-

Posts

2,276 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikiek

-

Elijah - like Bob said, the little items are what turn a model into a ship. And even though they are small they can still have details. Check as many period pictures/paintings as you can. Get a feel for how the work was done on board. You may find you can add (or remove) items for more realism.

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

Dave - good thought on cleaning the electrode tips. I need to get some backups. Those things seem to break real easy.

-

Thank you Elijah. It is almost a relief to have that behind me.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

Darrell - I have the deadeyes down. At least I did. There are some already installed on my mast tops. If I can just remember how I did them. Hopefully there are notes in my log too. It's the other pieces that I was trying to get away with not soldering, particularly the the one that mounts to the hull. I was also hammering 26 gauge wire. I'm OK with the look, just hoping that hammering them would close the end loops enough to hold. But while I've got you, the 26 guage was for the largest chain plates. Did you go thinner for the smaller ones? I really don't feel comfortable using 28 or 30 guage wire for this process. I have my doubts as to the durability when some tension is put on them. Also the plan is not real clear on the next plate up from the hull mounted one. It sort of looks like it just hooks into the upper loop of the one below it. Not really fastened.

-

Mark, Dave - OK you talked me into it. I do have a resistance unit. It's rather frustrating. The pincer electrodes (like in Dave's pic) work only about half the time. The rest of the time it does nothing. Can't figure out what's wrong.

-

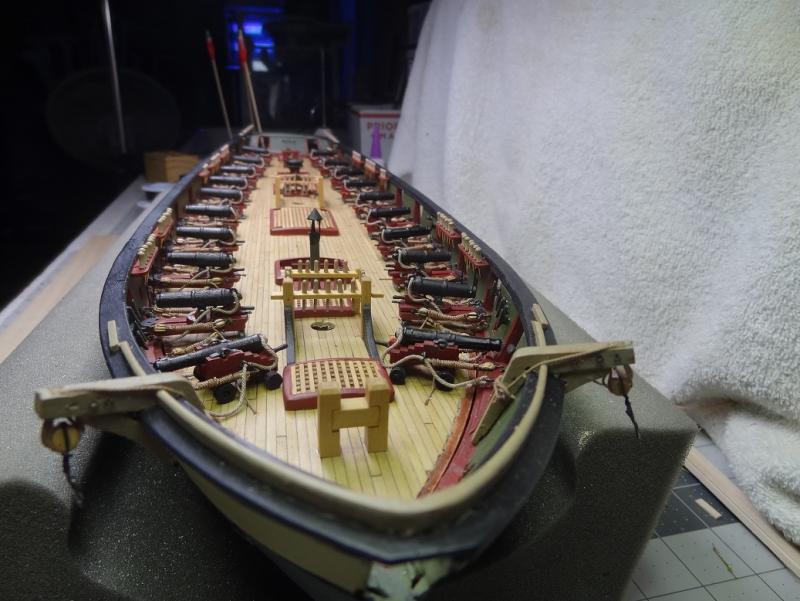

Bob and Don, thank you! It is a real mile stone in this process. Don, it's almost an illusion. The ship only carries 20 guns. Relatively speaking, that ain't many when compared to a ship o' line. I guess it's because they are all out on the main deck rather than below on a gun deck(s).

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

The pix don't look a lot different than the ones from last week. But I am calling the deck finished now. All the parts made and mounted. I will still do a final compare with the plans to see if I overlooked something. My thanks to Darrell for leading the way on the galley pipe. Was not sure how to do that one. Soldering brass strips to the brass pipe was quite annoying. Tried a mini torch at first. Get one soldered. Go to do the next one and the heat would melt the solder on the first one. Had to break out the resistance solderer. It took a while to get each strip in place with one of those third hand things. Then get the electrodes touching without knocking everything off. But the solder was quick and did not affect the other pieces. The little cone piece on top was made by turning a piece of wood. Actually my first attempt using a lathe for anything other than rounding square sticks for spars. I did some reading on galley stoves and it appears that early pipes were made of wood not metal. Not so sure about during the Niagara period. If it is wood then I probably have the pipe painted the wrong color. I know the top area would have been black from soot. Channels and chain plates are next. I've posted a question about that here. Feel free to add your 2 cents worth on that. Well here she is.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

Channels & chain plates and I will be ready to start rigging. The Niagara plans call for 0.016" material for the largest chain plates. Even thinner for the smaller ones. I don't have any brass rod that small (0.02 is my thinnest) and my calipers are telling me that 0.016 would be about 27 gauge wire. That's pretty darned thin. While there may be a few of you out there that could, I doubt if I could do any type of soldering on that - to close loops, etc. I did take some 26 gauge wire and wrap it around some nails and came out with the proper shape piece - just wire with a loop at each end. I then hammered it a bit which of course widens the wire and seems to close the loops somewhat. This is my first build so my first rigging too and what I don't know is this. When the rigging starts how much stress is actually put on the chain plates from standing rigging? Granted in real life there would be a lot. But in our modeling? Will the hammered loops be sufficient? Here's a sample part.

-

That stinks Mike. I hope you get some resolution soon. I am working this kit in between some others. Got the frames laid and the first strake of planking on. It was rather difficult. Quite a few folks opted for spiling the planks. I have gone with the instructions and am trying to bend them. Including edge bending. Also had Crown replace the kit supplied wood with pear. I suppose that might be why the plank bending is more difficult. Don't give up the ship!

- 129 replies

-

- finished

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you Julie! This kit seems to have a lot of detail packed into a rather small hull. All having to do with her intended use.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

The build just gets better and better looking! Had a cold front here today - low=60F/hi=80F Brrrrr

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Tool for Shaping Brass Strip

mikiek replied to mikiek's topic in Metal Work, Soldering and Metal Fittings

Good luck Mike. I hope the book helps you more than it helped me. -

I definately will put a finish on them. Problem is I keep finding little spots I missed or chipped off. I'd like to get those cleaned up first.

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

1:64 figurines were purchased here. Set of 6 different figures. Only downside I have run into is painting them. The blue in the pic is after 4 coats and it still chips easily. Maybe enamel rather than acrylic?

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.