-

Posts

1,190 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by AntonyUK

-

Hi Paddy. Still looking good. Every time you trash something you make... Is learning another way on how NOT to make it. Until success. And then you know how to make it. It's called learning by doing I know I spent a lot of my life perfecting things. The pictures are looking great. You know how to take a good photo Regards Antony.

-

Hello Rusty. From start to finish you have done an exceptional job and invasion into tasks that can be a little daunting. Congratulation's on compleasion. So the question is :- What's next ? Regards Antony.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

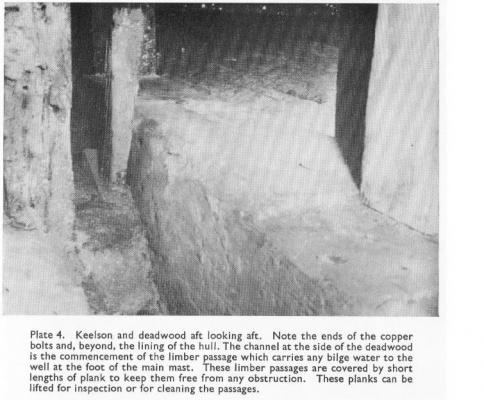

Hi Paddy. Nice work in the Keelson. The copper bolts look OK to me. I can remember reading an article on this.. The holes were drilled and the bolts forced through(not hammered) then cut off above the Keelson and bellow the Keel. Then they were peaned over with a concave headed hammer. Basic riveting. Info came from page 10 in Anatony of the ship " Victory" So mabe they would be proud. On an English ship... But copper would expand in the hole with hammering and the amount of area above the Keelson would be very little. That's the way I read it. Regards Antony. Edited. Found more info.. On page 71 in Anatomy of Nelsons ships there is a photo and discription of the bolts Will post it when I get to PC.

-

Hello Paddy. Nice work in the frames. A question :- are your scrapers flexible ? And how do you sharpen then.. Only asking as this is a tool that a elderly gentleman showed me some years ago. And he was a master model ship builder. Never used one for the purpose of wood removal only old paint removal. Regards Antony.

-

Hello Rusty. Very nice work on the ladders mate. I also like the display cabinet. A simple design and easy to make 100% from me on that one. Your work has been spot on throughout the build. Well done. Regards Antony.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Hi Pete. Another way to put camber into your beams is to cut then horizontal across but keep them in pairs Then glue them together with the required camber making sure they are in the same pairs. If kept in pairs no one can tell that they have been cut. This can also help if cutting rebates as you only need to cut the top one. I have used this method a few times. Regards Antony.

-

Hello Pete. Hello Pete. In your post above you put -:- I must disagree with you I think it looks just fine. All I can say is that your level of perfection is much higher than mine.( meaning that in a nice way of course). Keep going with it as you see best. Exposing the construction of a ship is better than a completed hull. And pulls much more interest in the model. Keep up the good work. Antony

-

Starting Solidworks

AntonyUK replied to AntonyUK's topic in CAD and 3D Modelling/Drafting Plans with Software

Hi Janos and Terry. I am not the best person when it comes to what's inside of my PC I know that the CPU is an i7 and the Graphics card is a Nivida. My son is a computer buff and looks after it for me. (Professional) I am very happy with what I have created so far. One compleat frame in sections at 1 /36 scale of the victory. And the keel and the keelsom. BTW . Janos I love the work you are doing on your CAD on MSW Regards Antony. -

Hi Danny. That's a easy one you left the name on the stern. LOL ONLY JOKEING That's a hard one. Not many clues on the stern to give away. Regards Antony.

-

Starting Solidworks

AntonyUK replied to AntonyUK's topic in CAD and 3D Modelling/Drafting Plans with Software

Hi Terry. Thanks M8 took me a few mins to figure it out. Works like a dream now Many thanks Antony. -

Hello. I think the figurehead will be the giveaway on this one plus the painters signature. Regards Antony.

-

Hi Rusty. Wow looking real nice. Are you going to enclose the model in a display case ? Regards Antony.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Starting Solidworks

AntonyUK replied to AntonyUK's topic in CAD and 3D Modelling/Drafting Plans with Software

Hi. Ok sort of stuck.. If I draw a line on a angle and I want to draw another line mirrored from the first line. IE same angle and length. HOW is this Done ? Photocopy of part below. Just spent hours and Failed. Have googled for videos Regards Antony -

Well done. Over to you. Regards Antony.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.