-

Posts

1,588 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hollowneck

-

I built this model years ago. I believe Chris designed this kit for Amati's "Victory" range somewhere in the early 2000's, perhaps even late 90's. These castings weren't terrible and, in fact, considerably better than some of the other offerings from unnamed Italian kit manufacturers. One of the main issues with these alloy castings is their ductility; very difficult to bend. I've heard that one should heat the metal, then with gloves gently bend them to suit. Silly process, but there was no alternative ...back in the day. Comparatively and more contemporary, resin rocks! - whether cast or 3D printed.

-

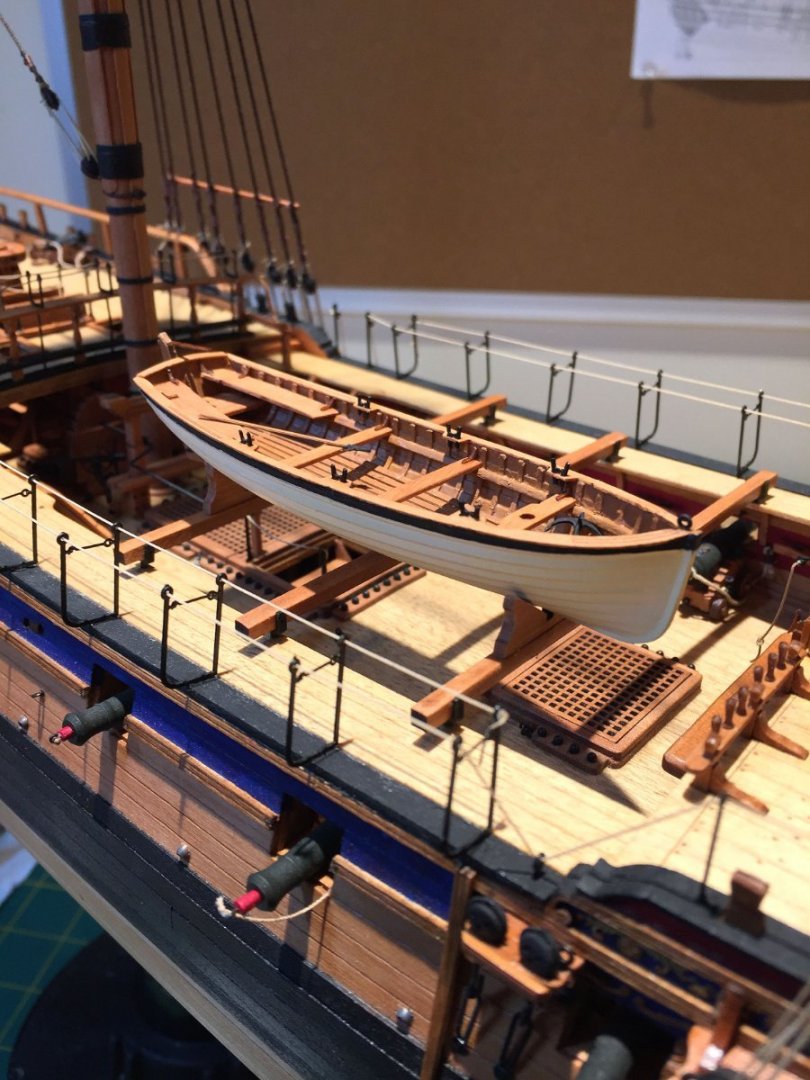

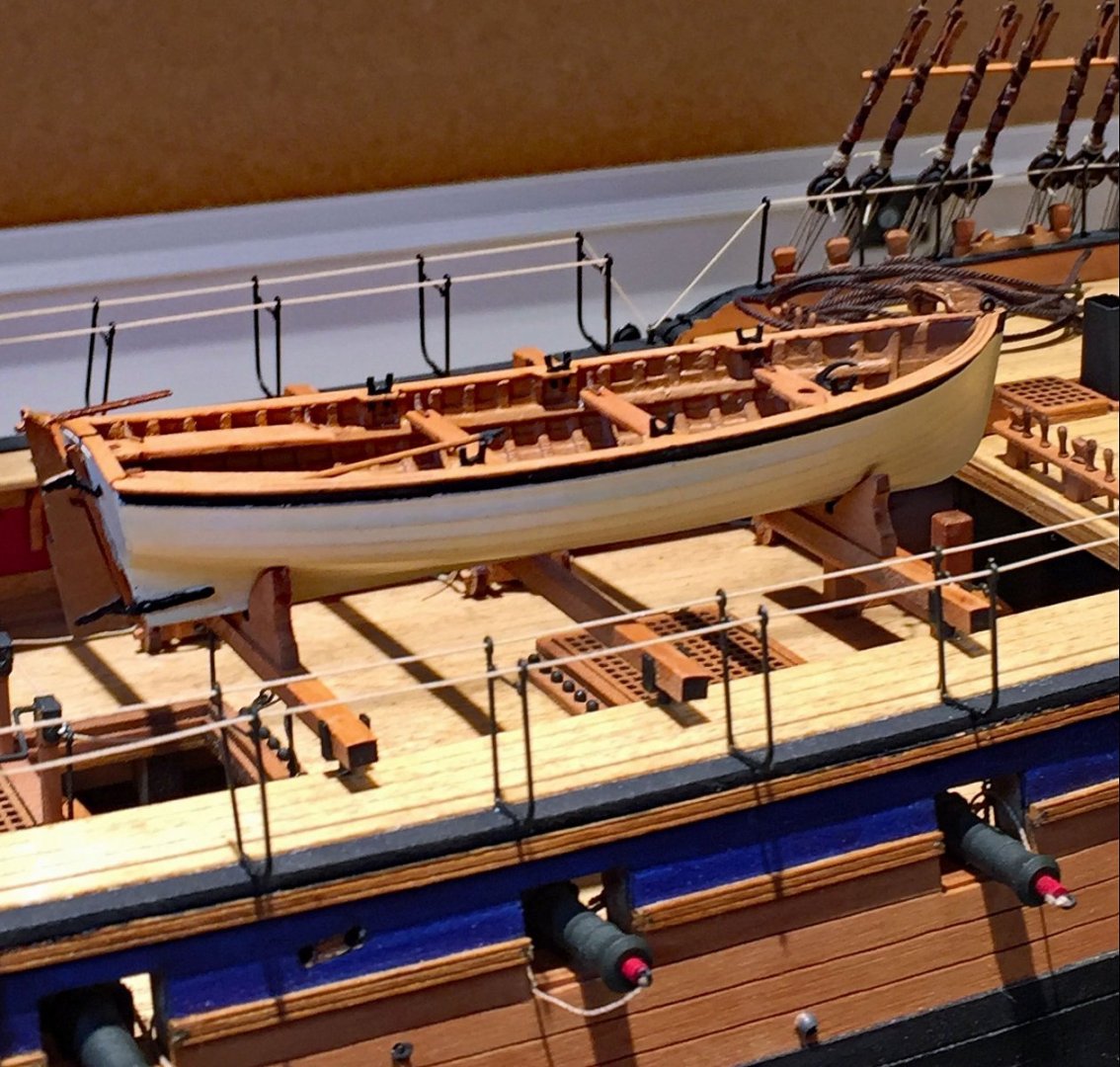

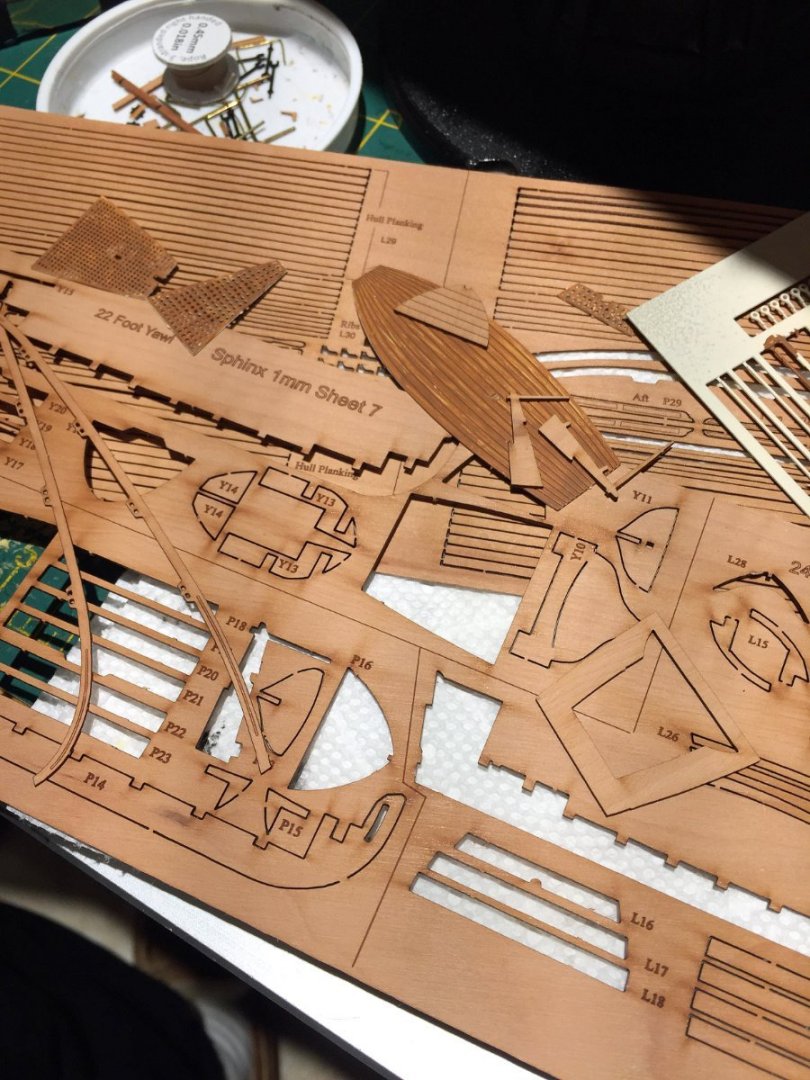

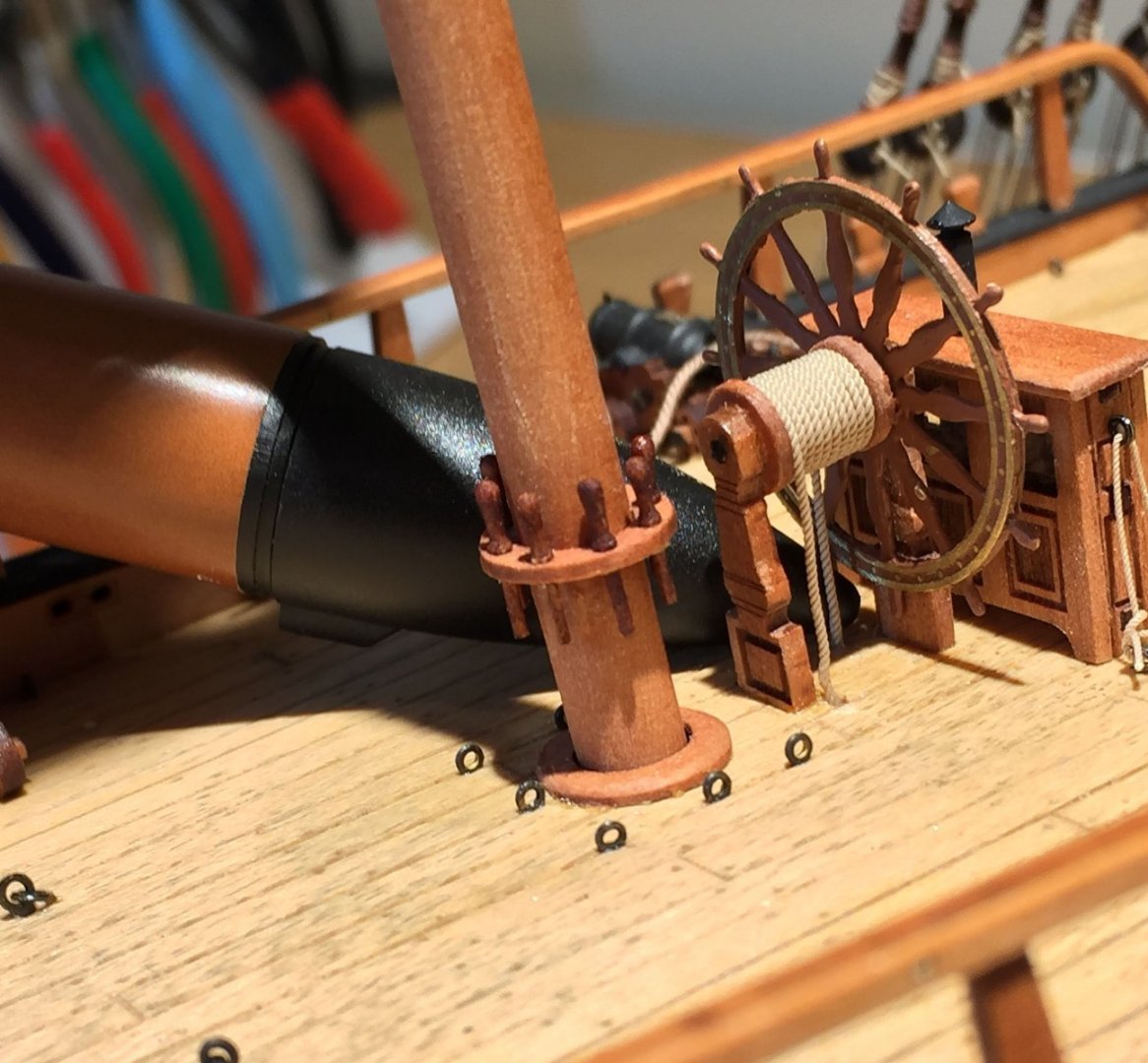

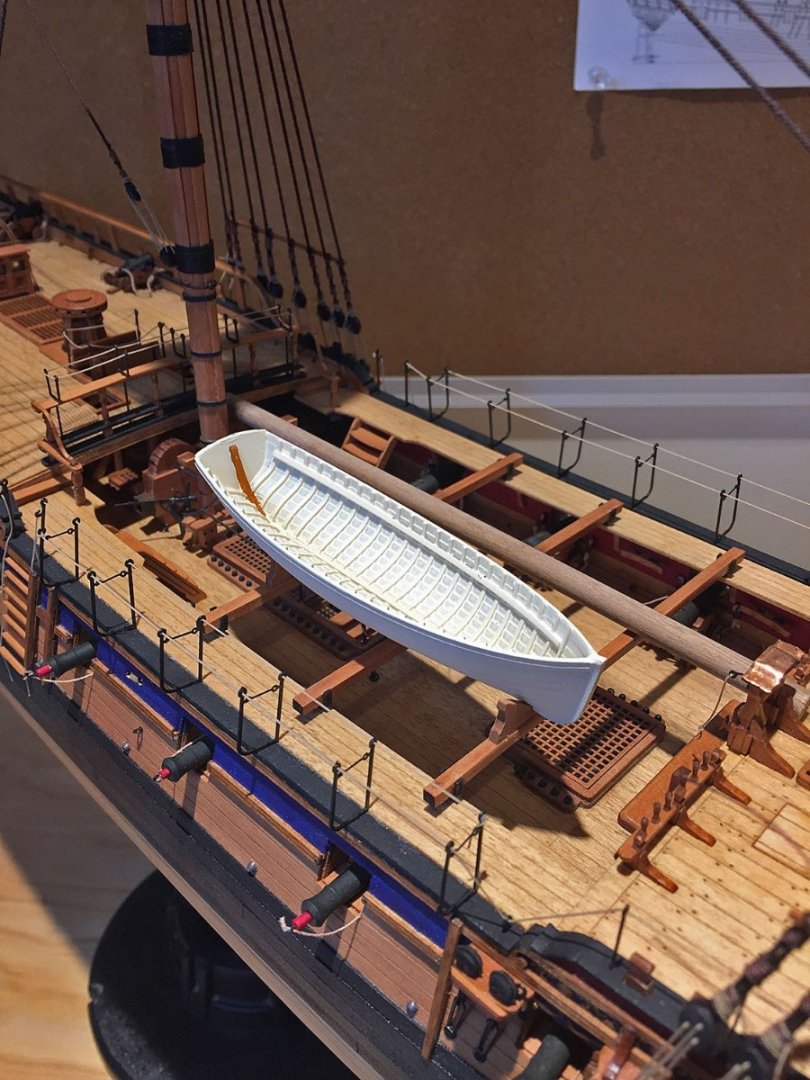

A holiday from rigging. Building a Better Boat. First, a little touch-up on the belaying pins on the Mizzen. The ProMarker tip works a treat for turning these pins into nice dark wood. The pen looks HUGE but the tip is quite small, pointed. The other end of this marker has the standard "Sharpie" point. The color is the same pen from my previous post. Captain Pennypincher inspecting the crew's paint job on his ship's only way to get from ship-to-shore, and vice-versa. The Sphinx kit has components for building three ship's boats. I'm only mounting one as my model is going to feature sails and attendant rigging and I didn't want to cover-up all the nice detail on the midships and weather decks. It's still amazes me when these 800% enlargement close-ups are transferred to my computer-🥵 Note: the tiny P/E oarlocks are reversed from the photos shown in the instruction manual; I believe these were intended to be mounted in the manner I've shown here, two pieces, facing inward to form a metal "U" in which the oar would rest. The brass P/E pieces to form these are a quite clever way to depict these miniscule details, and crucial to present an accurate representation of a ship's boat. "The Devil's in the details, right Captain 'P'"? Here is a partial collection of the bits n' pieces supplied in the kit for making three ships boats. I scrounged parts from these thin pear patterns as well as some of the brass P/E. There were plenty of choices that I modified to make my boat look like a PinnacleLaunchYa'wl. That's a hybrid. Your mileage may vary. I was very pleased to get one of Chris' new 3D resin cast yawls (24') with the amazing clinker and internal rib details. The challenge for me was fitting-out something credible from the kit's other components that were designed to make the boat's from a combo of pear and brass P/E. I'm certain most Sphinx builders will make all three boats from the kit when they present her as a "dockyard" model, san's masting & rigging. I need to make a reasonable length of coiled rope and attach it to the small anchor as well as detail a full set of oars (6, provided as nicely-etched pear patterns in the kit). These will rest inside the boat, across the thwarts. Of course, the boat will be lashed down to the skids. A view from the fore top. Grappling hook askew, anchor unfinished. I simulated the interior color of the boat to match the predominant color(s) of the other pear wood for the model. This was a combo of two acrylic colors which got me close to what I envisioned the boat's wood would look like. The "white" clinker hull of the boat is actually a creamy, tallow hue, not "white." The Liquitex acrylic primer spray (Titanium White) worked great for a second finish coat; the same color on the interior gave me a good primer base to then add the "wood" color to the resin and brass P/E. Another view of Camilla's only boat: a PinnaceLaunchYa'wl. .. made in Alabama...a rediscovered, 18th-century technology related to how a Russian Missile Cruiser can transform into a submarine (now resting on the bottom of the Black Sea)... And, one more, lower angle. Now, after some tweaking of a rope coil and fashioning a set of oars (provided in the kit)...I'm... ...back to rigging. Thanks for looking-in after my respite from this seemingly endless endeavor!

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

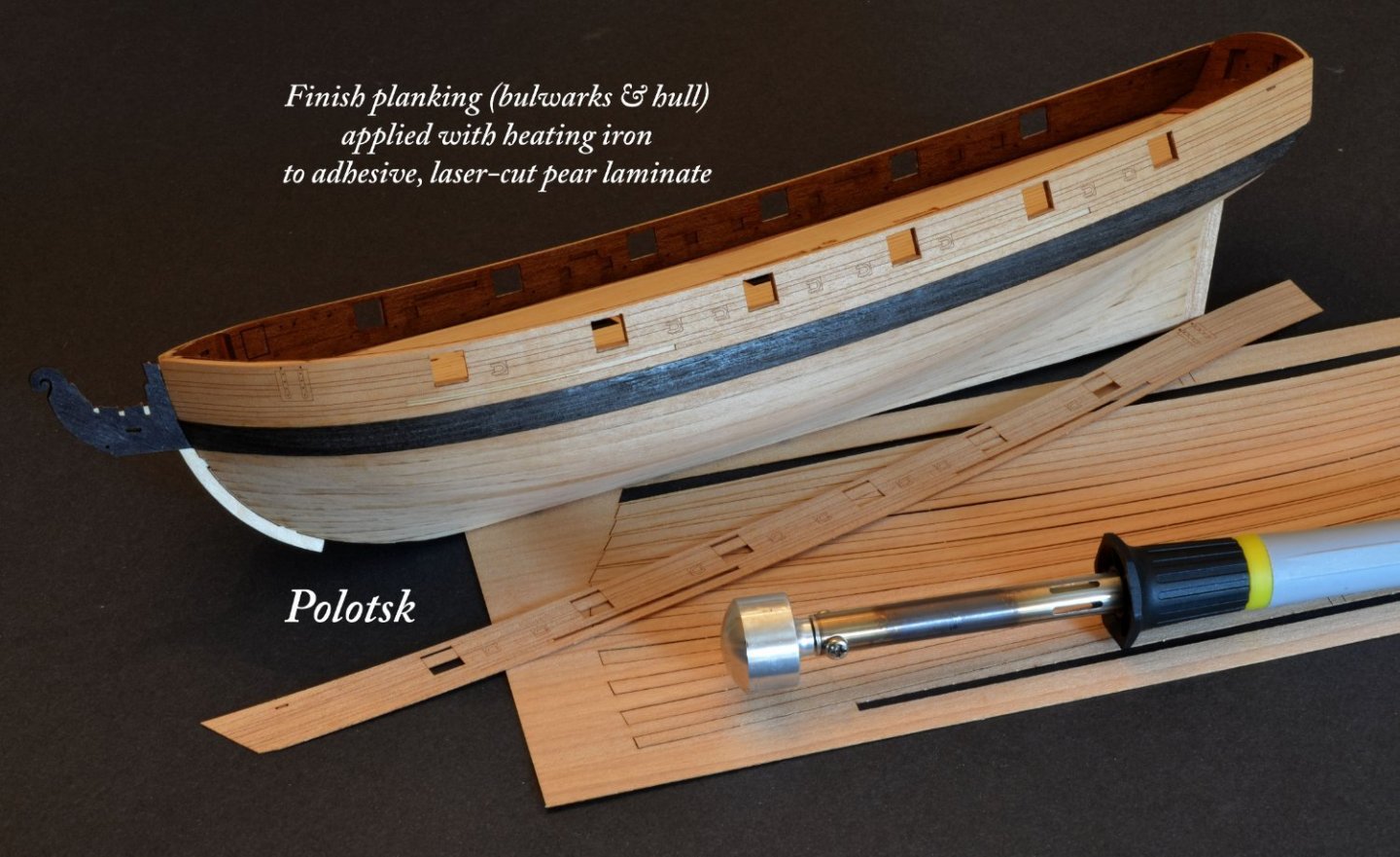

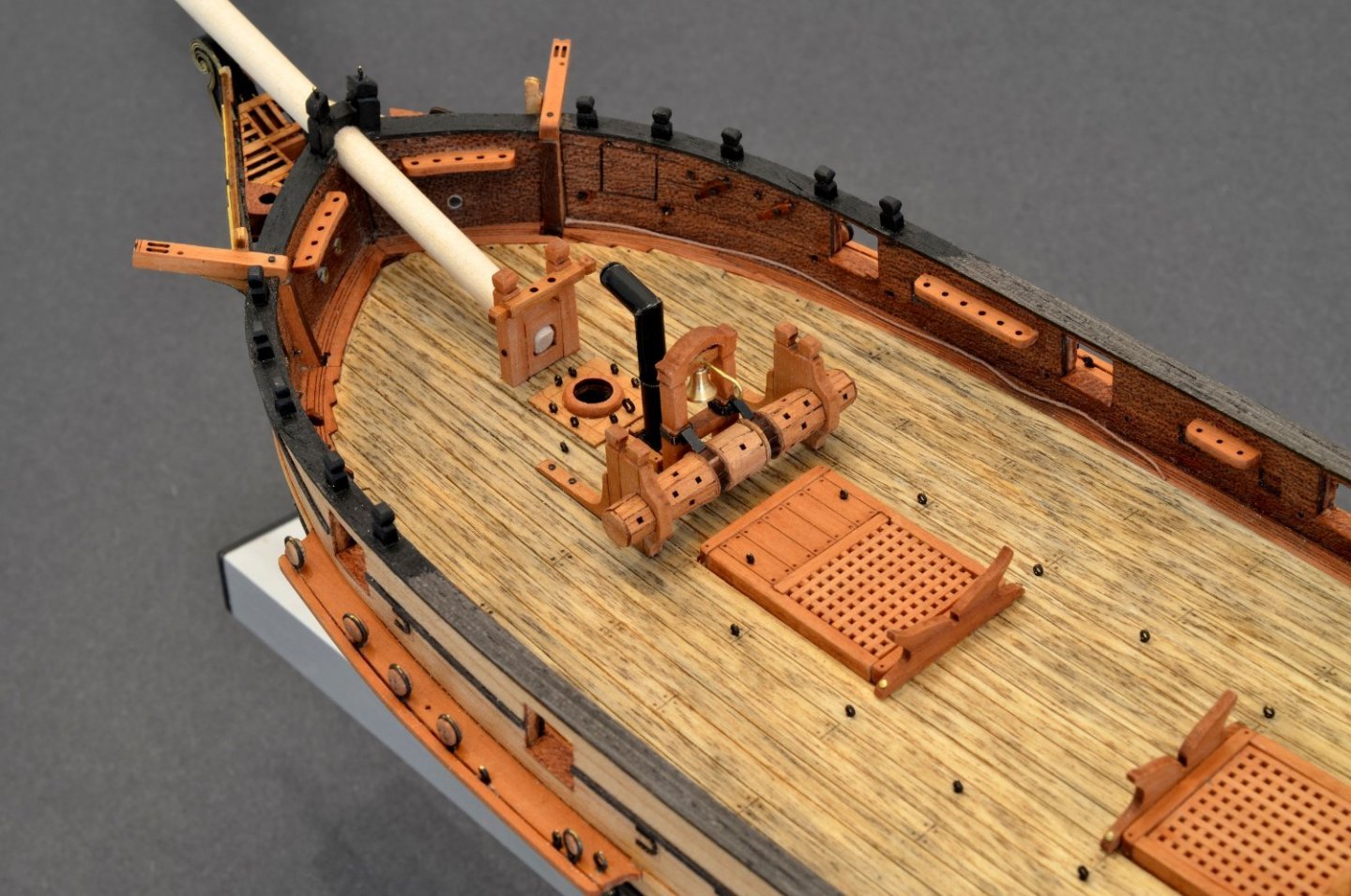

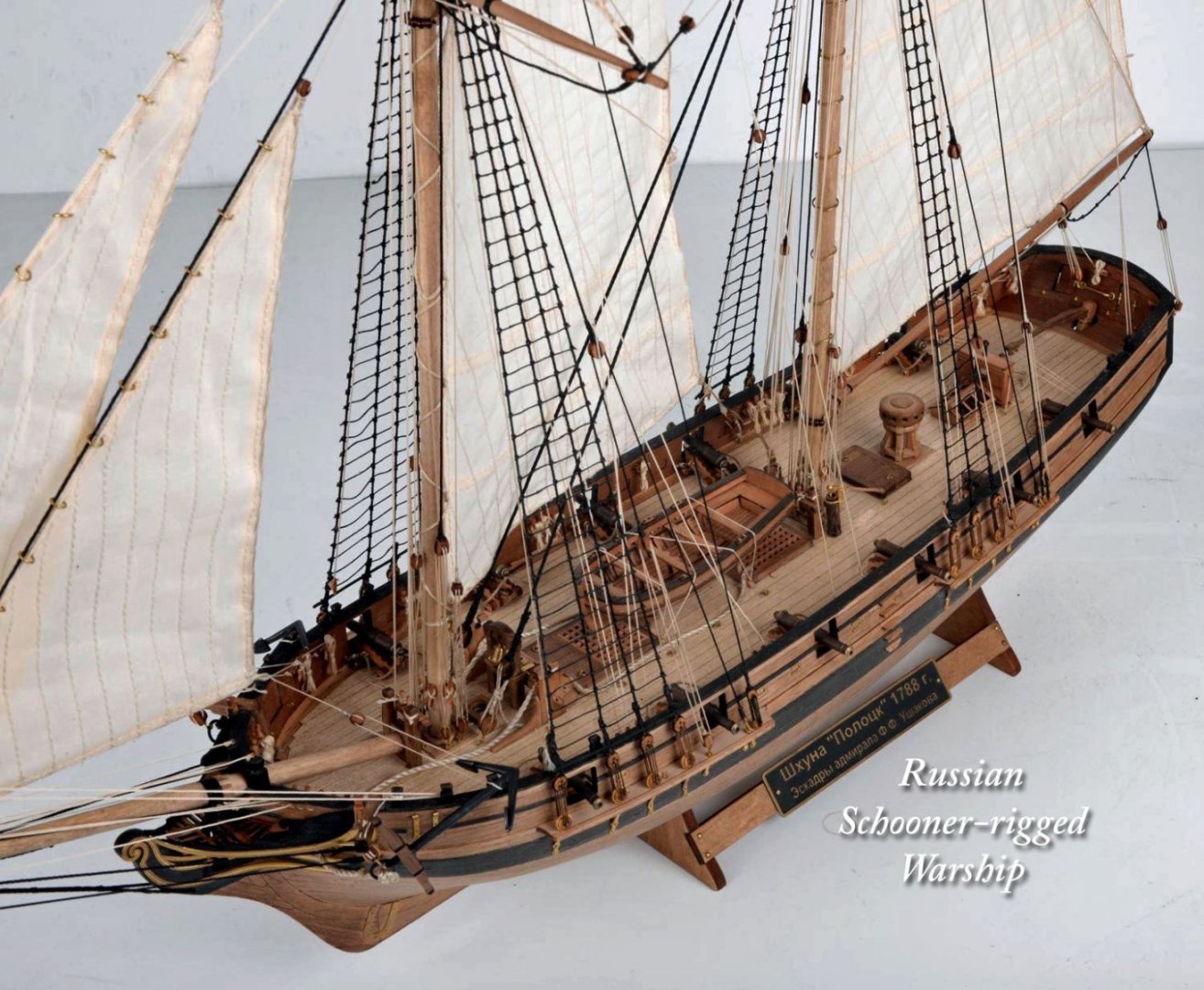

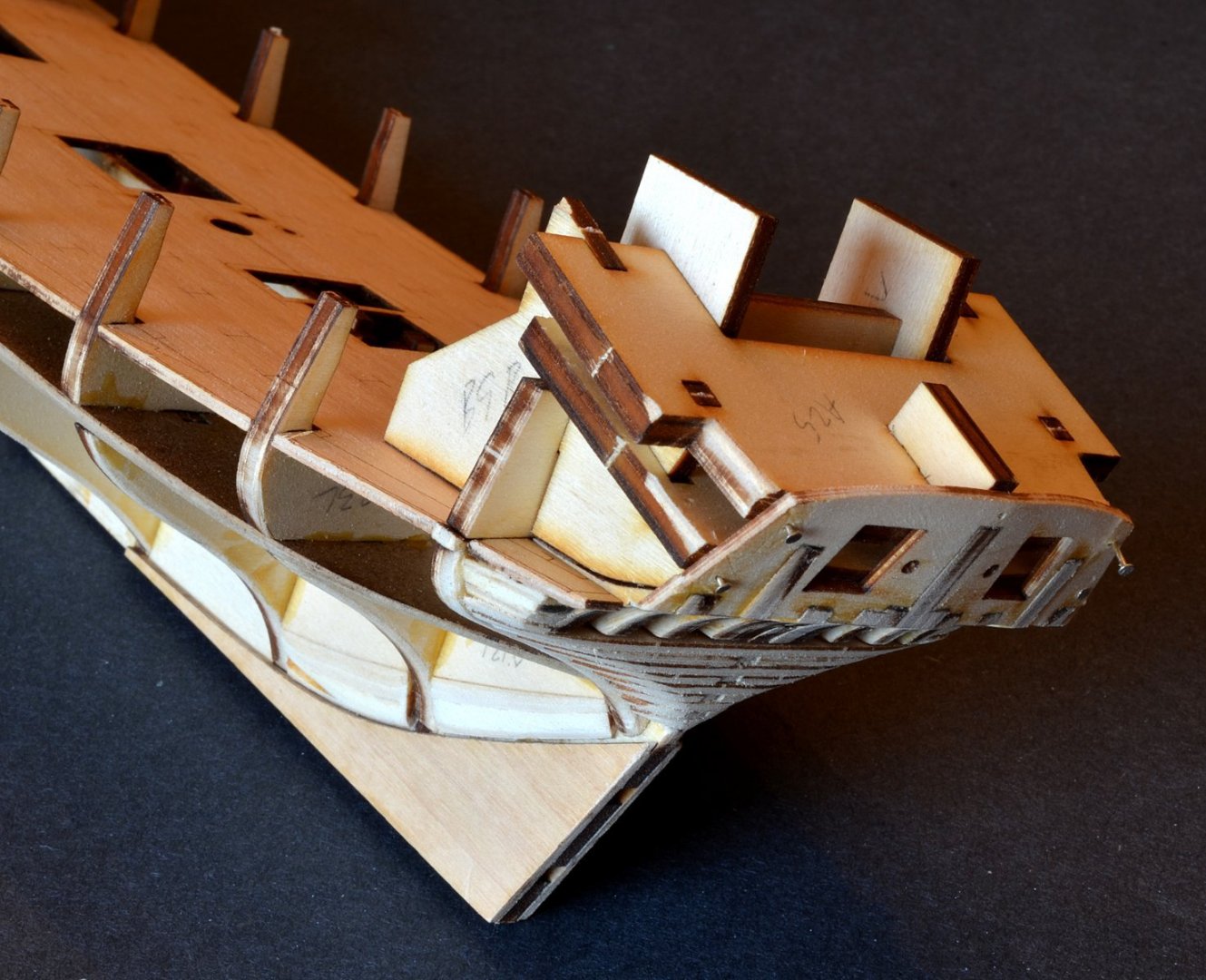

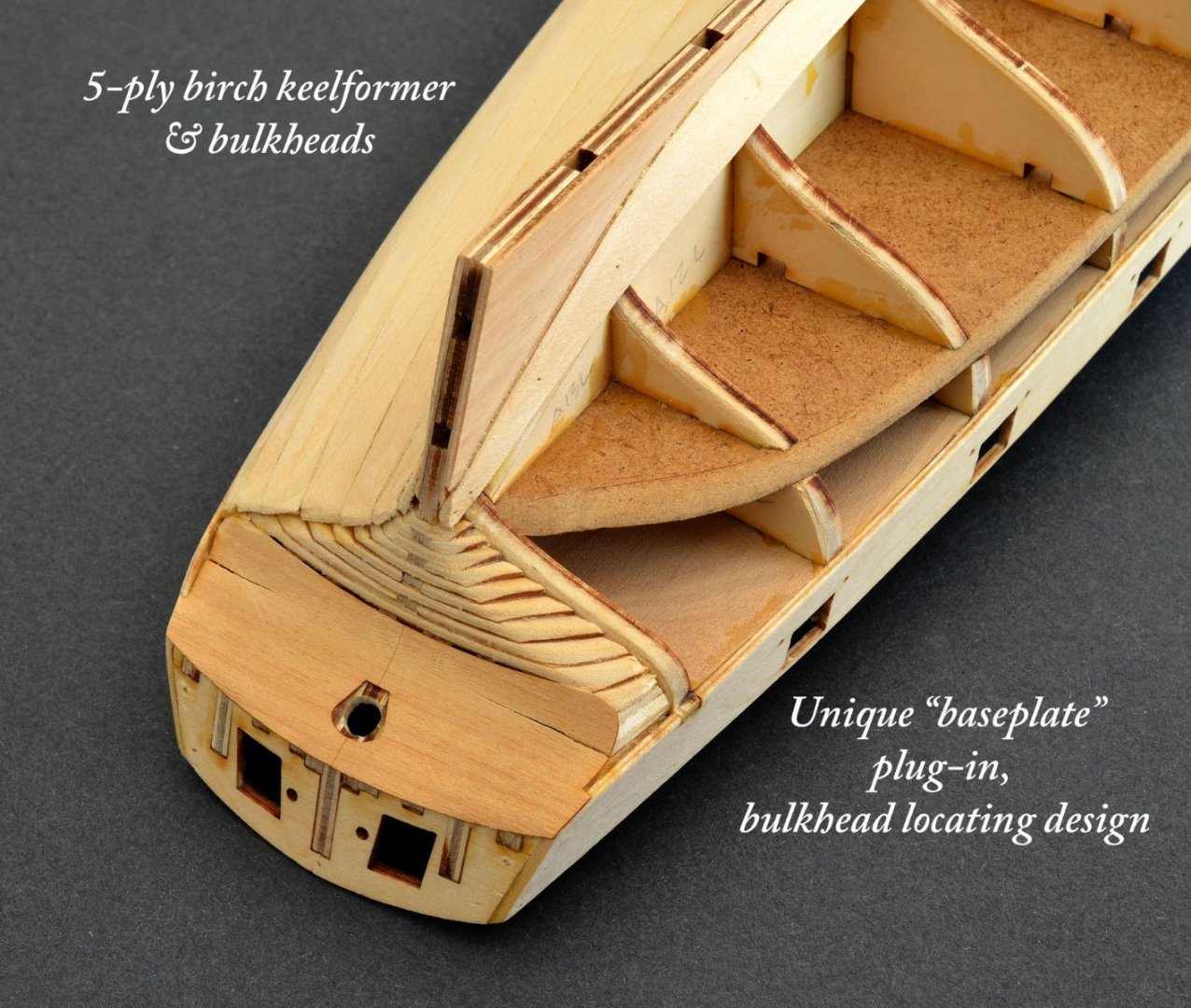

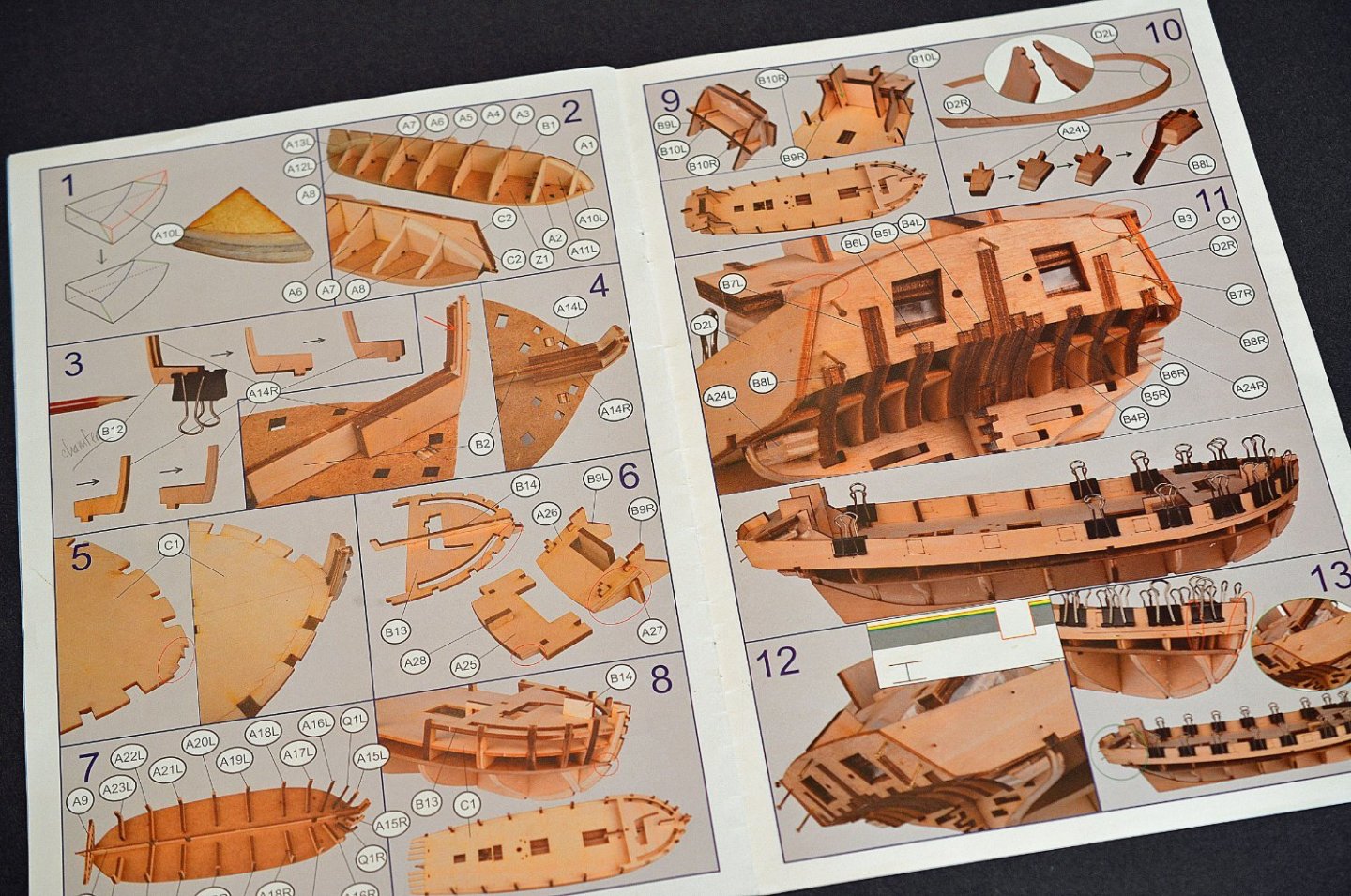

I can attest that the Russian Polotsk kit is superb - in so many important ways. The materials (especially the laser-cut & etched Swiss pear) are excellent throughout and the unique approach to the build is very innovative, particularly the stern as well as stem sections; an interesting and effective departure that utilizes jigs one makes to assist.The 1/72-scale Polotsk includes spiled pear "second" planking. The photos here are self-explanatory. The spiled laser-cut, thin hull planking has a self-adhesive backing and when heat is applied it firmly bonds with the traditional first planking. I have completed the model's hull and her rigging is ahead of me. The black wale is NOT painted; the supplied wood for both - as well as other hull components - are dyed black, presumably pear. The thickness of the pear wood spiling is approximately 0.5 MM that also makes the "veneering" of the hull easy to apply (with a heat wand) with resulting, excellent joinery. In addition to the hull planking, the upper bulwarks, including both bulwark interiors are also precision, laser-cut pear wood. The dyed black capping rails were too light and inconsistent in hue so I added a flat black acrylic to better match the wales, stem and stern areas. The windlass, belfry assembly and other deck furniture are detailed very nicely. The completed model photo is from a Russian modeler who has finished his build. As indicated here, the Polotsk was schooner-rigged and saw service in the Black Sea in the early-to-mid 19th-century. The basic bulkhead structure is a "plug-in" design that's quite effective. The keel is 5-ply plywood...just when we thought plywood was "Old School!" Sharp eyes will note that the thin pear transom has split on both sides when glued to the shaped underpinnings; this wasn't critical as there was a black veneer mounted later. The stern shaping approach with "stacked" sections worked better than I had anticipated it would. On the starboard side, the first planking has been applied; it will get the thin skin of pear pear in a second planking procedure. The holes in the keelformer accurately locate the actual pear wood keel/keelson. This warship model is considerably better built than most Russian army war materiels...tanks as well as Navy Missile Cruisers that serve double-duty as submarines... The provided jig (that one assembles) is used to get the stem bulkheads properly aligned. You'll toss it out once everything's properly glued. Note the beveled stem bulkhead. The stern also has a fixture for aligning all the pieces correctly, before planking. Lots of sanding here, but the visual guide is a good reference on how much to shape the upper and lower transoms and wings. Like the Stem fixture, you'll toss this one too once you've aligned and glued everything. A little tricky, but effective if one proceeds cautiously on this element of the hull's construction. The kit has a full-color instruction manual that is well-done. Like all instructions, look ahead in these pages before getting too far ahead of yourself. The kit does have written instructions in pidjin English: these are pretty useless (and not necessary). Throughout my build thus far, I only referred to the picture guidance (and the clear nomenclature identifying the parts). The stern view on my Polotsk's nearly completed hull. The "golden" trim, Russian eagle insignia and Cyrllic characters are nice, malleable brass P/E. One can see how accurately and cleanly the spiled hull planking meets at the sternpost. No stealers. No filler.

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

Teams. More than one "specialist" pro worked on the Navy Board models according to several pro model maker sources. The teams also had to "crank" these models out for their clients (typically the ship building companies competing for Admiralty contracts). Many fingers make light work.😄

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I have a solution! Purchase these for your wife this Holiday Season. Tell her they're trending on Instagram and are VERY fashion-forward. An important step before gifting: carefully adjust the diopter controls so that your model appears to be less than half it's actual size...I think these special glasses are mainly sold as a dieting option, however, they would be worth a try!

-

Good problem solving B.E. A little camber to the cap rails is O.K. Mine aren't perfectly level but must less awkward looking after I "tweaked" the bulwarks and supports. The hammock cranes , once rigged with their rope lines are easier to keep aligned. No glue in the openings, just the tension of the thin rope keeps them in-place.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Ditto, I found this suggestion to trim the gangway patterns in the instructions very curious and not necessary. Your improved steps for the gangway look excellent. Good researching on the McKay/Amazon information and coming up with a clever solution. I've noted a similar quirk in your waist capping rails to my wrestling with this area of my build: both caps lean outboard and by different angles. In dry fitting I was able to reduce some of this unfortunate disparity by carefully trimming the bulwarks - which process did result in having to remount several of the supports. When you proceed to mount the hammock cranes this "tilt" to the cap rails will be quite apparent. I improved this issue in my build, and you surely can too!

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Hello B.E.- many thanks for taking time to identify some info from your past Build Logs. I'll visit both. Much appreciated. Now - off to build a better Mouse (trap)!

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thank you, B.E. My "mice" can be improved, and this isn't difficult to re-do. However, will you please give me a pointer - or two - on how to fashion the tapered styrene tubing so that it becomes conically-shaped. I've used dowel, drilled thro' and tapered with sanding to fashion better looking "mouses" for previous models, so indeed I can do better. I'm curious if your tubing method will yield a better result and be easier to make? Your layering of "ladies hosiery" looks very effective from what I can see; I have several daughters (and granddaughters) who can help me out with this supply chain! However, as you've suggested, re-rigging my stays to pass over my shrouds is too far to go at this stage. Camilla's ship's boat will indeed be a yawl, the 24', 3D printed resin one I purchased from Vanguard. I'll follow the kit's instructions (mostly) on the various pieces needed to outfit the resin boat.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thanks, druxey. Now that I've properly dealt with a talkative avian (two more circling about), another pest crawls out of my woodwork: mice. Where there's one, there's more! Hmmmm...let me think about this. No Pain. No Gain?

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

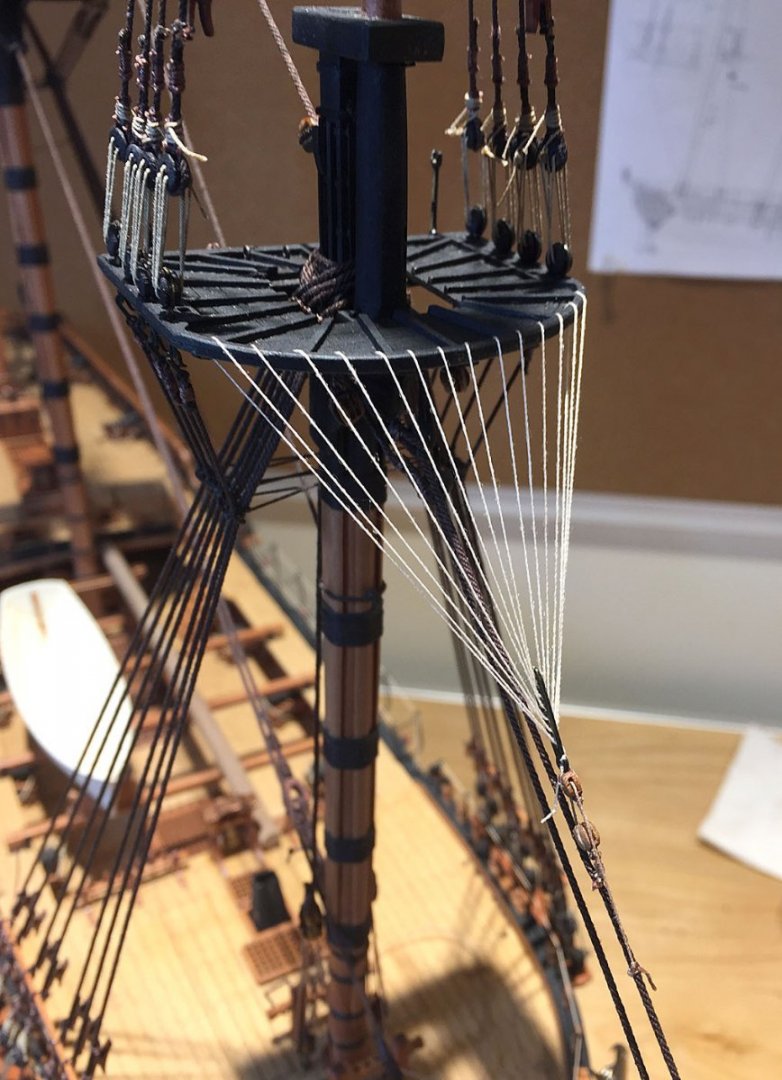

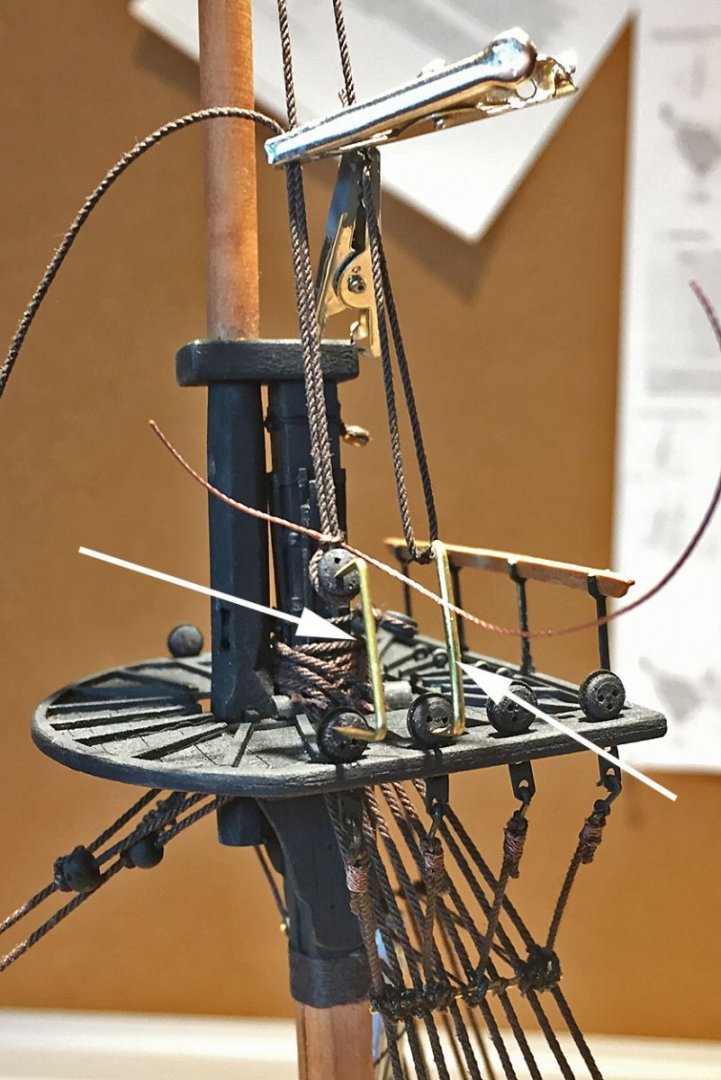

Back at it following the Annual Joint Clubs Northeast Ship Model Conference in New London, CT. Great models to see. Good attendance on a beautiful day at the beachfront venue. Here is an update I made on HMS Camilla just before I hit the road to New London. A better result with thinner rope for the crowsfeet - and a redux on the "over-under" threading required that avoids the doubling of the lines I'd previously rigged. I'm happy this has been straightened-out - thanks to B.E. & druxey who helped me to re-focus on my work. BTW: those small blocks that rig the euphroe block to the stay are 2.5mm pear singles. My promarker, alcohol-based coloring pens arrived and I immediately tried them out on some boxwood violin blocks and pear belaying pins. The color, raw sienna, is the darkest in the 5-piece "brown range" set I bought. I used both marker tips: the flat, wedged "sharpie" point and the "pencil tip" point. The belaying pins only needed one pass of the coloring whereas the blocks needed two to achieve a nice "chestnut-like" reddish sheen. Boxwood is a more tightly-grained hardwood than Swiss pear and therefore needs more than one color pass. Taking a small break from rigging, I'm now testing some paint colors for the ship's 24' yawl. The clinker-styled boat is the one I purchased from Vanguard and not provided in the Sphinx kit. Here, the resin boat has been primer painted in Titanium white with two coats from the Liquitex pro series rattle can. Not easily seen in this photo is the off-white color of this paint which may suffice for the boat's finished hull exterior. The thin brown line at the boat's transom is a test for color. This matches quite well with the pear wood pieces that will be added, namely the thwarts and aft seating. There are quite a few choices of internal boat components that are provided in the kit. Some of these will be brass P/E, the remainder in lasered pear. I'm only building one boat for my model so I'll pick n' choose the components that will best fit this 3D resin print. The kit includes a full, three boat complement in pear and thus there is quite a large selection of very detailed bits n' pieces to make all the ship's boats quite convincing, right down to tiny oar locks and decorative boards. As this mini-project develops I'll post photos, of course. Most builder's of this kit will opt to build all three pear boats provided and array them across her midships on the skids. I'm just not one of them. At this writing I'm seriously considering airbrushing a custom color mix for the boat's interior before I add the P/E and laser etched pear details. One other detail: the walnut dowel behind the boat lying across the beams is a 'test' piece for adding a spare topmast that's on my checklist. I'll make this piece when I get started on Camilla's yards since I'll be spending time on my Proxxon mini-lathe making them. Another view of the boat, prime coat painted. This view better shows the nice clinker'd hull and the ribs. Once completed, I'll leave the boat in this upright position, strapped down across the skid beams. This photo shows two brass deadeye rigging jigs in position for shroud tying. The shroud line pair (main topmast) has been cut to length and seated around the tophead crosstrees and brought down to the top's deadeye and brass jigs. Once wrapped around one brass leg (on the right side) to hold the shroud line in-place, I've left a small length to wrap a deadeye and it's subsequent lashing. The grey-tipped alligator holds the shroud securely in position as the opposite end of the line is wrapped around the deadeye's channel (on the left). After pulling the shroud line fairly taut, I lash the first of three lashings with the brown upholstery thread I use for nearly all my line lashings. Just the first tie-off is shown here. This lashing line will subsequently wrap 5 or 6 turns and then be tied-off. The shroud line to the deadeye is also held in place by a second alligator clip to maintain tautness. Once the shroud's left deadeye is secured, the line around the right brass jig is wrapped around a second deadeye placed on the jig; once the spacing is evened-up, the shroud is secured with it's lashings. This set of brass wire jigs have sharpened, tapered tips so they can easily slide into the miniscule holes in the 3 mm diameter deadeyes. For the larger deadeyes at the channels I use slightly thicker and lengthier brass jig sets of the same configuration that provide wider spacing between the deadeyes. A gull's-eye view of progress on Camilla and my out-of-control work surface! A view from the stem. The mizzen shrouds await.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thanks, B.E. Yeah, 0.10mm rope will be like what I envision its like for fly-tying fishing lures, as druxey has advised! Mmmmm... smoked rainbow trout.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thanks, Glenn. I confess I rigged my HMS Swan's (neé Pegasus) crowsfeet correctly. Why I didn't look closer at how I accomplished this years ago, is beyond me. I used old-school Warner blocks too. They are still beautiful looking IMHO. For kit building, there have been dramatic changes to the aftermarket for our hobby in just a few short years, accelerated by our MSW forum.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thanks druxey. I believe I have some .10 mm rope, hopefully enough to do all my tops! I neglected to mention in this topic that I have yet another important, accurate reference for rigging...😬

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

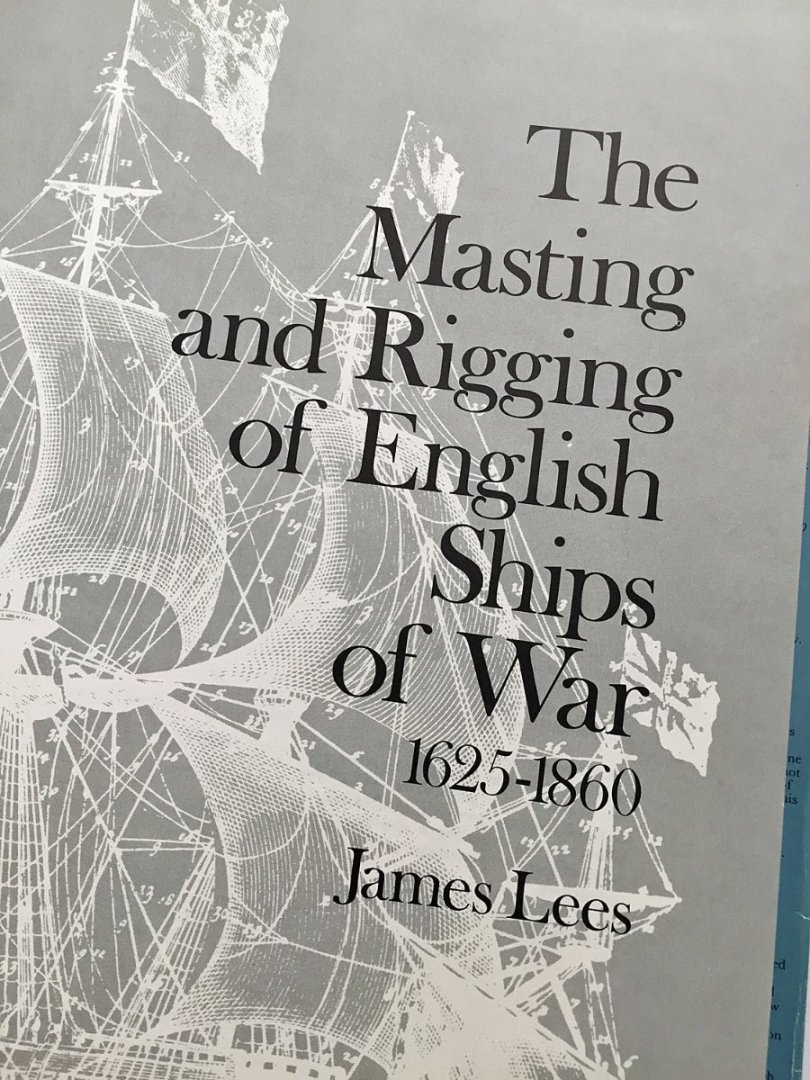

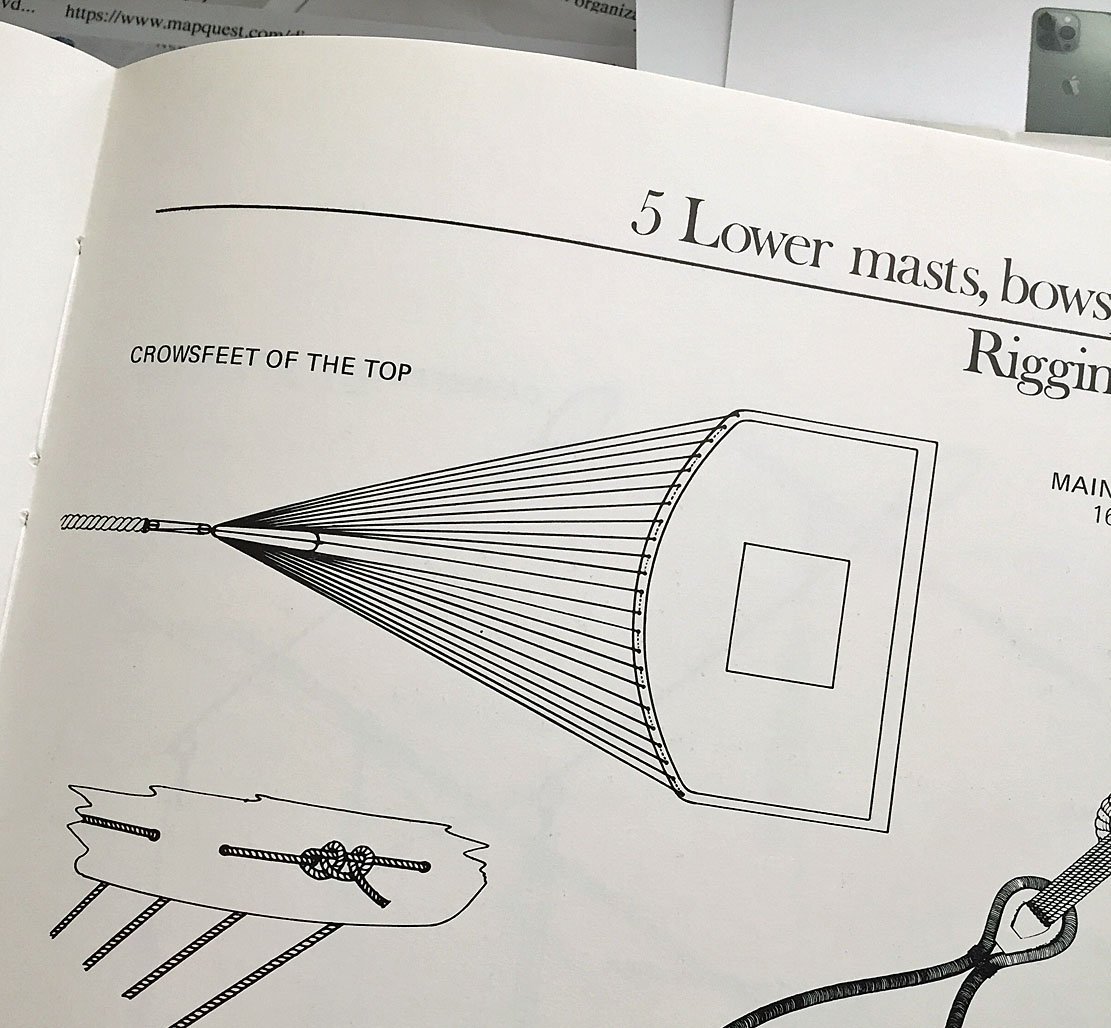

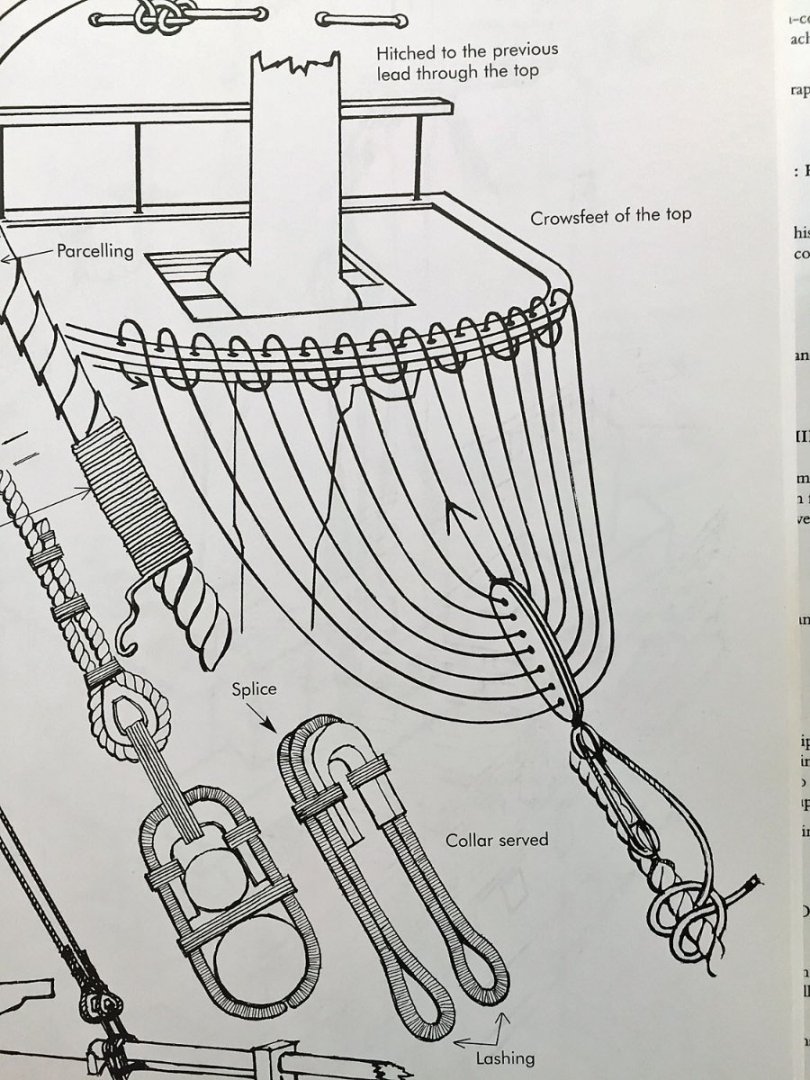

Indeed, my method is inaccurate, but not a simplification, per se; I used way too much rope and thus, this rigging reeving turned into a jury-rig. After consulting the following principal references I have for rigging, I'm up for ANOTHER re-do. Good eye, B.E.: it doesn't quite look right to me either. Thank You. Here's my solution, some background for thread readers: The standard reference for rigging, James Lees. The "Bible." James Lees, Pgs 44-45. Rigging to the Foremast. This is the only pictorial reference for crowsfeet rigging in the entire 212 page tome, which the text explains "...It [crowsfeet] ceased to be generally used by the end of the eighteenth century." The text does give a written explanation how to accomplish this artistry, but I found it confusing, even though I've done this rigging several times in my ship modeling life. Basically, for the foremast, I invented my own, semi-accurate solution. The English have a saying for this: "that's not cricket!"....so...in the next photo, my Dear Watson, I'll show you the evidence for a more accurate solution to fixing (undoing) my unique (call it "creative") method for rigging! "Elementary, Mr. Neilson, Elementary." This photo from Lennarth Petersson's Rigging Period Ship Models book (page 15), is my "go-to" main visual reference for rigging, including its extensive information on sails, their configurations, rigging and excellent info on belaying. You can see in Petersson a pretty clear depiction on how to go about accomplishing crowsfeet reeving. This procedure will apply to all three mast tops on my Camilla. Why I ignored this clearly illustrated reference I can only chalk up to "a senior moment." I'll fix my erroneous foremast crowsfeet rigging tonight, after an Eastern Conference NBA playoff game. Thanks again, B.E. for the sharp eye and the gentle query into my rigging madness. Where would I - we all - be without Model Ship World?!😳

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Ta-Da! Nice work, Toni. I'll be interested to see how you present this unique model.

- 52 replies

-

Good point. I'll certainly have all the anchor bits n' buoys mounted, including the possibility of adding an anchor lining. I thought about this possible addition as I was rigging the deadeyes...I did add a centre-deck spanshackle, so the crutches make more sense. How do you plan to handle the masts? Stubs with broken wood? Angled tops? A fellow artist/builder would like to know! Cheers!

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.