-

Posts

4,894 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by gjdale

-

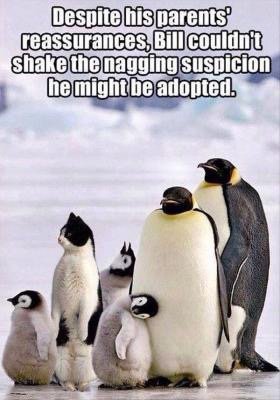

Once again I’m late to the party Glen - don’t know how I missed the start of this one! Looks like this will be another very interesting project. You’re off to a great start. And instead of penguins, you can insert miniature chickens! Now there’s a fowl thought……

- 174 replies

-

- Waa Kaulua

- bottle

-

(and 1 more)

Tagged with:

-

Your rigging looks fine to me. Your whole model is looking superb.

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Just thinking out loud here Chuck, but since you have done all of the design work and presumably all of the laser cutting is a “file”, would it not be possible to produce the POF kits “to order”? That would mean that you wouldn’t need to keep an inventory of either kits or raw material in stock until someone placed an order - that order being on the understanding that there would be a certain lead time before the kit was ready for dispatch. And if the cost of materials goes up, then so does the kit price. Just seems to me to be low risk (for you) while providing a degree of certainty for the would-be buyer.

-

Perhaps use a sanding sealer first? That should overcome the issue. A very light sand afterwards will give you a nice base to apply the paint.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

Despite some obstacles to overcome Ian, this is still very cool!!!

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

Congratulations on completing yet another outstanding build Glen. I can't wait to see what's next.

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

I would not worry about that Glen. It simply shows the tidal range. My advice is to “embrace the creep”.

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Great job on the water and colour transition Glen. That looks superb.

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Amazing work Ian. Congratulations on achieving a successful first sea trial. I wonder if you really need to increase the oar blade size though - with an extra bank of oars, would the speed actually look about right for the scale?

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

Love the cows Glen. Now all you need is to add a BBQ on the grassed area and invite the cows over for dinner………

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Looking good Glen. The texture you added to the timber parts is very convincing. Love the cows - from their colouring, it looks like they may be distant cousins of your penguin colony…….

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Looks great. Congratulations on your retirement - you’ll soon find yourself so busy that you’ll wonder how you ever had time for work!

- 217 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Further to Mustafa’s accurate conversions Sjors, I find that a handy approximation to remember is 1/16” = 1.6mm (approx) From there it is easy to work out any other fractional inch (bearing in mind that it is an approximation). So 1/8” is 2 x 1/16” or 2 x 1.6mm = 3.2mm and 1/32” is half of 1/16” or half of 1.6mm = 0.8mm and 1/64” is half of 1/32” or half of 0.8mm = 0.4mm and so on… Hope that is helpful.

-

It seems that my modelling mojo has been having a little holiday of late, however there is some progress to report - albeit little more than "proof of life". I have completed the first band of four strakes of planking per side. Three more bands to go, each of three strakes. I will now move my attention to the Sheer strake and work down from there. The trickiest part will be the final band that contains the turn of the bilge.

- 57 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

WOW! Just watched all the videos Glen. Either you did some serious editing, or the fight wasn’t as close as you say - looks to me like you had this under control pretty much all the way and had a counter move for everything the model tried! Well played Sir! My advice to you now is…..SDH (Start Drinking Heavily)….after all, you need more empty bottles for your next projects.

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

Ingenious solution to joining the hull halves Glen, but then we’d expect no less from you! Can’t wait to see this go into the bottle.

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.