-

Posts

3,249 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by realworkingsailor

-

Probably the captain’s cabin and radio operator’s cabin shared the small structure below the wheelhouse, on the forward end of the boat deck. I’ll check my model when I get home, but pretty sure the coal bunker hatch was located between this part of the superstructure and the funnel. It would be hard to see as there is no coaming. Aft of the funnel is the engine room skylight. Andy

- 330 replies

-

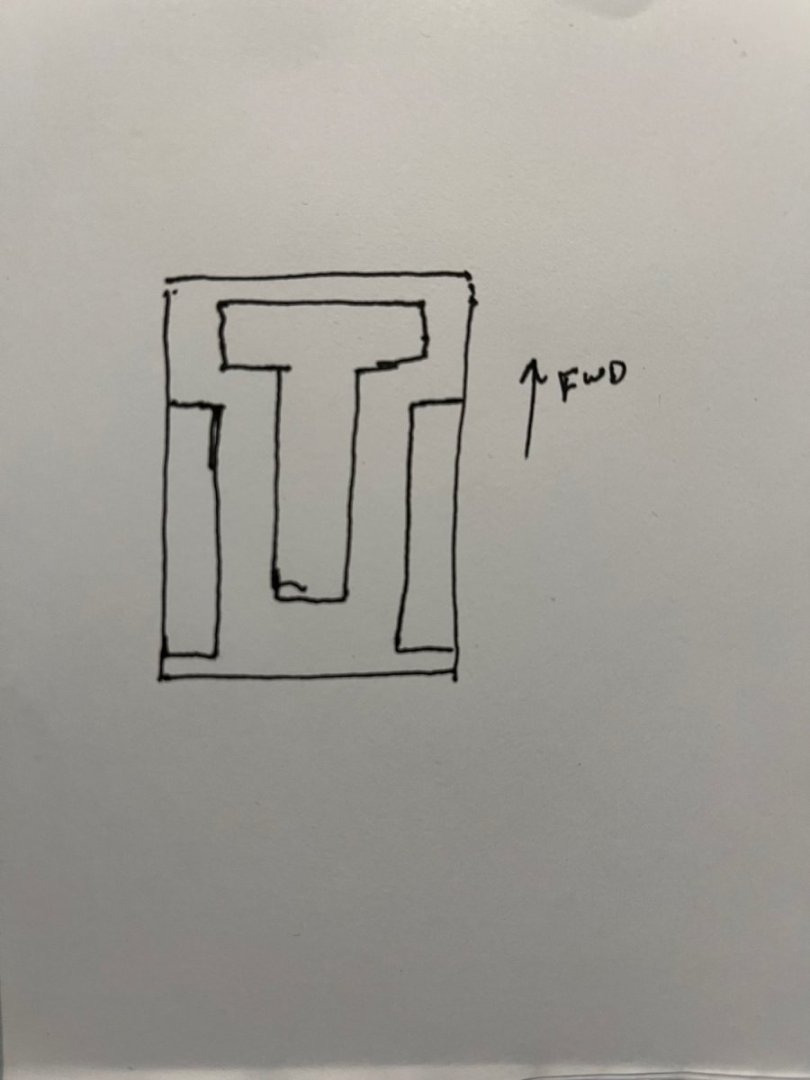

Hi Nils, Looks great! I have a few observations, you can do with them as you will. 😁 The upper deck layout on my model is a little different than what you’ve got. It looks more like this: The “T” structure incorporates the officers’ cabins in the forward part with the balance down the middle being the upper engine room casing. The two long “galleries” also comprise cabins opening inwards onto the covered passageways. They are also flush with the ship’s sides. I’m also wondering about your winch locations. As you’ve got them, the platforms obstruct the #2 and #3 hatch openings considerably, also the layout you have forward would put all the running lines across the hatches as well. Your poor crew and stevedores would be cursing for every pallet they’d have to lift! 😜 I would try to fit the forward winches in the area between #1 and #2 hatches, athwartships at the base of the foremast. If you rebuild your superstructure closer to my rough diagram, it might also give you some room to pivot your after winches clear of the #3 hatch. Again, these are just my own observations, feel free to ignore them as you see fit. Keep up the good work, Andy

- 330 replies

-

Looks great Nils! I’m sorry I couldn’t show you these earlier, but I have some photos of the Sylvan Scale Models kit that shows the porthole arrangements: They’re cast into the hull and crudely painted in (I started on this kit many, many years ago) Andy

- 330 replies

-

Not as much as you might think. The effective range of a ship’s rudder is somewhere in the nature of 30 to 35 degrees port or starboard. Any further and the rudder begins to act as a brake, and any gains in turning speed is offset by more dramatic losses in forward movement, a critical factor in turning a square rigged ship to be able to miss getting caught in stays. Andy

-

I tried to find images to compare, all I found were some ones from an Australian hobby shop: https://au.super-hobby.com/products/F4F-4-Wildcat-53784814.html Although it’s a different paint scheme, it doesn’t look too far different from your own. I’d say you’re doing very well (amazingly well) with what you’ve got. Andy

-

Good ol’ Pursey’s! Yes I agree some early steel ships did have bar keels, but from what I understand, by the time period of WW1 lake ships had long abandoned that design in favour of internal keel girders (duct keels). A keel hanging down below the hull reduces the amount of “useful” draft a ship can have, ie you carry more cargo if your 25’ draft is all ship, rather that if 6” of that was bar keel hanging down below the bottom. A significant amount of what we would call “modern” steel ship construction was developed on the lakes (the bulk carrier, for example). The lakes have long been about maximizing the ship size to fit a given space. Yeah, the centre line keel. Generally speaking, if you took a transverse section of your ship and drew a square around it, where the bottom of the square lined up with the flat bottom of the ship, and the sides lined up with the vertical section of the extreme breadth, the bilge keels should fit in the triangular section formed by the sides and bottom of the square and the rounded turn of the bilge. Andy

- 330 replies

-

Looks good Nils! Before you get too far ahead, you should sand the bar keel down the centre line flat. I think I read you based your build on plans for the wooden version of these ships, which had the old style keel, but that shouldn’t feature on this sort of steel ship. Andy

- 330 replies

-

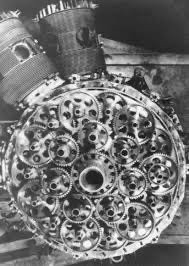

There was a little government assisted industrial espionage. From what I understand, the Air Ministry passed on quite a bit of the Napier’s technological information along to RR… The sleeve valve came about after a 1927 paper by Harry Ricardo that calculated a maximum HP limit for poppet valve engines. (Not sure if that was for single or multi valve engines, the prevalence today of DOHC multi-valve car engines might suggest only the former). The sleeve valve was a workaround that allowed greater optimal airflow, thus bypassing the theoretical HP limitation. Ultimately, as you say a turbine engine will always outperform a comparable reciprocating engine. Partly due to fluid and thermal dynamics, but also due to the energy, and therefore efficiency, loss caused by converting reciprocating motion to rotary motion. I think it’s more fair to think in terms of relative efficiency, rather than absolute, and the Sabre delivered in spades. Andy

-

Not arguing that technology leapt ahead during the war and that jet propulsion far outclassed anything that piston power could put out. My point was more towards the fact that, when you look at engine development, other engines were further ahead in development by the time war broke out. The RR Merlin was first run in 1933. They had 6 years to work out kinks and improvements before the outbreak of the war. Six uninterrupted years to commit resources and personnel to refine the manufacturing process and develop effective mass production strategies, and even develop potential successors. The Sabre first run in 1938, and at the time Napier was basically a “boutique” manufacturer. All their engines were hand built by craftsmen. They had no experience with mass production on the levels required by war demands. They also had minimal experience with other new technological elements of the Sabre engine, like the sleeve valves. And they had all of a year and a half to figure all these things out before the buzzer went off. Oh, and RR was slagging Napier at the Air Ministry, because they were legitimately afraid of what the Sabre could do. Napier didn’t finally catch a break from the government until Beaverbrook arrived in 1940. Andy

-

Napier was messing around with adding a multi stage turbo to their engine for high altitude performance, unfortunately this came at the detriment of remedying the flaws of the engine. When English Electric bought Napier, they scrapped the turbo project and concentrated on fixing the engine issues (I suspect the British government may have had something to do with the EE takeover, or, at the very least, the removal of red tape to accelerate the process). I suppose if it wasn’t for the necessities of wartime, the real untapped potential of the Sabre could have been unleashed. Andy

-

Thanks Alan! I was vaguely aware that there was something going on with a Typhoon resto, I didn’t know they were actually trying to get it not only airworthy, but with a Sabre engine too, if I catch the gist of your article correctly (repop or resto, doesn’t matter, it would be a thrill just to hear one start up after, what?, sixty something years, @egilman probably knows when the last Sabre engine flew). Andy

-

That planking looks fantastic! I trust that nary a copper tile will ever obscure any of your hard work? Also, I would be remiss if I didn’t say thanks for the “new” word to add to my vocabulary! Andy

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.