GrandpaPhil

NRG Member-

Posts

6,161 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

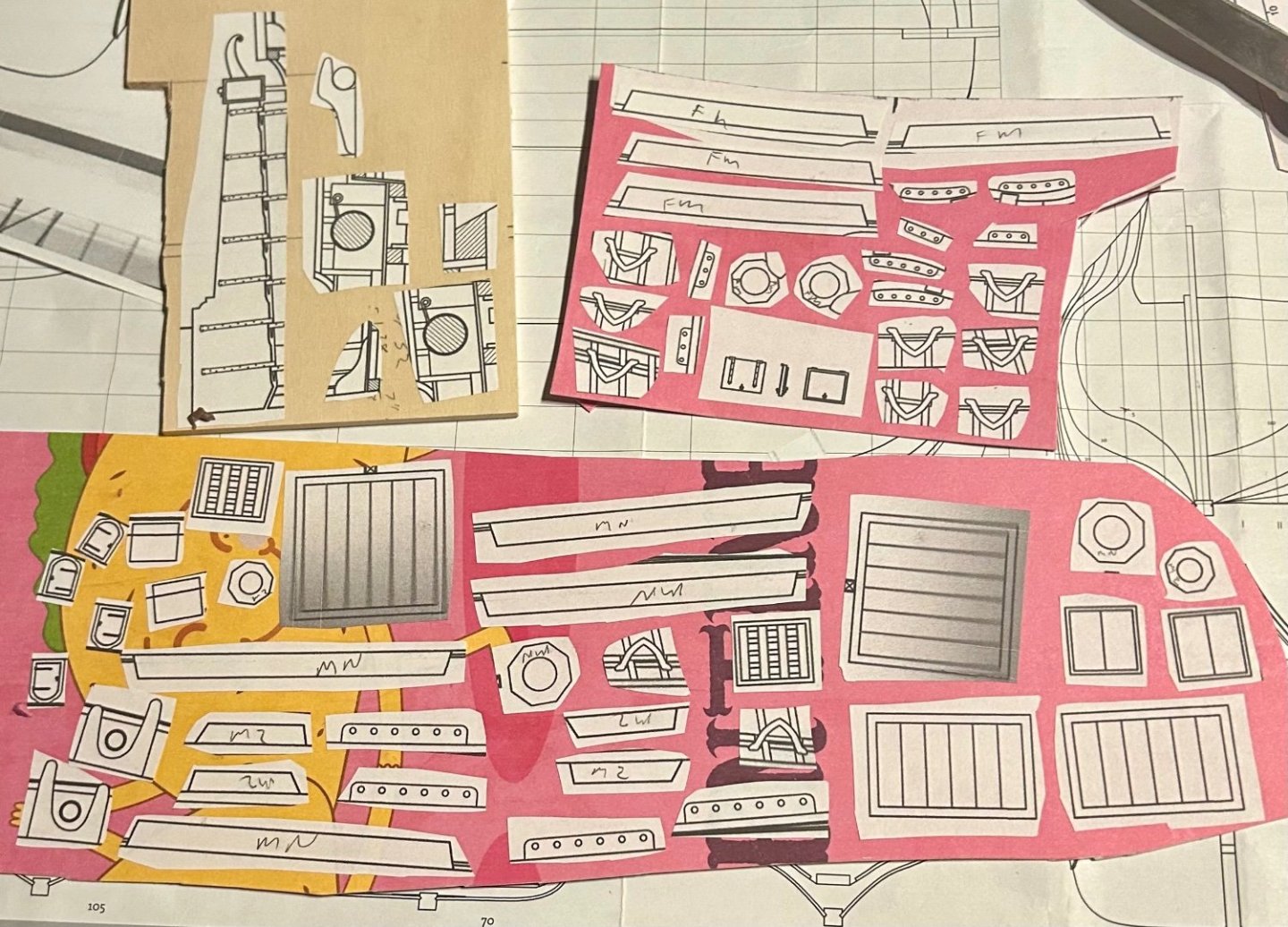

I have pulp board coming tomorrow, so I ripped off the initial hull covering and decided to focus on prepping fittings. Here are most of them, with the notable exception of bitts, belaying pins and the windlass: The rest will be made of strip wood. Most of the above will be two layers thick. I’ll cover the hull when I get my pulp board.

-

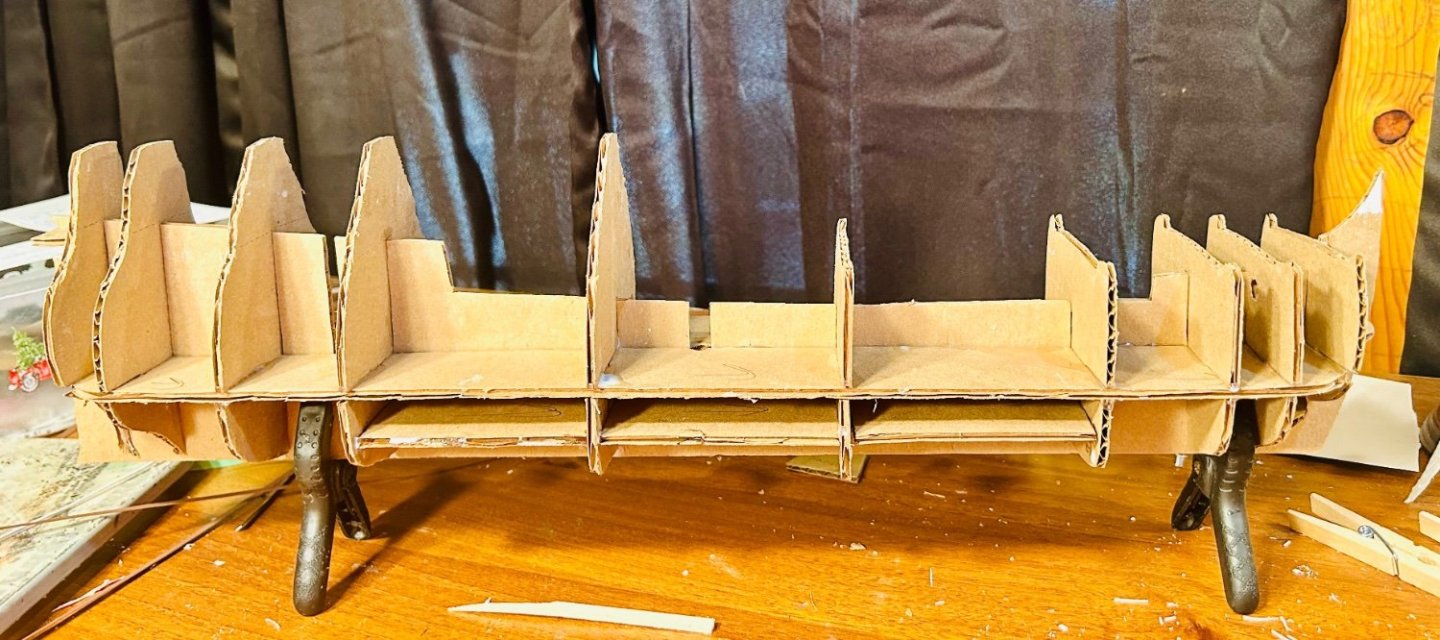

Lol! The pictures make everything look slightly crooked even to me! I had to double check the model after taking them! The hull is now faired and the rabbet pieces are on: Esther is ready for planking now!

-

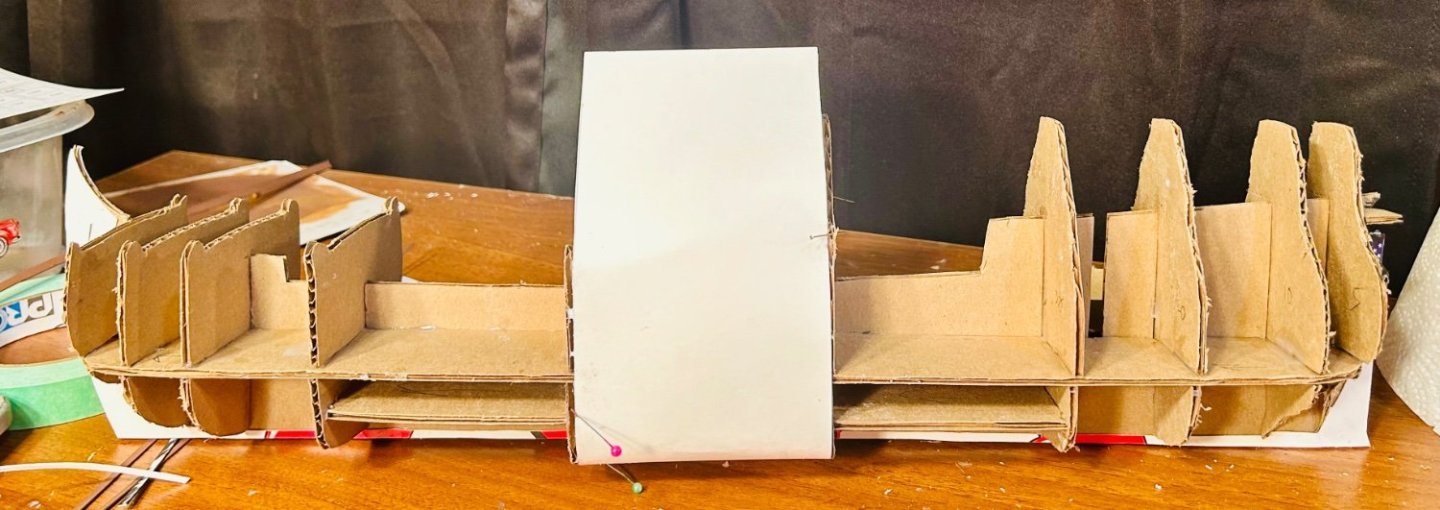

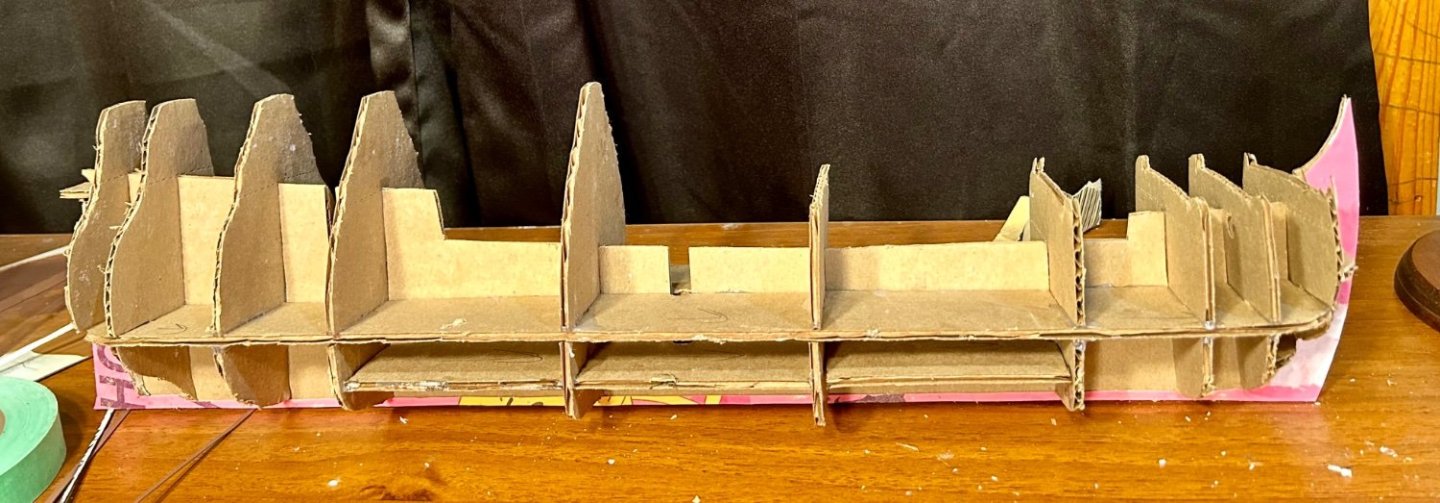

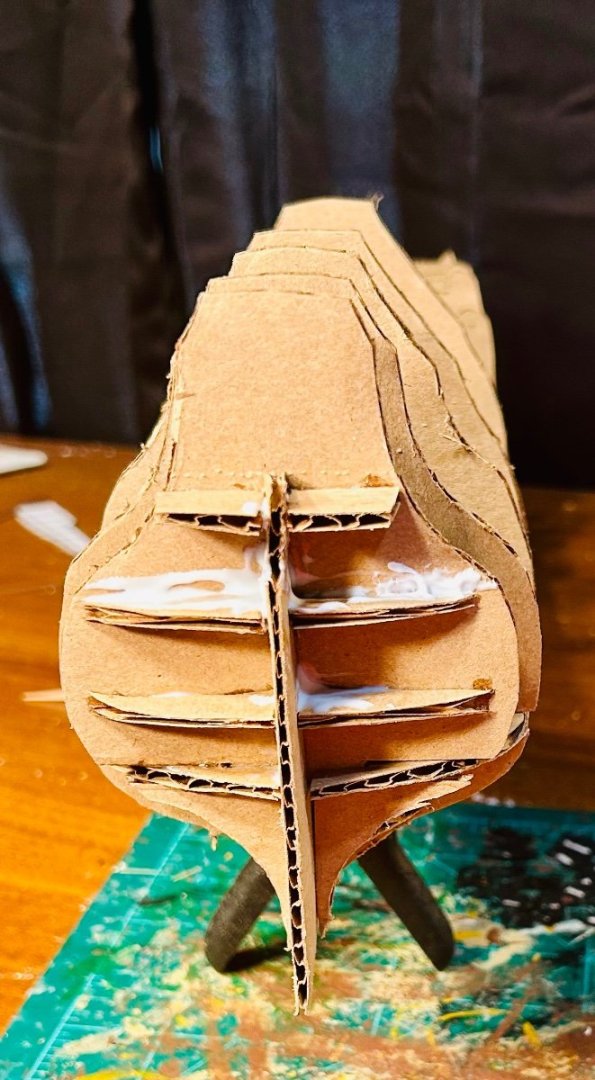

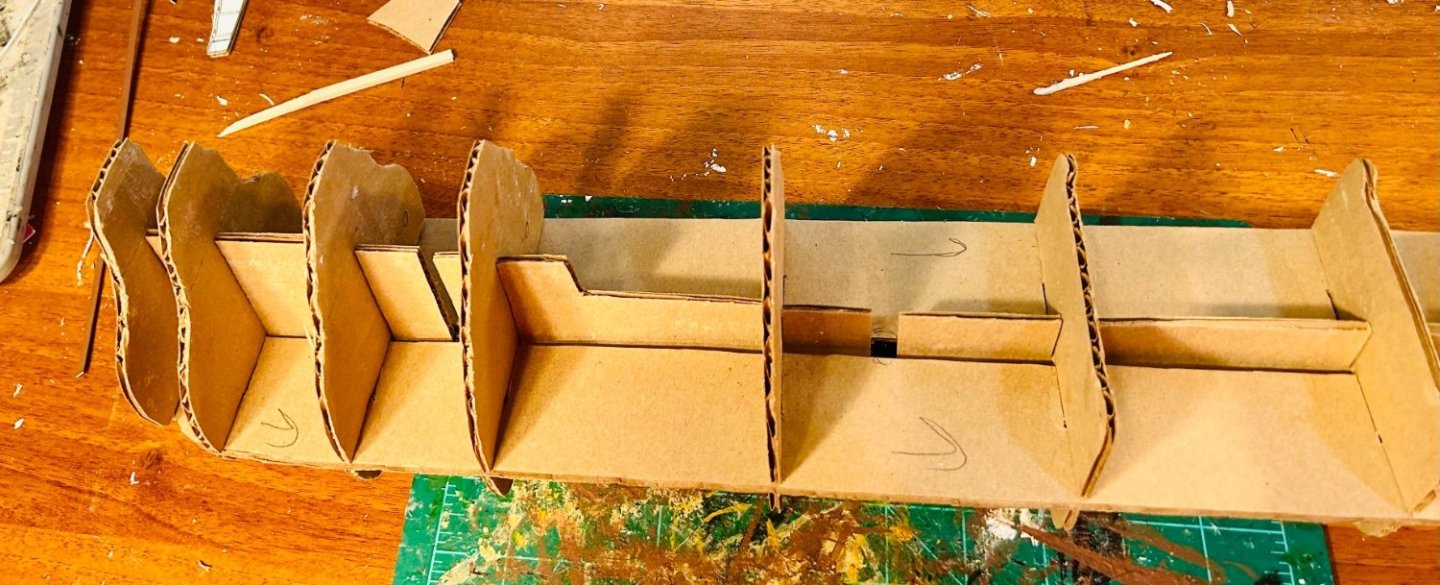

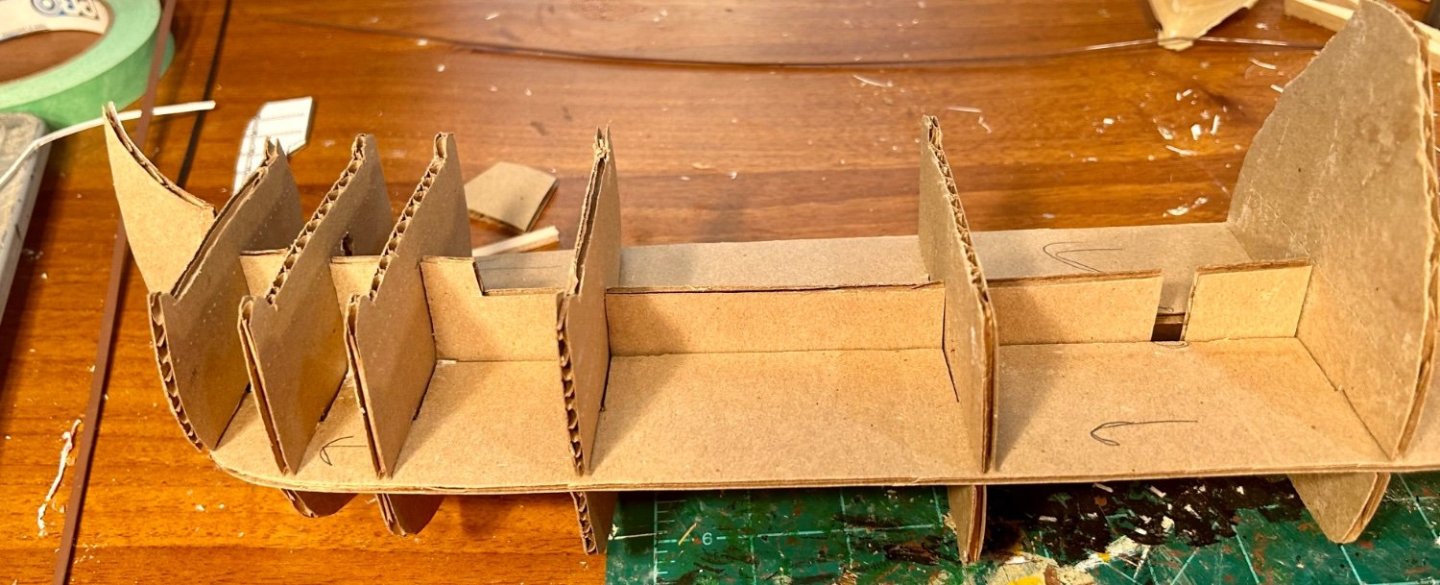

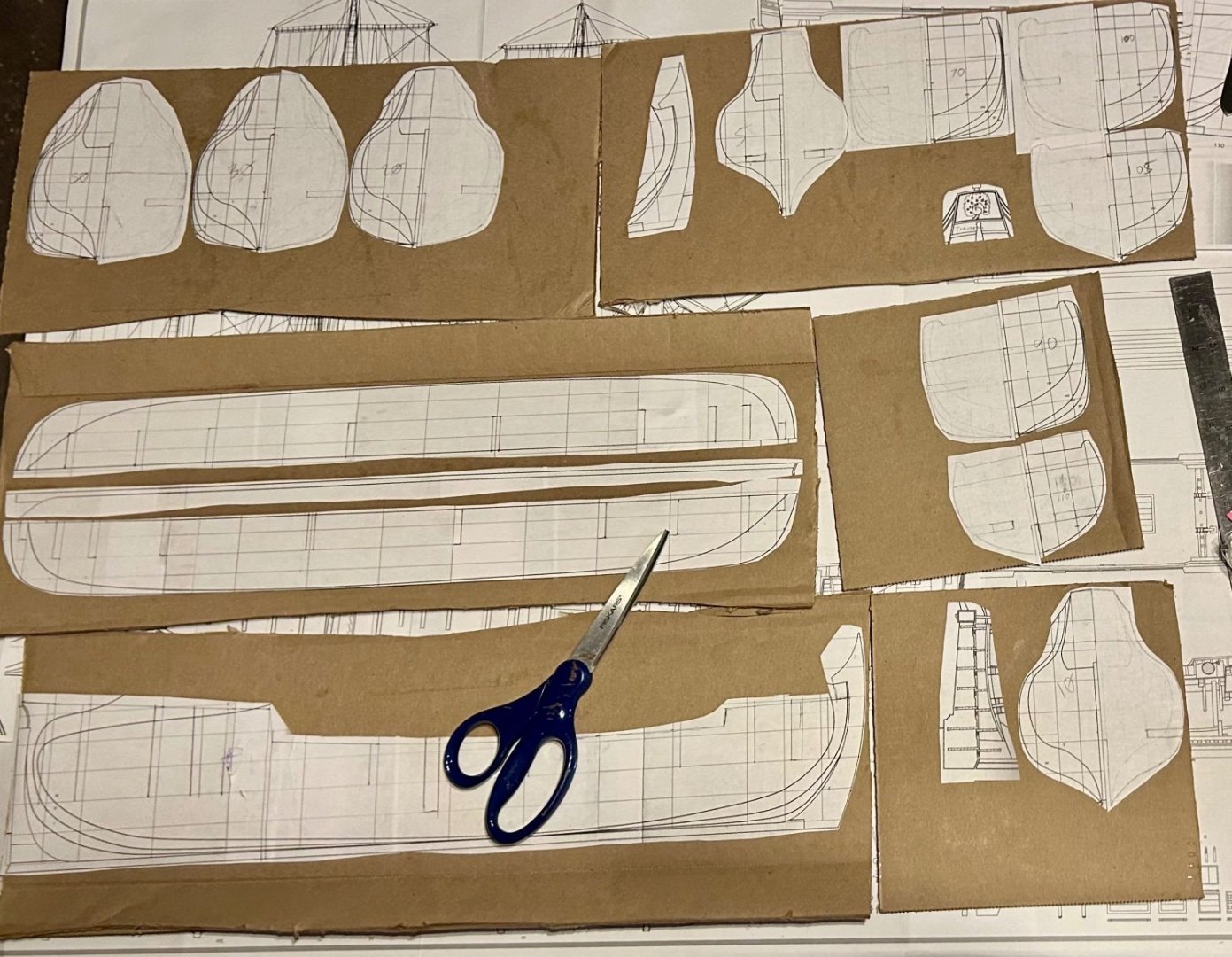

Ab, Thank you very much! I have used corrugated cardboard twice, once for my model of the Hannah and once with my model of the Solferino. It works well for framing, but it’s the cardboard equivalent of plywood for me. There will not be any corrugated cardboard visible once I get the outside covering on the model. I added reinforcing pieces to the middle sections: I added formers to both the bow and stern to facilitate fairing the hull and shaping the end planking: Everything is a lot more square than it appears in the pictures.

-

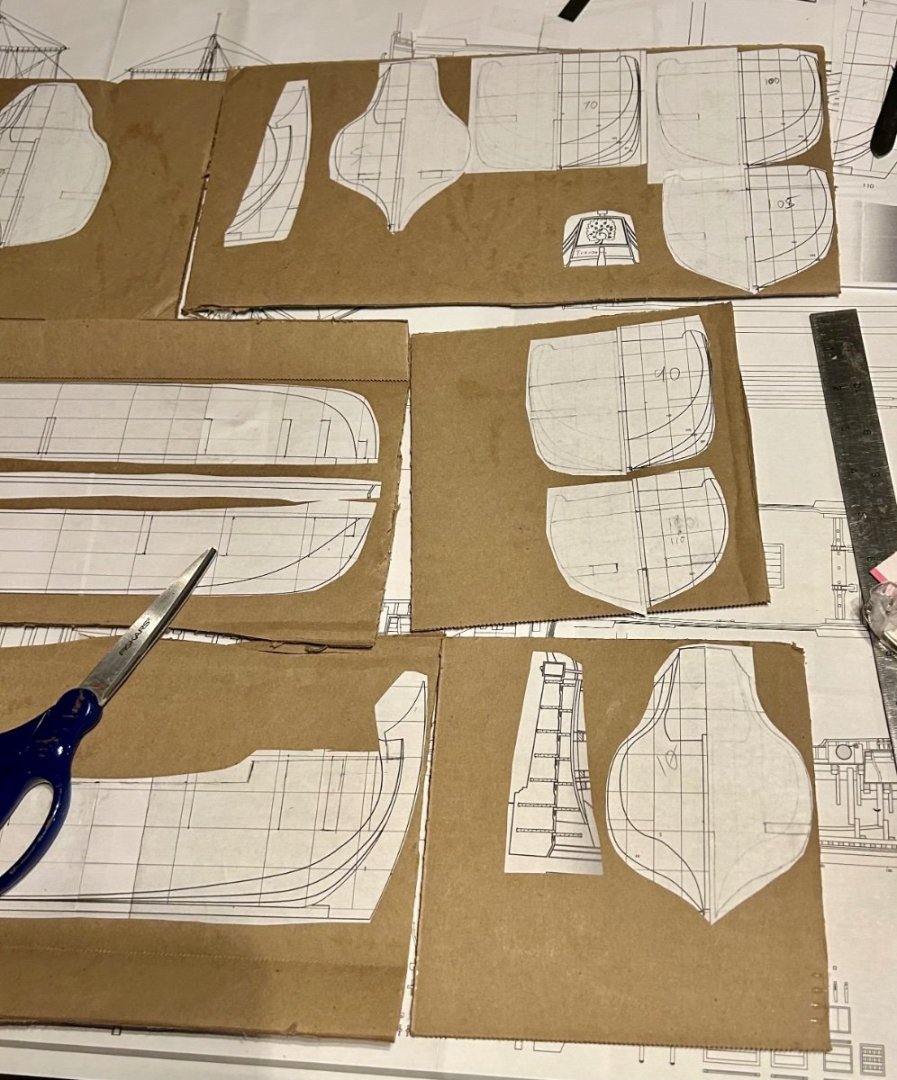

Patrick, Thank you very much! There’s not really too much to this one. The most difficult part is going to be the really bluff bow and stern. I’m basically trying to emulate Seahorse’s design with the side braces. I’m going to add additional pieces to the bow and stern to help the “planking” take shape. This one will have the vertical covering like my Prince de Neufchatel and Hannah, with the second layer being contact paper. The bulkheads are cut out and test fitted: The dry fit went well. For the most part everything is square. There are a couple of spots that need adjusting, but overall everything looks pretty good. I’ll adjust those and then plan on gluing. Next up will be keel and stem/stern post pieces to act as a rabbet. Along the way, I’ll make the former pieces for the bow and stern. The main covering will be hought-board.

-

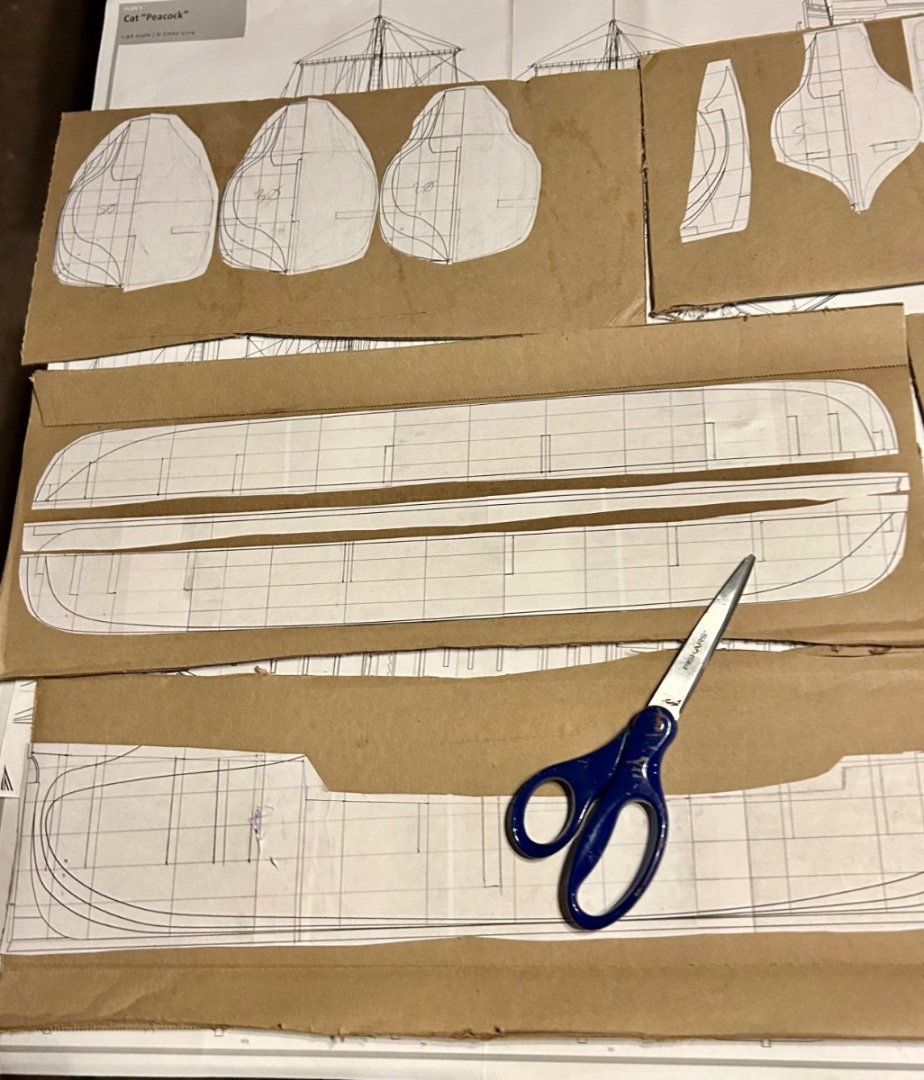

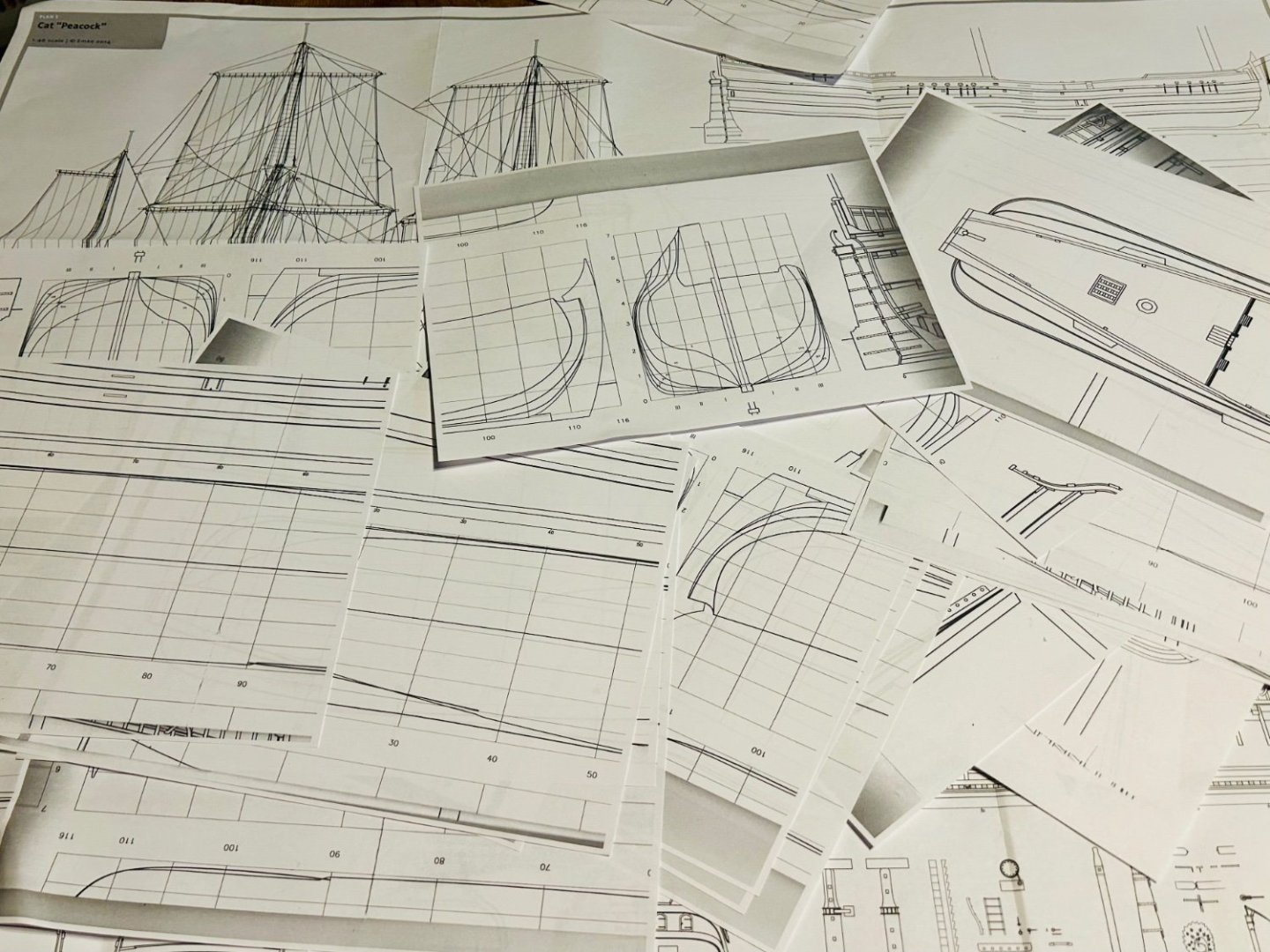

My Admiral had me order myself Ab Hoving’s book “17th Century Dutch Merchant Ships” for Christmas this year, as part of wish list. It comes with plans for 10 different types of ships. The cat stuck out to me when I first read the book. Cats were a type of wooden trade ship that plied the Baltic Sea. They had very shallow draft and would never win a beauty contest. They kind of remind me of a 17th Century version of a Mack truck. I have taken the initial steps and scaled everything up to 1/64 scale from 1/96th scale. That random looking pile of paper will soon be the framework of a hull. I’m using a giant cardboard box that I got from something we bought as my starter material. It is corrugated, which is a nuisance to cut, but it works quite well.

-

Welcome!

-

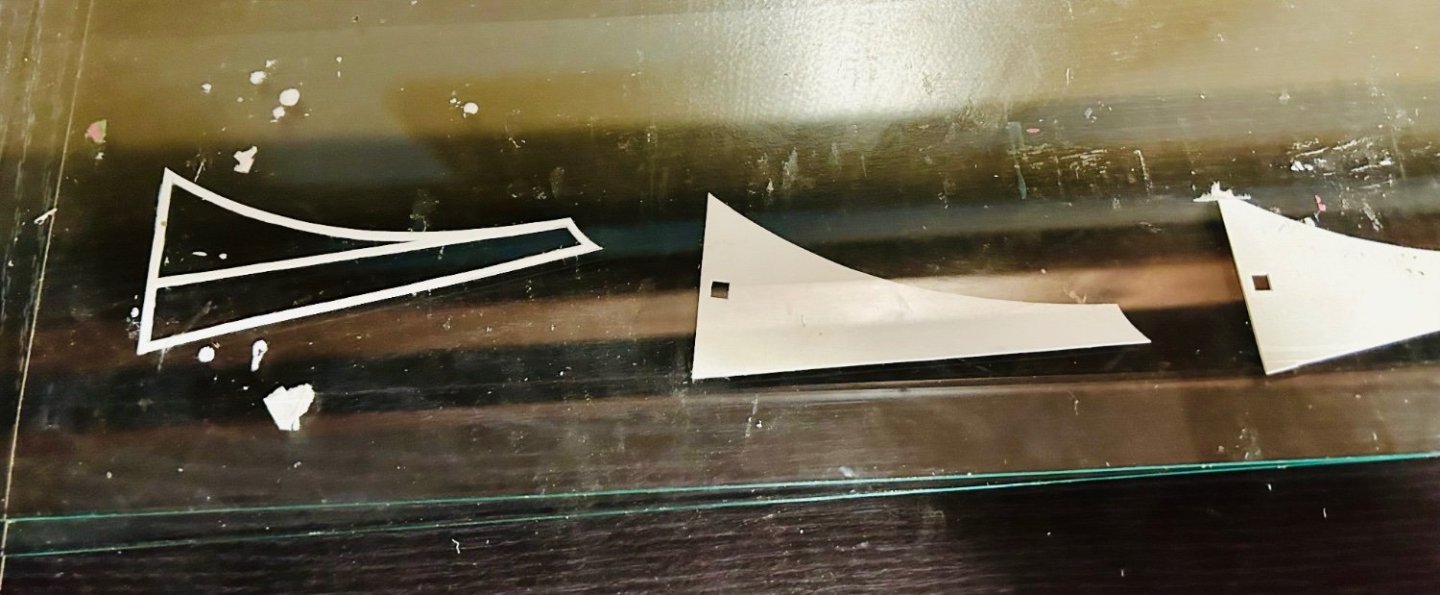

Here is the head grating on the model: With a side on shot of the model: The first scrollwork piece is cut out and glued to a carving board for final carving: It took six hours of very minute and precise cutting/carving to cut that out. It will be well worth the extra effort when it is finished and installed!

-

INTRODUCTION FROM A NEW MEMBER.....

GrandpaPhil replied to JOHN GARGANI's topic in Plastic model kits

Welcome! -

That looks really good! Very neat solution with the book repair tape! I will have to remember that!

-

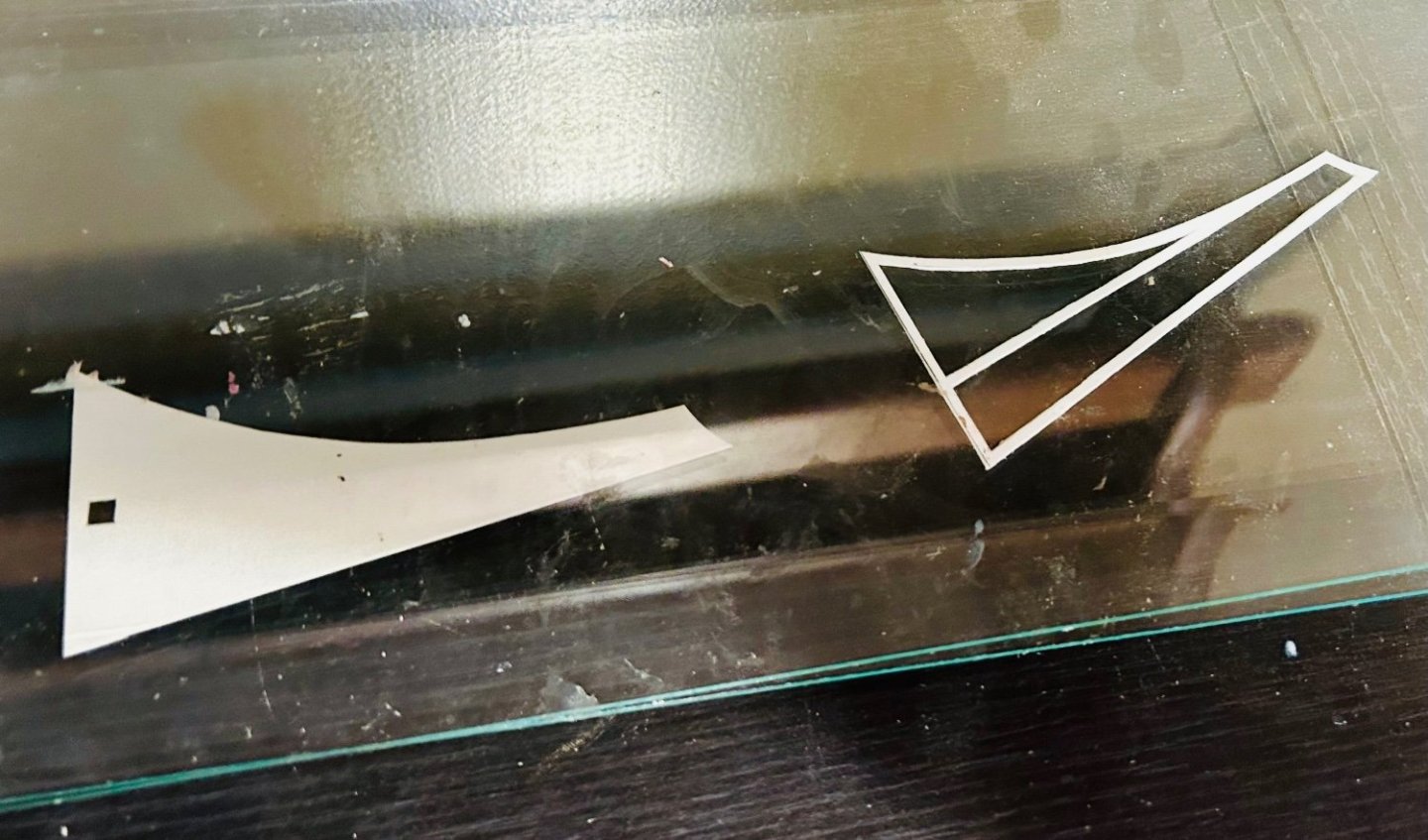

Thank you all very much for all the “likes” and for stopping by! The head grating is on and drying: The head bulwarks are drying under glass: Next up is to carve the scrollwork: Then to paint and assemble it all. Sometime in there I need to make a couple of seats of ease. It is also time to make belaying pins. I believe that I will carve them from toothpicks using a scalpel.

-

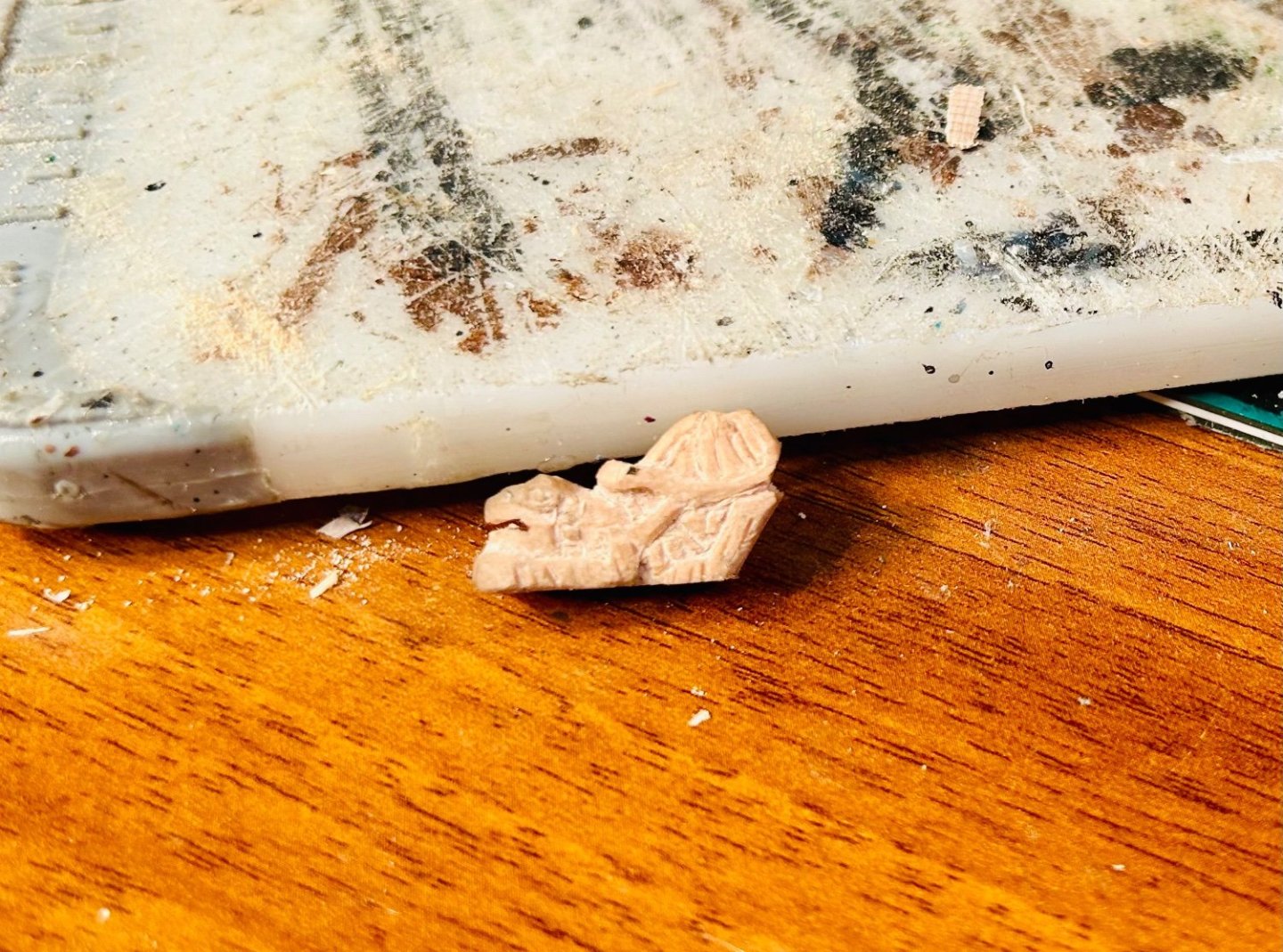

The figurehead is carved: That wooden block worked really well. It took me about 5-6 hours to carve that. It was slow going because it was definitely some kind of hardwood, but it never once split out or broke, even for small details. That entire piece is 7/8” (22mm) long. It’s not perfect, but I am happy with it.

-

Jeff, Thank you very much! This build did start out rough, lol. This was a very spur of the moment build and I’ve been testing out a lot of new techniques. I’ve been enjoying this build a lot. And, I got sidetracked again and decided to make the figurehead since I need to do more carving for the head, anyway: This is out of a wooden puzzle piece. I have a bin (a small plastic tote box) full of Jenga blocks and those wood puzzle pieces that I got at yard sales for crafts and to use as carving blocks. The wood is relatively dense and holds detail okay. This is the third figurehead that I have carved.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.