mikegr

Members-

Posts

826 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mikegr

-

how does this react to plexiglass? Does it keep it clear or make it whitish? Professionals are using a chloroform based glue which keeps the plastic 100% transparent. But this is extremely hard to be found and usually comes to 1 kg bottle sold for 60-80 euros.

-

Nowadays kits in 1:700 are so advanced that can be almost comparable in details to their biggest cousins.

-

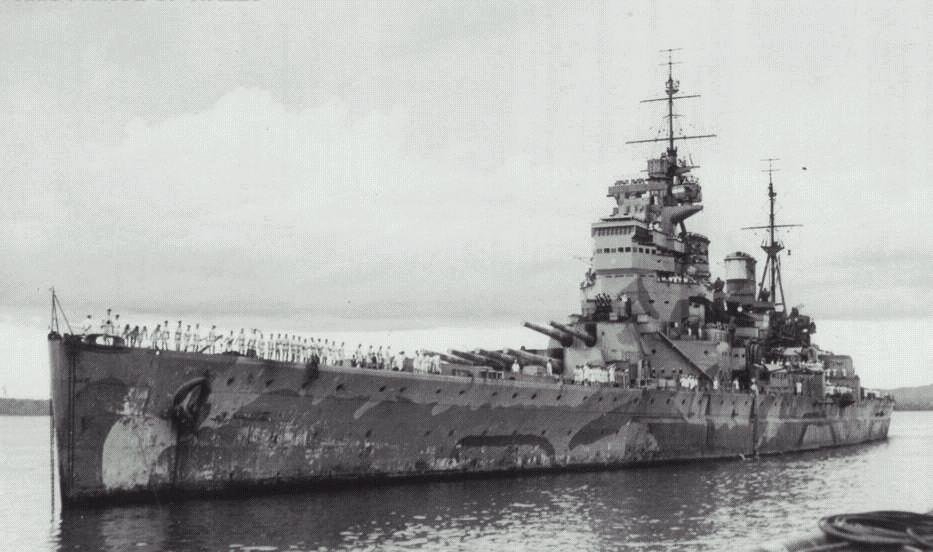

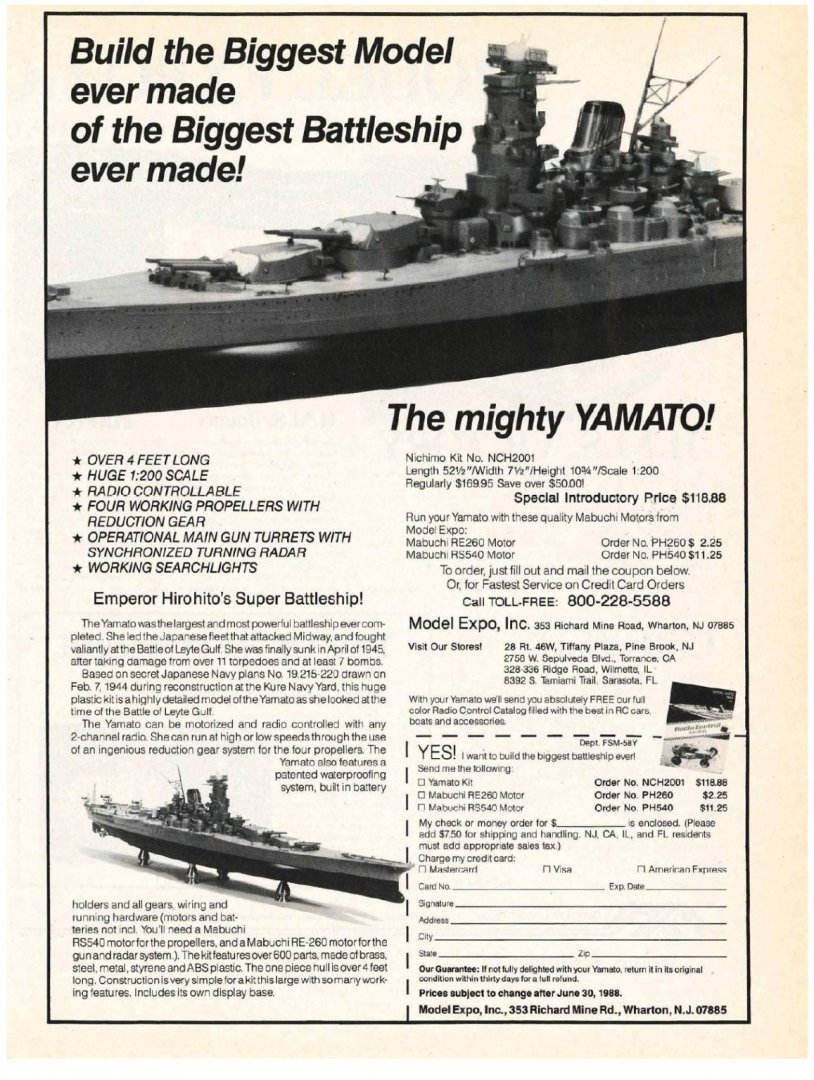

I remember this kit at 90's There was a toy store on my way to school had it along with Matchbox Seasprite as well as few other kits. Price was approx 10$. Finally I built it in 1/600. I have to say those double hangars made the ship look too tall. Definitely not the most handsome model, at least in my eyes. Maybe in waterline version looks better.

-

The Asian channel owner makes elite builds. The sea bed is top world class, comparing to Flodberg and Katseas creations. However require more materials and its more complicated to be built.

-

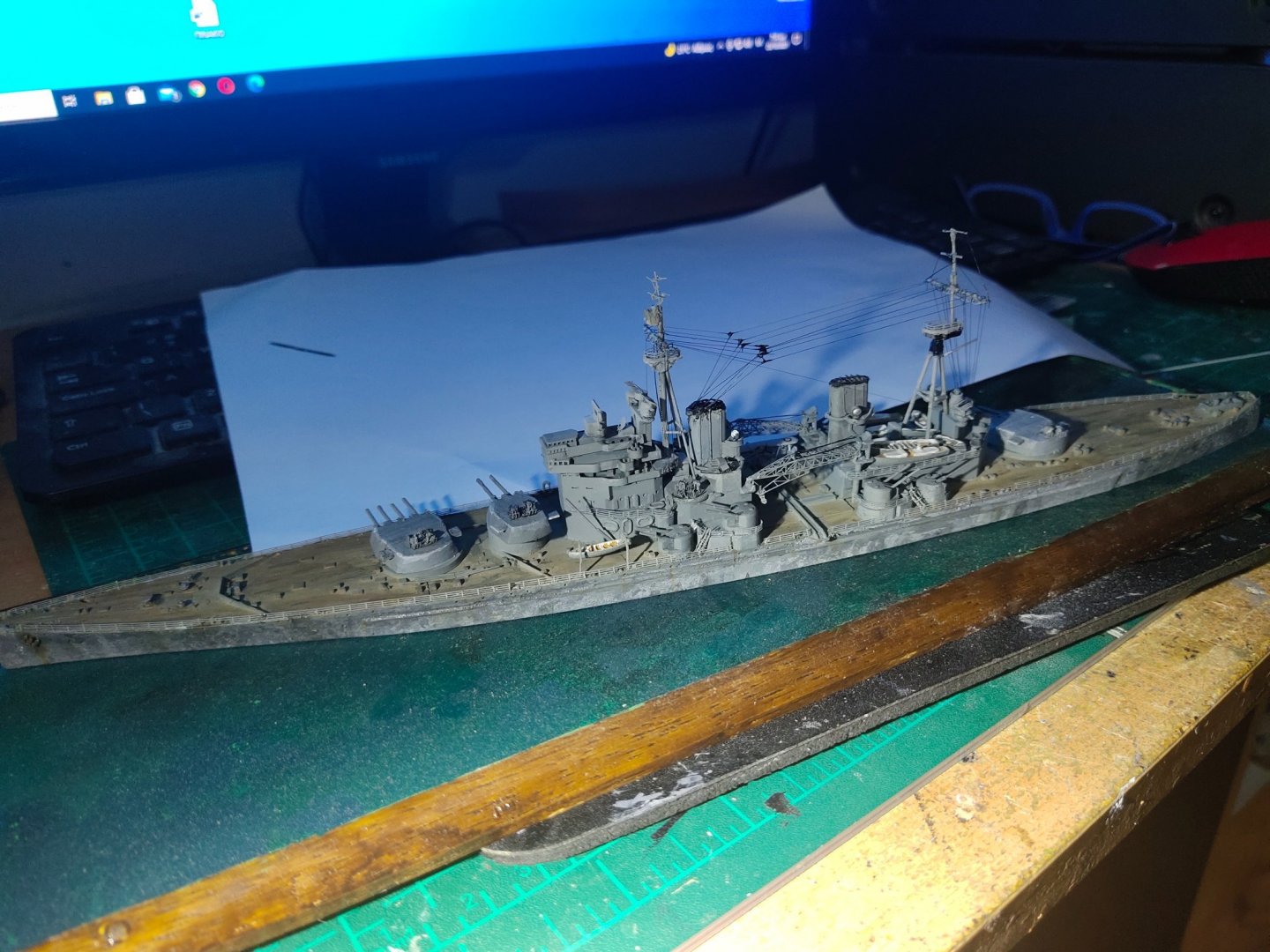

I am in a hurry to finish it by this Sunday at least the model if not the sea bed. I glued almost everything except few pieces left as well as rails on main deck. I did also deck weathering. After gluing parts, rigging and weathering. I do rigging first before works comes first , then pleasure(rigging is boring).

-

That is another type of addiction. Sometimes I compress my work time in order to post my updates regularly.😁 On the aerial picture I sent you can see the weird color of the Atlantic although this might be somewhere of North UK coast. The problem with aluminum foil is that sea will look a bit messy as the waves are not pointing to a specific direction. Of course this does happen sometimes in reality its just for me looks a bit unusual.

-

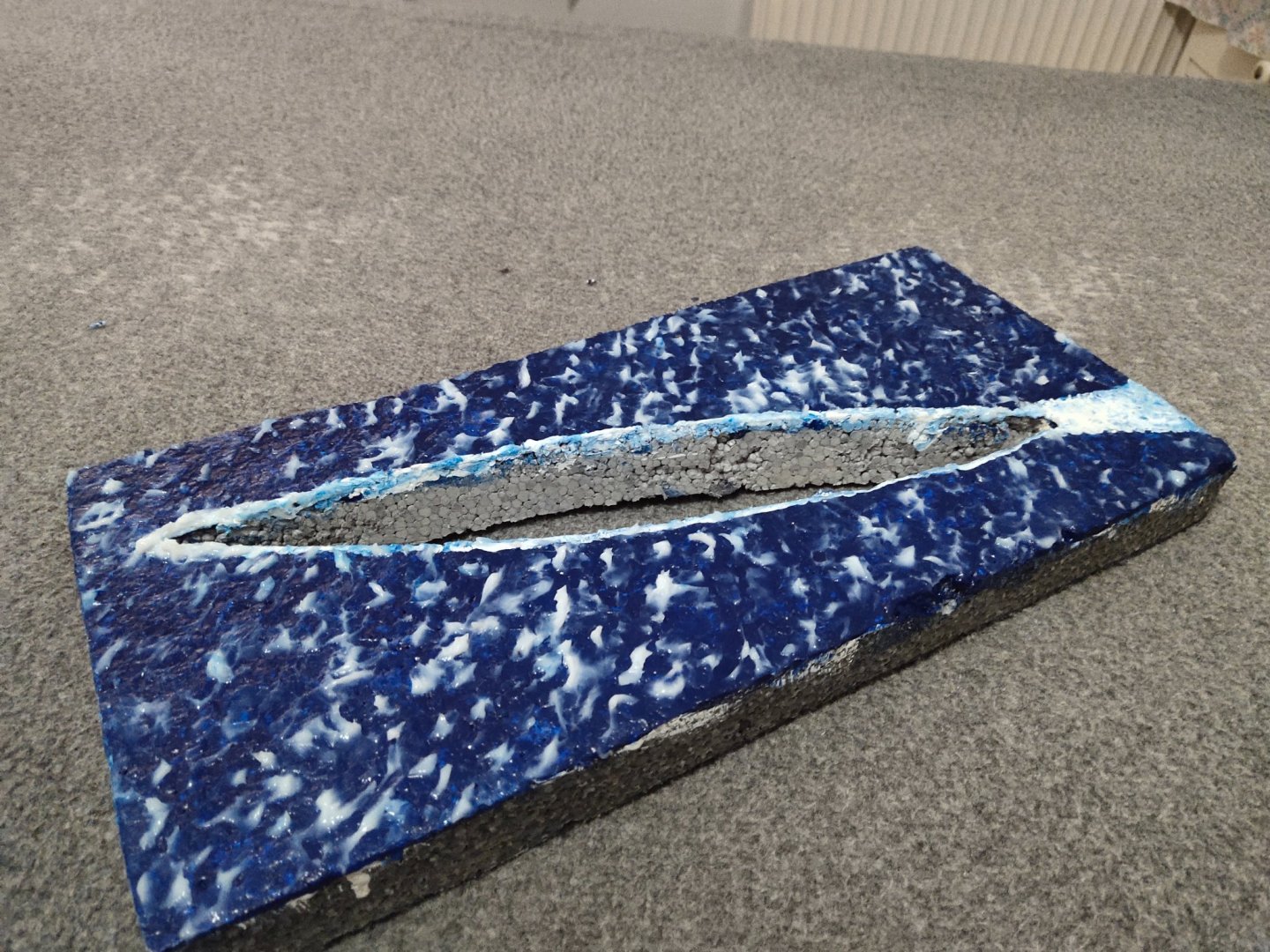

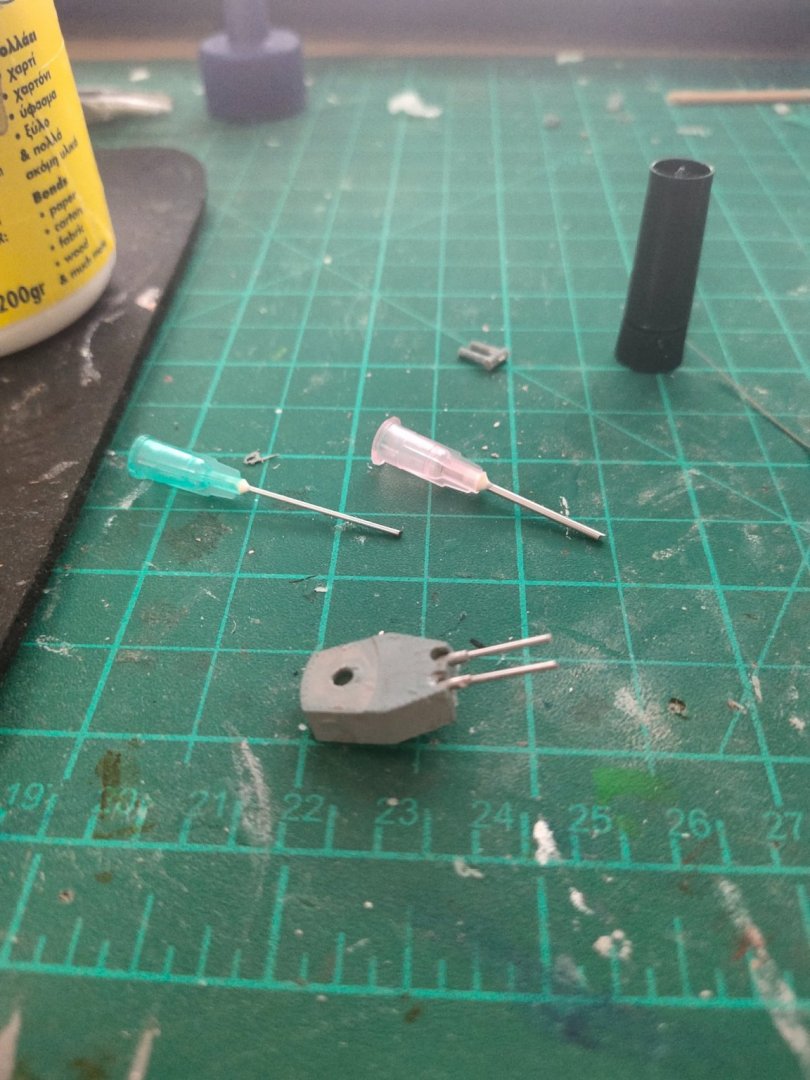

For wood I use dry type from 80 to 240 grit. For hull sanding and other tasks I use sanding sponges I like their grip and the shape. I also use rectangle ones which I replace the paper once it get worn. I glue it with PVA. Sometimes I combine grit. One flat side 240 grit, other with 120 etc...

-

I think slicing software does estimane the amount of resin needed. Is it reliable?

-

Because its for him. Otherwise a modeler wouldn't spend 1500$ for a kit with plastic deck🙂

-

Cap San Diego by mikegr - 1/160

mikegr replied to mikegr's topic in - Build logs for subjects built 1901 - Present Day

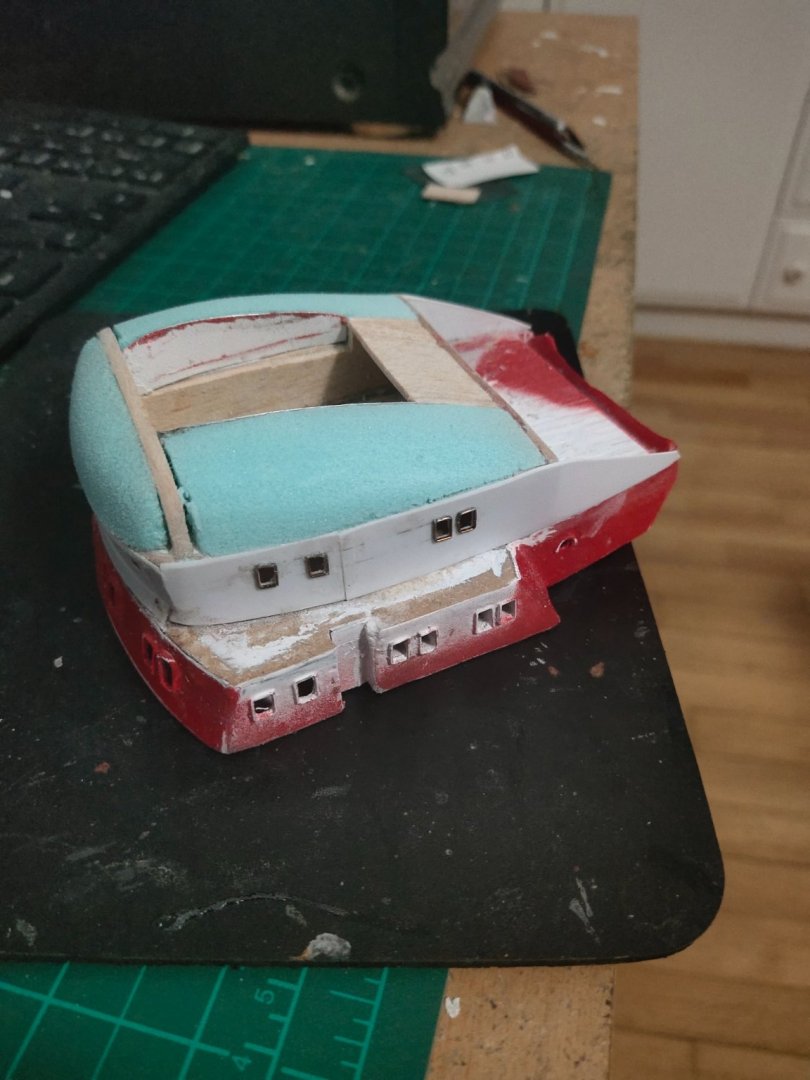

I finished the pool deck. The wood veneer color matched closely to the real one. I start working at the bridge deck. The complex shape will be made with the same technique. Polystyrene shaped, then car putty and sanding. -

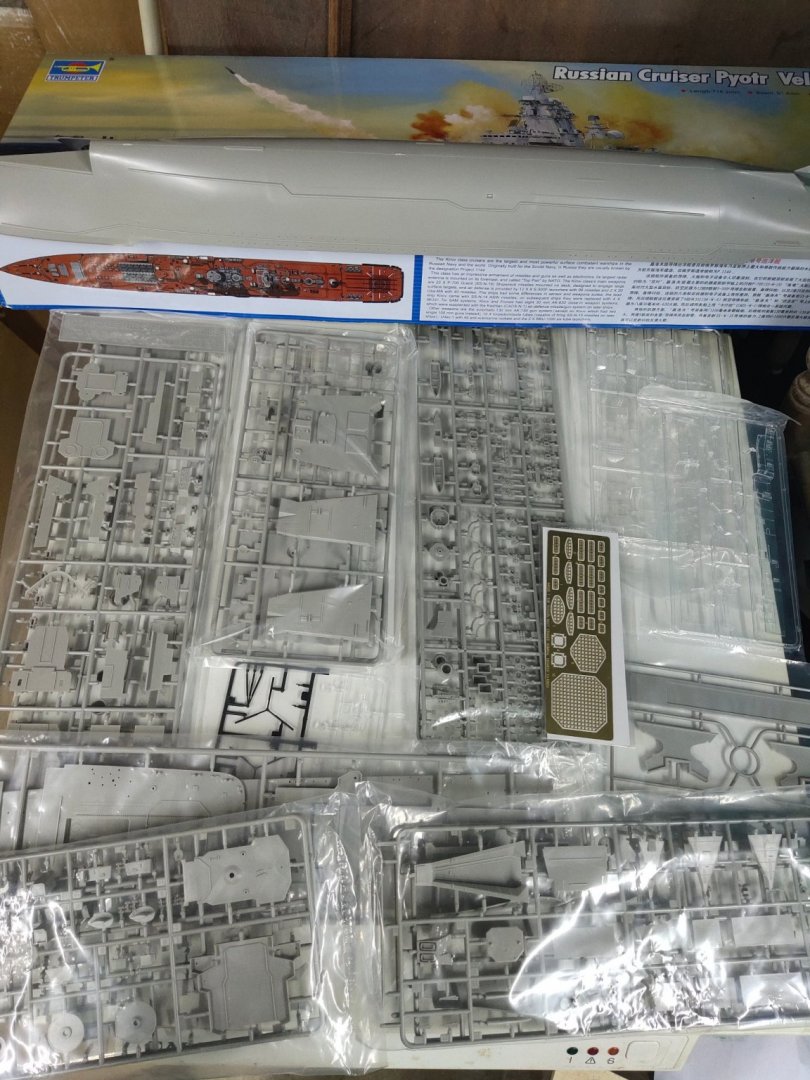

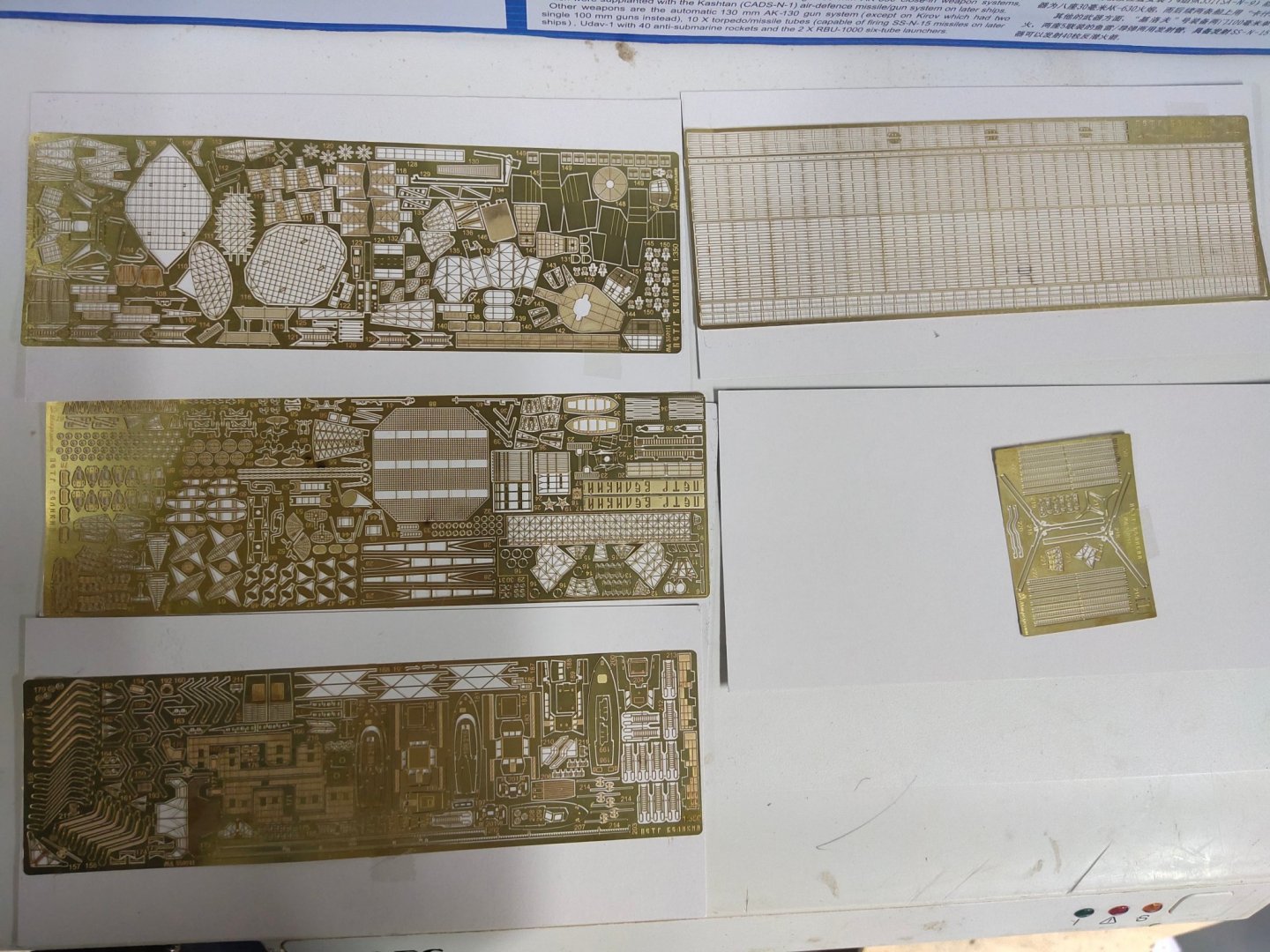

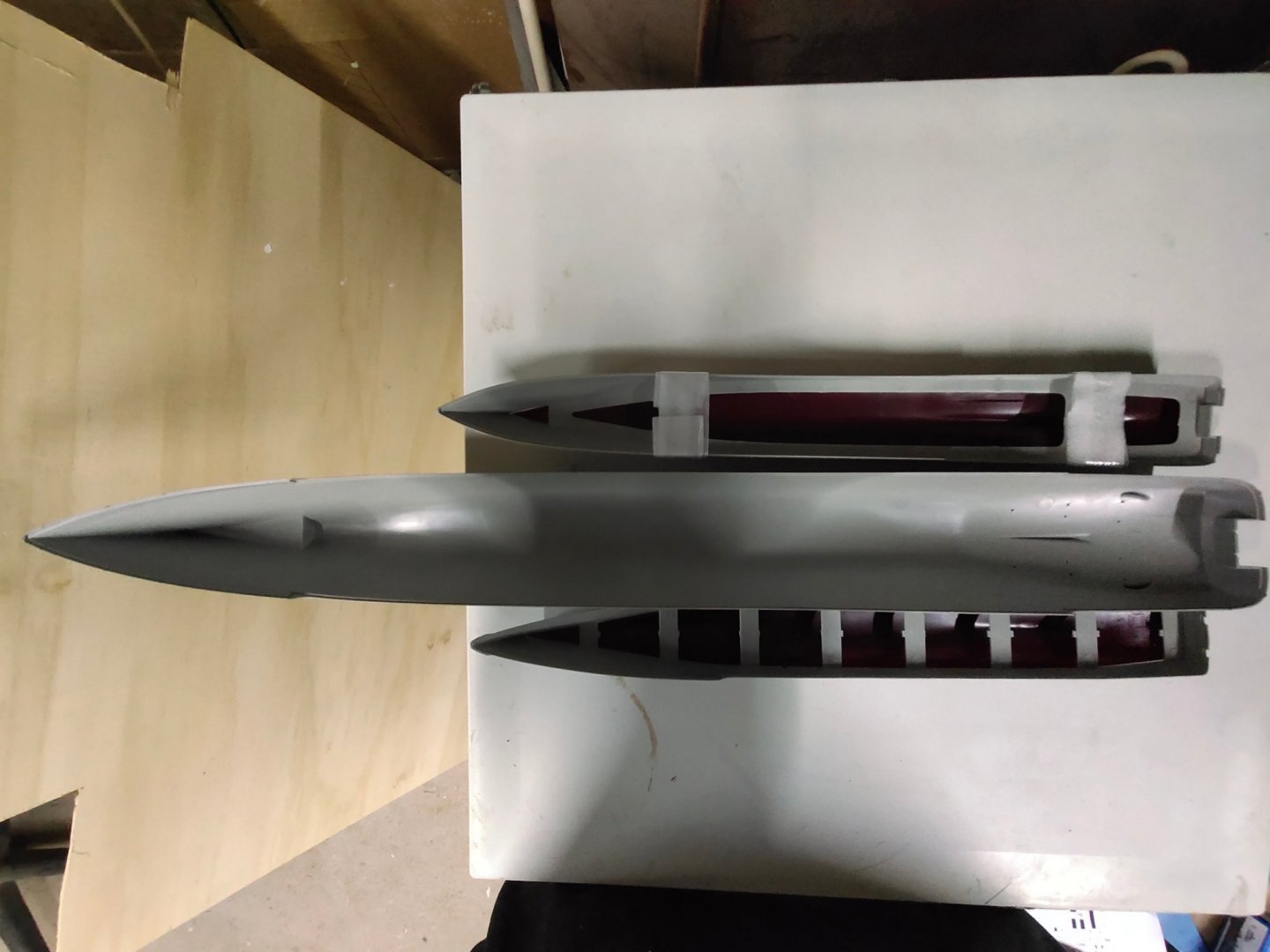

Opening the box of the Pyotr Velikiy , its easy for someone to realize why these ships are considered battlecruisers. Their size is close to ww2 battleships. My workbench is occupied so i took the photos on top of my deep freezer, the only available flat space in the room. The kits itself has 550 pieces and its 72 cm long. It has 16 sprues, 3 of them in clear color and one additional with PE radar parts. The radar parts comes both in grey and clear plastic as well in PE form. The instruction manual comes in 24 pages plus the illustrated sheet for painting reference. The hull is also in one piece, no waterline option is available . The PE parts as expected are more than the previous kit and certainly they wil take this ship to another level of details. The railings provided could be enough for two medium size 1/350 ships. Finally i took two comparison shots so we can better understand the size of the kits. Pyotr Velikiy is in the middle, Panteleyev on the upper side and Sovremenny at the lower. I resized Pyotr Velikiy to 1/700 and compared again. Still stands with dignity I hope i can take some comparable shots with the finished models soon.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.