-

Posts

5,520 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

Yes...you want an even consistent look.....not a look of dilapidation and leaching....that these pictures also represent. Unless, that's what you are looking for....then you need to treat your entire vessel in like manner. Weathering her consistently.

- 101 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

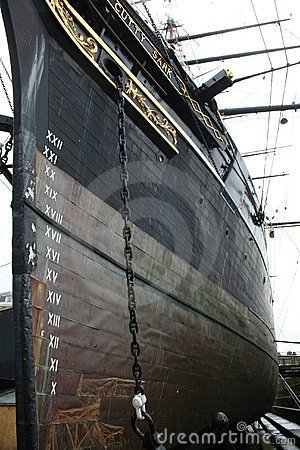

That paint coupled with the shiny copper...really lent itself to the aged muntz I was after. And the paint helps seal the copper to the hull and to each other. I used light coats so the copper itself would kinda shine through but not. Its an interesting effect. I used the old images of Cutty Sark in her drydock long before she was ever burnt and rebuilt. The older picture is a bit faded.

- 101 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

Good night nurse! You’re going at it the hard and technical way. I just spray painted my copper with metallic paint. As I applied it, it mixed with the copper color and took on the look of aged oxidized muntz. Which turns kinda brownish. I liked the result. Rob

- 101 replies

-

- Cutty Sark

- Sergal

-

(and 1 more)

Tagged with:

-

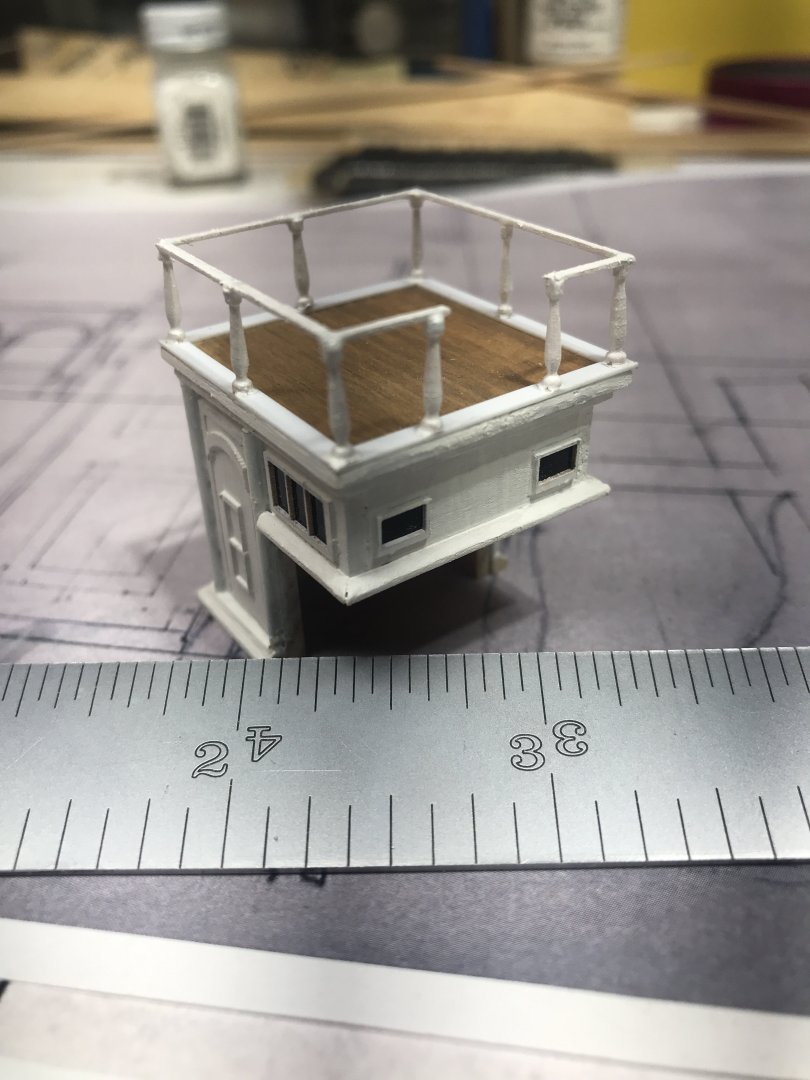

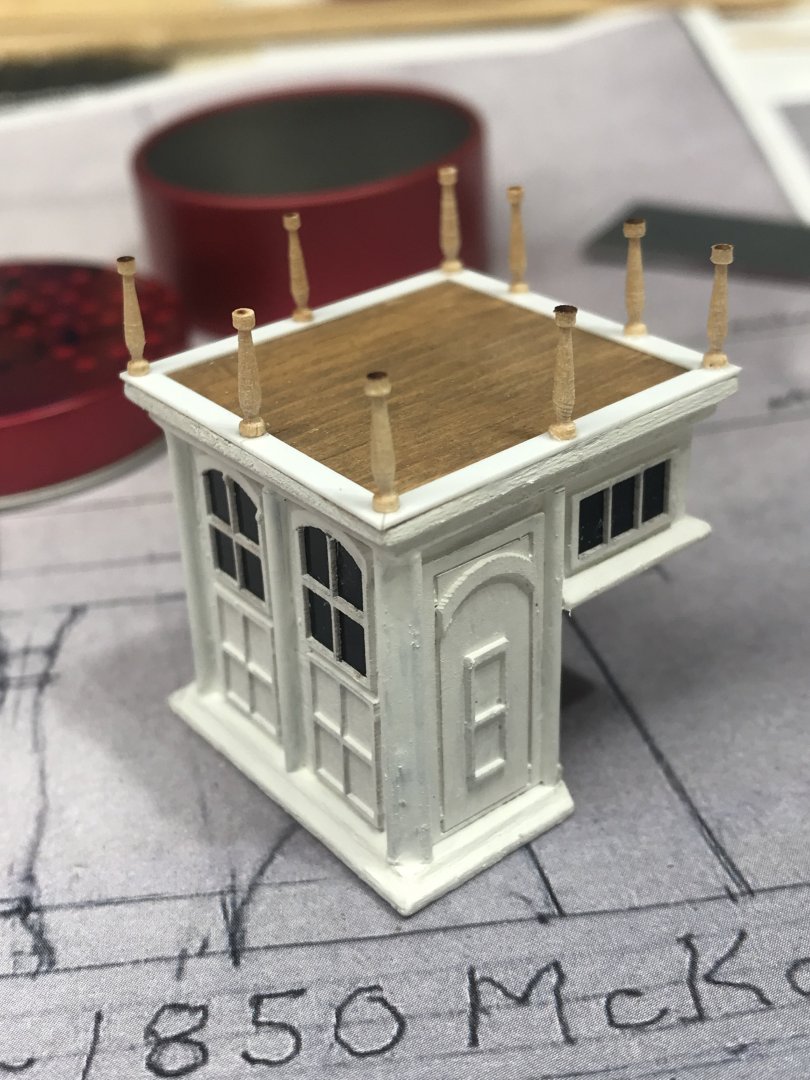

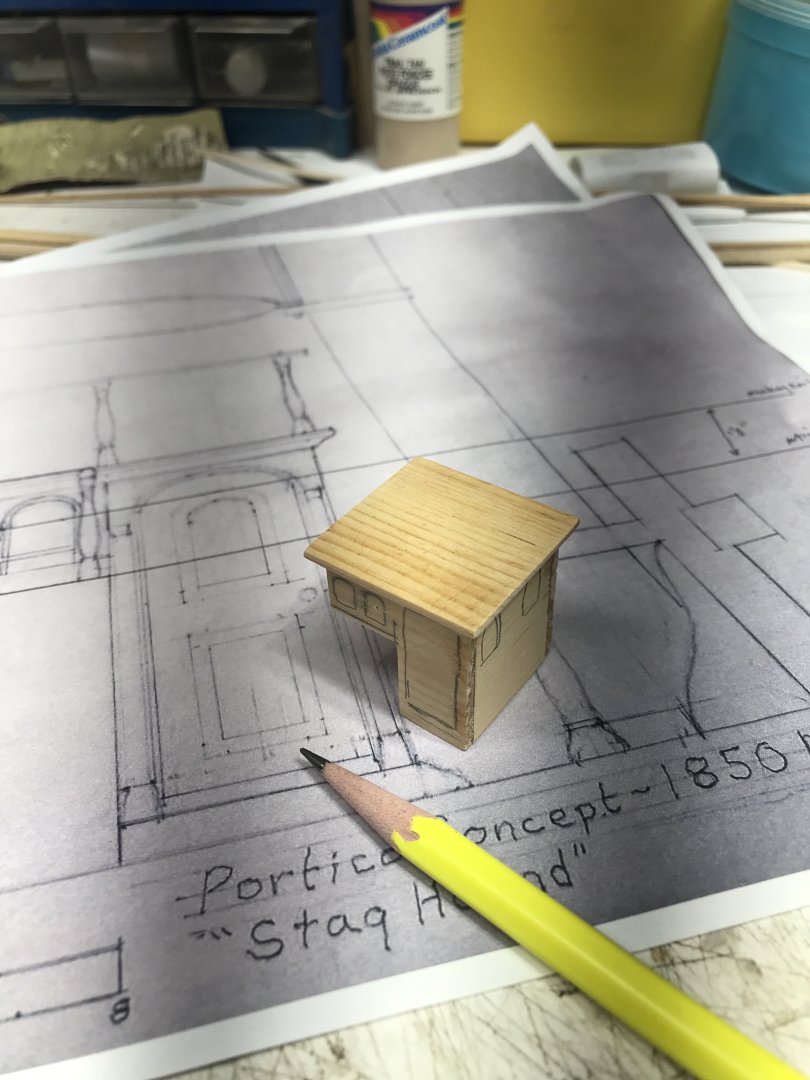

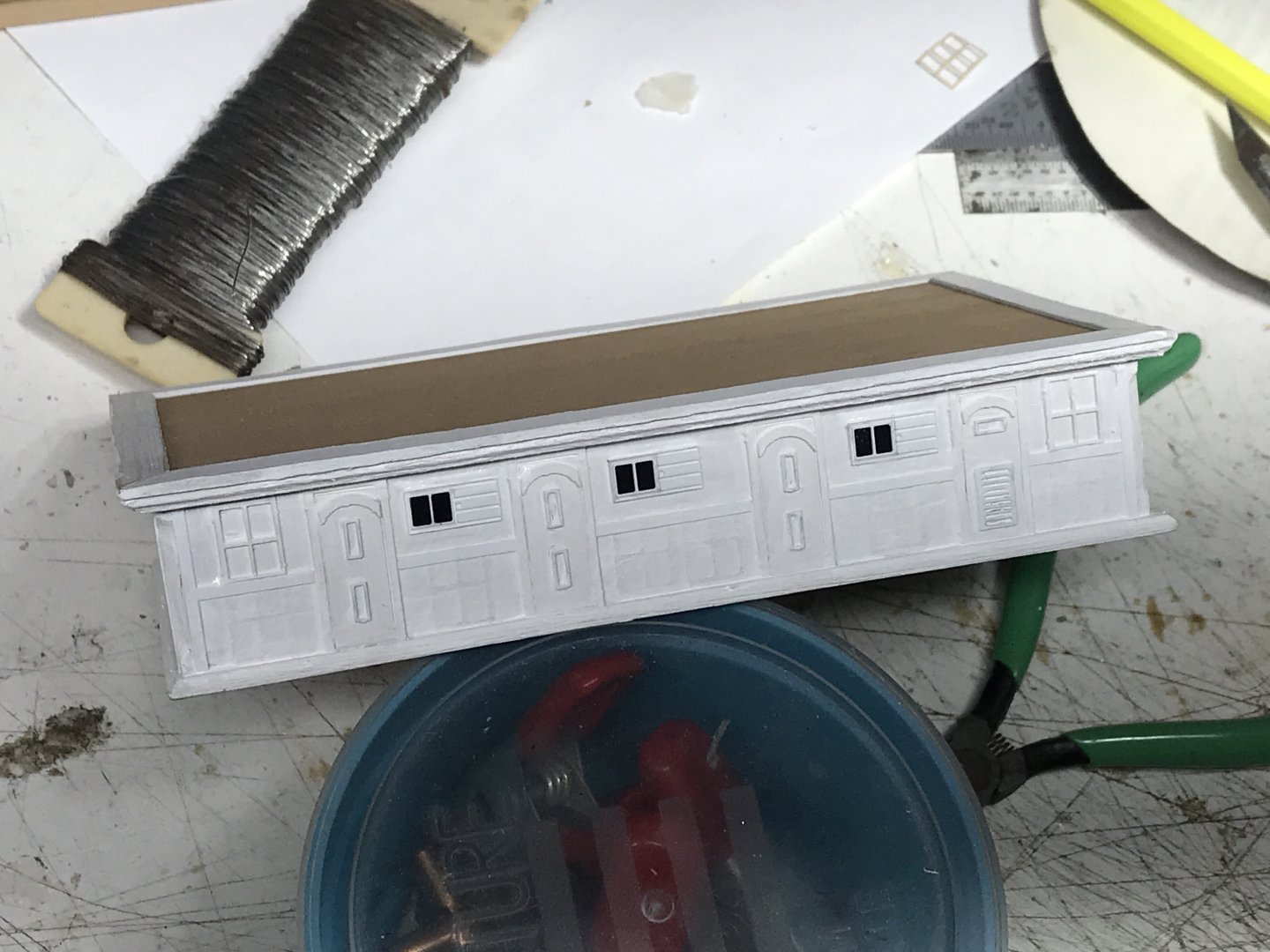

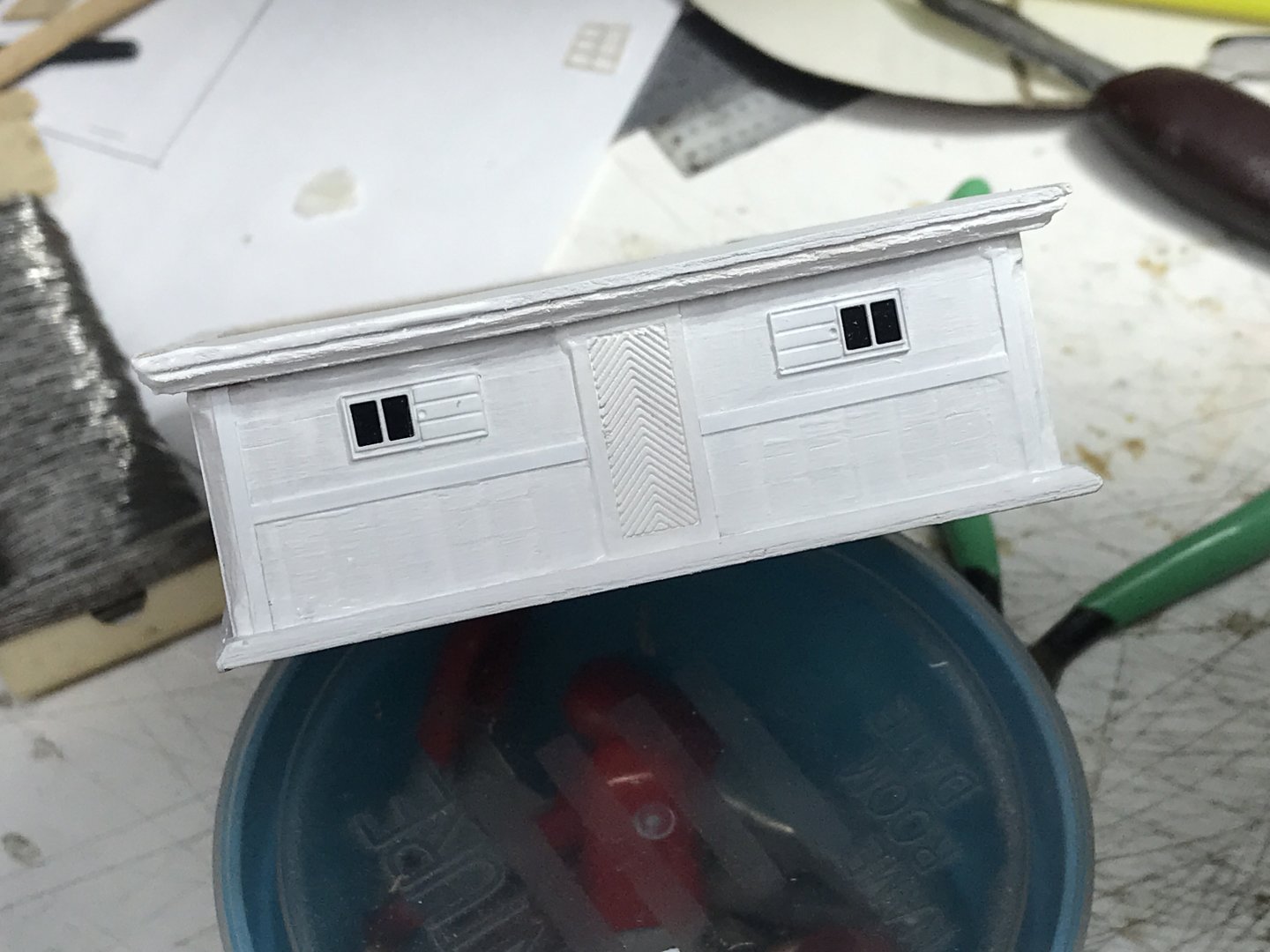

Thanks....I considered the idea that this is an entry way...and the aft portico that must have ornate facing windows and pillars. the panel work on its front is reminiscent of the larger carriage houses of McKay's larger clippers , which actually had poop deck cabins. A kind of captain's palace....per se'. Next, I will be adding the stanchion base peripheral trim and stanchions....and possibly the steps and their railing...after I add the exterior deck base trim around the aft end of the portico. Rob

-

Yeah...when you consider that the entire portico is only an inch square...loading it up with all the details...such as pillars windows and such it gets tiny tight. the space from the door trim to the edge of the house is just about a 1/16". Leaving little room to snug a 1mm+ pillar. I hope to get more done tonight and possibly a first coat of paint. Rob

-

Tooth picks are Waaay to large. Each pillar is slightly larger then 1mm in diameter. I think I might fill in the slight gap between them and form a corner for the portico that incorporates both corner pillars. Slightly different design for the corners, but still in keeping with the original architecture and maintaining dimensional interest. I hope to address it today and add the square/rectangular rear and side windows. Rob

-

As we were discussing this I realized that the portico is nothing more than an access to the floor below(3ft)....but it is also acting as a skylight...in conjunction with its larger companion, just aft. The skylight will have square windows...so square windows on the sides and aft end of the portico will blend in nicely in this scale. The front windows will remain as you have drawn them and as they are presented on Glory of the Seas....depicted in Mike's drawing. Rob

-

I've decided to keep two windows on the front...because I want them to mimic the aft windows... Meaning the 2 in front make way for the mizzen, as the 2 aft make way for the steps. Balance. Since Glory of the Seas was McKay's final clipper..... We can't assume he had finalized his Decore for his houses when he built his first clipper, Staghound. My effort will be to copy the forward windows as you have depicted them...by way of example from Glory's and Mikes rendition. That seams fitting as the portico main face. However, due to the extremely small size I am dealing with...I might settle on square windows for the rest. The curved top is harder to make then you would imagine. I'm experimenting...but have not been satisfied thus far. We'll see. but I think I may be settling on square. Kinda like a skylight. Rob

-

Wonderful job and very nice display....she has a great home. Again...super job. Rob

- 235 replies

-

- Banshee II

- Bottle

-

(and 1 more)

Tagged with:

-

Beautifully drawn. I love the embellishments. Only one question.....what made you decide on a 2ft overhang? Is that to mimic the roof overhang on the main cabin? Which is what I was going to do....but I was thinking more like 1ft. Review Glory's overhang on her main cabin. It's not even an overhang...but more like a gradual step of descending trim. Great job by the way. Rob

-

I wasn’t offended. I look at every aspect. And evaluating Intent based off historical actualities. Somebody may say something, but if it flies in the face of other known facts……I’m questioning it. I’ve changed my mind, in the light of community concurrence and one eyewitness’s vague description. Mind you, it’s Duncan McLean’s description……vague as it is. IMV. Rob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.