-

Posts

6,725 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

Mine fly off into the abyss never to be seen again. I guess it's food for the modeling gods?

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

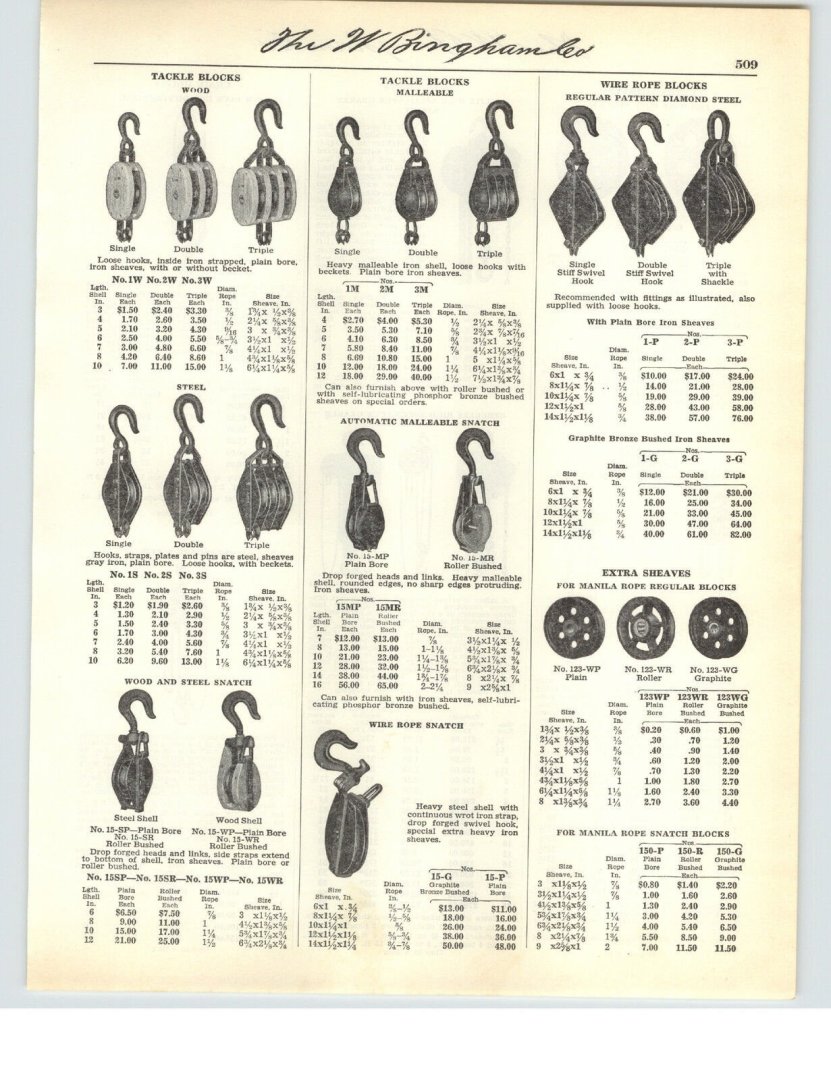

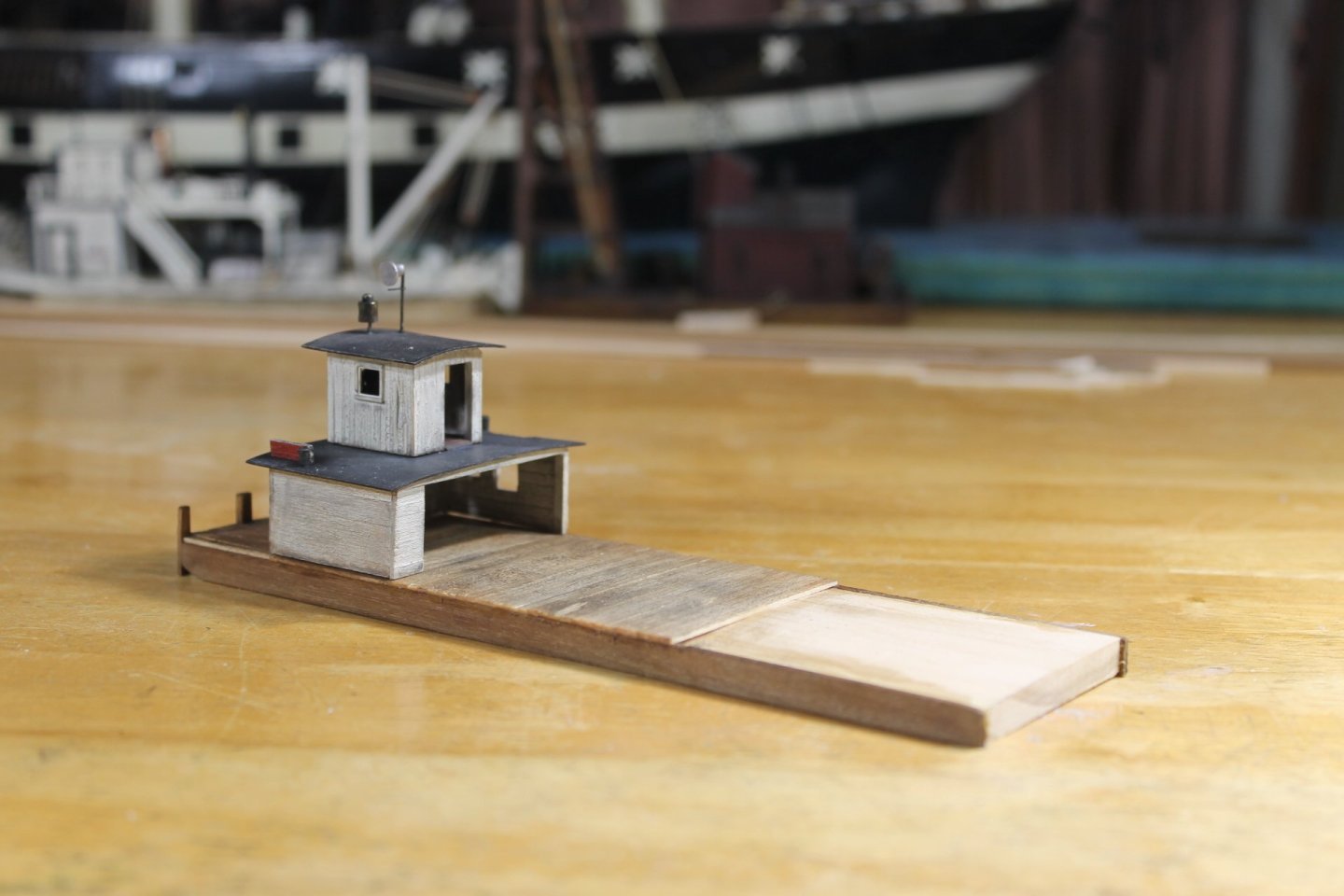

Thank you to all for the kind comments and the likes. A bit of play and a bit of progress. Nothing is glued to the deck as I'm still trying to determine the exact hull length. I'm close and I'm thinking 67 feet is going to be the magic number. I need to get a rough boiler in place and start trying to get some idea of the coal auto feeder shapes and dimensions. If anyone has photos or drawings of large scale auto feeders for vertical boilers I'd be forever grateful, please post anything that might be helpful. I think it was either belt or bucket fed because the wire rope blocks hanging above the coal crib as seen in both the bow and stern original photos. I did some preliminary work on the deckhand, sill more to do but he looking the part. The chain winches need to lowered a tad. The stairs are glued to the roof of the engine room, much more work on the stairs is required. The coal crib and support for (this is where the wire rope blocks hang from) the auto feeder's tail. I don't know of it was belt or bucket that took the coal to the crown table. Did the crown table shake and then coal went onto the slide or did gravity alone get the coal onto the slide? The top right group single is what I see hanging from the support. Thank you for your support and for being part of the journey. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Okay, okay. I'm just sayin' I'm ready to see another one of your beautiful SIB projects come to life. Thank you, Keith. Thank you, Gary. John, how very kind of you to say. I do believe I've found my niche. I've enjoyed, am enjoying creating models of vessels most wouldn't give a second glance. Not all boats come off the ways with beautiful lines but if one looks hard enough at those that don't, one comes to appreciate their persistence to keep moving forward in their work a day world.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Thank you, Glen. Hey, when's that "TBD" gonna change?

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Thank you to everyone for the comments and likes. There is a hull in the action. I added some color to the bow. In the original photo the decking on the bow runs fore to aft but the decking aft of the engine room fore wall runs from side to side. The only reason I can think of for that being the case is another layer of decking was laid down on top of the old decking at some point as the bow decking takes the most beating. I also added a little color aft of the engine room. More will be added as the build progresses. I've let the aft run wild till i know exactly where to make the cut out for the wheels. Thank you to all for your support and for following along. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Rodney would be pleased, Bob. She looks great.

- 44 replies

-

- Scientific

- Billings Boats

-

(and 1 more)

Tagged with:

-

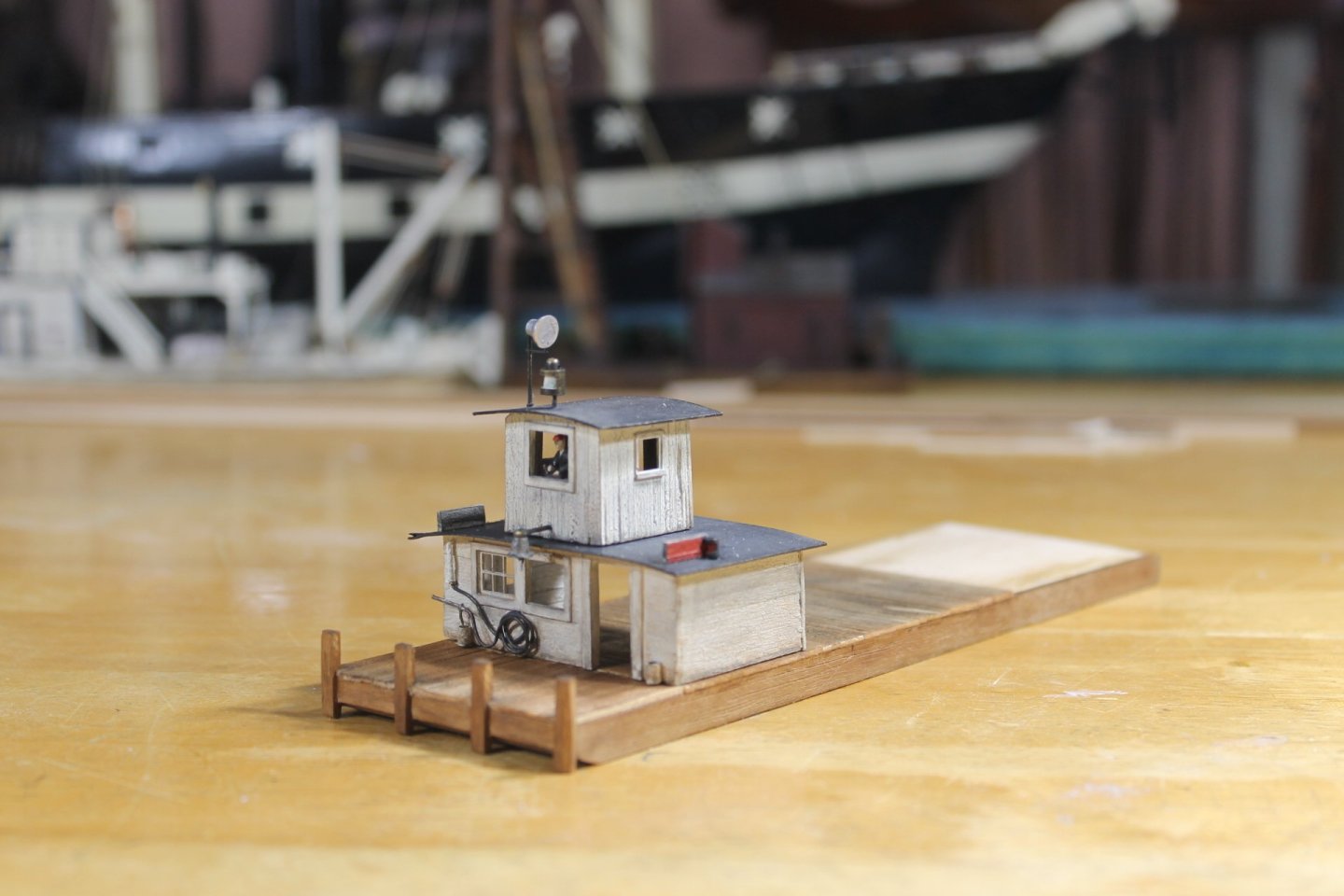

Thank you, Tom I agree, the pilothouse was more coal sooted as it was higher up and it was worse on the aft side. The engine room was more of a tan color because of the dredged material being primarily on the side and fore walls. If anything, I think I need to add just a whisper of tan to the pilothouse side and fore walls.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Thank you to everyone for the comments, laughs, and the likes. I repainted the pilothouse and got it weathered. There is enough weathering on the engine room, I don't think it needs any more. Weathering requires a light touch and I'm prone to be heavy handed. I really have to reign myself in to keep from going overboard. I also do better in natural light as artificial light cast shadows. My worktable lights wash the weathering effects so these are actually a bit darker than pictured. I added the pilot. This particular resin figure was perfect for the pilot but both hands had broken off. These figures are so small (the tallest is 0.60 inches) and fragile that the extremities are easily broken off. I removed the hands from two other figures that were badly damaged for the pilot figure repair. I did my best job yet sculpting away the navy uniform and I think the figure turned out pretty okay. He looks the part of the pilot in the original photo. Time to quit messing about and start on the hull. I've been dragging my feet because the amount of space between the furnace and the wheels is unknown but I've got to go with my best guess. Between the furnace and the wheels is the furnace's automatic coal feeder, the coal crib, and the twin cylinder steam engine and shaft to the wheels. The water pump/pumps and gas engine are all on the port side. Thank you for your support and for following along. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Danged keyboard! It outta know when I mean following. Thanks for making me laugh, Eric. Golly knows I needed that.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Heaven, welcome to MSW. Glad to have you aboard.

-

Keith, it seems we all have more time for modeling in the winter. Thank you to everyone for the likes and the comments. The first attempt at weathering is done. I say first attempt because I'm not keen on the results. Too much on the pilothouse and not enough on the engine room me thinks. I've got to get the pilot painted and in position not that it will make a difference but it delays repainting the pilothouse and starting over on the weathering. Thanks to all for your support and for flooring along. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

New to the Wooden Ship Assembly/Build Community

Keith Black replied to rturcic72's topic in New member Introductions

Rob, welcome to MSW. Glad to have you aboard. -

Thank you, Erric. Thank you to everyone for the comments and likes. Let the weathering commence! Before. 😢 After. It's not perfect but it's a lot better. I think I was so disappointed in the quality of the bells I received that my efforts matched the bells. The ship's bell sits at the correct height and looks much much closer to what the original photo shows. The searchlight looks more like the photo searchlight and less like a loudspeaker mounted atop a 1934 Ford van blaring out propaganda to the masses. The bell I'm using for the searchlight is 0.15 inches in length. Thank you guys for being part of the journey and for your support. Keith

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.