-

Posts

1,218 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Overworked724

-

-

1 hour ago, CPDDET said:

My "I need this yesterday" attitude hasn't helped either. But who can argue with almost instant gratification.

And with ship model building, there is always a persistent feeling of being rushed!!! 🤣On a more serious note. Had to restart my pintles and gudgeons. Realized my original cuts were too thick.

My goal is to ‘prefit’ my P&G’s so that my rudder is functional as well as removable. But I don’t want to mess with fitting 4 sets of these buggers after coppering the hull. I know I’d start scarring the copper and the illusion would be lost. My goal is to remove one area of anxiety and focus on coppering…then have my P&G’s sitting in the wings waiting for install.

…he said no so confidently.

-

Wow. Didn’t think my Amazon ball bearing purchase would destroy Model-expo! 🤣

Well…two things…Model Expo doesn’t sell 2mm ball bearings I need. But if I need to go down in size…they do sell 1.5mm balls but at like twice the cost.

But I do agree Amazon has done a fantastic job killing local manufacturing and business interests.

-

9 hours ago, niwotwill said:

You might check with Model Shipways that multiple size cannon balls.

Good suggestion, Will. But I found some cheap 2mm diameter bearings on Amazon cheap. 👍🏽 Arrive tomorrow. -

Meandering thought led me to a quick realization…the cannon balls for my replacement carronades are way too small…by amount 1mm. I did a bore measurement of the carronades and it’s just shy over 2mm. So, I need to replace the kit beads (~1mm) with correctly sized bearings.

Amazon to the rescue.

-

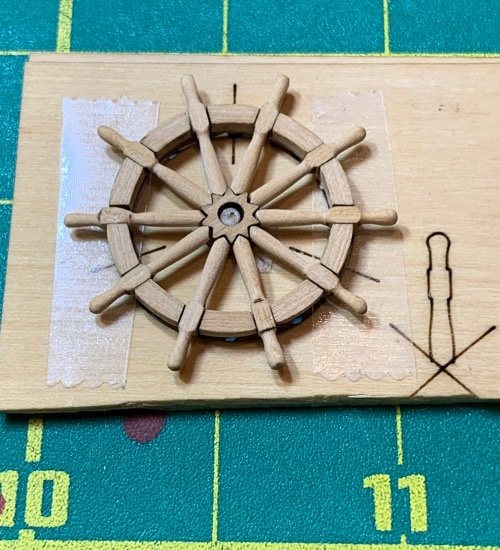

Small detour to bash the other metal pieces. Ship’s wheel was certainly not something I planned on using from the kit.

I opted for one of the boxwood ship wheel kits made by Chuck’s company (Syren). I got the 15/16” boxwood ship wheel pack which was actually a lot of fun to put together. It also had a lot of extra parts in case I screwed up!

Here are a few pics…

Template worked great to manage the little bits.

My rotary tool made the creation of the wheel spokes a fairly quick job.

And a quick coat of Golden Oak on the final product made it obvious why I went with a wood wheel. 😁 Wouldn't even know how to make the metal piece look realistic!!

Moving on…

-

-

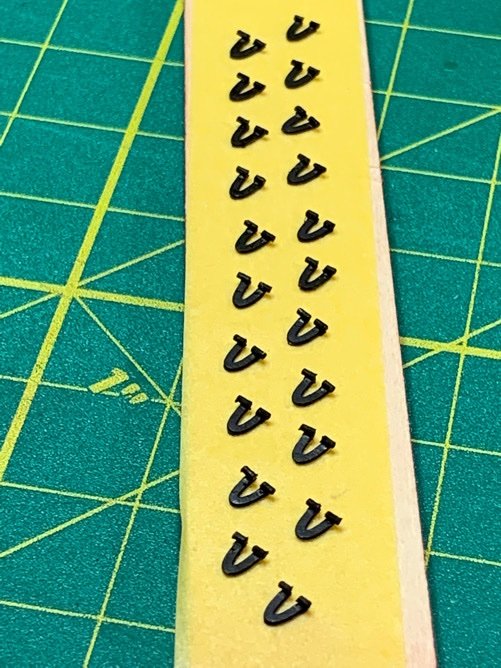

The sweep doors are done. Not certain if the hinges look ok or not…seem to be passable. I painted the interior side red and stained after the pics below were taken.

I’ll glue them in once the coppering is done. That’s next on the agenda..,once I finally figure out my pintles and gudgeons.

Here are a couple pics. Interested in feedback if anyone has any.

Moving on…

- abelson, GrandpaPhil, CPDDET and 4 others

-

7

7

-

-

Ok. Not sure how everyone else did their sweep port doors, but I’m approaching this like the galleries. I’ll get them set for gluing on then put them off to the side until later.

I sanded them flush so they aren’t proud of the side of the ship. I’ve decided I’ll put a single coat of ship’s bulkhead red on the interior sides. Then I’ll pencil the edges, glue on the hinges, test fit…then set them off to the side until I’m ready to glue them in…which will take only a few minutes.

Im a bit afraid of snapping off the little hinges or worse…and once those things are in they aren’t coming out.

🤔

- CPDDET and Ryland Craze

-

2

2

-

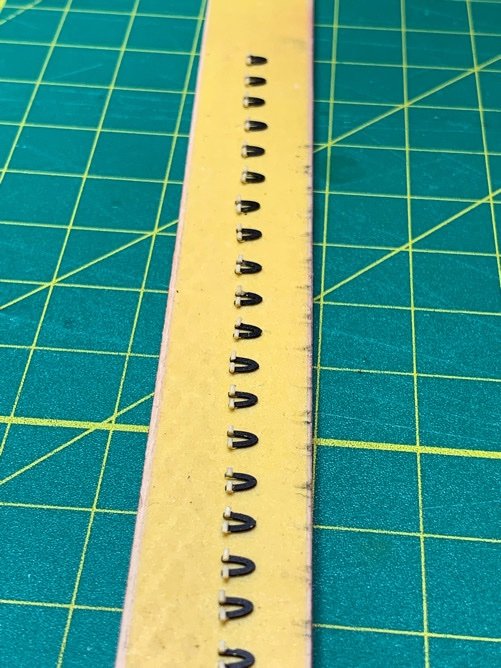

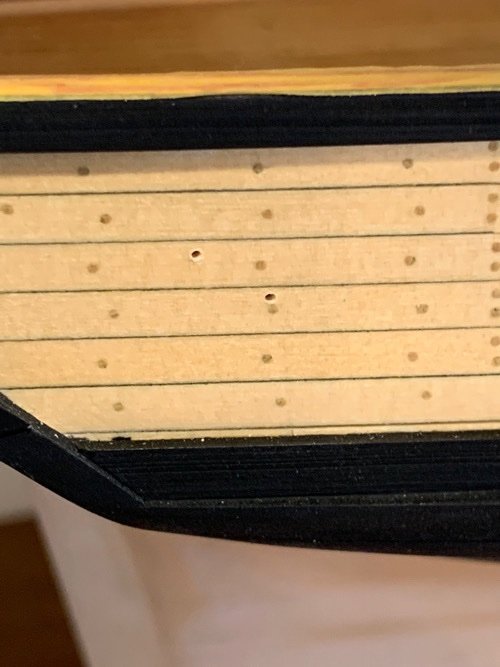

Got the sweep port doors made for both sides. Took a while as some of the openings were more trapezoidal than rectangular! 😖

Unstained, they do pop out.

I checked the fit/look of the hinges on one of the doors. I’m satisfied that I can align the hinges cleanly.

I also tried using a simple red sharpie to ‘color’ the shipboard side. Since the sweep ports are so small, you can’t really see any details for the sweep port doors. So I figured a quick slap with a red sharpie would be fine.

Moving on…

- GrandpaPhil, Ryland Craze and ccoyle

-

3

3

-

Ken, every model has warts. Kind of like houses. My Syren does not follow the typical symmetrical butt shift pattern, because I butted the sections at the points where a frame was located. Actual ship framing would make this job fairly simple. So, my Syren is not ‘historically accurate’.

Just saying…no model is perfect. 😁 But I love doing stuff in my shiproom…the hobby is filled with great people/historians/shipwrights which make this a great forum.

Enjoy the day!!! I think your perseverance is inspiring. 👍🏽 I continue to watch your build with great interest and I am learning from your challenges as well. 🦃🍁🍽

-

The little wooden hinges for the sweep port doors actually turned out looking ok. They weren’t that hard to put them on, just finicky work.

We’ll see if I can do justice to making the doors. 🙏🏻

Moving on….

- Ryland Craze, GrandpaPhil and CPDDET

-

2

2

-

1

1

-

Ken, we all run into these types of setbacks. Pics help (and embarrassing as it might seem…my screw ups brought a lot of brilliant feedback from experienced modelers). Don’t be afraid to post them. This forum’s value really comes from the helpful feedback.

Gun port doors closed is one way to fix the cosmetics. Remember, it’s your model, and as long as your learning and having fun (marathon…not sprint) then that’s all that counts.

👍🏽

-

Great way to plan those plates, Dave!

-

Sweep port doors. I’ll be doing these before the hull coppering…because I’m a procrastinating chicken.

One problem I found was making the little hinges consistently. Tried nylon, wire and wood. Finally decided to take a swing at these using wood. The glue sets up quick and I can easily shave the two sides evenly. No pics yet…but I have a plan using the tiny wooden tree nails I made which I used for the deck/bulkheads. Have tons left over, and they are almost the perfect width. So…we’ll see if the results bear fruit.

Also while I’m at it, I need to remake the gun port doors…because I made the originals too narrow! 😖

-

-

Looking sweet, Will! Nice work on the chains. Do you use a solder iron or a torch?

-

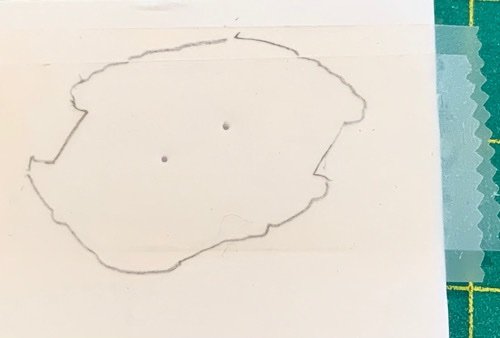

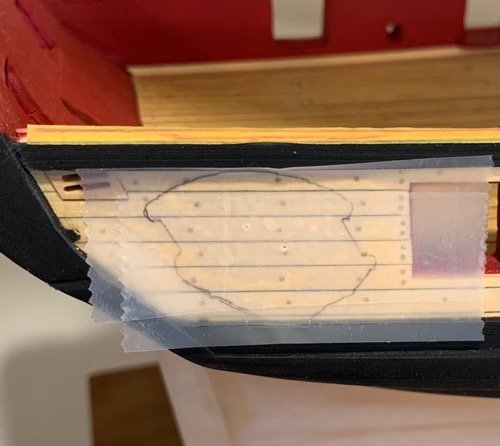

Just because I knew these custom galleries were going to be a tight fit, I decided to button up my train of thought and make certain the guide holes were in and the positioning was good…since I didn’t want to mess with it later…especially if I mucked it up.

Here’s how I did it.

The pins in each gallery were created as a mirror of the other…so I couldn’t accidentally glue them in onto the wrong side of the ship.I got some foam display board from Walgreens. Cut a section out and layered it with Scotch tape. Pressed in my gallery, and traced out the outline in pencil. Note how I left some tape hanging…

Remove the gallery and you get your image trace with pin locations.

Pull up the tape and position it on the ship at the correct location (I have to eyeball a bit since my double blocks don’t sit flush against the stern). Then used a T-pin to scribe in the pin hole locations. Removed the tape. And drilled in the guide holes.

Test fit the little monsters and if you did a good job tracing, they should fall right in place.

Now I am settled, and the galleries are put away…to be glued in when I feel like it. But ready for that day. 👍🏽. (I still can't believe how friggin nice these things came out...it was worth the journey...and makes me remember the ship model is 1000+ projects which all come together to create something wonderful).

I can safely say that I am NOW officially moving on. 🧐

- Gahm, Matt D, GrandpaPhil and 8 others

-

11

11

-

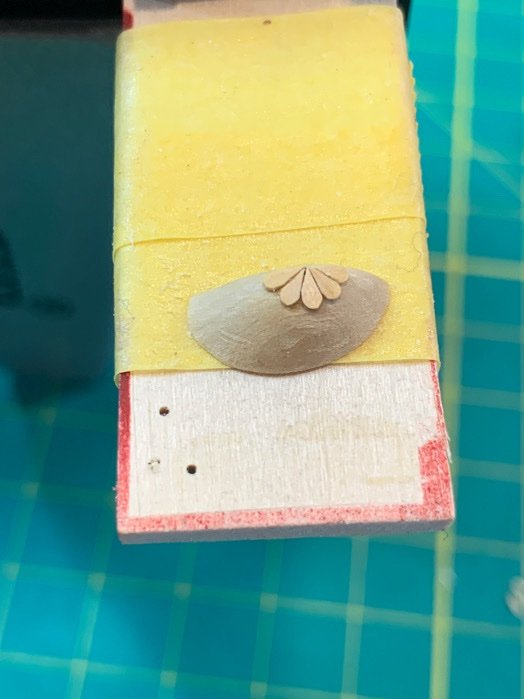

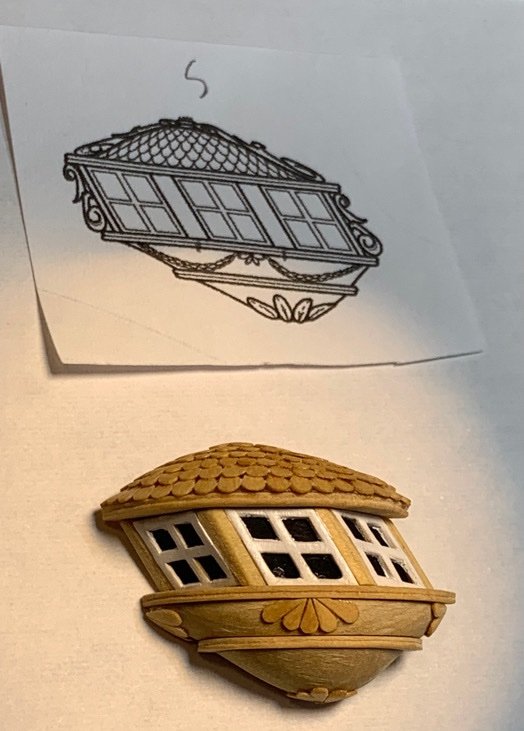

Ok. I’ll call this long winded side project done. I’ll put these in the ‘glue on last’ box of goodies. I’ll put in the guide holes later.

Here are the baby pics!! They aren’t perfect, but they are pretty. I’m not unsatisfied with my efforts. 👍🏽

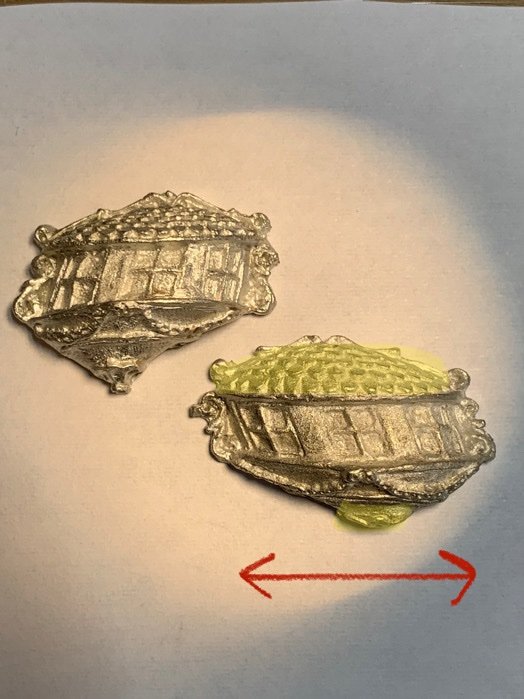

Here are the mismatched kit pieces:

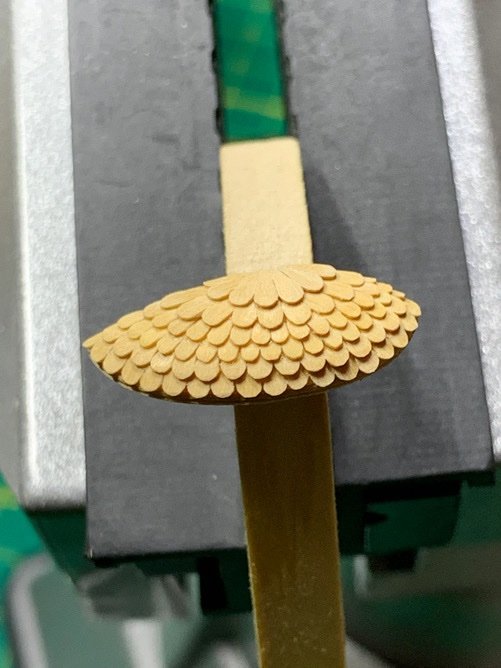

Here is the front view of mine:

Bottom view:

Top view:

Here they are all tucked in! 🤣

Moving on…. -

Finished (at least as best I can manage) with the galleries.

The bottom portion was easy. I can make a tear drop shingle in 2 seconds. So making the lotus pattern at the curved apex of the base was simple. Sanded a bit and waalaa!

The flower pattern in the middle section was a bit cleaner and easier than trying to create the wreath. So opted for that simple decoration in the front and sides. Threw it together and here is the result. I may or may not try the volutes again later…I can always add them if I can make them cleanly enough.

t

And again compared with the metal cast piece from the kit (starboard side).

One thing I did before putting the windows in was ensuring I had predrilled my pins. The back shows the sandwich sections quite nicely.

It is certainly worth the extra time to make these. The lack of consistency between the two metal cast pieces from the kit are comical. They have different lengths and patterns between the two…Shame on Model Shipways!

But in truth, I’m a crappy painter and there was no way I’d be able to make a realistic looking product from the metal kit pieces.

Another minor hiccup…my handmade galleries just barely fit between the upper shear strake and wales. So I needed to trim the needle heads and sand down…can’t even tell I did that. 😎

Next pic will be the final product after some tung oil and test fit on the sides of the ship.

Moving on…

- VTHokiEE, Ryland Craze, WalrusGuy and 1 other

-

4

4

-

-

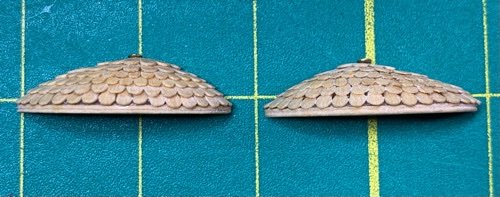

So, I can say the roof sections turned out pretty nice. My second attempt (left) gave moderately better results as my technique improved. Took a while to complete, but hopefully worth the time. Call it practice for the arduous task of coppering soon to come. 🤣

Moving on…

-

Second time around was much better. I got the shingles much more symmetrical and aligned…not finished, but the roofs are done. Hard part’s over.

Cant wait to see what they look like when finished. Right arm is holding up well. 👍🏽

- ccoyle, Ryland Craze, GrandpaPhil and 2 others

-

4

4

-

1

1

-

Yeah. The roof was the bug bear. More ‘art and eyeball’ than ‘exacting measurement’. Now noodling over the scrollwork.

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

in - Kit build logs for subjects built from 1801 - 1850

Posted · Edited by Overworked724

Doing better! It’s a journey, but I’ve been religious with my exercises and physical therapy. 👍🏽