GrandpaPhil

NRG Member-

Posts

6,139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

Rob, Thank you very much! Here’s the second mammoth: That’s both of them. I’m pretty happy with how they turned out. I hadn’t done any significant amount of miniature painting for a long while. I have quite a few that I am most likely going to be painting for a bit. Thank you all very much for following along!

-

Alan, Thank you very much! I am basing the general color scheme off the Carthaginian war elephants and I’ll do the same for the Song of Fire and Ice elephants that are sitting in line for the near future. Here’s one in 54mm scale that I painted a few years ago from a resin garage kit: The color scheme for that one was from the Battle of Zama in the 2nd Punic War in 202 BC against Rome. I would assume that the red was to induce fear in addition to the inherent fear (read panic) that elephants induce in horses. Alexander the Great also previously had had severe problems with his cavalry’s horses panicking during his India Campaign due to the elephants at Hydaspes in 326 BC.

-

Question about Apostle San Felipe - OcCre Model 14000

GrandpaPhil replied to Bill Jackson's topic in Wood ship model kits

The San Felipe is a different ship and was a ship of the line from around 1700. The Apostle Felipe definitely looks like 16th century or early 17th century to me. That may have been a translation error on the part of Occre. They also have a kit of the San Felipe, and probably thought you were talking about that one. -

Thukydides, Those look amazing! With small pieces in card, I use CA to stiffen them up. I don’t know if that would help for this application.

- 39 replies

-

- Black Seas

- wargaming

-

(and 1 more)

Tagged with:

-

Thank you all very much for the comments and the likes! I ended up prepping a bunch of other miniatures in addition to the mammoths. I got most of these a long while ago and had them shelved. The mammoths themselves are primed black now. The six legged cat looking thing with tentacles is a displacer beast from the DnD universe. It is done now because it was very simple to paint. Most organics (monsters, creatures and the like) are very easy to paint. It just involves a lot of dry brushing. Here is the finished displacer beast which is off to my curio cabinet:

-

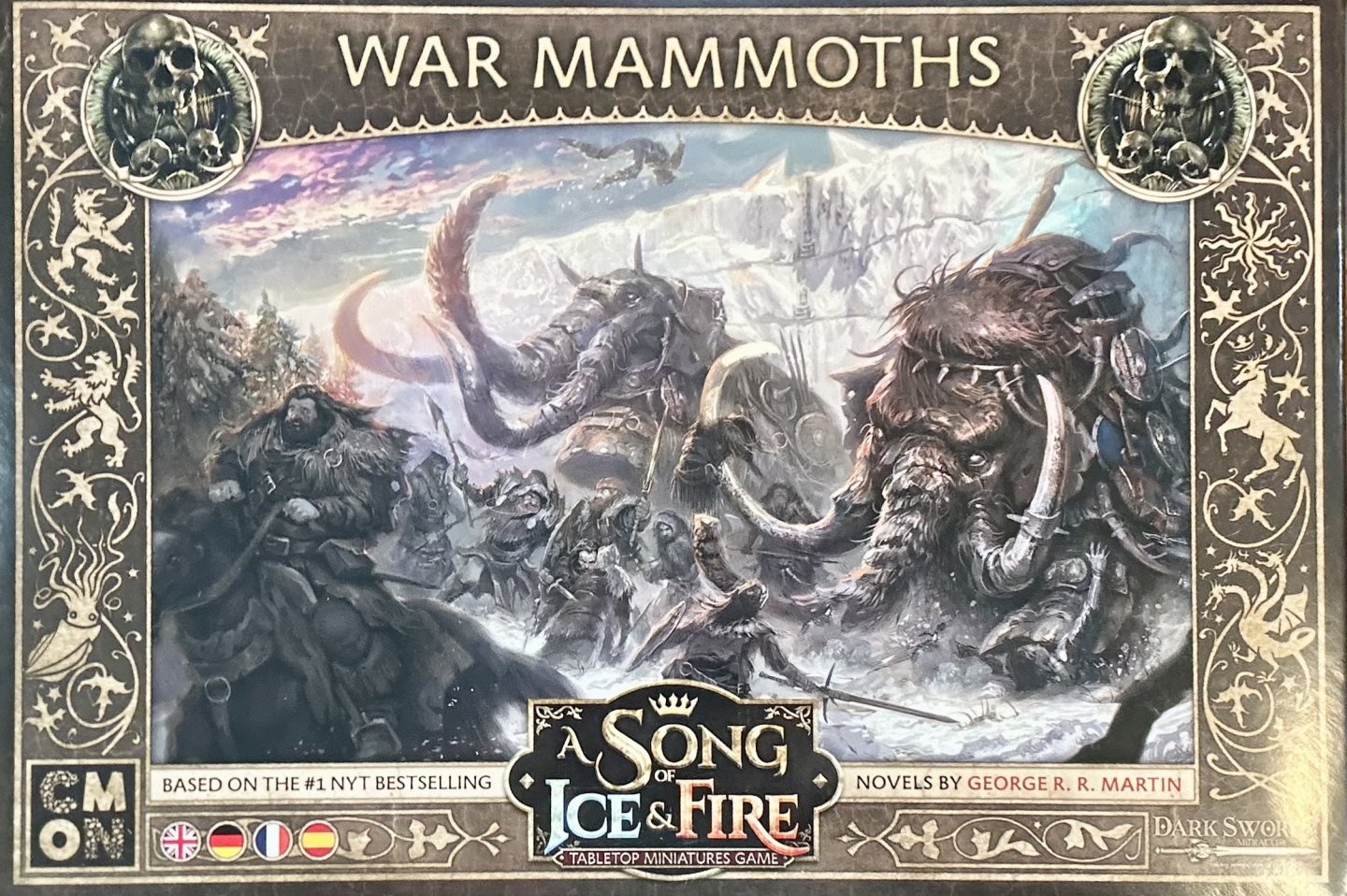

I am painting a box of two War Mammoths in 28mm from the game A Song of Fire and Ice (Game of Thrones) by Cool Mini Or Not (CMON). I learned to paint by painting miniatures belonging to the Imperial Guard from Warhammer 40K many years ago. I have not gamed in well over twenty years but I still thoroughly enjoy miniature painting, including an army or two (or three) every now and again. The miniatures are resin and of pretty good quality (most of CMON’s miniatures are of incredible quality). I cut the mammoths off their bases (these are ready to field if you don’t want to paint them). I am currently in the process of cleaning them up and filling gaps. They may go back on their bases with some extras added (like rocks and logs, read twigs), or they may get fancy wooden bases since these are destined for my curio cabinet. I haven’t decided yet.

-

Dream of building full size to reality of building models

GrandpaPhil replied to J Snyder's topic in New member Introductions

Welcome! -

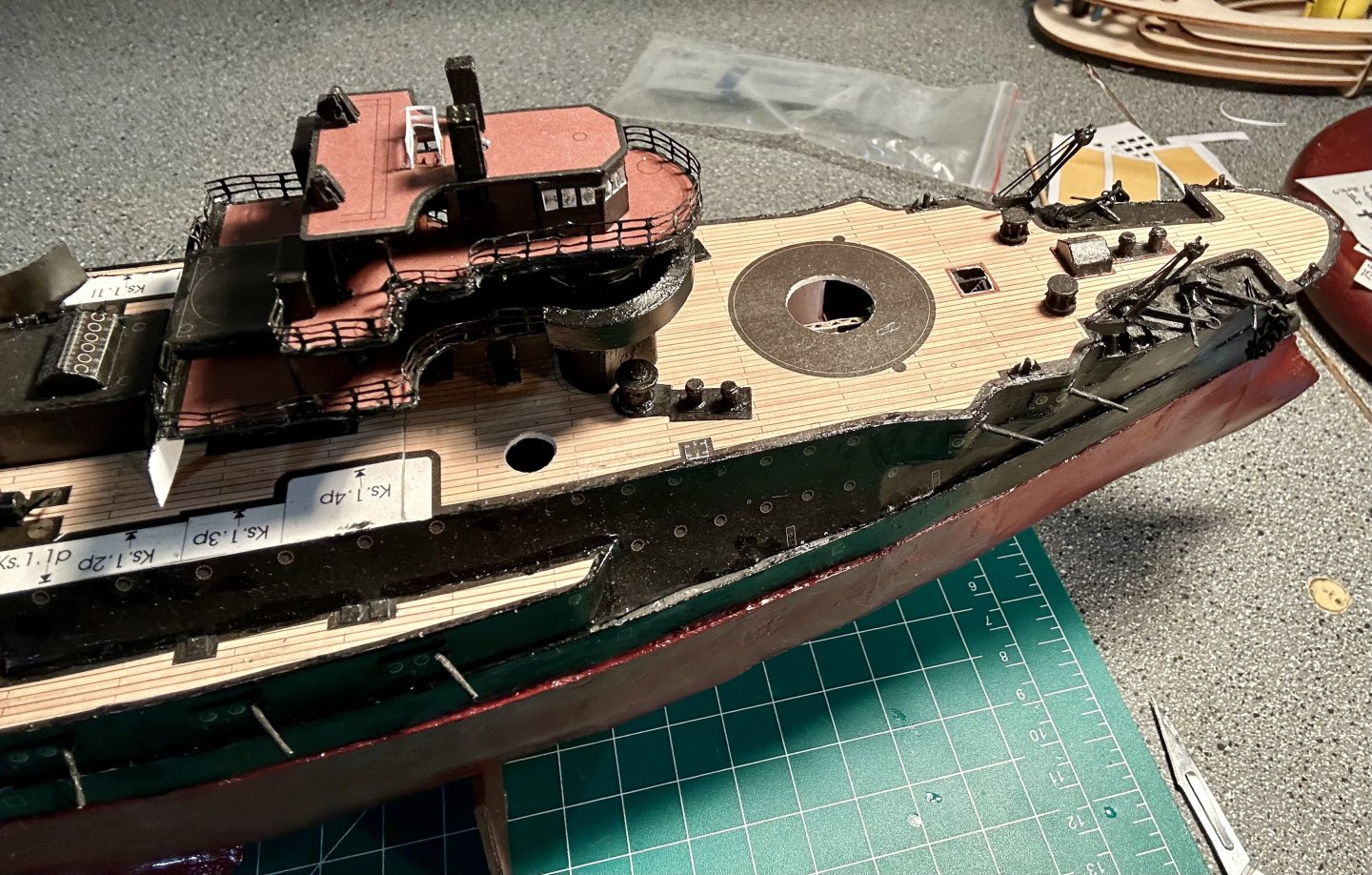

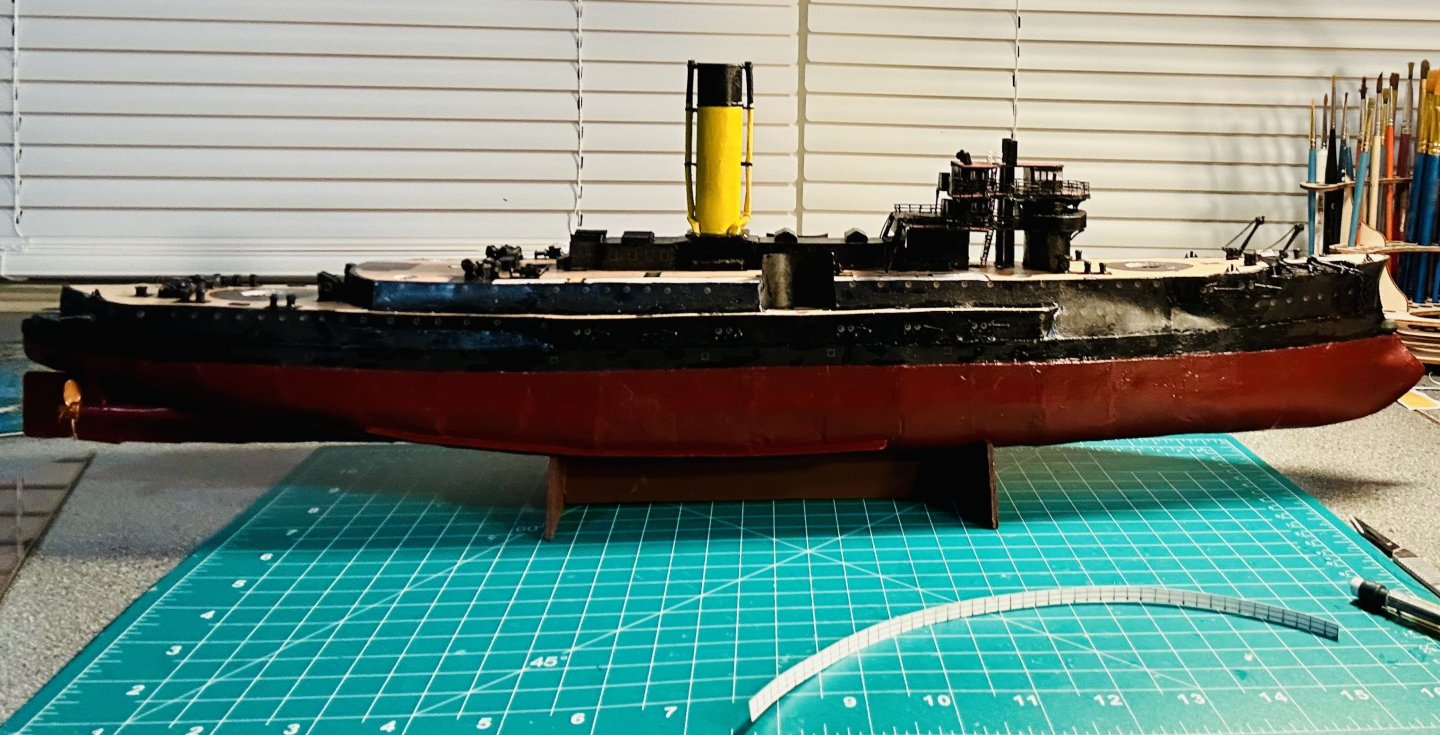

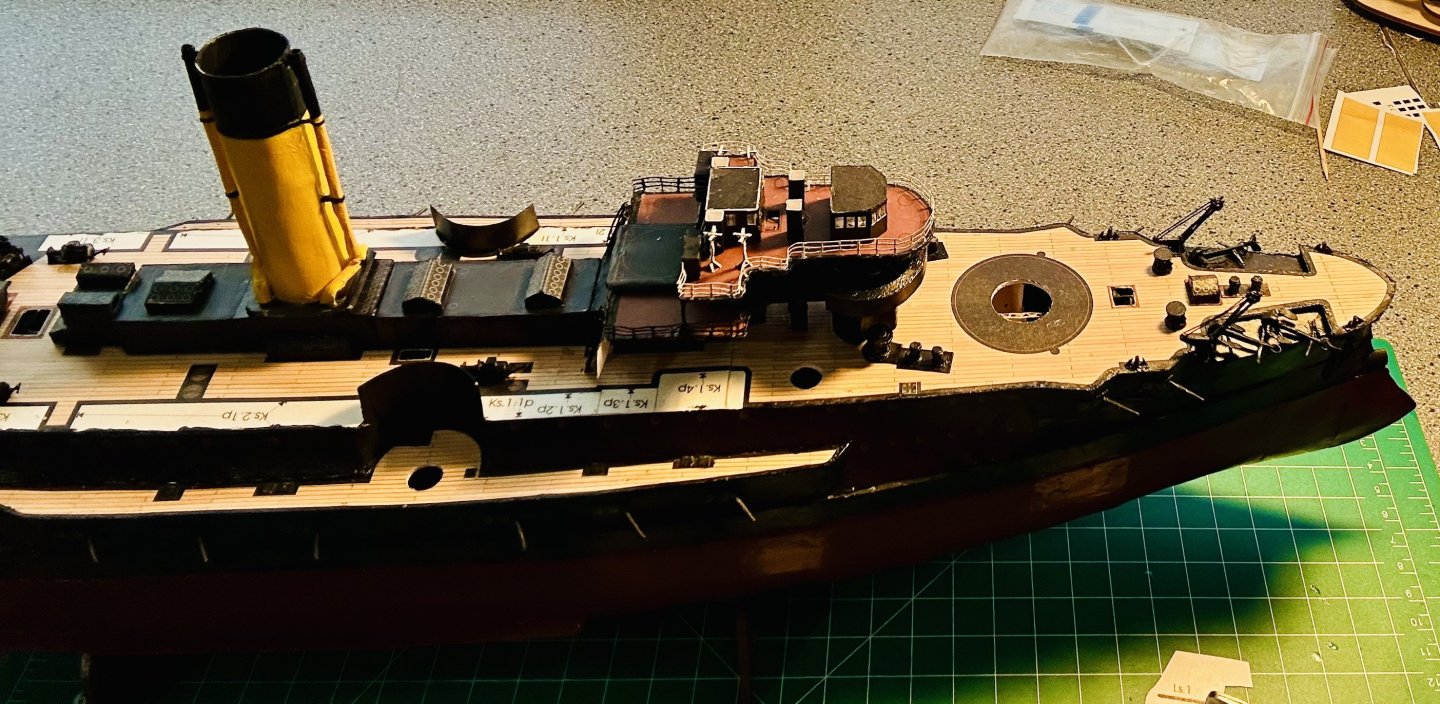

I’m trying it with printer thickness card, the 110 lb sort from Walmart for the upper deck of the bow tower on the superstructure. It worked well for the railings for the railings around the ladder well on the upper deck. It gave them more rigidity and made the first railings easier to install. I have used steel pins for railing posts, with string tied for the railings themselves. 1/200 railings in photo etch are available on EBay too for reasonable prices. I just like to make parts myself. That’s the fun part for me. It’s why I tend to predominantly build card kits or build from plans. Speaking of which, here is my progress for the day, with the next railing awaiting the second coat of sealant prior to shaping. The forward tower is almost complete.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

I would go with plywood bulkheads and use basswood for the rest. I go through a lot of basswood. If you’re painting anyways, the type of wood used is less critical from a visual standpoint. Bass is relatively easy to work, cheap, and holds a fair amount of detail. For carvings I have been using cedar grilling planks and old Jenga blocks due to their ability to hold details. I used them both on my model of the Revenge.

-

Welcome!

-

Mark, Thank you very much! I am going to adjust my methodology and try to use my basic printer card stock and make the next set of railings from that, and make them a little more durable. Glen, Thank you very much! I’m learning quickly on this one! Steve, Thank you very much! To tell the truth, this hobby is how I learned and developed patience over the years. Hopefully those 200 belaying pins will become thousands as the years progress and I build more ships. The top deck of the forward tower is on: This one just has a ladder to the next deck down, a couple winches, a couple of what I assume are deck lockers and a bunch of railings. That is except for the 47mm guns and search lights that I will make in mass once the rest of the superstructure is built up.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Roel, Thank you very much! The railings and the support structure for the top decks are now in place and awaiting some paint work:

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Here is a current picture of my Prince de Neufchatel along with the type of sealant used (or equivalent). I built it six years ago. The hull has aged well.

- 20 replies

-

- Indefatigable

- copper plates

-

(and 1 more)

Tagged with:

-

I used my standard sealer, a basic acrylic sealant for my last two coppered hulls. It works beautifully and both hulls have aged well and developed a patina.

- 20 replies

-

- Indefatigable

- copper plates

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.