-

Posts

683 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gerhardvienna

-

Cutty Sark by NenadM

Gerhardvienna replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Hi Nenad This will not be too hard to do. I would use boxwood, turn it to shape and cut the lines with a sharp knife or scalpel. The rings and hinges can be made with thin black paper, the top plate with thin plywood. This is just how I would try it! Regards Gerhard- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

A little progress was made at the pump, the hardest part is still to come. I want to have the ability to have a "working" pump, driven by a small motor, so I cannot solder all parts. Pistons with basic rods "A-Beam" before soldering. It is enough to hold the parts with pins, no extra form needed. Both Beams soldered, they wil carry the pump lever, and one side wall also fixed. Thank you all for watching, Regards Gerhard

-

Hi Mark The new version of the rudder looks a lot better than the first one. Well done! Regards Gerhard

-

Hello once more Thank you all for the (so many) likes! The first steps to the decks pump are made, the center of the handles, the pistons, and the cylinders with their case are cut from different brass material. The center of the handle bar The pistons before soldering Cylinders soldered to the basic case, smaller parts in the foreground Regards Gerhard

-

Hi Antony Great progress with every new step. This is a very strange construction, compared to the usual ships we know. Regards Gerhard

- 99 replies

-

- turtle ship

- korean

-

(and 1 more)

Tagged with:

-

.................... But you have still to bring it to measure, and make the whole things look as good as they are. And they are GOOD! Regards Gerhard

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Servus druxey That trick is so often needed, even when I`m making the pump. For all "working" soldered parts you need something to avoid contact between fixed and moving pieces. Baking paper is good for that, it is really thin, but strong enough not to be soldered trough. But; there is one more trick on that: NEVER drill holes for the axels, just stick them through the paper. Every drilled hole wil be too large, and the solder will come to the places you dont want it to be. Regards Gerhard

-

Hi druxey This is one of the most elegant builts i`ve ever seen! THANK YOU,for allowing us to see it! Regards Gerhard

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

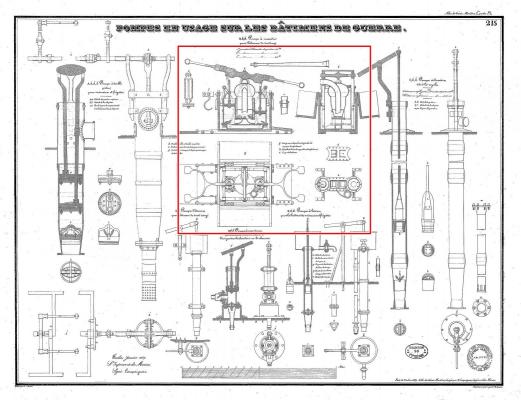

After the davits are mostly done, I was searching for new things to do, before I can start with the ships hull. Remember, I cannot build large things at the time, until my home renova<tion is completed So I decided, to build as a next part the pump, which had been on deck, as I have read the diary from Eduard Arendt correct. See the last part of this page, sorry, it`s only in german language. I choose the pump in the red marked sector, the drawing is (as mostly) taken from the Atlas du Genie Maritime! I`ll be back.............. with more abut that soon! Regards Gerhard

-

Hi Nenad It`s just a matter of practice. I`ve needed lots of trials to get to this point. I never quit, when things dont go the way I want them. If some solution wont come fast, I do some other things, and somewhen I get it. I came to that baking paper trick, by baking "Apfelstrudel". So I thought, when this does not stick to the paper, I will try it for soldering. And it works! Regards Gerhard

-

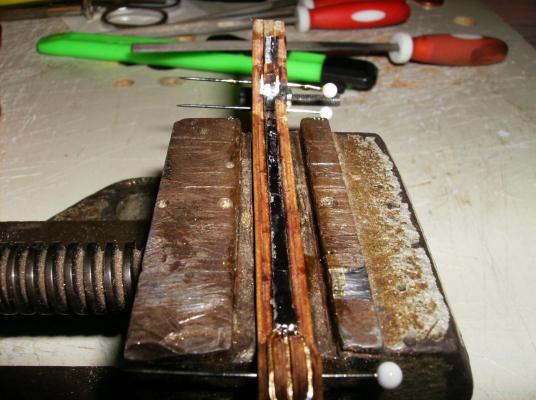

Hello and first of all, many thanks again for your likes, and watching in The last days were filled up with a lot of work for my home renovation, but I also found time to complete the new davits. I had to solder the last levers in the form, then some smaller parts were mounted, the levers mounted to sets, and some eyelets soldered to both sides of the davits. Small parts to be soldered to the levers, use baking paper to solder. This will keep the rollers running. Mounted rollers and eyelets 4 Sets (two pairs) of davits Eyelest for both ends of davits, here will blocks be hang in. Use baking paper here, for the same reason as above. Completed end of one lever, with all small parts set into place Best regards Gerhard

-

Cutty Sark by NenadM

Gerhardvienna replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Hi Nenad So tiny things, I like it. Thats what makes a model , never give up when something cracks. Regards Gerhard- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Hi Paul Alternative you can also make working hinges http://modelshipworld.com/index.php/topic/12842-sms-danzig-1851-by-gerhardvienna-radio-150-scale/?p=393467with a little bit of soldering Hello druxey Perfect work, incredible, that is done in such shotr time! Regards Gerhard

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Hi druxey Just stunning! Wish I had that skills................. Regards Gerhard, who must even learn a lot!

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Hi again, and thank you all for your likes !! Today was not so much time for the ship, so I made only the first of the straight levers, and the soldering form of course. The method is the same as before, and I could manage to set the first set of levers together for a first fitting test. Everything looks fine, when all levers are done I can make some changes at the soldering forms to complete the whole sets. Best regards Gerhard

-

Cutty Sark by NenadM

Gerhardvienna replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Hi Nenad Fooling around? I would say it fits! To make a bucket at this size is true hard work to do, you made it well. Keep it on! Regards Gerhard- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

Gerhardvienna replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Hi Nenad The buckets will not be easy to make from wood. If your ship is not meant as a floating model, you could make them out of cardboard. It`s the easiest (and cheapest) way to do it. Regards Gerhard- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Hi Glenn Will take some time, til it comes to the engines. But I`m curios too, how they work in the ship, the revs are calulated to a max of around 60per minute, so the engines can drive the wheels at original speed. Before I build this engines, I will try to build a smaller one of the same system, which I constructed myself, but only about 50mm high and 70 mm wide. Hi druxey DANKE!!! (Thank you!!!) I`m always trying to do my best, when something goes wrong, I search for the mistakes, and build a new one. But that was not necessary with this levers, took just a lot of time. Including all the drawings and preparation time I spent about 2 weeks with that. Hi to all interested Today I could finish with the first set of levers, all 4 are soldered, a little grinding work is still to do. Next will be the set of 4 straight levers, and combine them all to working parts. Regards, & thank you for watching Gerhard

-

Hi Glenn Be sure I WILL! But there is so much to do for my Danzig, so it will take years until I can start with the Cairo. Lets get back to your build, incredible work even with the smashed wheels and all the damage you show. I would never be able to do that without crying , this is modelmaking at its best! Regards Gerhard

-

Hi Glenn What`s new to me is, is the single cylinder pitman engine, I know them always as two cylinders. One of my planned projects for the future is the USS CAIRO, with working ptiman engine, so I saw she had two cylinders, as the most paddlers had. Regards Gerhard

-

Hi Glenn Thank you! I too want to see it all thogether, but still some way to go there. The now made levers will get some "extensions", then are some rollers to be mounted, and axels and eyelets are to fix to complete the whole levers. When it comes to machinery, the SMS DANZIG was powered by two oscillating 2-cylinder steam engines, this will be the same in the model, see the first post in my thread. Today I made the third lever, so there are no pics, they all look equal. Soory for being so boring Best regards, thank you all for watching, and your so many likes! Gerhard

-

Hi Glenn Wonderful work, I like those steamers! The pitman and full engine lokks like original ones. Regards Gerhard

-

Hi druxey Great built, and getting even better! Regards Gerhard

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

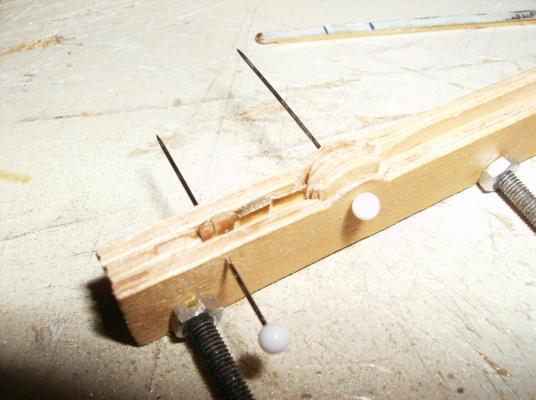

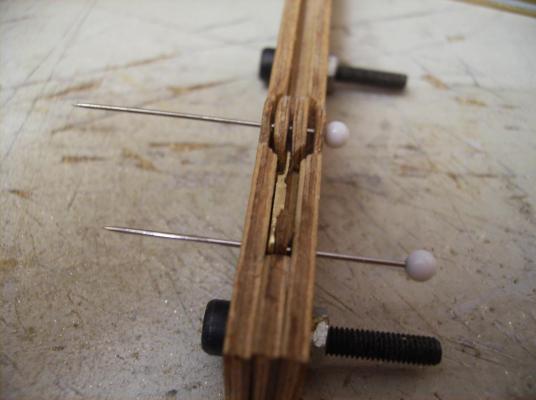

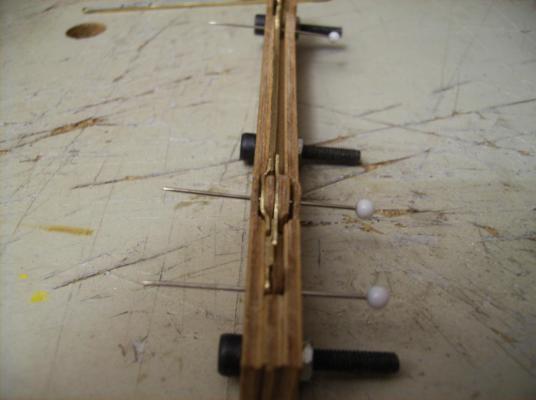

Hi Jim YES; it is a lot of "blacksmithing" work for the davits going on. Every one of them needs some hours of preparing work, and about 5 minutes of soldering. To show, how many small parts are needed for one lever, see the first photo. The second pic shows the first pair of levers in their mountog plates, just pinned with needles for a test. Everything is fine, the levers move free! Best regards Gerhard

-

The last days were filled up with work for my home renovation, so there were not too much time for model making. But the first one of the new levers is done, it took hours of preparation, and only a few miniutes to solder. The photos show, how the parts are set into the form, and the soldered lever. Each of this levers is made from 1mm Brass sheet, and consists of 9 single parts. Thank you all for watching, and your comments.... Regards Gerhard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.