donrobinson

-

Posts

1,909 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by donrobinson

-

-

You have left lots to see and learn in your log Frank, a truly fantastic build. I'll be looking forward to your next one.

Take Care Buddy

- mtaylor, mattsayers148, Elijah and 1 other

-

4

4

-

-

-

-

It all looks very sweet Mark, some real good ideas you have. Paint job is awesome

-

I likey, looking real nice. Why is it that most of the cool looking wood is so brittle? Some day, when I'm in charge, I'll have that changed

- marktiedens, mtaylor and Seventynet

-

3

3

-

Hey Mike, I just caught this and thought I would comment. MarisStella is a wonderful place to deal with, it is one thing to get a great kit but also to receive support such as I have is almost unheard of. When MarisStella first joined as a sponsor I was intrigued with their kits and then literally bombed them with questions, which were all answered. Now during my build my questions are still relentless and the answers still come back in the same courteous manner.

These "smaller" manufacturers are something we should be looking at if you want something different and unique to build.

Dusek kits are another one to look at, I mean check out Nigel's log it is fantastic( love to be as good as Nigel). I myself have built Dusek's "ship's boat" and it was a great little kit(Nigel has yet to build it

) it is, however, part of his kit.

) it is, however, part of his kit.I guess what I am saying don't be scared to reach beyond the boundaries of the "Big Guys", I mean if all else fails ask here at MSW and you'll find all kind of guidance

-

-

-

Best of luck bud, and I wish you the best. On the brightside it sounds like re-construction.....you could maybe show him a thing or two

- Canute, SawdustDave, Omega1234 and 8 others

-

11

11

-

-

Any more developments on this beauty, she is a great looking ship. Would be happy to see more!

- MarisStella.hr, maggsl_01 and mtaylor

-

3

3

-

-

-

Thanks everyone for your comments, likes and for stopping by

Elijah: Thanks, I'll see real soon if they are actually going to work or not. I'll keep you posted

Mark: I thought the same thing but this is one sturdy boat so far and it will only get stronger as the inner and outer planking get added. Right now I'm getting close to where I have to spiel planks on the interior, a little opposite from what I'm used to

David: You are more than welcome to join along, good to see you here at MSW. I haven't noticed any build log yet for your Connie are still planning on starting one here?

-

-

-

-

I took a bit of a play day off from the builds and made up these sanding sticks. The interior of the Trabakul is planked and with the bulkheads and support beams there is not room to get your hands inside to sand. So I'm hoping these will help. The feet are made from 1/2" square stock and the handles from 1/4" stock. A wooden pin is used to attach the foot to handle allowing it to swivel. I made extra feet so that I can have variety of grits. I'll attach the sandpaper with double sided tape, I'm just waiting for the poly to dry.

Have a good night all, and Thanks again for stopping in. I'm off to town tomorrow Wackowolf ordered some cold apple cider that I need to pick up.

- Cabbie, Kees Meijer, Eddie and 23 others

-

26

26

-

Thanks everyone for your comments and likes:

Mike those are ones that I made, they are made out of 1/4" square stock

Chris I agree about the tv nowadays, but I think a video is out of the question until I clean up my language

, But thanks for the vote of confidence.

, But thanks for the vote of confidence.Don F you are so right about these kits they are fantastic, I wish I had a small hammer as you say, it sure would have been handy. Do you have a log started?

Take Care

-

-

Hi everyone. Thanks so much for all your comments and likes, I was caught off guard by all the responses here so I took some time off to get more chairs, re-stock fridge and grab some snacks

Hi everyone. Thanks so much for all your comments and likes, I was caught off guard by all the responses here so I took some time off to get more chairs, re-stock fridge and grab some snacks

. I think we should be good now for awhile so I'll continue with the build.

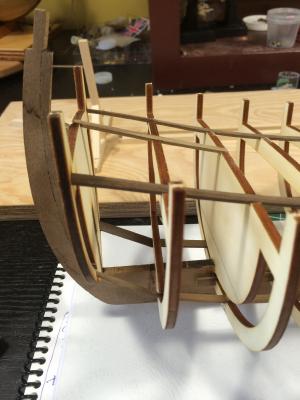

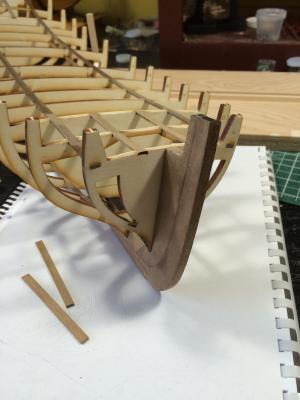

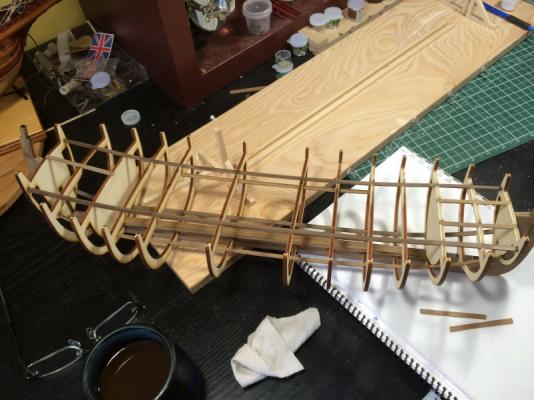

. I think we should be good now for awhile so I'll continue with the build.Next step up after sanding the keel is fitting the bulkheads and test fitting all the notches on them. Unlike most where a snug fit is wanted between bulkheads and keel to allow for glue the Trabakul requires the bulkheads to be tight as there is no glue applied to the notches. The bulkheads all fit great with only very minor adjustment required on one of them, the last three bulkheads are left off until the four pieces for the keelson are slipped in. When the final three bulkheads are installed the two side pieces of the keelson are glued into place the last two pieces are glued into place in between the side pieces. The top piece needs to be aligned properly as this forms the ledge for the floor.

After keelson was completed the support beams were all installed, again everything fit with precision, only at the front bulkhead did I need to do some minor filing and that was just put a little bit of an angle on the notches to allow beams to fit properly. After glue dried I removed her from the cradle and glued the bottom of the bulkheads. This was a little overkill as once the keelson and support timbers were installed this boat was absolutely tight and sturdy.

This ends the first part of the build next up is the interior, wish me luck.

Have A Good One

- Cabbie, Seventynet, Eddie and 21 others

-

24

24

-

-

USS Constitution by David Lester - FINISHED - Model Shipways

in - Kit build logs for subjects built from 1751 - 1800

Posted · Edited by donrobinson

She is looking real good David, copper plating turned out nice