ejgray52

Members-

Posts

31 -

Joined

-

Last visited

Recent Profile Visitors

-

ejgray52 reacted to a post in a topic:

Stagecoach 1848 by John Bartley - FINISHED - Artesania Latina - 1/10

ejgray52 reacted to a post in a topic:

Stagecoach 1848 by John Bartley - FINISHED - Artesania Latina - 1/10

-

ejgray52 reacted to a post in a topic:

Stagecoach 1848 by John Bartley - FINISHED - Artesania Latina - 1/10

ejgray52 reacted to a post in a topic:

Stagecoach 1848 by John Bartley - FINISHED - Artesania Latina - 1/10

-

greenstone reacted to a post in a topic:

Curved deck planking.

greenstone reacted to a post in a topic:

Curved deck planking.

-

greenstone reacted to a post in a topic:

Steam Pinnace colours

greenstone reacted to a post in a topic:

Steam Pinnace colours

-

popeye the sailor reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

popeye the sailor reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

-

Ryland Craze reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

Ryland Craze reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

-

mtaylor reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

mtaylor reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

-

lmagna reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

lmagna reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

-

Old Collingwood reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

Old Collingwood reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

-

Canute reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

Canute reacted to a post in a topic:

Bismarck by ChrisLBren - FINISHED - Agora - 1/200 Scale

-

Have a look at the ‘World of Wayne’ channel on YouTube, he has been building it for a while; as he says, “I make mistakes, so you don’t have to!” Some of the parts are small and fiddly, there’s a lot of wiring too, but it seems quite straightforward. Enjoy!

-

popeye the sailor reacted to a post in a topic:

St Nectan by Kevin - FINISHED - Mountfleet Models - 1/32 - Steam Trawler - Completed June 2020

popeye the sailor reacted to a post in a topic:

St Nectan by Kevin - FINISHED - Mountfleet Models - 1/32 - Steam Trawler - Completed June 2020

-

Gregory reacted to a post in a topic:

Squaring furniture/cabins

Gregory reacted to a post in a topic:

Squaring furniture/cabins

-

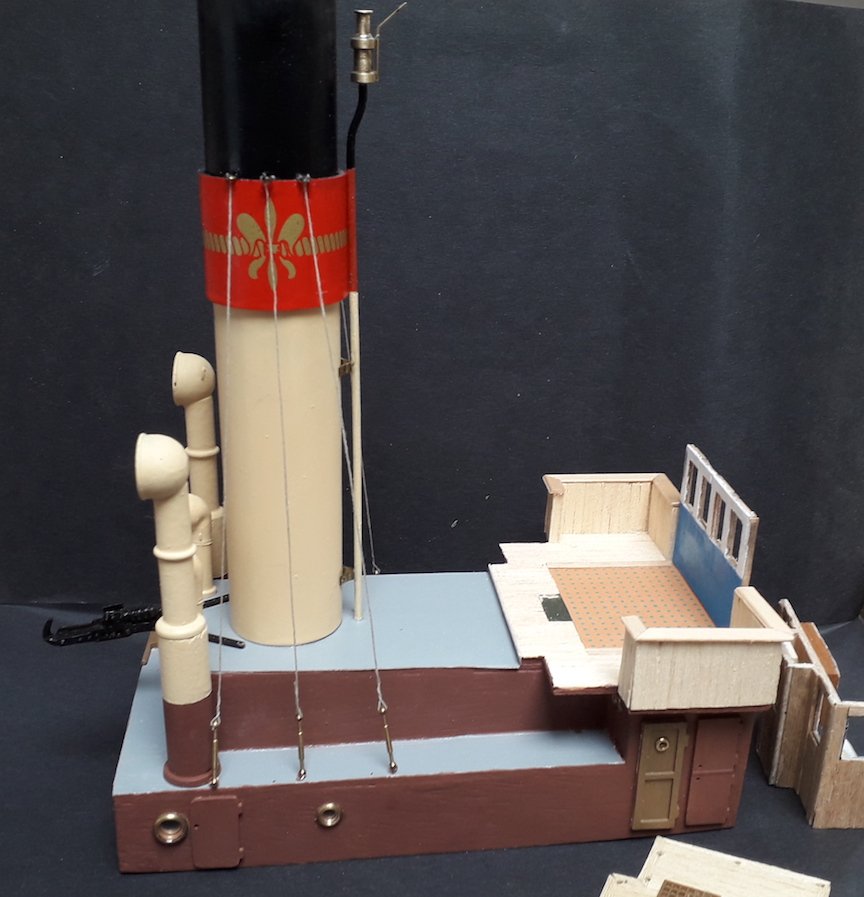

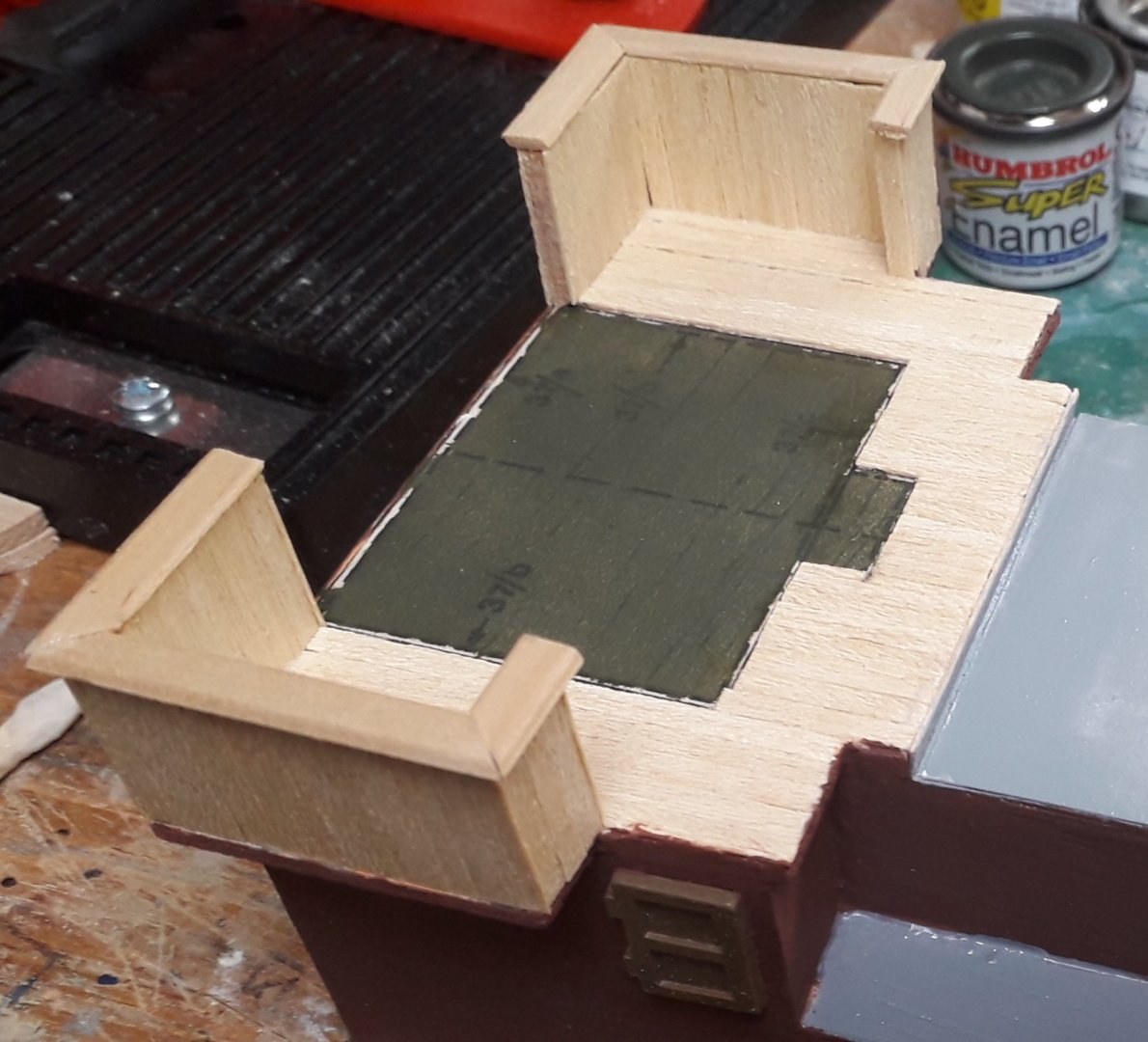

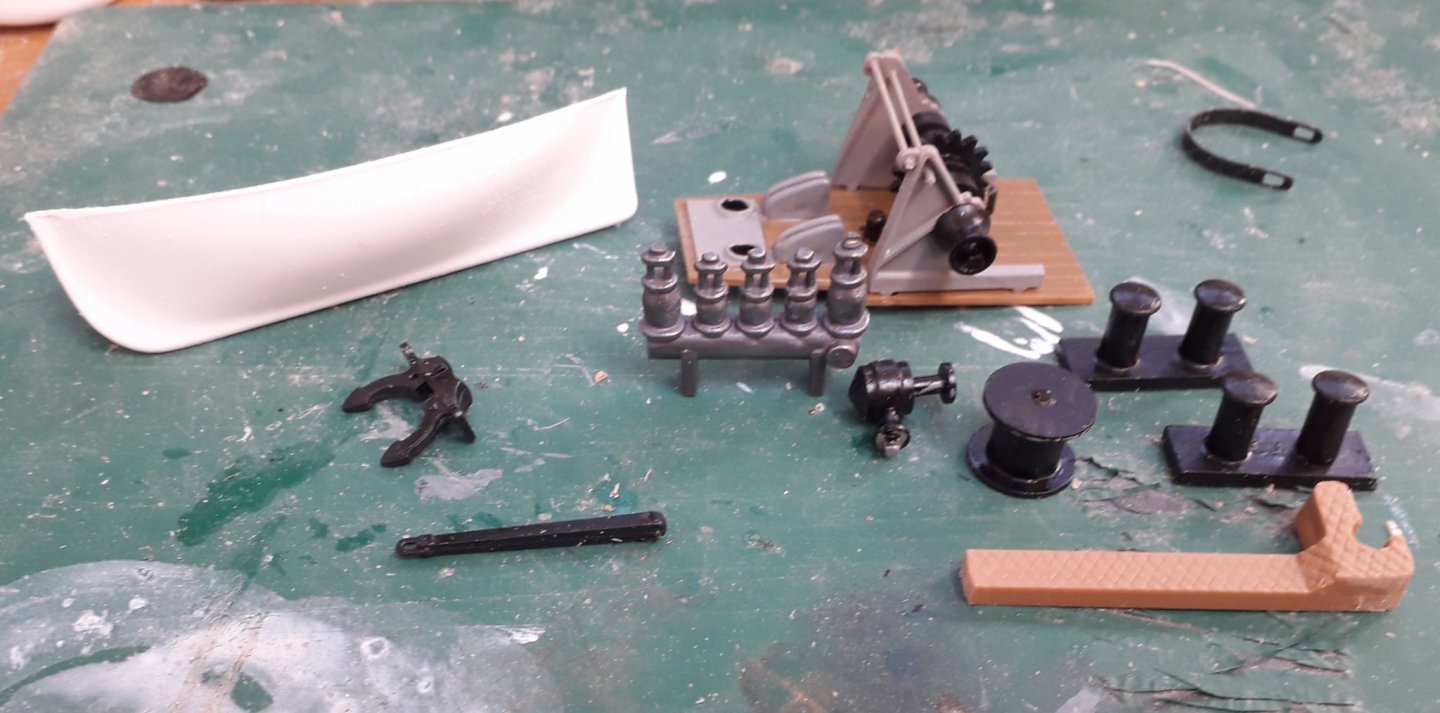

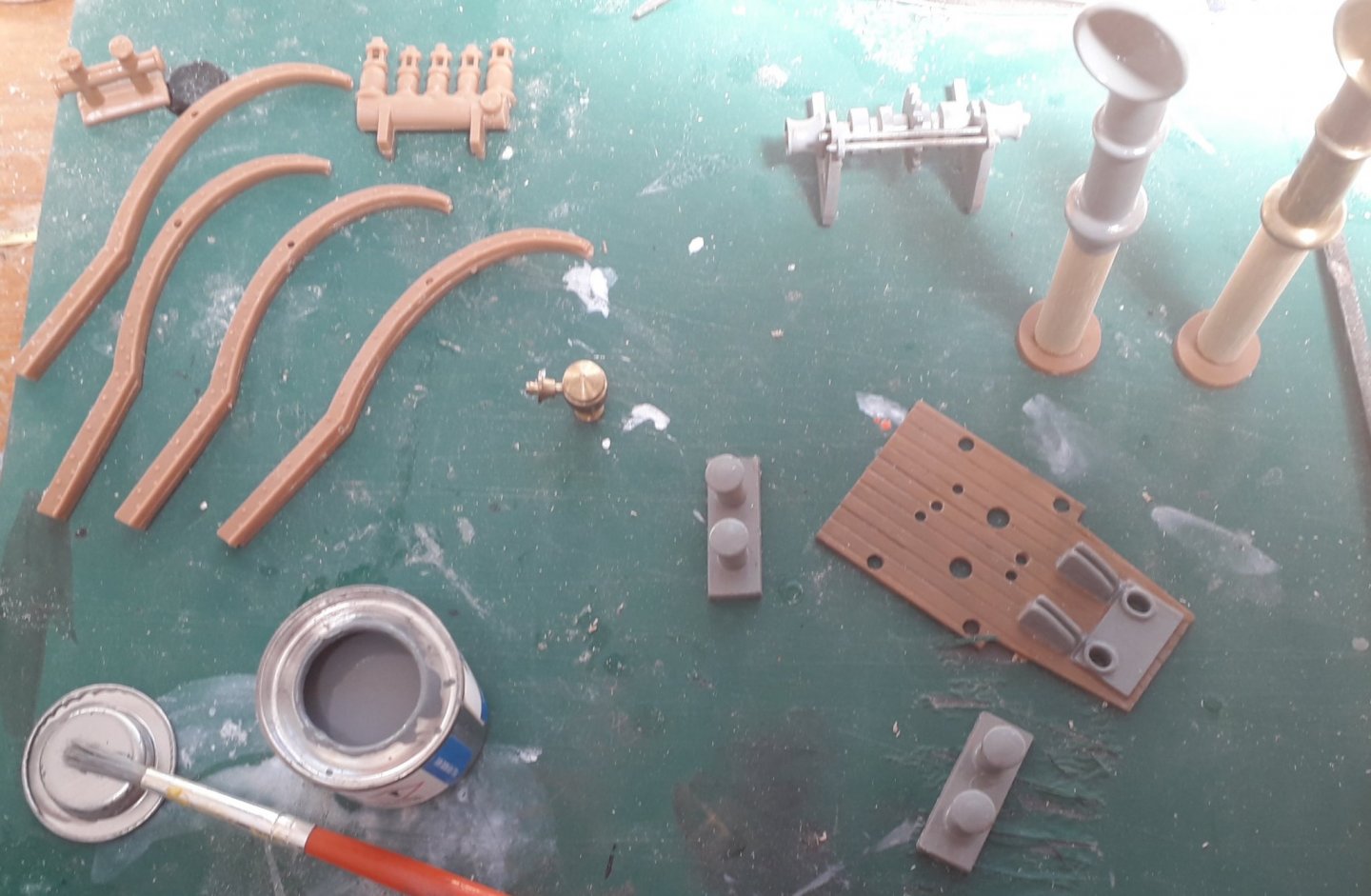

Been a while since I posted any updates; life got in the way... Still working on the deckhouses and fittings; the wheelhouse is still an on going project, the photos show up areas which need to be redone etc.I can see why people take years to complete projects! The funnel is complete with just the ladder to go, the capstan area has been remodelled to represent what is actually there, instead of the rectangle of wood supplied. I've had a go at weathering it, just needs the colour added back to tone it down - the photo makes it look a lot rustier than it is. Working at the moment on the davits, building a plausible method of hoisting the boat in and out. I am thinking of a double block at the davit end and a single block at the boat end with the line going from double to single back to the double and then to boat, so that it is lowered by the occupants of the boat. My logic being if the crew needed to abandon ship, they would all want to be in the boat! However I am happy to have advice on this.

-

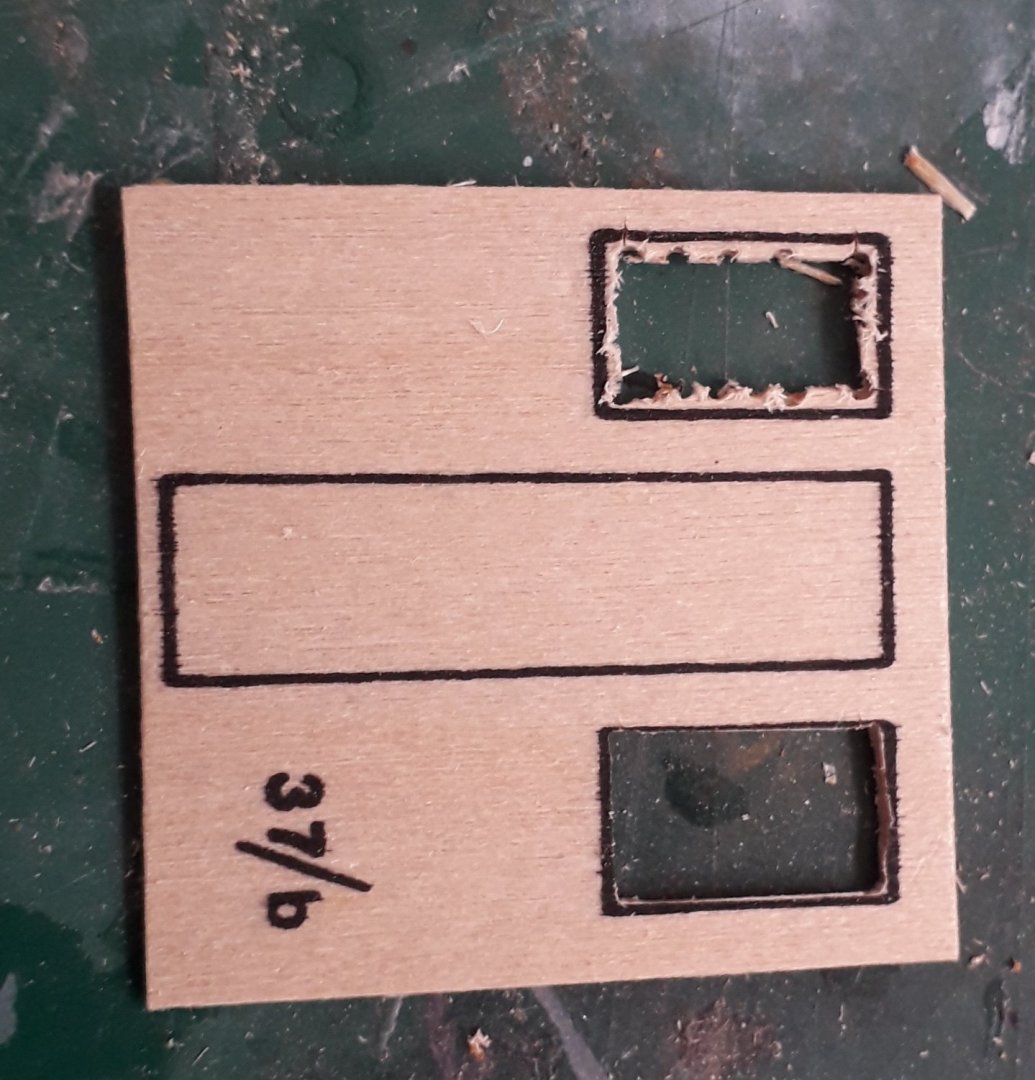

I had backed the wheelhouse walls with cartridge paper as suggested in the instructions, to prevent the wood from splitting as the openings were cut out (It didn't work!). As you can see in the previous photos, it reacted with the paint I applied. So it was time to remove what I could and start the walls again... I've added some more details, which are based on the original, so looking through the windows will not reveal an empty space. Other equipment such as the wheel, binnacle etc. will be sourced from the spares box and fitted. I'll modify the kit provided fittings for the duplicate wheel etc. on the wheelhouse roof. The rest of the work so far has been second coats of paint, filling odd gaps and improving the capstan area, where a rectangular wood block represents a box with a cylinder either side with various pipes connected.

-

Not had much time in the workshop, what with the family and a couple of days when it was too hot in there... Been pressing on with the deck houses and fittings, using the various resources to add additional details. Just added some bits and pieces to the wheelhouse using photo images generated on Photoshop; looked for similar items on the web and then arranged them and reduced the finished item to the right scale. The chart is actually the area where I volunteer as a Coastwatcher - well it is my model, after all!

-

Here's the portholes after the PVA has dried. For me it's a lot easier than trying to cut them out from plastic sheet to fit and better looking than backing them with plastic. These particular ones are only as deep as the plastic squares they sit in; the wood behind them is painted black. However, the photo does show up some flaws which I need to sort out!

-

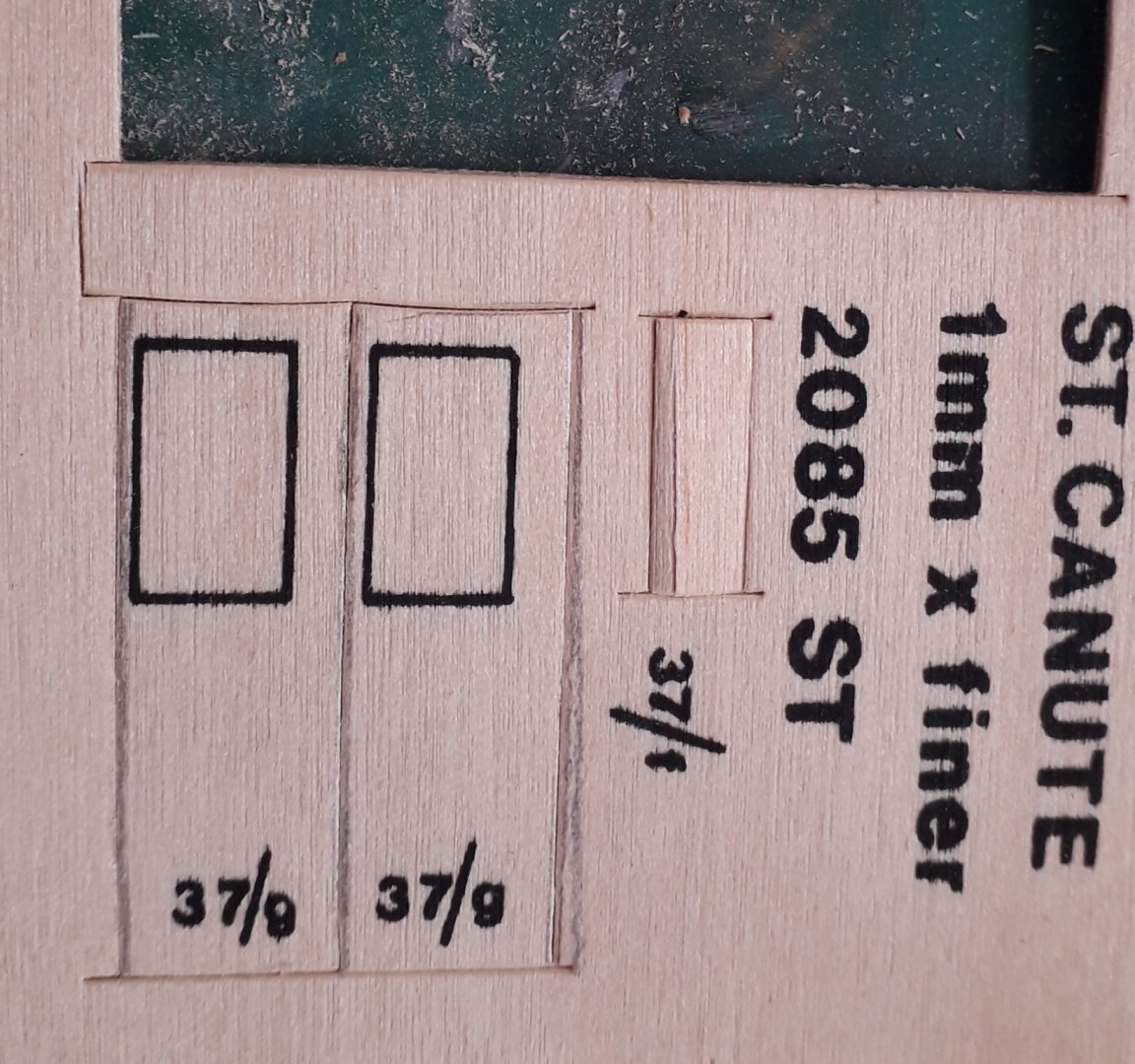

Progress has been slow the last week or so; planking the hull is taking longer than I expected, so I am pressing on with the deckhouses. I have a spare set of some of the St Canute fittings, so should be able to furnish the wheelhouse with a wheel, binnacle and telegraph as well as the open bridge. Finished the planking on the bridge wings and added a capping rail to them. Also realised my workbench was getting untidy, so build a tool workstation out of some spare pieces of wood that were lying around. It's a 'work in progress', as I have left space to add/rearrange things if I need to. completed the engine skylight; the white substance in the portholes is 'Glue 'n Glaze', a type of PVA used in plastic and card modelling to glue clear parts or make small windows. It dries perfectly clear and is ideal for small portholes. Might even try it for the wheelhouse windows later.

-

You have given me some inspiration for the St Canute I am building, many thanks.

- 337 replies

-

- finished

- mountfleet models

-

(and 1 more)

Tagged with:

-

Started on the superstructure, as the hull was damaged; one of the frames broke when I used a little too much force with the pin pusher. I have repaired it, but decided to have some time away from it. The material used is very lightweight and resembles balsa wood; also on the deck houses I've noticed what look like deep scratches after painting a primer coat, which are the grain showing through. Any ideas what the wood might be? The kit is an original version I think, judging by the die-cutting of the major parts.

-

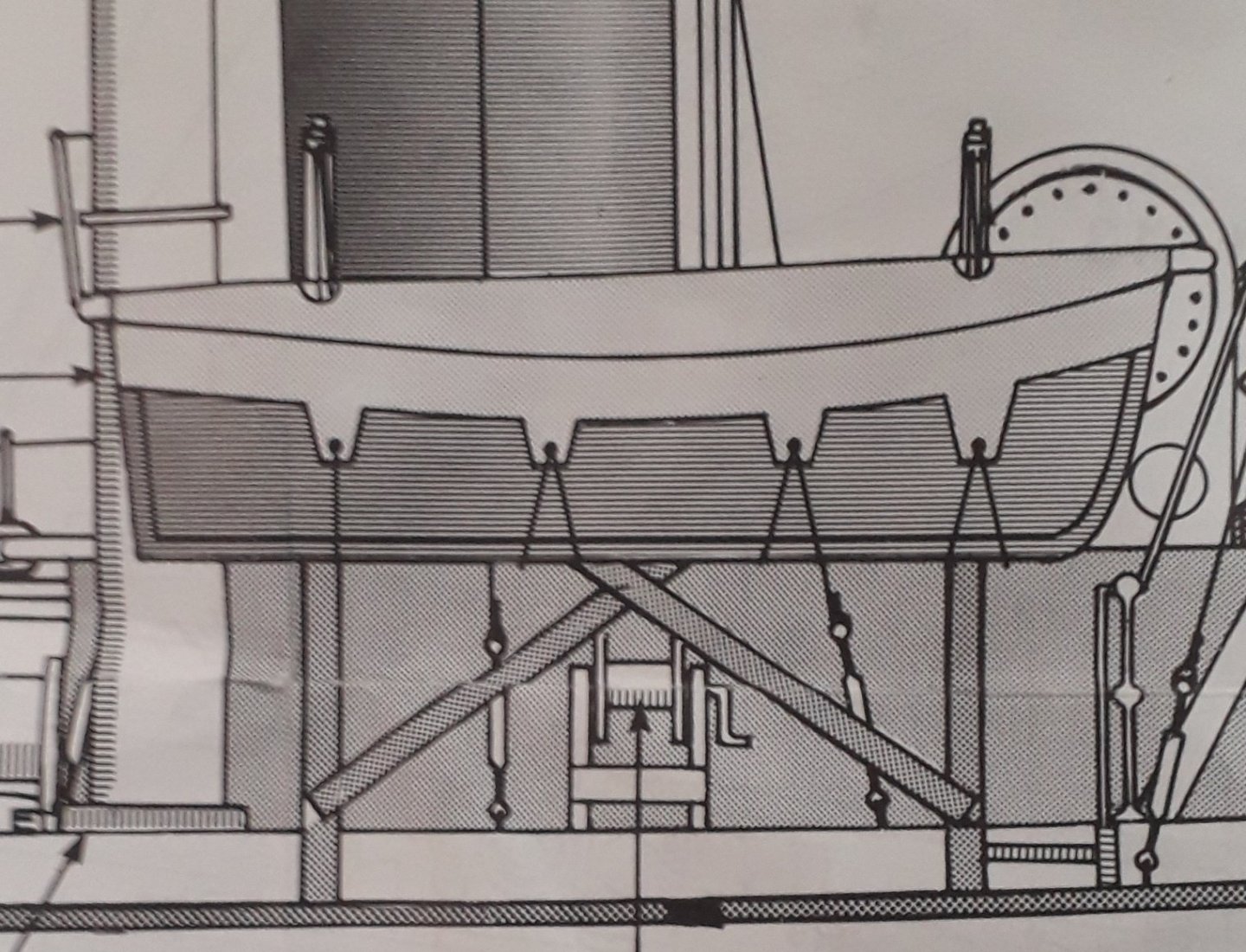

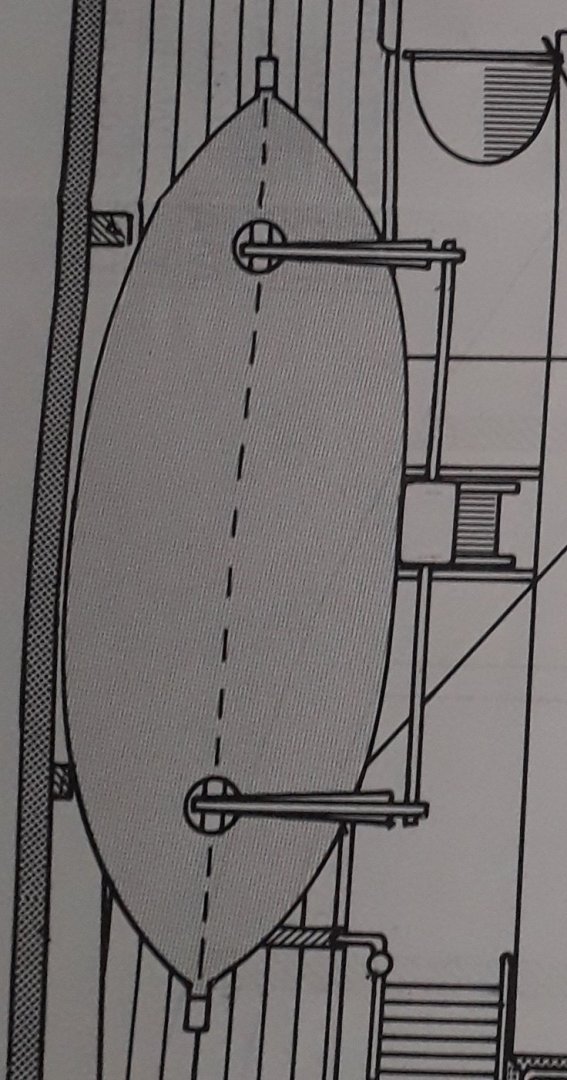

Many thanks for the references, the Fowey ones are new to me; surprising how much is available. I was thinking of inserting a small piece of brass rod across each davit towards the base to simulate a hinge, then connect the winch to the tube marked as F622 in the drawing. Looking at the photos of it at Fowey, it didn’t have any davits or boats, so there is another option 😊

-

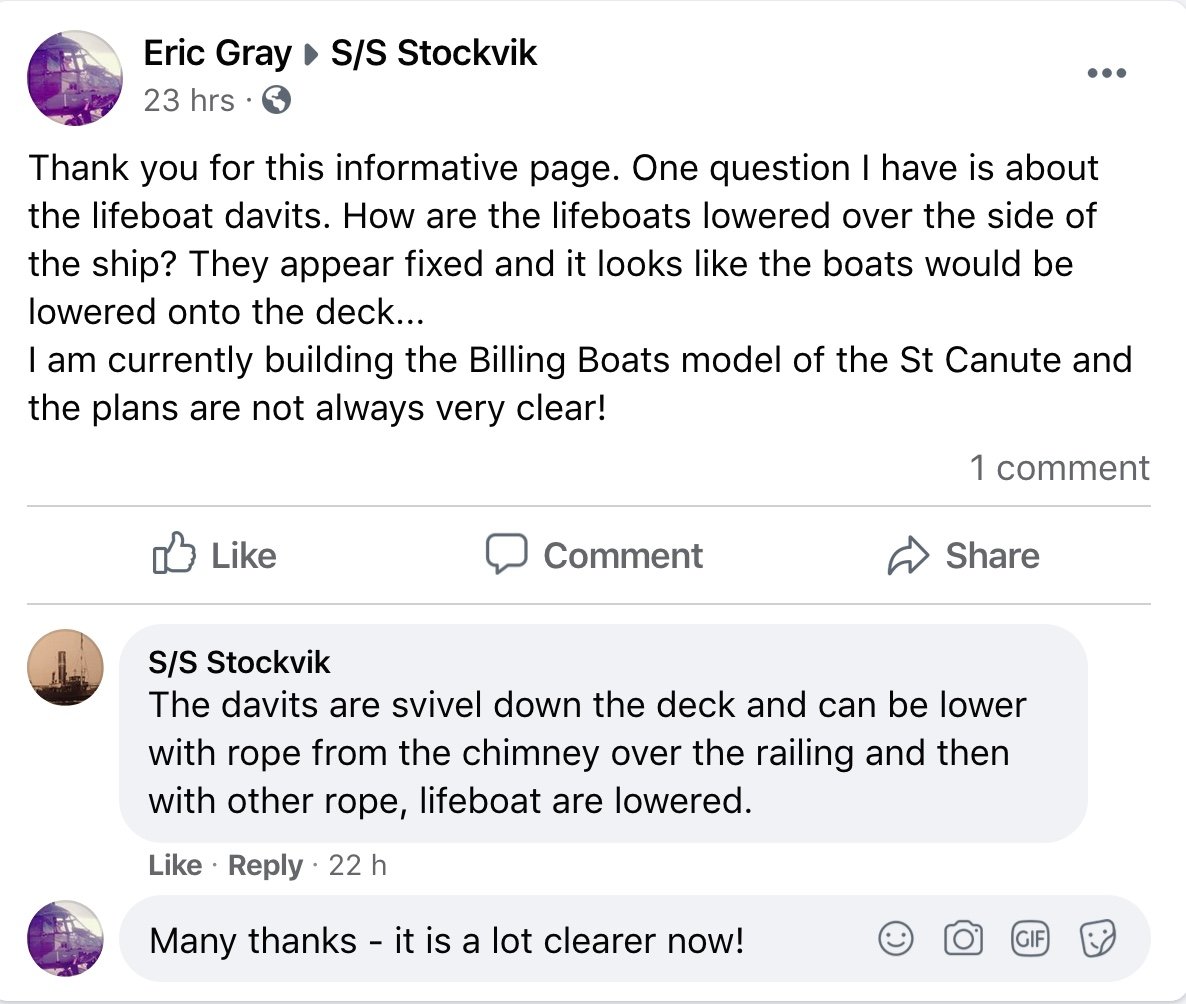

Thank you for your encouragement, I will do my best to finish it! Began building the deckhouses today and found some clamps I had bought for making card buildings very useful. They are supplied by a company that produces online card kits for model railway buildings and are 3D printed; they contain small magnets and make sure you have a 90 degree angle at the corners. Due to the age of the kit there is a lot more work to do compared to a more recent products, with printed parts for example. Some of the die-cutting has gone out of alignment, so will have to be corrected. Quite easy as it only needs some redrawing. Some research is required regarding the ship's boats. The davits are glued to the sides of the deckhouse according to the plan, which means they would be lowered straight onto the main deck. On the deck above between the davits is a hand operated winch, with no information about it's purpose - although form it's position it must have something to do with the boats. The photos show all the information supplied. Time for the crystal ball! Eric

-

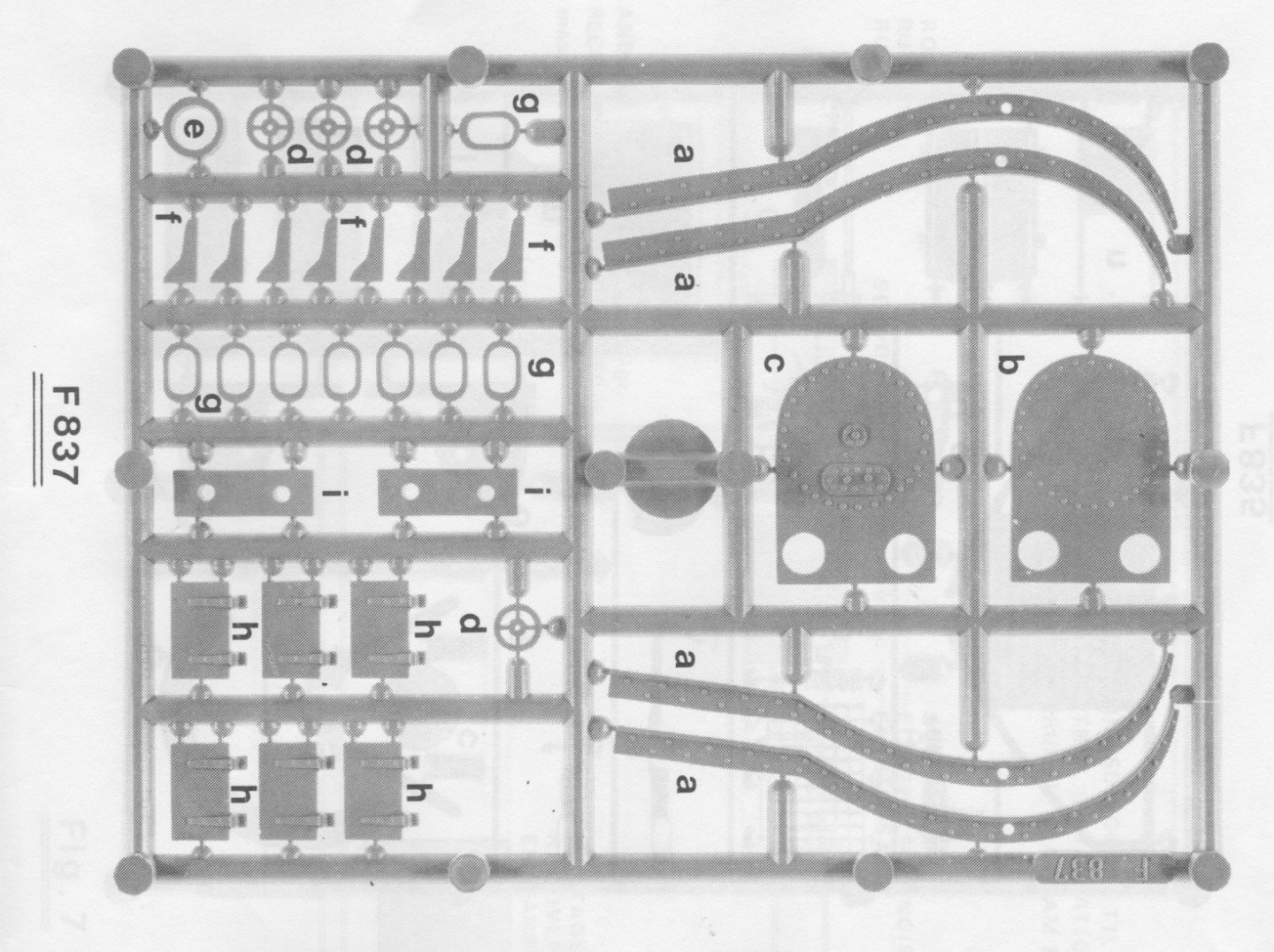

Explained to the Admiral, that although my workshop seems full of tools, there is always a need for others.... Waiting now for a pin pusher and a new set of razor saws, so I will take a break from the hull and start on the various fittings and deckhouses etc. It is interesting how Billing uses a variety of materials to create them; for example there are two tall ventilators, made up of a brass tube, cowl, ring and base, a piece of wooden dowel and a plastic base. The plastic items for those who haven't built any of their kits are one sided mouldings; some require assembling to make a 3D item - for example the davits, towing hook, etc. The parts are identified by photos of the individual frames in the manual. However, you then have to search the instruction manual and the plans to find them.... Parts F 837f look like they are for the capstan, but so far I have failed to find them anywhere on the drawings... I have also downloaded the manual and plan from their website, which appears to be a later version. It's a challenge, but an enjoyable one so far; certainly not like a 'shake and bake' modern plastic kit!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.