the holes for the fairleads. The first new thing that needed doing was the spencer jackstays on the fore and main masts. They are theoretically 1" or 0.01" at scale. I built mine from 24 gauge black steel wire and 0.75 x 6 mm brass eyebolts that were chemically blackened. That would make them about 2x scale, but it isn't terribly noticeable. The jackstays on the yards were smaller and I will likely use a finer wire when I make them. Here is the foremast with the spencer jackstay. Next I made the futtock shrouds from deadeyes and some fine gauge black wire. The ends were threaded through the pre-drilled holes in the top and attached to a large eyebolt that is filling in for the individual mounting points on the relevant iron. Finally I drilled a hole in the masts for the gaffs and mounted a piece of 24 gauge wire that will eventually become the gooseneck. I have seen people use circles cut from blackened copper tape to make fairly convincing hinges at this scale and that is the plan for these gaffs. Here are photos of the fore and main masts with the jackstays and the futtock shrouds. This picture also shows that I installed the amidships ladders. I ultimately used the castings, they seemed as good as I was likely to make on my own, and (on the fore) that I've started installing the blocks for the bunt and clew lines. Ideally the blocks would be of four sized (two different sizes on the main/fore) and a second (smaller) set of two sizes on the mizzen. The kit comes with three sizes of single block and functionally all 4 block sizes were closest to the 3/32 inch size - so all 24 will be the same size. The mizzen required a spencer mast, which I built from a dowel and a some strip brass bent to accept a 24 gauge wire that will be the gooseneck, the spencer and then wraps around the lower mast. I also added the futtock shrouds, and here is a photo: So, the ship looks like this now with all of the masts in place (but not yet glued in). The mizzen is slightly more raked than I want, but the picture makes it look worse than it is. I am going to get in there with my Dremel so that it will stand at the same rake as the fore and main. Finally, a view of the ship from the bow showing the masts which. Again, the alignment appears a little off because they have no shrouds and are not glued in place. Next up - on the right of the final photo you can see the brass belaying pins that I hit with some patina. I think I need to give them another treatment to make them more uniform, but otherwise they are ready to be placed. Finish stropping the rest of the blocks that are mounted on the tops (16 down, 8 to go) as well as a couple of blocks for the mizzen braces that mount on the top, and then it's time to make the topgallant masts. I build (but don't rig) the entire mast before doing it's final mounting and starting to put the shrouds in place. Hopefully that time will start to come soon. In the interim I will probably start to rig the boswsprit to give me another area to make some obvious progress. As always, thanks for looking in and the encouragement. Regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

I wound up chickening out on my Passat. 1 fewer mast but at 10/inch, what a mess. And the Heller Ratline maker was a joke. One thing to check, the current Passat only has ratlines on 3 of the shrouds per mast, did Preussen use them all or did they only use the inner ones? I don't think people went aloft as much on the newer windjammers as compared to say a 19th Century warship

-

Saw this yesterday, thought people might be interested. It's a 1 minute clip of HMS St. Vincent (1815) making sail one last time before going to the ship breakers in 1906. No sound, but one of the few moving images of a Napoleonic era 1st rate. https://mobile.twitter.com/simonharley/status/1534068550935236609

-

I think we can agree that McKay was a great naval architect without beating up on the Cutty Sark. The two ships were designed for different purposes (tea trade vs. going around Cape Horn) and Linton designed around composite construction rather than all wood. It would frankly have been interesting to see what McKay would have done with composite construction (and steam) had the yard survived. The Essex that he built in 1874-1876 (although I don't know if he designed it) wasn't stricken from the Navy rolls until 1930(!) George K

- 359 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

On the other hand, because the mizzen has a Spencer mast there would be no problems with catching the hoops when raising the spanker.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

My assumption has always been that you use built masts when getting solid masts of the correct diameter is too expensive. As @ClipperFan points out, the mizzen is narrower than the bowsprit. I'm going to guess and say that McKay could get 2 feet diameter solid masts but 3.5 feet was becoming prohibitively expensive due to more than 2 centuries of logging around Boston. The photo of Glory in Alaska (where finding big trees would be less of an issue) with a fished main, and solid fore and mizzen would seem to bear this idea out. Given that, and the fact that the description of the fore and main (but not the mizzen) mentions fishing, I think I'm going to go with a solid mizzen. The iron hoops are more open to question. In a straight pole, I would think that the hoops would be useful in preventing the mast from failing due to forces acting along the axis of the mast (i.e. downward forces that would tend to split the wood fibers apart) and not forces that are applied parallel to axis of the mast (i.e. forces from the winds on the sails). If there are proper engineers out there, please correct me. Both paintings have value to get the proper look of the ship, but both have issues. Butterworth, for example, removed all of the deadeyes from the shrouds and backstays, the China Trade painting doesn't have the masts that are known to be fished, but has hoops. Actually, calling them issues is a bit harsh, in both cases, I'm guessing they worked.quickly and/or from sketches because they didn't have photos available, and so inaccuracies crept in. But they are both models in a sense, artistic representations of more complex real things. Ideally, an engineer tells me if my supposition about the utility of the hoops is right or wrong. Barring such information, I think I'm going to go with solid mizzen, no hoops given that the photos of Glory's masts don't show them when they are poles and not built. it's fun, kind of like a detective story to go with the construction. Warm regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Thanks for the info. My carriage house also curves toward the stern although I don't think it leaves perfect catwalks. Whether it is too narrow forward or too wide aft, I don't know. I think it's about 5 ft forward and 3.5 to 4 ft aft. The Fish is smaller than Glory and might have been tighter as a result. I'll see how much I can file away on the tops without endangering the fairleads. 1:96 ca be unforgiving at times. George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

The description of the Fish's masts (which I know you've seen) says that "Her fore and main masts are fished on every square, and closely hooped, and the fishes extend two feet below the lower deck partners. No ship belonging to this port has such massive lower masts." There is no mention of the mizzen, which I presume is why Ben Lankford ultimately went with a stick mast. The Butterworth painting does show a fished mast, and the China trade painting shows sticks with hoops on all three masts. Would it have been common to put hoops on a stick mast? I don't recall seeing them on the Pacific photos of Glory when it had switched from but to stick masts. It is probably possible to open up the lubber's hole a bit before I seat the mast. The holes were defined by laser cut pieces and are between 1.5 and 2 feet on the short side at scale which are narrow, but I don't have very good reads on the actual size of such a hole. Do you know if the tops in the photo are the original ones or added later?

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

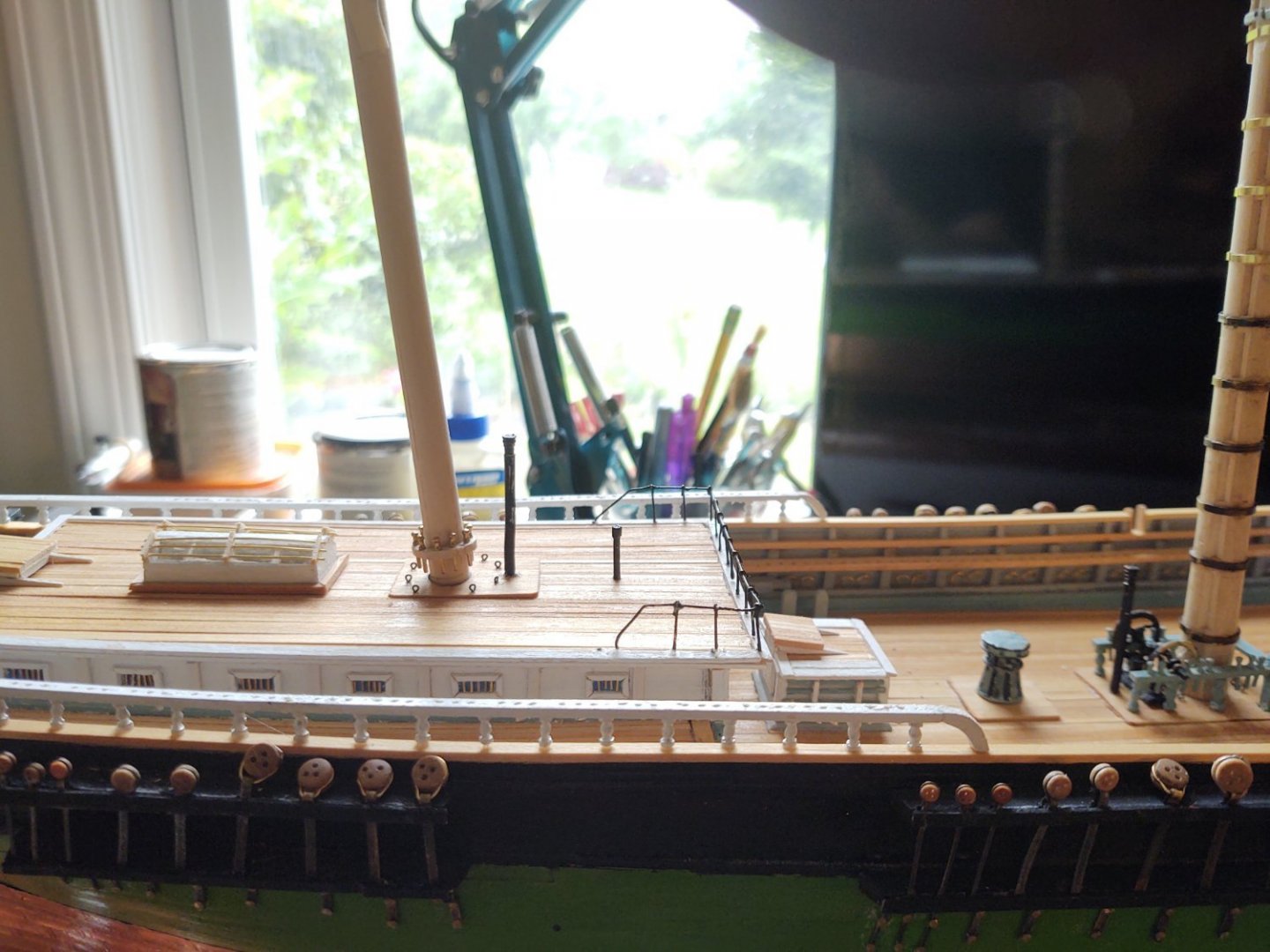

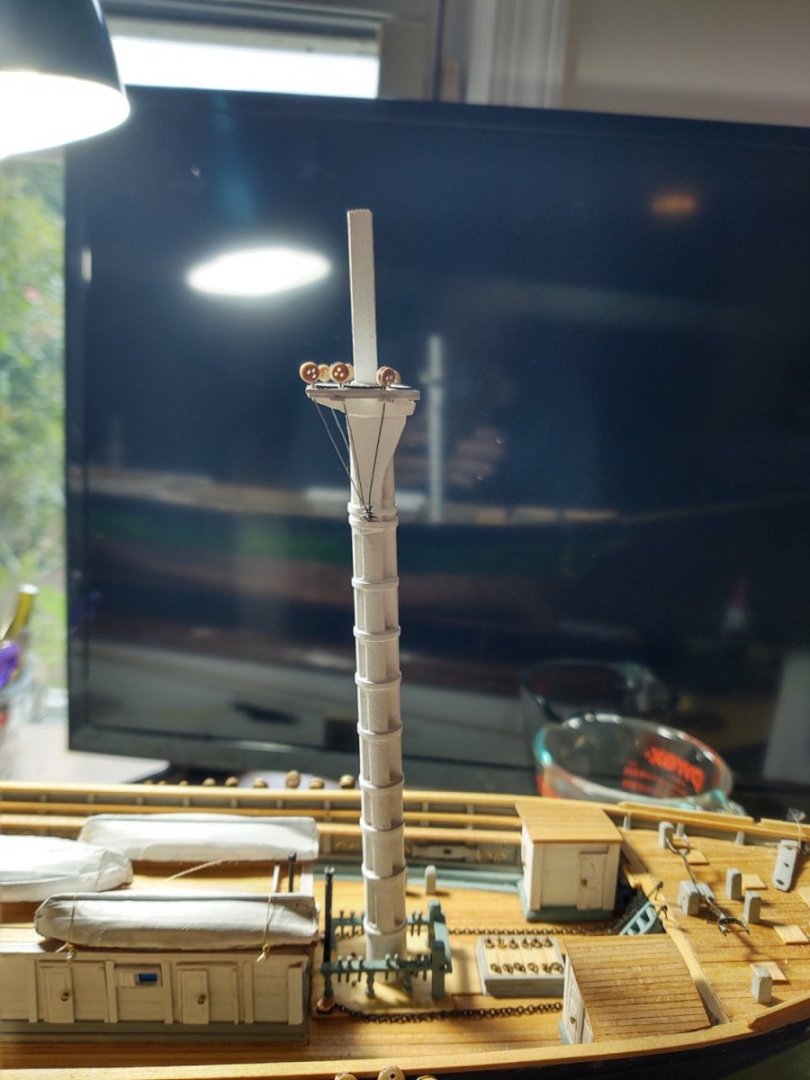

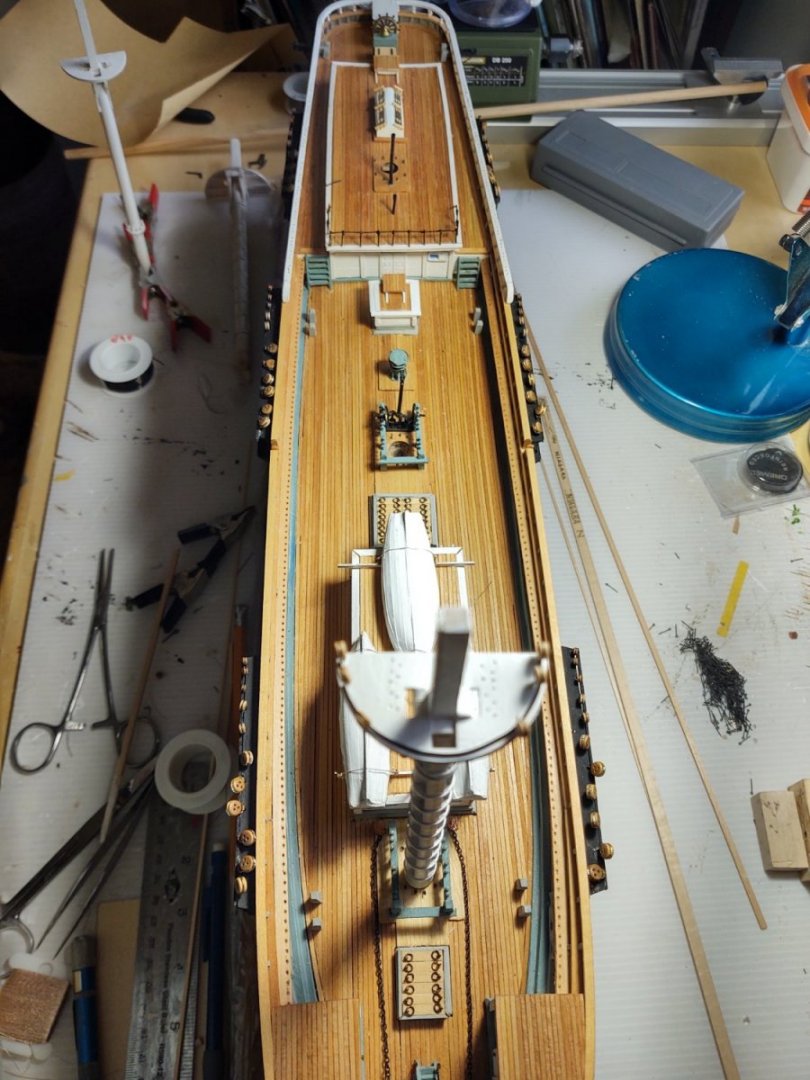

Well, some progress on the lower masts. The fore and main were mostly constructed, but not painted or any additional details added. The mizzen needed the ring of belaying pins, which is the next item I worked on. I marked out the relevant circles on a piece of appropriate thickness wood from the kit, drilled a pilot hole and then used a conical grinding bit in my dremel to make the hole. I then drilled out the holes for the pins, and finished the outside with a sanding bit. It was the only way I thought I could make it without having the whole thing break into a million pieces when I drilled the holes for the belaying pins. As it was, it split in two, but a little glue and we were back in business, as seen below: Next up was to paint the lower masts. I started with some Tamiya flat white from a spray can to get a base on the pieces, followed by brushing on Tamiya flat white to get good coverage. Unfortunately, I ran out of paint, so I've only done the fore and mizzen. The photo below shows the mizzen and the main, and you can see the difference between the spray only and the final look (the unpainted portion of the mizzen will be out of sight). Oh, while i was waiting for paint to dry I mounted the ships boats on the main deck house (the mast is not yet attached, and it's an optical illusion that it is facing forward). I then spent some time on the foretop. After painting, the holes for the futtock shrouds and fairleads had to be reopened. In addition, the plans indicate that the tops had an iron band around the curved edge. I made this with some black, 24 gauge steel wire, bent to shape on the edge of the top, and leaving the holes for the futtock shrouds uncovered (so basically there were 5 pieces of wire, each between one of the 6 holes). The futtock shrouds were made from 1/8 deadeyes (the closest I had to 10" at scale) and black 32 gauge wire, anchored onto the futtock band using a large eyebolt. Here is a picture of the mast from the starboard: And a similar shot showing the mast top from above, with the 'iron band') Finally the same shot of the whole ship, but with the focus on the deck, rather than the mast top. Next up are the rest of the mast tops and futtock shrouds, and the belaying pins. Then the topgallant masts and I can start putting some shrouds in place. As always, thanks for the likes and encouragement. Please have a good Memorial Day weekend, however you choose to mark it. Regards, George K.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Discovery has actually changed a lot from its 1904 appearance. The deckhouses have changed, two masts were moved forward various amounts to improve sailing trim, and the rig modified to use split topsails among other things. As to the color of the funnel, I can't really say... Regards, George K

-

Yeah, the plans suggest 2 different sizes of iron plate and I had two sizes of brass, one that was 3" at scale, and the other 6" at scale. Using the 3" was probably too small for the shrouds and 6" too large. I don't have tools to mill the material to a smaller size and couldn't find intermediate sizes online. So, I decided to go slightly too large but retain the different sizes of plate. The deadeyes themselves are also off a bit. There are something like 5 or 6 different sizes mapped to three sizes in the kit, so some of the mizzen deadeyes are too large and some of the ones on the tops are going to be too small. One of the reasons I'm thinking about doing Discovery at 1:64 is so I don't have to deal with some of those choices, the 1/32"/0.5 mm spacing in commercial wood, brass, deadeyes, etc. is 2" then. Easier to get things properly in scale. Regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

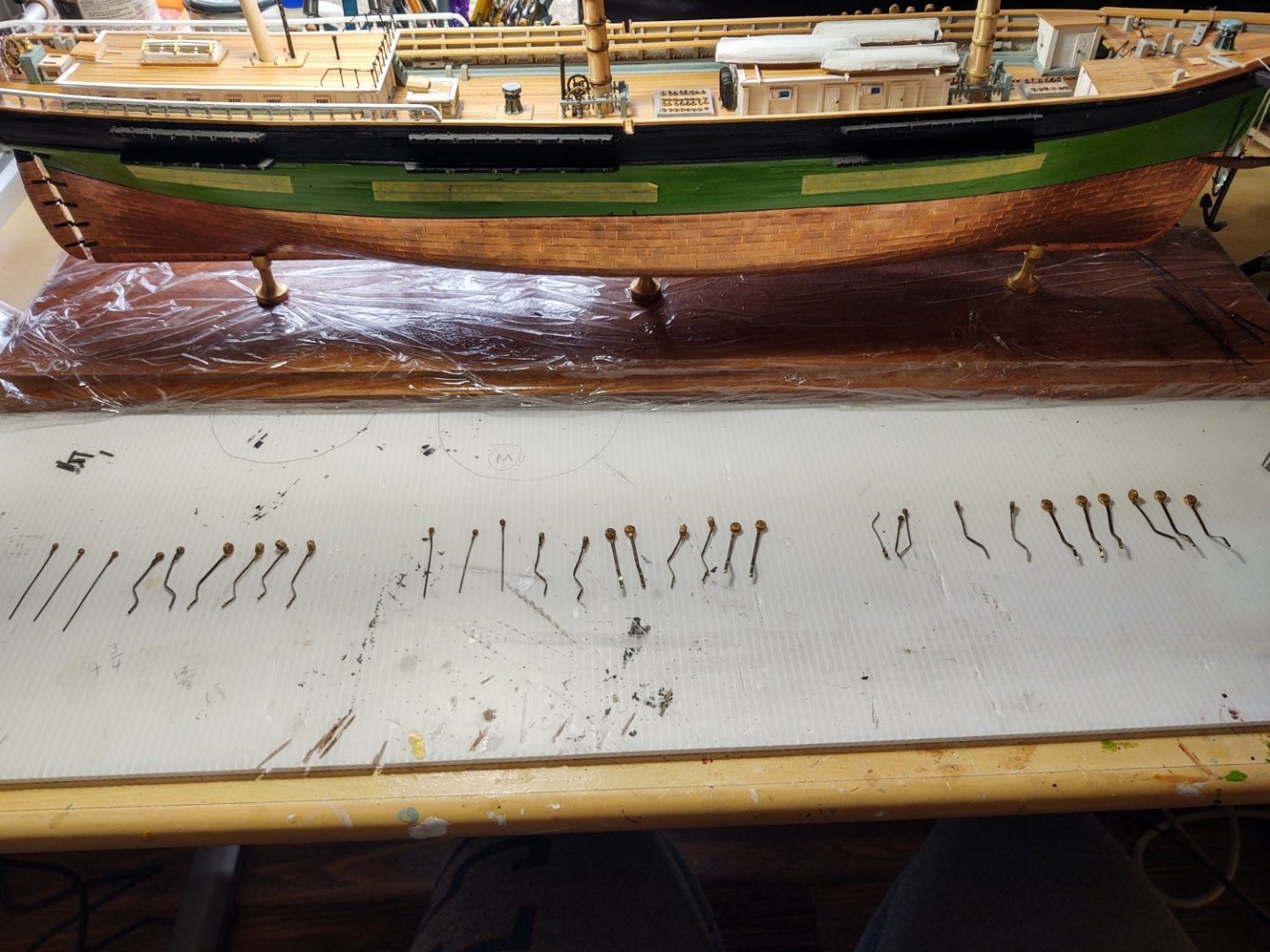

Well, I've reached a couple of milestones, although for whatever reason it was a much longer slog than was consistent with the actual technical/physical complexity of the task. So, the first milestone is that the chainplates are finally complete. As I mentioned before, the cuts in the channels for the plates were aligned to the plans so that the plates themselves should align with the path of the shroud or backstay. Because that means that getting the 'bolts' to align properly will require that each plate have a custom length, I put tape where I wanted the upper bolt to land, and drew a line on the tape where the lower bolt should sit. I then fitted the stropped deadeye with the plate, bent the brass as needed and marked the 'bolt' locations with a pin vise, drilled out the holes with a (power) hand drill, and opened it up further with a pin vise. This opened the hole wide enough without mangling it. You can see the 31 chain plates (11 fore, 11 main, 9 mizzen) in the photo below, with three sizes of deadeye and three different chainplate materials. (Also the tape, which had to come off before I mounted them onto the hull). After that, I glued each plate in place in the channels, and on the hull, covered the edge of the channels with a pre-painted black wood strip, and drilled the holes in the hull where the nail that represents the bolt would sit. The nails were then glued into plates. As mentioned before, the upper backstays are quite narrow, so rather than drill holes, I glued the plate to the hull, glued a short segment of similar diameter blackened brass below it, in line with the path of the plate to represent the preventer, leaving an approximately 1 mm gap with the chain plate. I then drilled holes above and below the "preventer" and glued the nails in. Here are some photos: There are imperfections, but working ships had imperfections. That's my story, and I'm sticking with it. I also installed the irons on the jibboom and mounted it on the ship. It has the necessary holes drilled for the various lines that will eventually grace it, and the eyebolts that are representing the endpoints of much of the standing rigging on the bowsprit and jibboom. Finally, the extra brass arrived from Model Shipways, and I've put the bands on the lower fore and main masts. They need only the bolsters on the tops and I can paint them white, and start thinking about installation. Here are three (not particularly good) views of the ship to date. The first from above showing the lower masts, the second showing the whole ship up to the bowsprit, and the third, a (poorly lit) view of the whole ship. So, I still have some work on the main deck (tie down the ship's boats, build 4 ladders, attach the forward bell, blacken and install the belaying pins in the pin rail, but we are pretty much starting the transition to rigging, which is pretty cool. One question for the cognoscenti. According to the plans, it appears that many of the connections between the bowsprit and the hull are mediated by hearts, rather than bullseyes or deadeyes. Shrouds and backstays seem universally to use deadeyes. On the Niagara the bowsprit standing rigging was a mix of deadeyes, bullseyes, and hearts. I assume that there was a reason for these choice, curious if anyone knows why. As always, thanks for looking in and for the likes! Regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

That photo doesn't look like it was taken while they had any kind of sails set. I see that it is lightly attached to the rails, but you might just as easily suggest it is a mooring line (I think I see it going into a chock in the upper part of the photo) being kept off the deck, perhaps to prevent it from sitting in water and rotting?

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

That's a great looking Connie! No reason to stop, everyone breaks things and had to repair. Once the basic hull is done, assume you are going to break something at least once every three sessions until the standing rigging is in place (it helps stabilize all those spars in the model as in life), at which point it'll drip to maybe 1 in 4 or 5 sessions. That's why we put them in cases (well and the dust). I more or less mashed all of the rigging on the bowsprit and broke off the jibboom of my Niagara at one point (a story or almost mind boggling stupidity on my part). It was fixed and moved on. Both ships are looking great! George K

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

This intrigues me. Do you mean the estimate of how much the spar projected from the deck was 4 feet shorter than you thought (caused by thinking that a spar of length n was stepped further vertically in the hull)? Or something else?

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Yes, Lars' site is a great resource. The numbers from there and the plans definitely match up, although you need to know (as I do now) the the dimension being listed for the ropes are circumference not diameter. I assume you mean iron for the futtock shrouds? That is consistent with the plans and I approve since it's way easier to make them out of wire 🙂 than string. Regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

That makes sense. 10.5 inches in circumference is a 3.4 inch diameter which is 0.035 inch at scale, against a .028 largest diameter thread provided with the kit. I knew something was off in my read of the plans. Thanks! George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

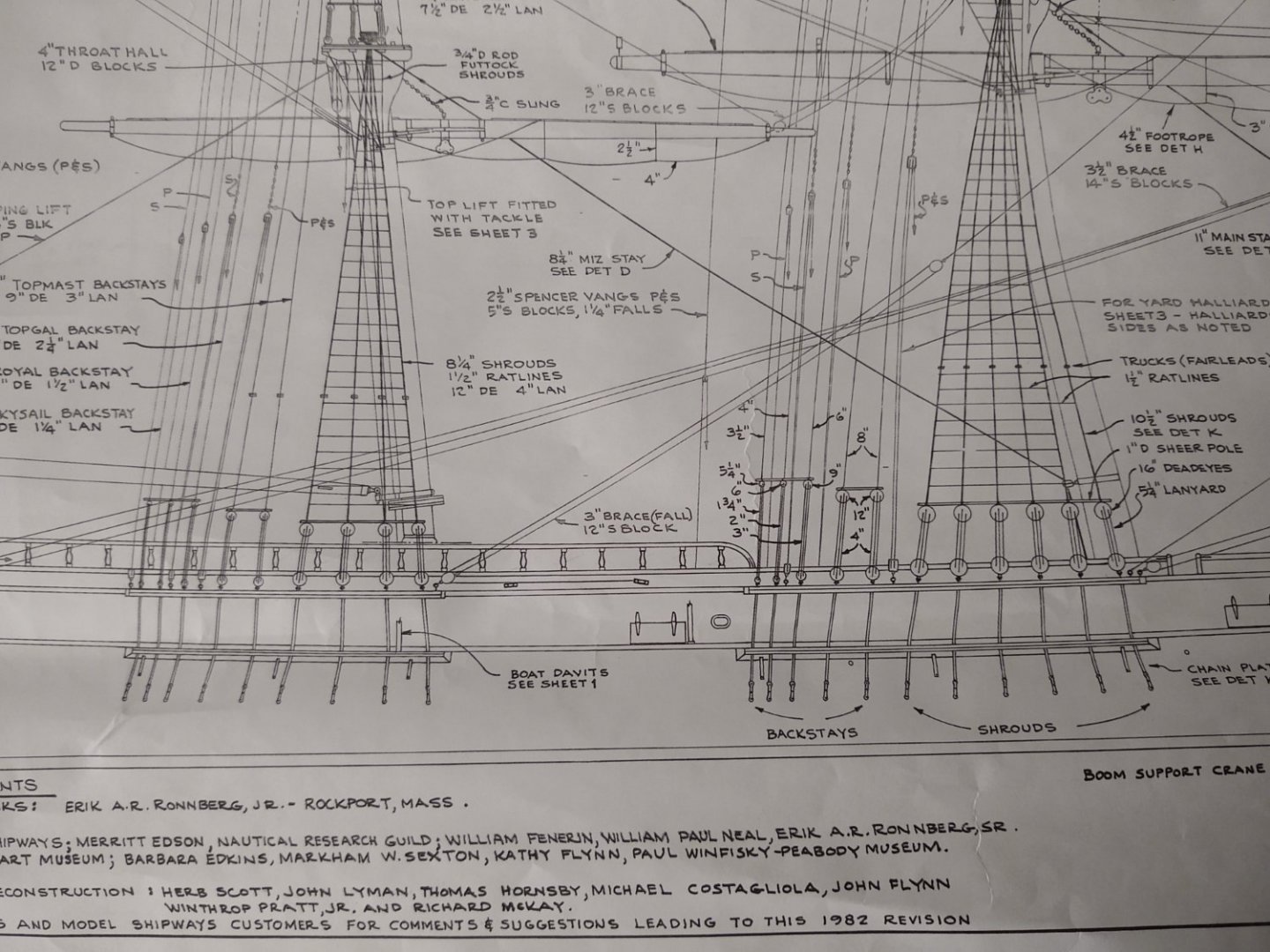

Hi all. I was hoping to reach out to the collective wisdom of the FIsh and McKay clipper ship builders out there. Having finished fabrication of the starboard side chain plates for the fore mast has me thinking that I will soon be able to start running shrouds, and I find I often need to spend a few days staring at plans to understand everything that needs doing properly. Usually the shrouds are pretty straightforward, but this time the plans do not make much sense to me, so hence my questions to you all. Take a look at the segment of the plans below showing the lower shrouds for the main and mizzen masts: Most of it makes sense. For example, looking at the main, we have 5 different size deadeyes (16", 12", 9", 6", and 5.25") that are reduced to the three supplied deadeye sizes supplied with the kit (3/16 for the 16", 1/8" for the 12, and 3/32 for the rest). Fine. But the rest of the numbers make no sense to me at all. 10.5" shrouds on the main with 1.5" ratlines (right side of the image just over the shroud lanyards)? 8.25" shrouds with 1.5" ratlines on the mizzen (right side of the shrouds, halfway up)? That can't be right, those are the sizes of mooring lines on aircraft carriers, not shrouds on a clipper. The lines arranged side to side would cover more than 1/2" on the model at the top. And at scale a 10.5" line would be 4 times the diameter of the largest line that comes with the kit. I must be missing something here. Open to any suggestions as to where I have gone astray, or thoughts around 'typical' shroud sizes on McKay clippers. Thanks in advance, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

A short update on the progress of the Fish. For some reason, the chain plates and deadeyes were turning into a bit of a blocker for me. However, I received the material for making the plates for the lower backstays from BlueJacket and so no excuse. I have finished channels and plates on the port (or as I called it earlier the non-display or "practice") side of the ship - 16 for the shrouds, 6 for lower backstays and 9 for the upper backstays. The starboard side should now follow pretty shortly. The photos below show them reasonably well. I started with the main, moved to the mizzen and then finished with the fore, and you can see that the practice helped. The mounts on the hull are a lot straighter by the time I got to the fore, so hopefully that will continue on the 'display side. While that has been going on I've been continuing to work on the masts. As you can see in the image below I've added the cheeks to both the fore and main, and have begun putting on the mast bands prior to painting. I had thought about having the mast bands be black iron, but the available evidence (the Butterworth and Chinese painting) all suggest that the bands were painted with the lower masts, so white they will be. The main isn't fully banded yet because I ran out of brass of the right size - however, I got an email about an hour ago from Model Shipways indicating that they are shipping me some additional brass in response to my request, so that should be resolved pretty soon. I had earlier asked about people's experiences with their part replacement policy and it appears that I am another satisfied customer. Finally - as hinted in the above, I've been building the mast tops. The photo below shows the fore and main, more or less ready to mount on the cheeks. The mizzen just has the two laser cut pieces, I'll get it soon enough. The holes for the fairleads and the futtock shrouds are already in place. The real ship has an iron band on the outer edge of the upper side of the top, which I will add once it is painted. I'm debating using pre-bent 1/32 square stock or some 24 gauge black steel wire. The steel wire is about 1.5" at scale, the wood stock is 3" at scale. I'll probably try both and glue the one that looks best. You can also see that I am working on the jibboom. It's drilled, it just needs another "iron" band and 3 eyebolts and it will be ready to mount. So, the plan moving forward has three things going on at once - doing the chain plates on the starboard side, finishing the lower masts and tops, and starting to rig the bowsprit. I've chosen to conclude that this allows me to make progress in several areas while things are drying rather than suggesting that I have a disorganized mind and un-diagnosed ADHD. That is my story and I am sticking with it, plus I find that adding line tends to get me motivated to do more. Actually make that 4 - there are a few things left to do on the hull (a couple of ladders, lashing down the 3 ships boats, maybe emplacing the myriad belaying pins). Anyway - thanks for looking in and for the encouragement and likes. Regards, George K

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Some more photos. Not that this will surprise anyone, but the protuberance on the left is a privy. All water comes from cisterns fed from the roof which I can tell you is not free of gull excreta. it's possible that it used to be less of an issue, but they lived rough back in the day.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.