-

Posts

68 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Tonphil1960

-

-

Hi Mark, Haven't checked in for quite some time. I've been busy building and flying balsa planes. Your progress is really is fantastic. You're maintaining the exacting accurate work you started with. Your work will continue to be my major reference. Hoping to get back on mine in a couple months. Love your shop ! Tony

- Keith Black, mtaylor and No Idea

-

2

2

-

1

1

-

-

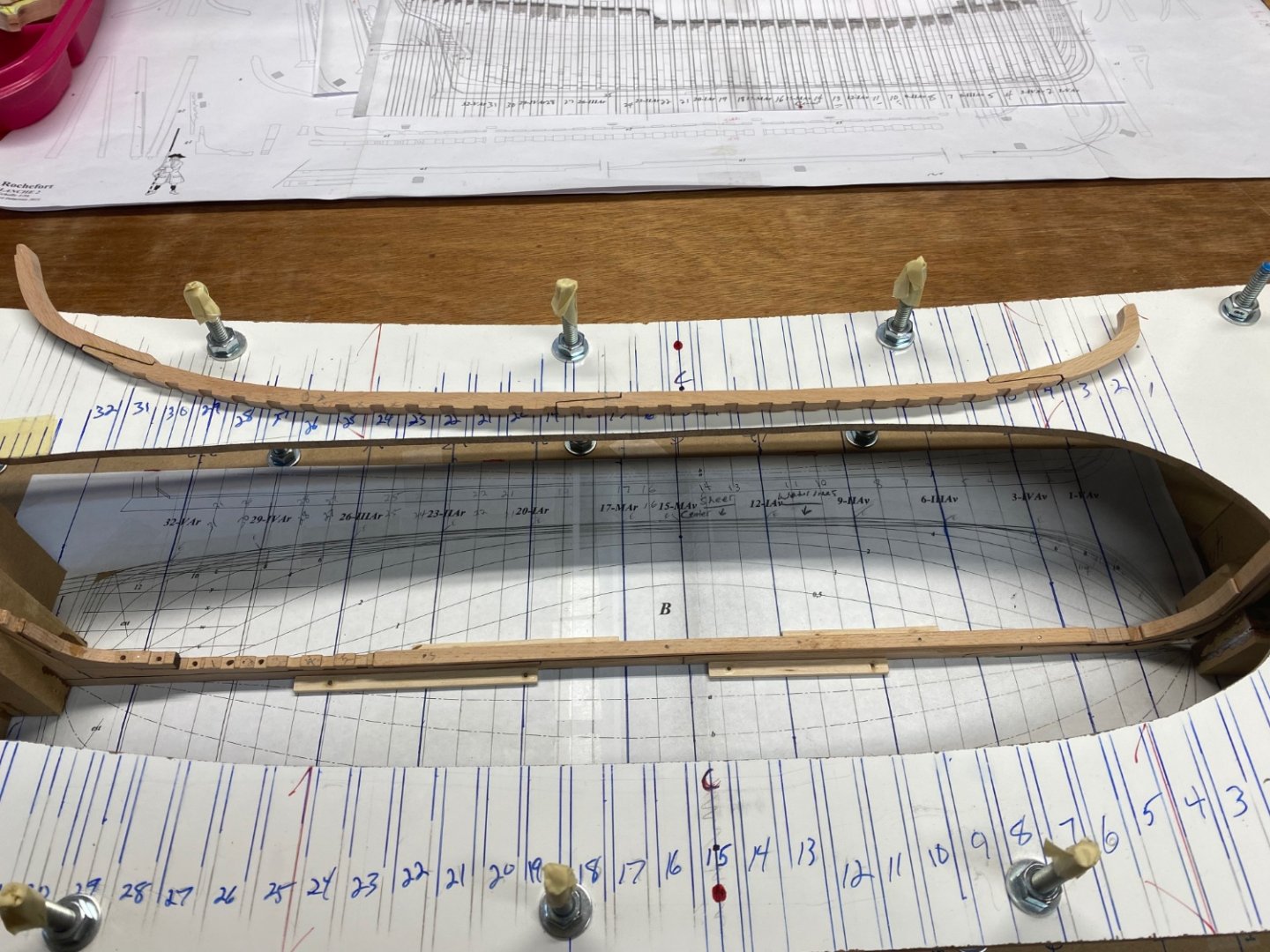

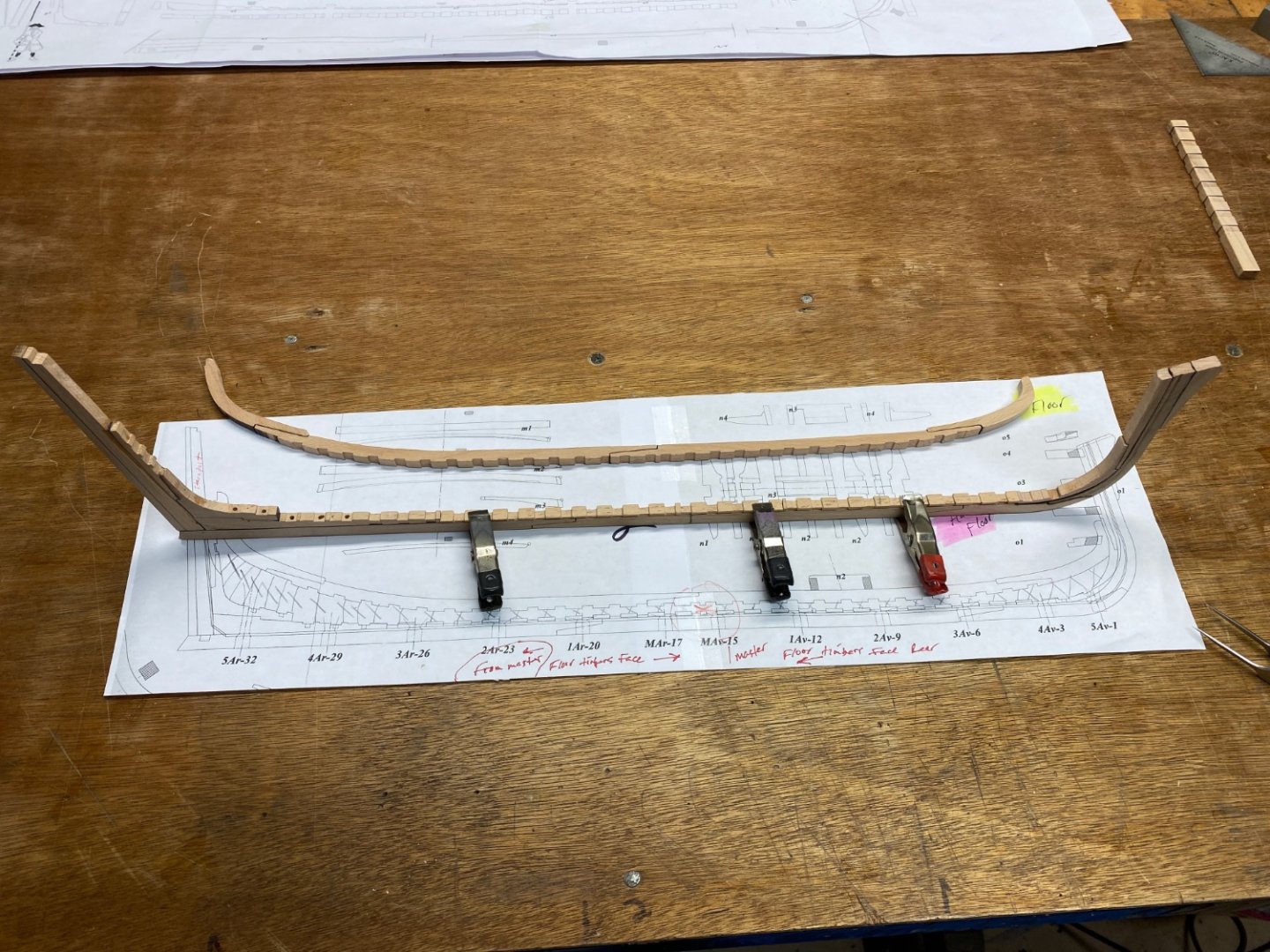

Made progress before taking another airplane break. After fitting, adjusting, and fitting and adjusting I’m satisfied the frames will fit the jig properly now. Next step is to cut the notches for the spacers and cut the spacers themselves. Then finally I’ll get the frames in place. Slow progress but that’s the way it goes.

-

-

-

-

Beautiful clean work as always Mark ! I'm taking a break for a bit working on some planes but Ill get back on Rochefort asap

- Keith Black, No Idea and egkb

-

2

2

-

1

1

-

Incredible clean perfect work. Wow

-

- mtaylor, Prowler901, dvm27 and 1 other

-

4

4

-

-

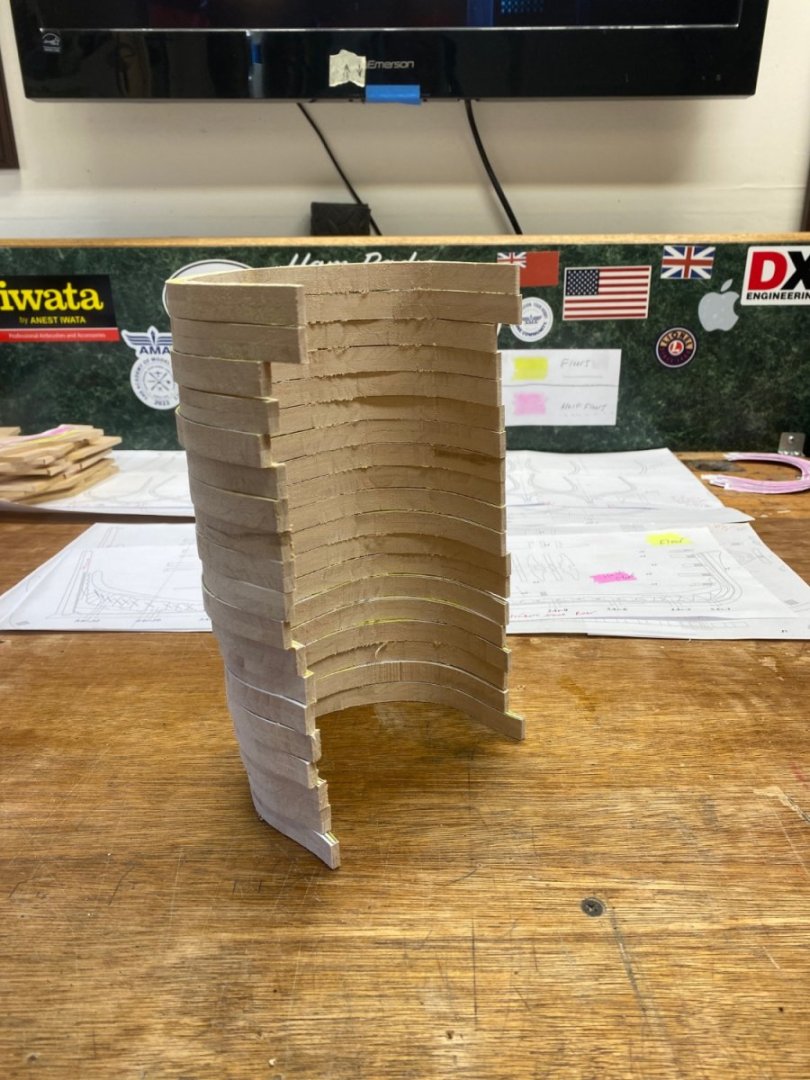

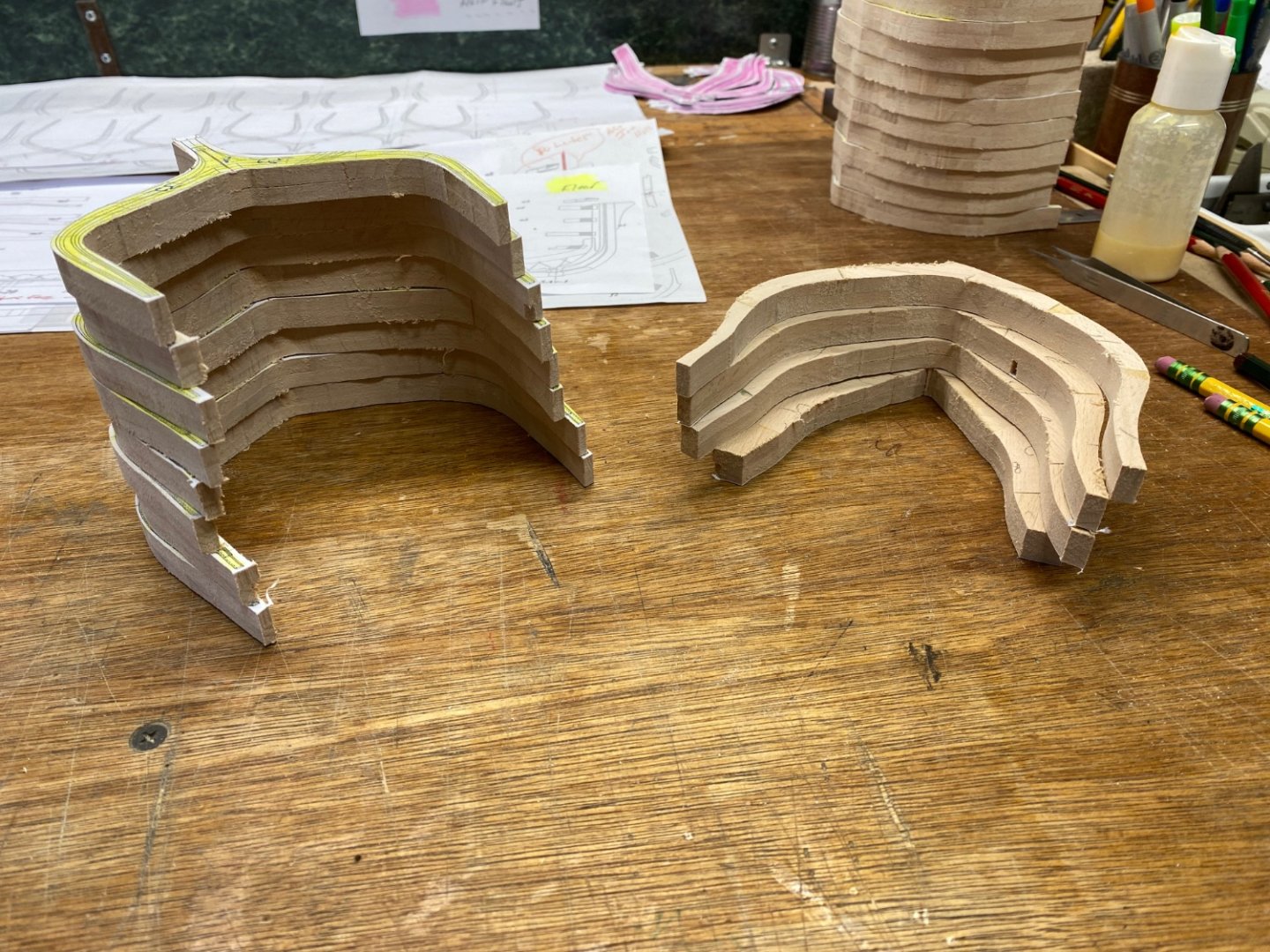

Exactly not even the frame spacing, that’s staying as per plan. I’m only using his frame building method of making blanks out of 5 pieces glueing them together and cutting out both twinned frames at once so there are actual joints as opposed to what you described. I have all the frames cut I just need to sand the remainder. That and I’m changing the way the frames are connected at the keel and I’m making a new keelson to fit my frames on the top side. The rising frames in the stern since I do still have slotted rising wood there I’ll mill to fit that rising wood. As long as my spacing and frame height in on the money as per plans I don’t see a problem either. Thanks Tony

-

Oh yes I understand. I’m just looking for opinions and answers. No offense taken at all. You are right. Accuracy of frame connections aren’t there with this method. I see it this way. The only change I am making is in the frame to keel connections and the joints of the frames of course aren’t in the plans position. No measurements or part positions have changed or will change. I am only using that framing method, the rest I will be built as per the plans. Either way I’m thus far and don’t want to start over so all I can do is carry on and do it the best I can. I wish someone that knows more than you or I will pitch in here ! Thanks Mark

-

Right. I'm not trying to simplify the process. I cant see any other way to do it using Hahn frames. I can make new rising wood to fit my frames and a new keelson the same. they will have slots for the frames. I'm trying to understand this. As soon as we go to the Hahn method were taking away accuracy of framing. If my frames are notched to fit over the rising wood and the keelson is notched to fit over the tops why is that an issue ? I really don't see it. Thanks Tony

-

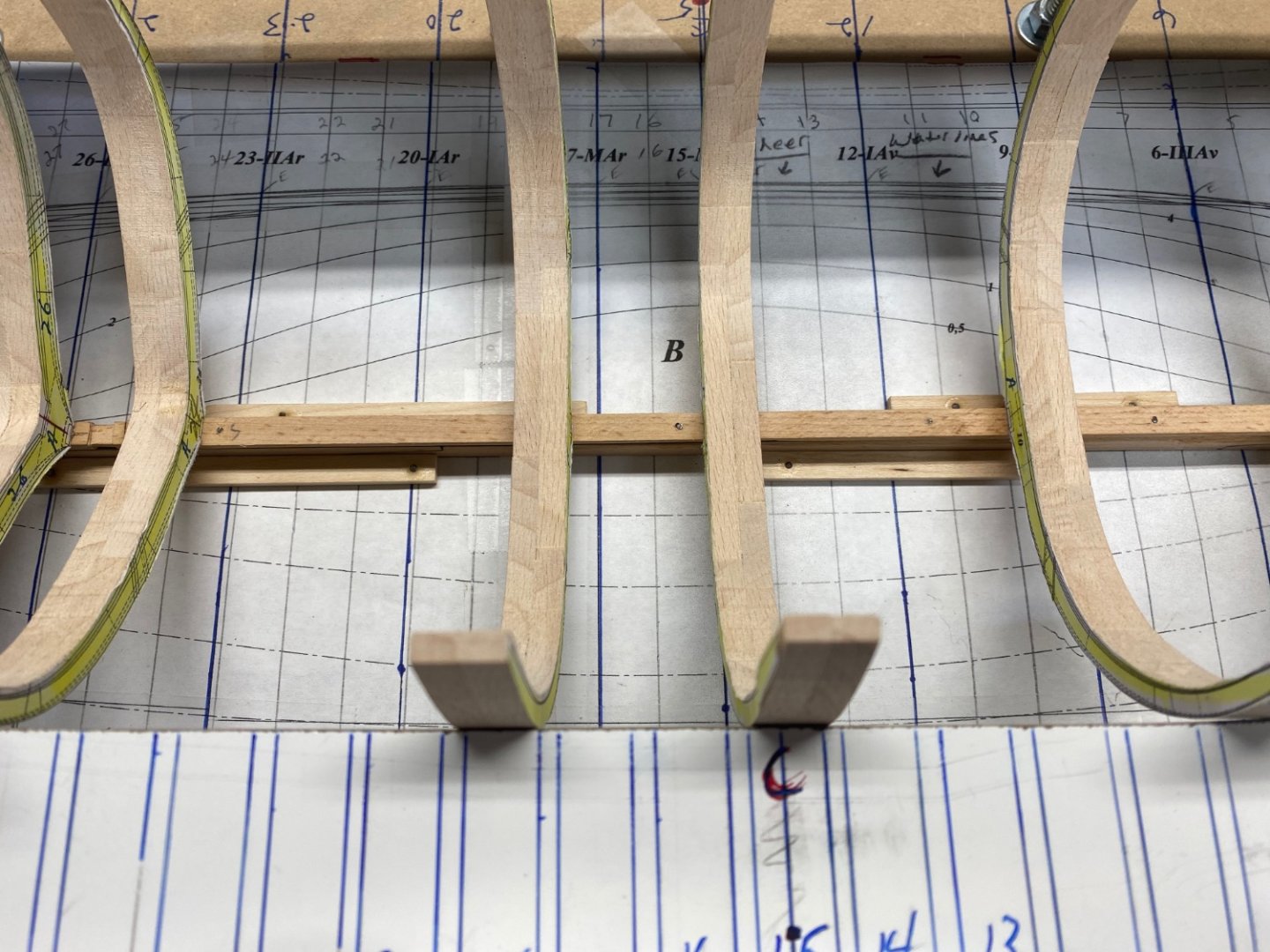

Question on the Hahn method. I’ve been looking but haven’t found out how do the bottoms of the frames get where they fit the rising wood.

On the Rochefort the floor and half floor have different slots to fit over both the thinner slots and full size width of the rising wood.

Putting the frames together as I did (glueing both frame blanks together before cutting) with that method doesn’t leave much possibility of milling out those slots. I did so one but I just can’t see myself doing then all that way.What I am doing now “right or wrong” at this point is I installed a solid piece of rising wood only where the square frames are from 5 to 25. The frame slots I will cut will now fit over it. I think I’ll have to do the keelson too this way. Haven’t really looked into it yet though. Maybe make a new keelson with properly sized slots to fit my frames. Opinions needed please. Thanks Tony

- KARAVOKIRIS, bruce d and mtaylor

-

3

3

-

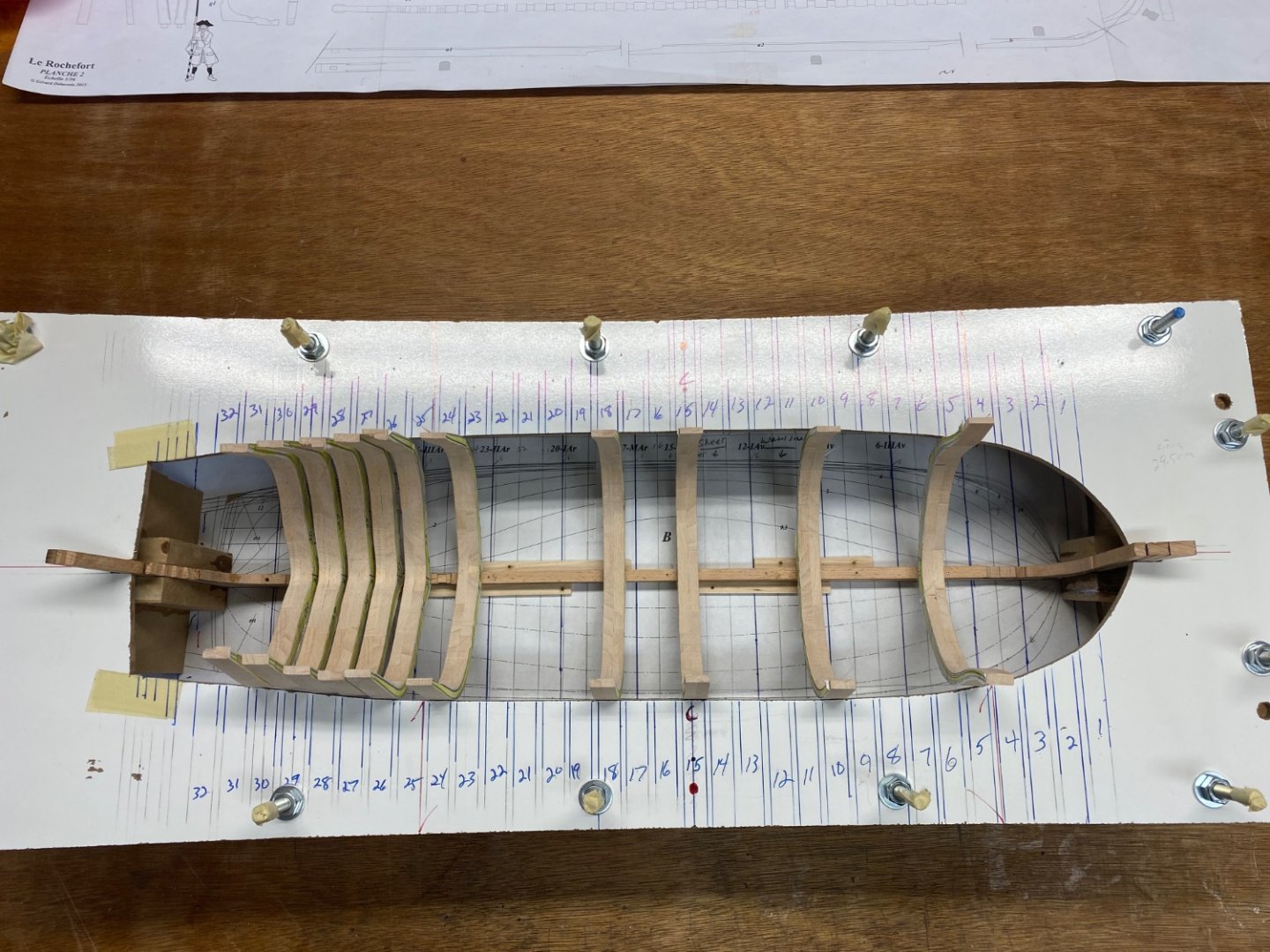

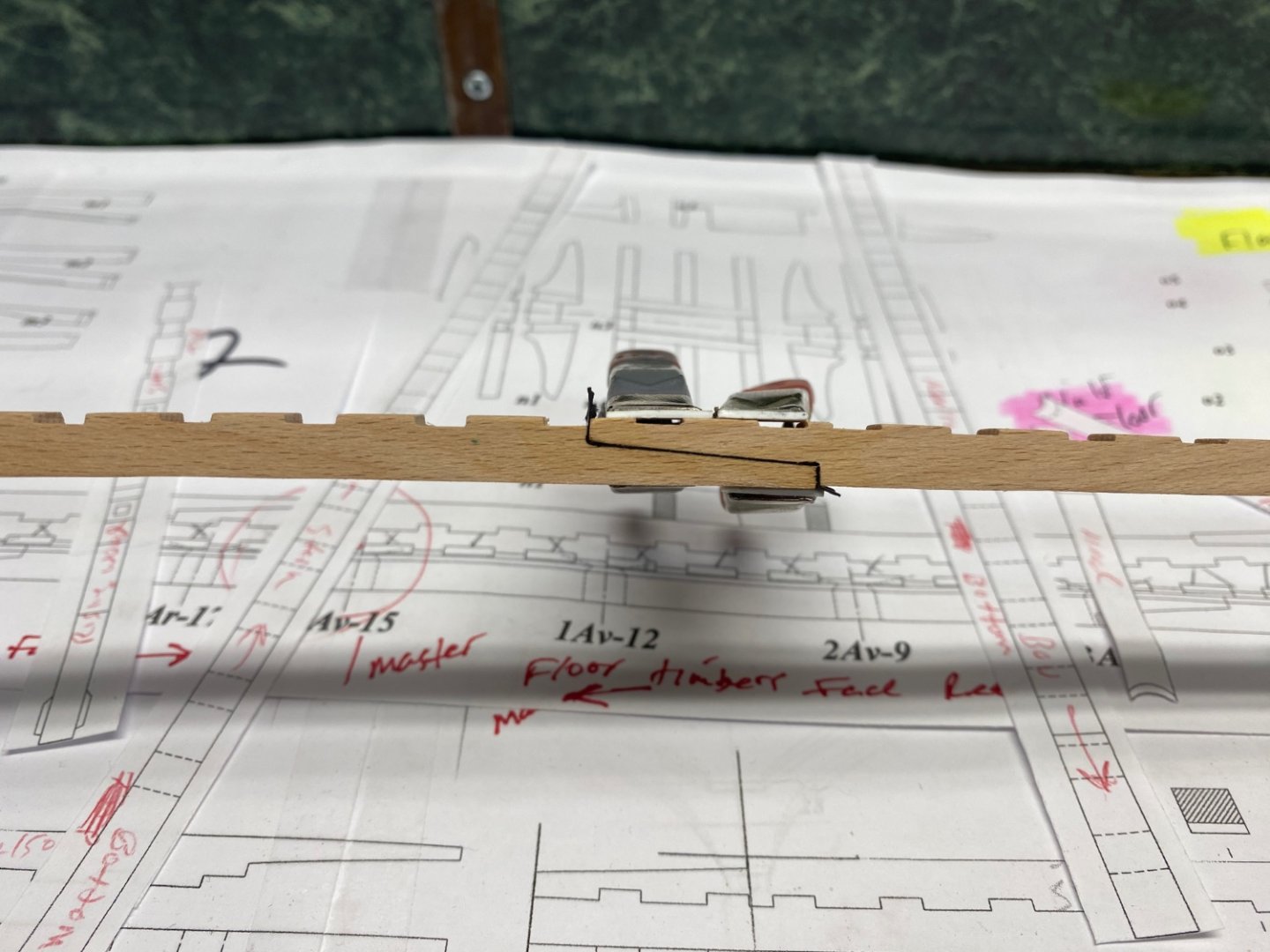

Progress. I’ve spent a lot of time working on the axial parts and stern. I made a second set of stern fillers and a fourth wing transom as the first just weren’t right. The transom isn’t glued up yet. I’m using black paper for the keel caulking because I like its look. I may make new rising wood to make it easier to fit my Hahn style built double frames unless I can figure out an easy way to mill two different sized slots on either side of bottom of the doubles frames.

- mtaylor, No Idea, KARAVOKIRIS and 2 others

-

5

5

-

Yes I’ll put the keelson I made aside and see how it looks when the frames are in. Building it to fit is the way to go. If the rising wood slots and keelson slots aren’t spot on it’s going to be a mess. I still have to figure out how I’m going to cut the slots in the frames. That’s going to be a headache. I may make new rising wood too to make sure that’s a good fit also. Thanks. Happy New Year !

-

Thanks Mark, yes I finally got my keel together it’s drying now. It’s not bad but it’s not great either. In the bigger picture though small flaws aren’t as noticeable when they’re attached to an entire ship. One thing I just saw going through your log again is you built the keelson after you installed all the frames. I built a keelson but I see if I wait I can build it to fit perfectly to fit its place and especially the frames. That’s what I’ll do.

-

Mark, no matter which other refs I have and or other builds to follow for advice yours is the one, Tobias's will be another. Looking again closely since I've started mine I may as well just throw all of it in the bin and start over !! I won't bet its tempting. Your joinery is fantastic.

Tony

-

Thanks Greg, yes ill have to build a jig and cut the mortices and fit each frame. I'm going to also make a few bottom frame sections as I said to see how to go about cutting the two different sized mortises on the floor and half floor frames. One thing I did not pay attention to is where my frame joints actually fall on each frame. they're not in the same positions as the plans. Some are on or very close but some are just where they fell due to how I cut my blanks. It wasn't an issue in my mind and I'm not sure if I should keep it this way or not. I really don't want to make up new blanks and cut new frames out at this point. Strategically placed planks might be my answer but I really didn't intend to plank at all except for the wales and possibly a few down at the keel. I have some testing to do now.

-

1 hour ago, No Idea said:

Hi mate - when I raised my frames I realised just how important accuracy of the frames were. But also the fit onto the rising wood because this determines the accuracy of the final build. Accumulative error is a real problem when raising the frames as if each one is 0.2mm out by the time 32 frames are raised the whole frame is 6.4mm out of kilter.

I think that you can do both versions of what you suggest. Either cut them by mill and hand or make the rising wood flat and just simply mill out each side of the frame the same. I'm sure that someone must have made these frames the Hahn way before who can give some advice too.

I’ll have to make a few frames just the bottom section and see how milling and finishing by hand goes. Yes understood tolerance creep adds up fast. I haven’t run into anyone doing Rochefort frames the Hahn way. Haven’t seen how anyone treated the floor and half floor side either.

-

1 hour ago, dvm27 said:

There are several Hahn style jigs wherein the height of the top timbers and the mortises for the floors are accounted for. I suspect his version may be depicted in Ships of the American Revolution.

I’m not using acHahn jig just his frame building method.

-

I’m not sure. I was thinking about milling as far as possible and cutting the rest by hand. I don’t know how it’s “supposed” to happen the Hahn way. Possibly I shouldn’t have glued the frames together ? I guess I could just make the joint however is easiest for me too and not worry about accuracy in the joints as long as it’s clean.

I’m really not sure at all. I have a lot of analysis to do.

-

- Mike Y, Prowler901, KARAVOKIRIS and 3 others

-

6

6

-

Le Rochefort by No Idea - 1/24th Scale - First POF Build

in - Build logs for subjects built 1751 - 1800

Posted

Mark. Your progress is amazing and quality fantastic. Mine had been sitting not touched since April ! I will get it together and analyze where to start next after I'm finished with the plane I'm working on. Might never get back to Hope I do though.