-

Posts

1,918 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by hamilton

-

-

-

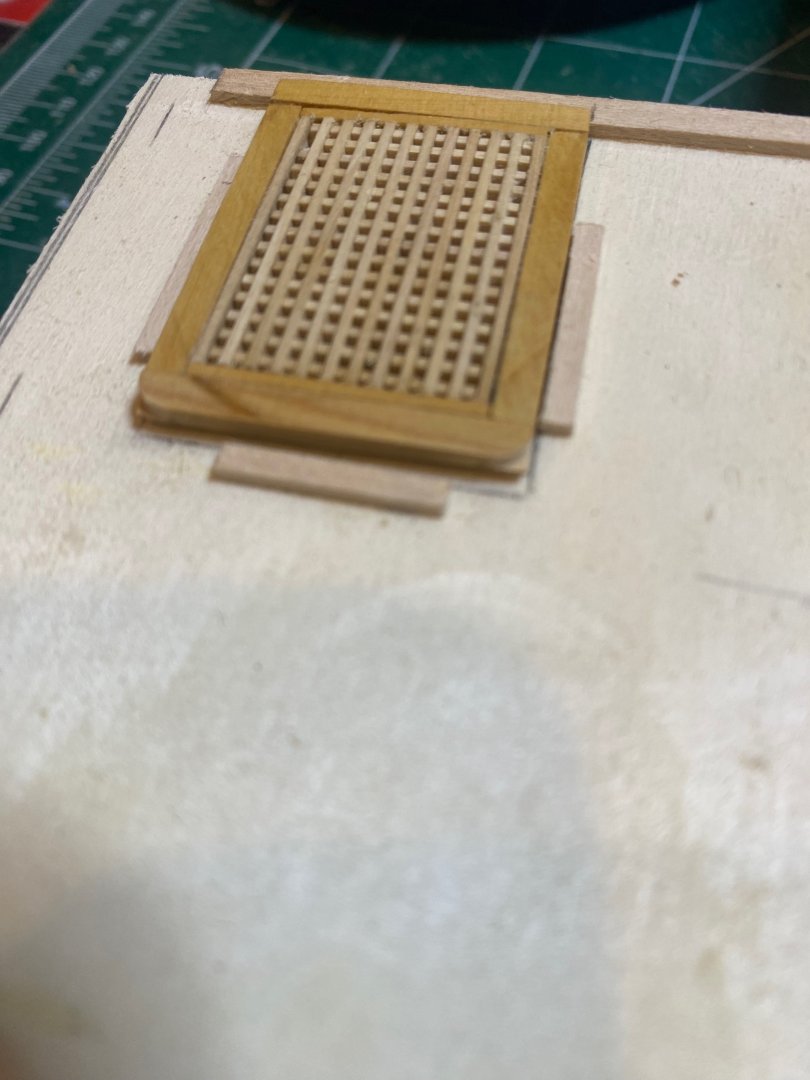

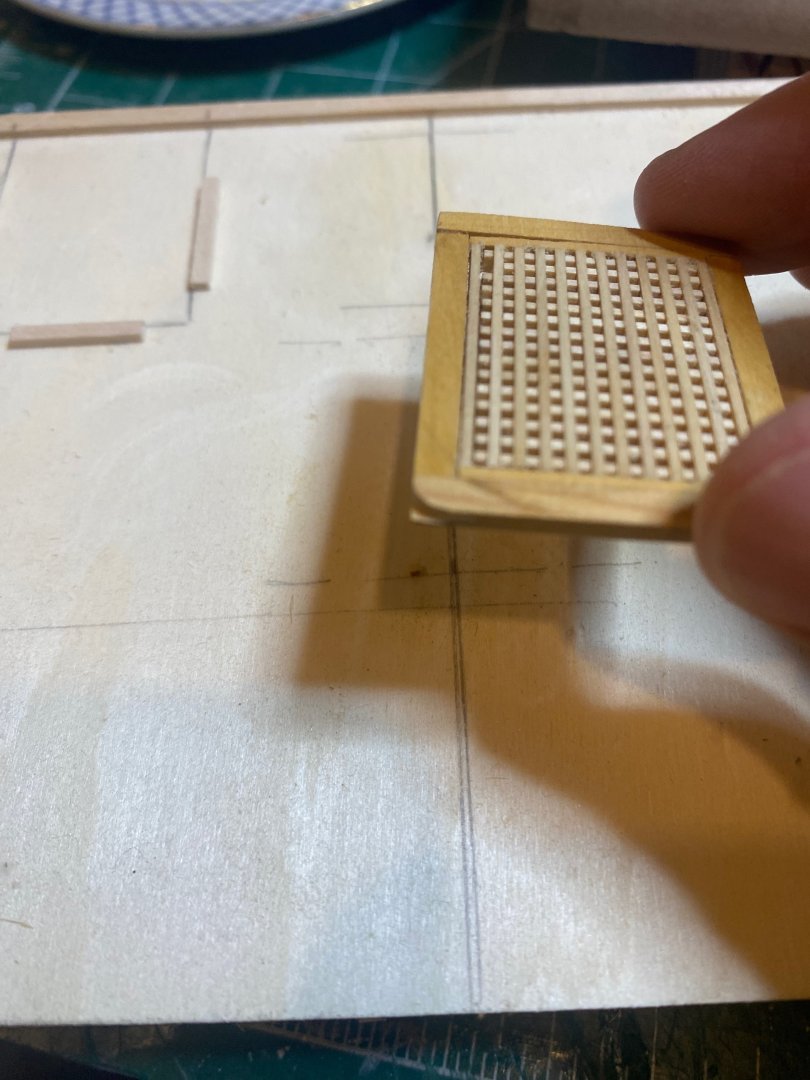

After spending a week looking at the lower hatch, I found myself becoming increasingly dissatisfied with it. So today I rebuilt it. The most difficult part of this was prying the old one off the model - I used a micro saw for this and worked very slowly and gently until it came loose. Sanding down the deck framing and re-applying some wipe-on poly made it look fine - a couple of blemishes, but these are hidden by the hatch itself, so not a big deal. The blanks for the partners are obviously just dry fit for now - lots of work to do on those before they're ready to be installed!

It's still not perfect, but I think it looks much cleaner than the last one. I had intended to spend today milling the pump shafts, making a mast dummy and starting work on the lower mast partners, but that now is put off to a later time.....

I hope to be able to find some time in the workshop this coming week - work is in a very temporary lull until the week after next, when we have our spring break at the university - a time for the kids to go to the beach and the grown-ups to mark mid-term assignments.....fortunately I'll be doing that at my parents place in the woods of eastern Ontario with a decent supply of beer and cookies (obviously not consumed together!).

Enjoy the photos and bye for now.

hamilton

- CiscoH, vossiewulf, KARAVOKIRIS and 11 others

-

14

14

-

Such a nice sleek hull...

hamilton

- JacquesCousteau and Greg Davis

-

1

1

-

1

1

-

Just came across your build log - I've not seen anyone build this one (though maybe there's a log or two in the archive here...) - very exciting to see!! The work looks good so far

hamilton

- Paul Le Wol and mandolinut

-

2

2

-

Small update...realised that I forgot to round the upper corners of the lower hatch coamings and headrails, which I did this evening - had to lightly pry the part off the model, but this was not too tough. To do this, I placed the part into the holding jig I made for its initial assembly, then ran a #11 blade horizontally at the corners - the battens defining the jig are at roughly 2" (at scale) so the perfect level to the rounded portion of the coamings which stands proud of the 2" planking.

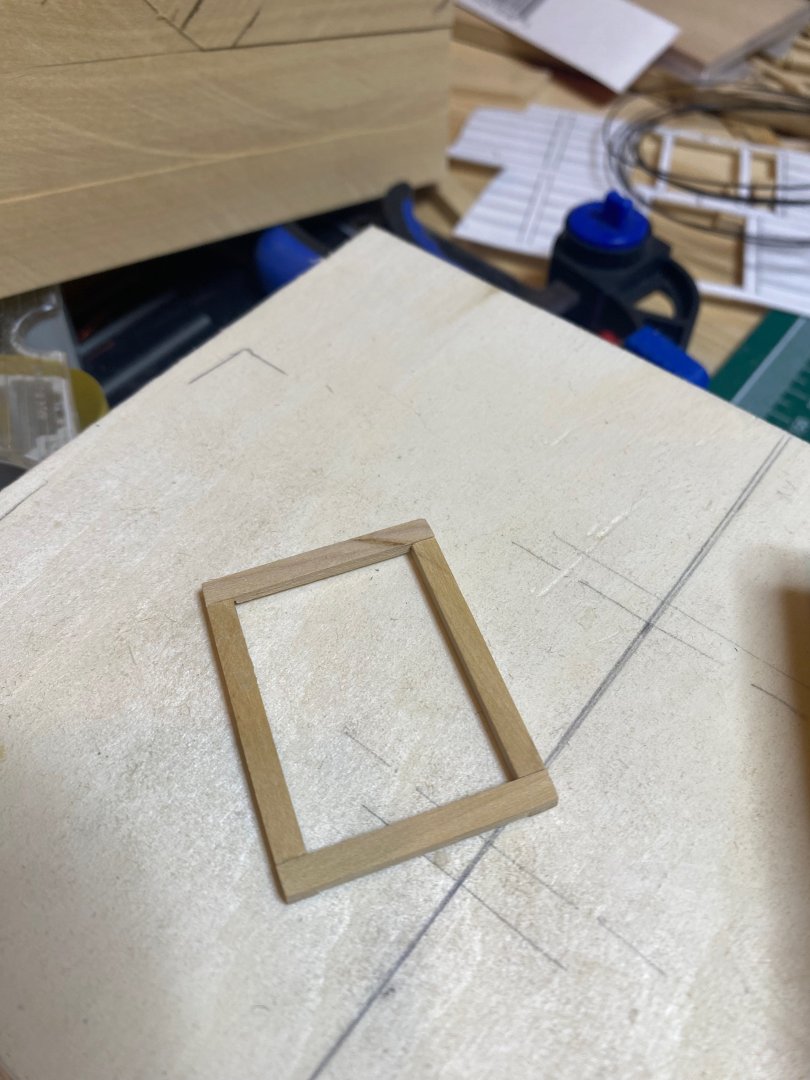

I also milled a small piece of 4" thick (at scale) boxwood and made two small blanks for the two halves of the lower mast partners. I cut a card template to the full dimensions of the partners, divided this with a centreline, and then used that to cut out the halves - which you see below dry fit in place. There is a lot of work to do on these - and some other things to work out in process - before they can be installed.

Happy modelling and bye for now

hamilton

- yvesvidal, dvm27, JacquesCousteau and 3 others

-

6

6

-

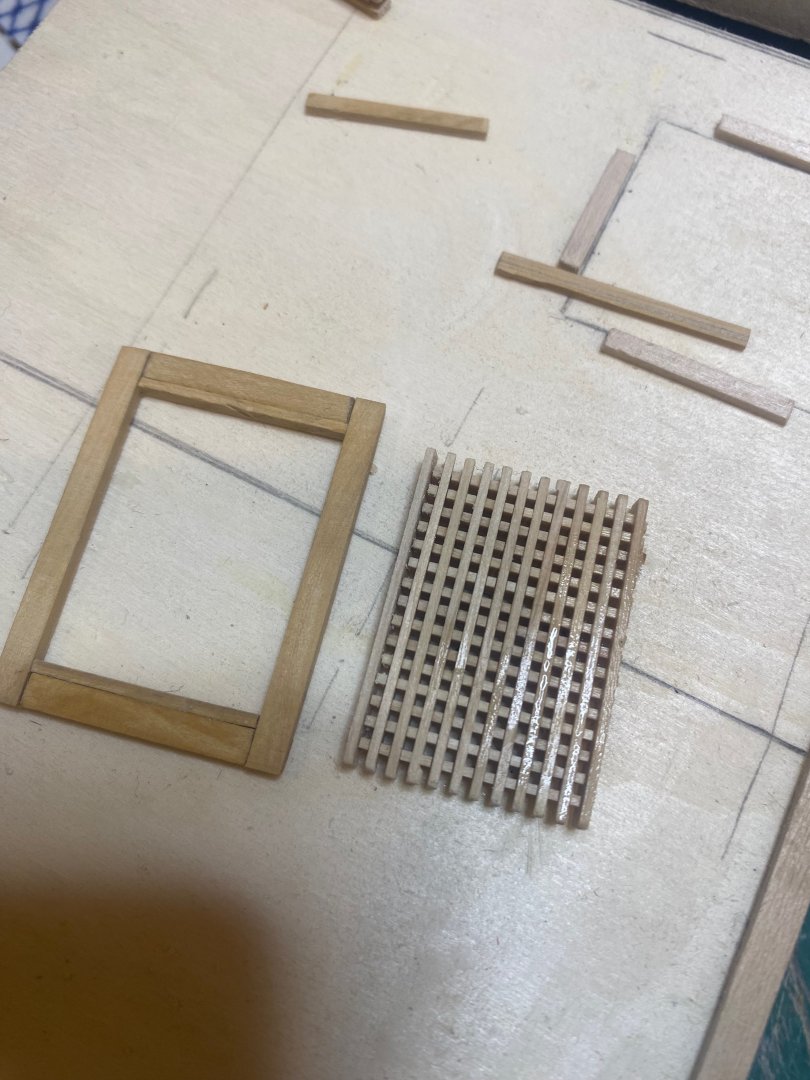

A bit more work at the bench this weekend - I decided to make the lower deck hatch. Here the practicum is a bit at odds with the model. The practicum speaks of a partial "aft hatch" behind this one, but this can't be, since the mast partners are immediately behind this hatch. There is also a lack of information in the practicum on the exact locations of the sheet and jeer bitts, so I'm a little confused as to where these should be - there is some info on this in the photos provided with the practicum, but it isn't really adequate to locating them....In any event, I did also go so far as to mill 11" and 10" square strips for the pump shafts (6) and the bitts (4) to use as blanks for working out the mast partners - though the upper deck framing will need at least to be partially complete before finalising these.

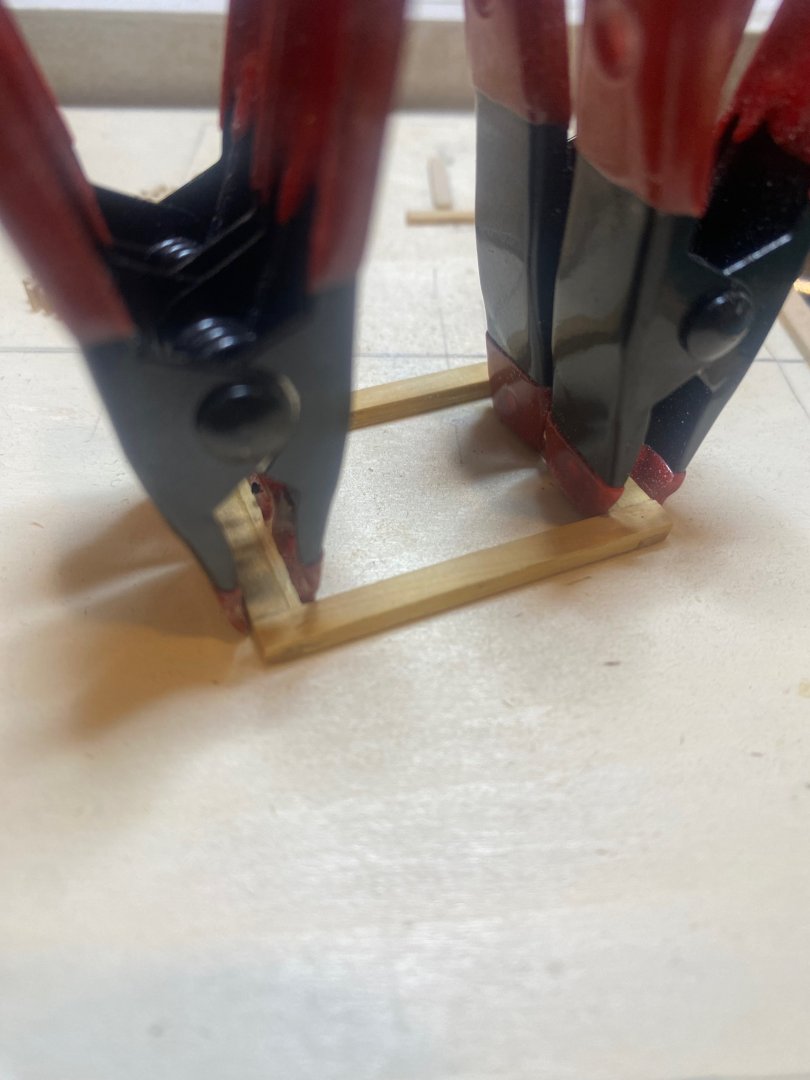

The hatch came together pretty easily. I took a card template of its basic dimensions and laid this out on a sheet of scrap ply. I then arranged some battens around it to lock in the head ledges and coamings in the proper place. The head ledges and coamings fit together with lap joints which are pretty straightforward.

The gratings were made from material scavenged from my never-to-be-finished Syren kit - these gratings are of roughly the correct size and were of sufficient quality (unlike those often supplied by other kit mnanufacturers) for these purposes. Because the gratings when assembled did not fit exactly right, I needed to add a couple of battens along the head ledges (image with clamps below) so that the gratings looked correct.

Overall this went very smoothly. And it's nice to start creating more of the superstructural features of the model, which immediate (I think) make it more satisfying to the eye even in its unfinished state.

Enjoy the photos and happy modelling

hamilton

-

Yeah - my mum used to call me "knobbly knees" when I was a kid, and now I have not only 2 but maybe as many as 6 of them!! if it's not too tricky I might try prying the nails out and re-doing the bolts with just the shafts, but since they're now installed I worry about doing damage to other parts of the model.....so I may just write this off as a "learning experience" - it's nice, in my mid-50s, to still be having learning experiences!!

hamilton

-

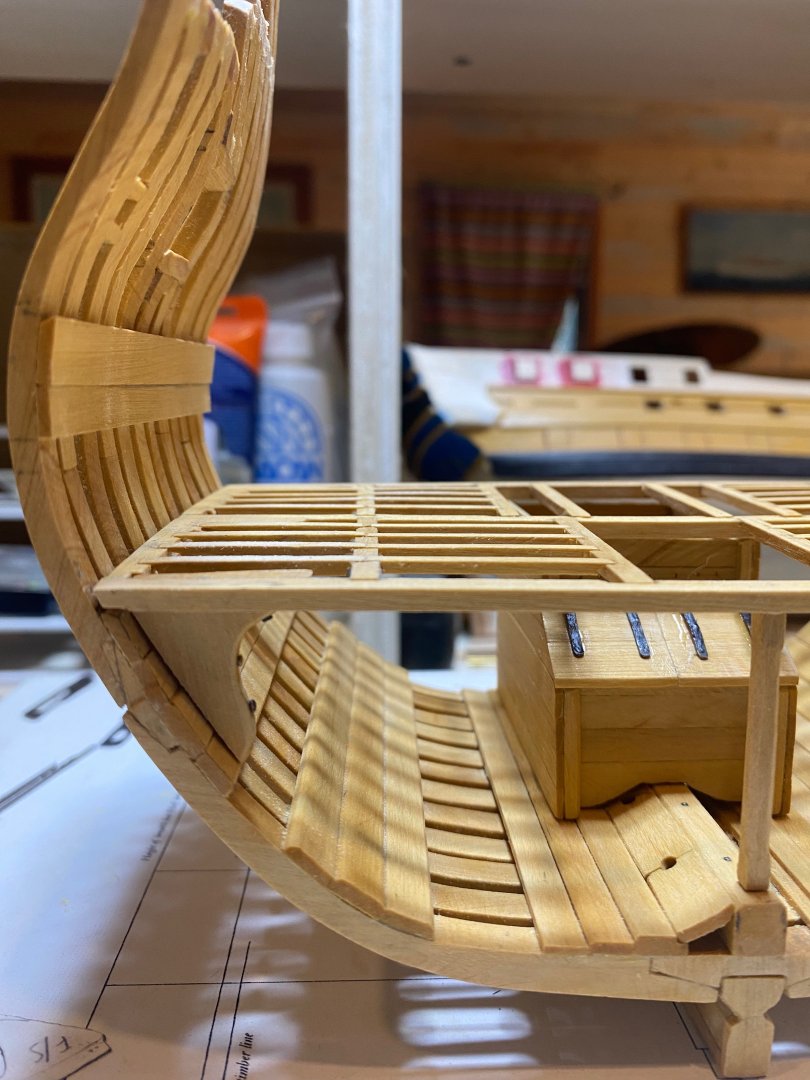

Whoa - I see my last actual update here was way back in October!! There has been precious little time for modelling, unfortunately, though I did spend a bit of time over the holidays doing some planning for the MS Flying Fish, which I don't plan on digging into for a while, but which drew my attention while taking a look through my inventory. Figured it never hurts to start planning and it was a nice break from inhaling sawdust and trying to wrap my head around the hanging knees. But I bit to bullet today and managed to complete these nettlesome parts....

I made a card pattern from the plans and tested it against each of the hanging knee positions (there are only 4 in total, so those of you building a full model in this style can please ignore or forgive my whining). It worked reasonable well for all of them so I traced it into some 6" boxwood sheet that I milled for this and other purposes.

I decided it was best to go through the process of fabricating and fitting one of the knees before doing any of the others. I was not aiming for perfection, but for as nice a fit as I could achieve with my limited experience. In trying to fit and adjust the part I realised that it would be much easier to do if I committed to installing the well, pillar and lower deck framing assembly - so I did that first. It was then much easier to lightly clamp the part in place and test its fit and positioning. After applying a couple of coats of poly, I drill out for bolt heads on the inboard edge and aft faces where they bolt onto the deck beams - using brass nails for the bolts. In retrospect it would have been better to use only the shafts of these nails as the heads are pretty large at this scale....

In any event, once the first knee was in, the others went quite quickly. For next steps, I'm not entirely sure what I'll do next - I know I need to make blanks for the various pump shafts and bits, so I can mark out their positions on the lower deck framing prior to planking & completing the lower deck mast partners and hatch....but I also don't think it would hurt to do the waterways and in-board hull planking between decks....On the other hand, I feel like I should consider the upper deck framing, even if installing it is a ways off, since positioning of the pump shafts and bitts is necessary there too and it would make sense to mark positions on both decks to ensure decent passage of these parts....Regardless, it's also hard to say how much time I'll have in the near future - work is busy, lots going on with the family, and the Canadian economy is about to get pretty shaky, meaning we're tightening our belts up here.

In any case, enjoy the photos and happy modelling!

hamilton

- gjdale, Thukydides, dvm27 and 11 others

-

14

14

-

Quick PS - just looked through my stock of St Roch photos and I wasn't able to identify anything on the lower hull that would look like a scupper for the sea chest - but I will head down to the MM to have a look around

hamilton

-

6 minutes ago, Lecrenb said:

Thanks Hamilton...

Actually there is a topic I have reached out to the museum curator about, unfortunately with no success so far...

There has to be a sea chest or similar in the lower hull to provide cooling water for the engine, but my plans give no reference to this and neither do my photos.

Not an urgent requirement, but if you're going to be visiting the museum can you please and thanks take a look at the lower hull for such an opening?

Regards,

Bruce

I'll be able to get there next weekend - do you know what the general location of the opening would be? The ship is dry docked in the museum and it's possible to go down into the well, so to say, and examine the lower hull - I'll take a look through the photos I already have and see if there's a likely candidate....I can PM you a couple of images to see if they're what you're looking for and if not, I can swing by next weekend

hamilton

- FriedClams and Keith Black

-

2

2

-

Your work is excellent! I live about a 15 minute drive from the St Roch so if you ever need specific photos let me know!

hamilton

- Keith Black and FriedClams

-

2

2

-

The kit might be challenging, but the work looks great!

hamilton

- yvesvidal and JacquesCousteau

-

1

1

-

1

1

-

You address the challenges of this build well, Yves! This is a great tutorial for anyone building this model in the future!

hamilton

- yvesvidal and Ryland Craze

-

1

1

-

1

1

-

Nice going with the planking! The holly looks great - those little planes are nice too - are they from Lee Valley? Also - that marking tool in your first photo - what is it? And where did you come by it? In any case - planking the cabin will be a nice relief after this exacting job.

hamilton

-

-

-

-

A very cool looking model! And nice work, Yves!

hamilton

-

I learned that phrase as - "order in the environment, order in the mind!" This was supposed to be incentive for us kids to clean our rooms....let me tell you it didn't work!

Your Glad Tidings looks really great, though, Al - nice finish and beautiful workmanship!

hamilton

- Paul Le Wol, alde and Ryland Craze

-

3

3

-

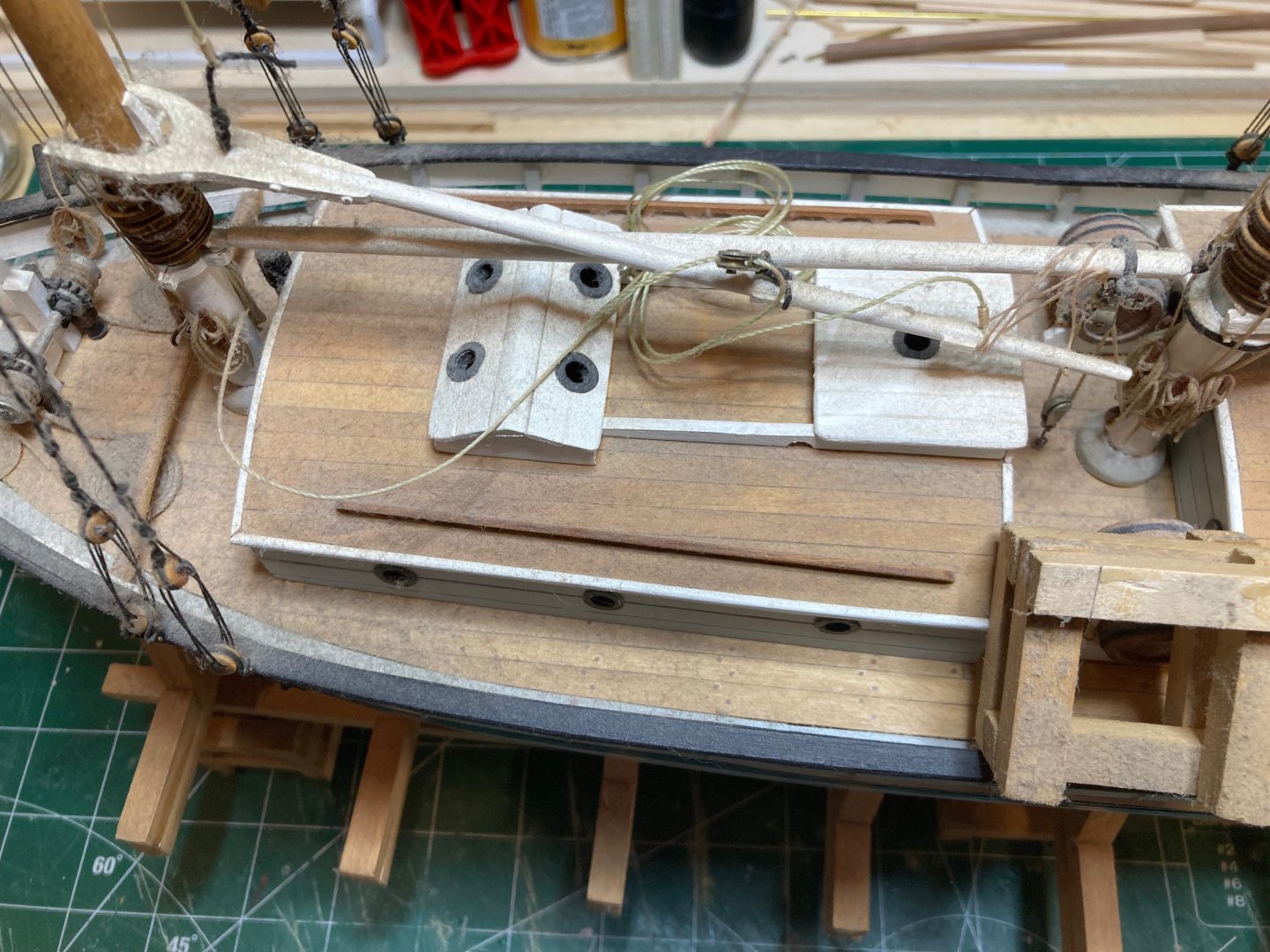

It's been nearly 12 years since I finished the Glad Tidings, but as it says in my signature, it's been in need of a refit for quite a while. I gifted it to two close friends of ours on the occasion of the birth of their first child, and since we visit with them quite often, I've had the opportunity to watch as time, cats, dust and kids' play have taken their collective toll....we went over there for dinner the other night and I sat looking at her throughout the meal and finally resolved to make off with it then and there, and bring it back to the workshop for some much needed cleaning and repair....

After a bit of study, it was clear that the damage was not quite as severe as I had thought - here's an inventory of the parts that needed repair or replacement:

-- forestay

-- all shrouds & lanyards

-- main boom peak halliard

-- fore boom peak and throat halliards

-- port side bowsprit shroud

-- jib downhaul

-- the cutwater plate (which had peeled off)

I cut away these elements and then spent quite a bit of time with a soft fan brush dusting off the model - this in and of itself was very satisfying and it was nice to see that underneath the dust the wood was still in very good condition. In the end, it was a matter of a couple of afternoons at the bench to fix these, and now it's good as new again! These photos may be a but redundant, but......And now I have to fgind time to get back to Echo and Bellona....!

hamilton

- davec, yvesvidal, Paul Le Wol and 1 other

-

4

4

-

It's exciting to try something new! I got into this hobby just after we had our first child - 16 years ago now....As a joke, I Googled "what do retired people do?" and this was the first hit that caught my eye.

I started with the Model Shipways solid hull Phantom Pilot Schooner (1:96). They had a deal where they sold it with a rudimentary tool set (very basic but more or less what's needed for this kit - pin vise & some small bits, 2 hobby knife holders and various blades, a small saw) so I got that. I also got a dremel rotary tool after reading a bunch online. It took about 3 months of occasional work at my kitchen table to finish it. I did not concern myself too much with the results, but approached it as something to learn through and see if I liked it - turns out I did!

Start with something small and easy - get a few necessary tools but no more and then level up as you go. That's my advice - this hobby can be pricey, but it also goes on for years so there's lots of time to acquire things along the way as you find you "need" them.

hamilton

-

Just catching up on your build, Greg - was that Corel's La Couronne behind Phantom? She looks nice too!! You are sorely tempting me (and my pocketbook) with this build....

hamilton

-

Looks like an interesting approach - assembling in situ will likely give a more accurate assembly. 88 seems like a big number!

hamilton

-

Phantom 1868 by Greg Davis - Model Shipways - 1:48 scale - New York Pilot Boat

in - Kit build logs for subjects built from 1851 - 1900

Posted

The ironies of ship modelling.....from the photo any imperfections are completely invisible!

hamilton