TOM G

-

Posts

127 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by TOM G

-

-

Check out, "Law of asumption Neville Goddard" on youtube. You can over come this... no matter what the doctors say.

- Keith Black, Canute and Ryland Craze

-

3

3

-

1 hour ago, Keith Black said:

Jack, for cutting out windows I use x-Acto chisel blades

That's the way to go.👍

-

-

-

-

21 hours ago, Javlin said:

seemed to be working till the last coats Tom don't know why?

Look's like what is happening is the air brush needle point tip is loading up. ( this reduces your volume output making a dryer coat ) This will realy hapen bad when you set the air brush to the side, waiting for flash time between coats. Take the front end apart clean it, and if your going to set the brush to the side for flash time.... spray Windex through it. Also make sure you have the right needle in the brush, you want the one for a high volume cause your covering a large area.

-

-

I always get amazed at how you can cut your stock at such high tolorences.👍

- Jack12477, FriedClams and Keith Black

-

2

2

-

1

1

-

I made a model back in my 30's.......... But she dump'd me for a rich guy. 😟

-

Great looking build ! I have this kit, and the first thing i noticed was that life boat..... ( went in search of ) and found the prize. I think in time the vinyl strips will loose their grip and start to curl. I've built models where i had to drop the ball on...... But it haunts you, every time you look at the model you see that one area that is not in perspective. These life boat kits are plank on frame, they have the length you need. Get them at model expo type in life boats in the search box. 🙂

-

spray slow dry lackuer thinner over it..... you might have to do it 2 to 4 times you will see it slowy disapear . don't flood it , one pass at a time, and wait between passes till the surface is dry to the touch.

- thibaultron, mtaylor, Canute and 1 other

-

4

4

-

Your skill's run very deep...... Great work.👍

- Keith Black, Glen McGuire, Jack12477 and 1 other

-

3

3

-

1

1

-

If you sand & re paint..... the hull will look like the bottom is a fiberglass hull. Best way out is to mix up a black wash ( 2 tsp of india ink into 1 pt of 91% alcohol ) put the wash over all your bright colored paint'd area's using a brush...... you can re coat the wash after it drys if you prefer. The result will be a weathered hull witch will give a more real look to who ever views it.......... When you get to your sails soak them in tea and they will match up with the rest of the vessel.🙂

-

-

-

-

I know it's going to be a well detaild build......... I'm going to enjoy watching the progress.👍

- mtaylor, Keith Black, FriedClams and 3 others

-

5

5

-

1

1

-

-

It's looking good.👍

- LyleK1 and Knocklouder

-

2

2

-

Yes, it's worth your time to make it "ship shape".

- mtaylor, Santa Rogge 1600, Peanut6 and 2 others

-

5

5

-

-

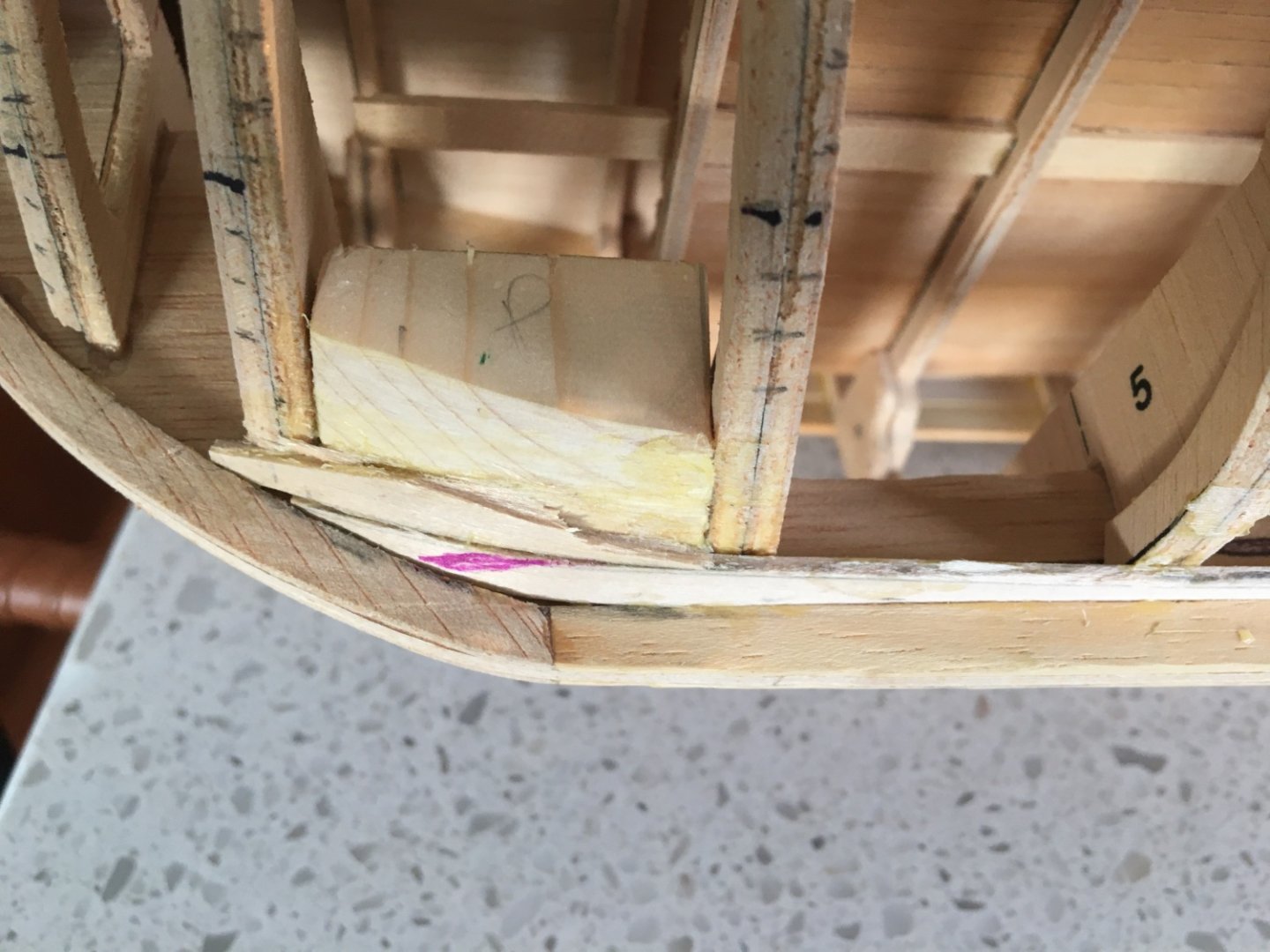

You want to pay attention to the garboard plank........ check this out https://modelshipworldforum.com/resources/Framing_and_Planking/plankingprojectbeginners.pdf

-

-

1 hour ago, LCdr Dave said:

Thanks for checking in. I did read and re-read the primers, YouTube videos and “how-to”s but I am a visual learner and it seems that I am still missing somethings (obviously). The planking primer suggests that the garboard plank might be wider but I’m not sure how wide. I ended up making mine narrower because I was trying to keep it going up the stem. I guess it needs to actually curve inwards (I marked a purple line where I think it should go).

To my (again) untrained eye it would appear that the garboard plank and the ones to follow will have a wicked “hook” to the keel-side - but maybe that’s just me… It also suggests putting a temporary batten at “max width of the plank to be used” which I did do the first time but not at the width of the plank so I will put it down at the 6mm width and see where that gets me.

I didn’t want to pull out the existing planks but they came out without too much problem so I guess that’s something.

Thanks again for the help,

Dave

The plank flow's into the keel.... no wicked hook.

Worst Planking Job Ever

in Building, Framing, Planking and plating a ships hull and deck

Posted

DON'T GIVE UP THE SHIP....... Take a long break, review things. And when you are no longer fustrated come back to the work bench, and it will all begin to fall into place.😉