-

Posts

6,724 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

Eric, it's ALL conjecture on my part at this time. I have many many holes to fill with hour upon hours of research before I can say with some certainty that was the way it was. In the end, putting a dinghy would probably be the simplest solution.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

I assume so, Eberhard but not sure how a geared drive system would have been engineered. I had a good B&W close up view of a center geared wheel but I'll be danged if I can locate it at the moment. I'll continue to try a find it. The image below is for a center drive chain system. If I could figure out how to make a steam driven chain drive I'd go that route in a New York minute.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Eberhard, the only chain driven paddle wheels I've seen were/are run by internal combustion engines but this vessel is definitely steam driven. I'm inclined to think the half wheels were gear driven which would have saved space by eliminating pitman arms.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

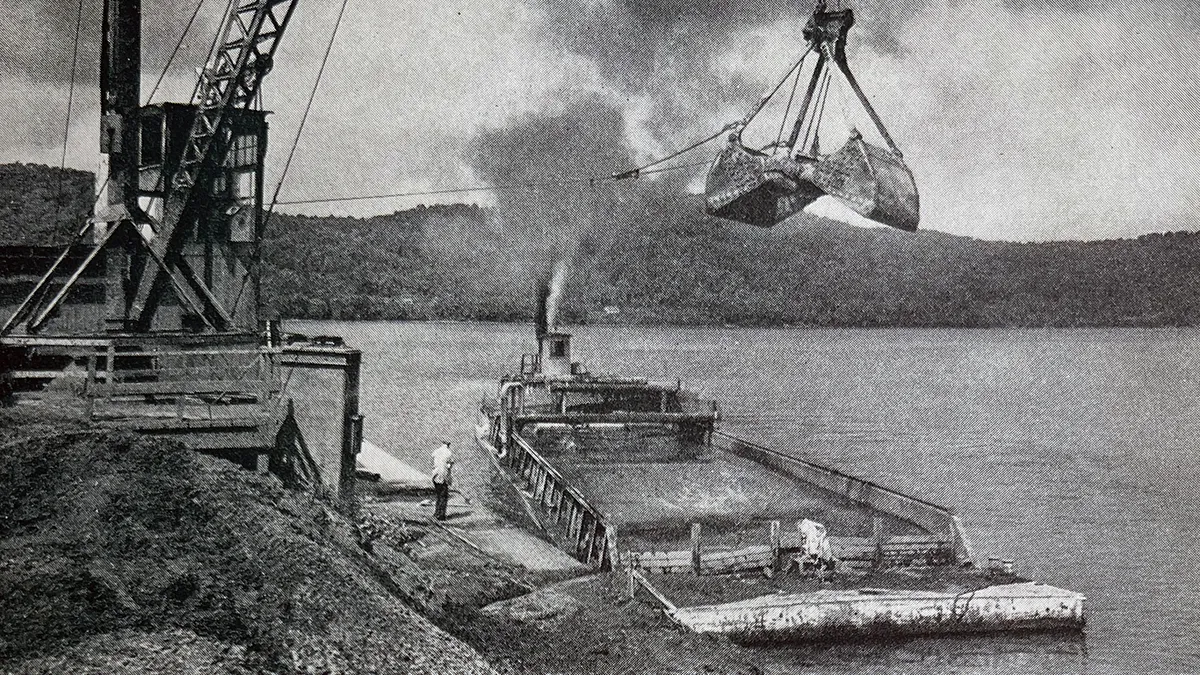

This short video is a great look back on the subject at hand. The sternwheeler in the background (not the one pushing the barge) is a split in two halves paddlewheel. One of the main questions is, how where these split paddlewheels engineered to turn. I'm starting to think they may have been gear driven. If you'll note, there's a very narrow width at the center of the two halves, it doesn't appear to be enough space for two cylinders unless the shaft was made with offsetting journals and the pushed at an upward angle. So much research and not knowing where to look is a killer. For whatever reason the last video link does not alway play. in the first link you have to click the link and then click the far left image to bring up the video. https://www.google.com/search?q=https%3A%2F%2Fmedia.gettyimages.com%2Fid%2F2104816477%2Fvideo%2Fsusquehanna-river-bottom-is-dredged-by-laborers-for-salvage-coal-run-off-from-upstream-mine.mp4%3Fs%3Dmp4-640x640-gi%26k%3D20%26c%3Dn-LdslyjCMPXAAQ5VTzYzbTr9i2ORyt7P0AEneuitJU%3D&sca_esv=7fef18164babfbf6&source=hp&ei=YR1OaLb_JfrIp84P1qLnmQc&iflsig=AOw8s4IAAAAAaE4rcWLxqF8GmSh8Mh3YCHahhR0Si6mZ&ved=0ahUKEwj2s8v-nvKNAxV65MkDHVbROXMQ4dUDCA8&uact=5&oq=https%3A%2F%2Fmedia.gettyimages.com%2Fid%2F2104816477%2Fvideo%2Fsusquehanna-river-bottom-is-dredged-by-laborers-for-salvage-coal-run-off-from-upstream-mine.mp4%3Fs%3Dmp4-640x640-gi%26k%3D20%26c%3Dn-LdslyjCMPXAAQ5VTzYzbTr9i2ORyt7P0AEneuitJU%3D&gs_lp=Egdnd3Mtd2l6ItYBaHR0cHM6Ly9tZWRpYS5nZXR0eWltYWdlcy5jb20vaWQvMjEwNDgxNjQ3Ny92aWRlby9zdXNxdWVoYW5uYS1yaXZlci1ib3R0b20taXMtZHJlZGdlZC1ieS1sYWJvcmVycy1mb3Itc2FsdmFnZS1jb2FsLXJ1bi1vZmYtZnJvbS11cHN0cmVhbS1taW5lLm1wND9zPW1wNC02NDB4NjQwLWdpJms9MjAmYz1uLUxkc2x5akNNUFhBQVE1VlR6WXpiVHI5aTJPUnl0N1AwQUVuZXVpdEpVPUgAUABYAHAAeACQAQCYAQCgAQCqAQC4AQPIAQD4AQL4AQGYAgCgAgCYAwCSBwCgBwCyBwC4BwDCBwDIBwA&sclient=gws-wiz#imgrc=dKKHNdGkDUEucM&imgdii=JAkcoAbrXzNgcM https://www.gettyimages.in/detail/video/the-bottom-of-the-susquehanna-river-is-dredged-by-news-footage/2104816477

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

The skylight turned out very nice, great job. if you wanted to give the skylight the look of glass you can cut thin clear plastic from processed food containers. I've done this a number of times and it woks really slick. You have to do all the painting or staining first and once that is done just add a tiny dab of CA on the inside corners, only doing two corners will work to hold the plastic. Just add enough CA so it doesn't smear onto the visible area.

-

Good morning, Eric. I've got some windows arriving from Itchy Train today and I'm about to start building the hull. Did you see Lula and the pile driver in the Album images section? About a week ago I had a chance to check out the port side area next to the pilot house and I don't think that's a skiff/dinghy, If you look through the engine room window toward the port side you can see a vertical pipe with a circular valve handle near the top. A diagonal (?) crosses in front of the vertical pipe just below the valve handle. There is a horizontal pipe more to center of the vertical pipe. All this piping could be part of a centrifugal pump system with parts of it next to the pilot house on the port side? Though small, the photo below is the best view of the area on the port side next to the pilot house. For that "white" to be bow, the stern would hang off the edge and would make for a crazy storing angle. Thank you for checking up on me. I should have a final answer on surgery this coming Tuesday. As of last Tuesday the surgeon wanted me to travel to Detroit for surgery but after further discussion he is going to get with two over vascular surgeons and go over all the reports to make sure everybody is on the same page. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Well, that tugs at me ole heartstrings.

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Jacques, don't waste the box. Close up the open end, put some outside bracing and turn into a crate. It's the perfect size.

- 312 replies

-

- Chile

- Latin America

-

(and 6 more)

Tagged with:

-

Congratulations, Chris. A lovely model, very well done.

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The more I look at the "rock" the more I like it just as is. There are natural steps on the left side leading up to the SIB.

- 106 replies

-

- Kentoshi-Sen

- bottle

-

(and 1 more)

Tagged with:

-

Plywood has its place but that place isn't for parts that will be out in the open. It's that kind of attention to detail that turns a good model into a great model. Well done, Mark.

- 257 replies

-

Welp, the first one doesn't do too much for me but that second ONE! It's got my Zen-O-Matic 2000 vibrating on all eight universal cylinders. All joking aside, Glen, the second one is really beautiful, the rock is just right. You know, you ain't gonna have much of a place left you keep including stuff from the homestead in these SIB projects.

- 106 replies

-

- Kentoshi-Sen

- bottle

-

(and 1 more)

Tagged with:

-

It's not a black hole, Glen. It's the tweezers, the devil's own tool.

- 235 replies

-

Mashuno, welcome to MSW. Glad to have you aboard.

-

Thank you, Eric. There are so many questions about parts of this push boat that are hidden or the view obstructed. I think what I need to do is build the hull, replicate the engine room, and pilothouse as faithfully as possible and then start adding those obscured items including, the boiler, wheel's steam cylinders, mud drum, beam engine for boiler feed, hand pump, and coal bin.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

I've got this sternwheeler virus bad. Now there's a working boat that you need to build, Keith. That's a fine example of one. Thank you, Eric. Yes, please because I'm having a devil of a time seeing it but as I said, I'd dearly love for you to convince me it's a dinghy because it makes life much easier. Glen, I very much wanna believe but I don't see a dinghy, then I don't know what I'm seeing. As far a being a dinghy cover, I'm not sure a dinghy cover was a priority item aboard this vessel. One of the many things we've yet to discuss is crew. Only two crew members are pictured and I don't see hide nor hair of a third which would have been the engineer. Could they have gotten away with just a two man crew? That seems a bit sketchy.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.