Emmet

Members-

Posts

401 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Emmet

-

My kit is new and I have the same problems you fellows are talking about. My drawing re: gunports was not to scale. I have had t guesstimate where to put them. I made a tracing and tried to keep them relatively aligned. It is in my log. I also found that after planking my upper deck did not fit both on the sides as well as fore and aft. It seems to be part of the game.

- 395 replies

-

This is Emmet. Welcome aboard. It will be interesting to see the 1737 ship.

- 41 replies

-

- artesania latina

- hms victory

-

(and 1 more)

Tagged with:

-

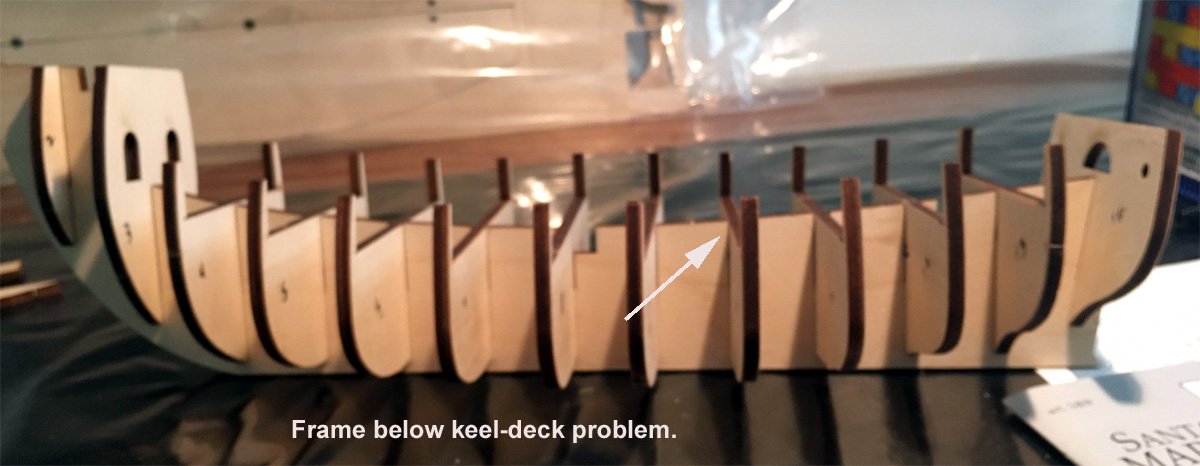

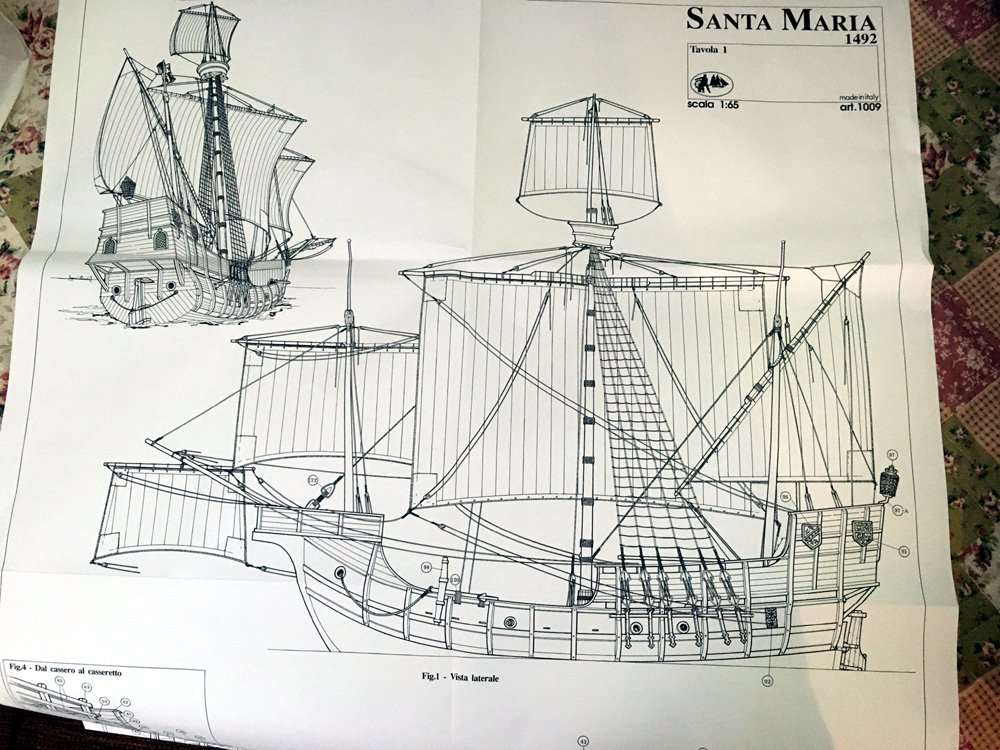

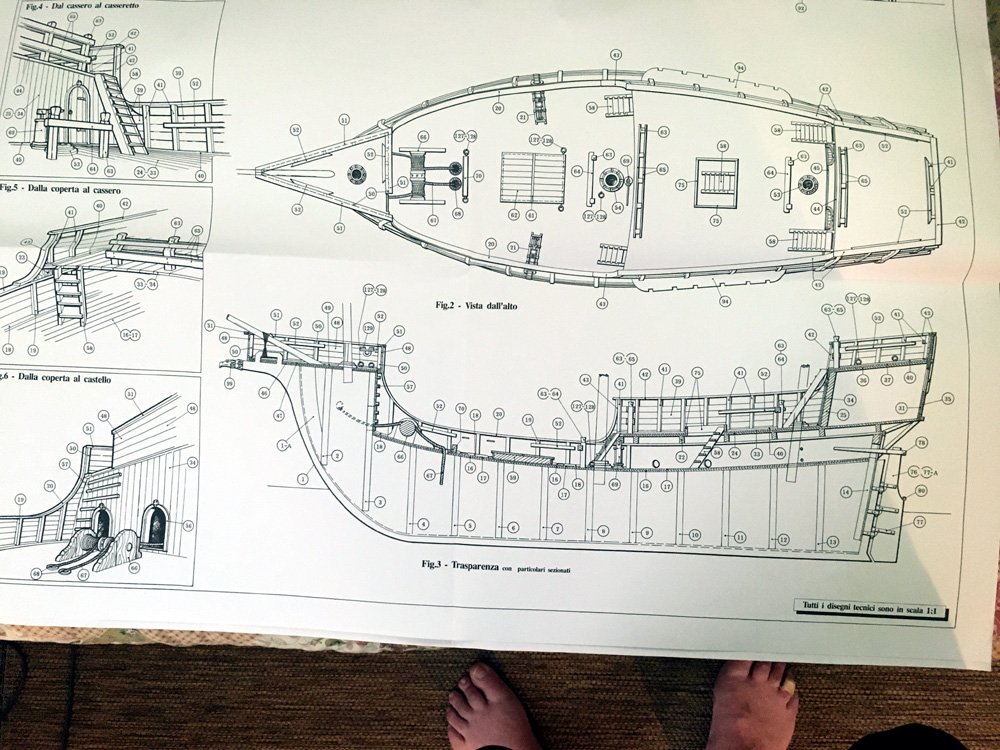

I completed La Nina in 2019 and am currently building HMS Victory 1805. I am building the Victory in New Hampshire. I travel south in the Winter and Victory is too big to take a long. So while I am south I will build smaller, less complicated ships. Santa Maria is my choice. I am only in New Jersey now to see a couple of doctors. The coronavirus is worse here in New Jersey and we are better off in New Hampshire. We also have a grandson graduating from high school and we are going to congratulate him, unfortunately at a distance. So for a start I am putting the basic drawing in along with the frames on the keel. I see already that a frame is below the keel and will have to remedy that along with truing the frames in general. I did not bring my shipyard for this short trip so I will only have this entry for now. I will be back here in November and resume the Santa Maria. Sorry about feet.

-

Thank you Keith. I am using some thumb tacks that have a wide head. They work best when pushing down into a frame. But they also work out OK in other areas. I am getting Some of those pins and I realize that you can push them sideways to gain some pressure on the plank. While the hole in that section will be copper I want it to be as good as possible anyway.

-

Thank you Christopher for the wood info. I bought my Corel kit on Victory from Cornwall. It was delivered to my home in Sandwich, New Hampshire within three days. The shipping was expensive but there were no kits in stock here. And it was a lot cheaper anyway. I enjoy hearing where people live and while I have been in the UK and Ireland I never made it to Wales. The town your sister lives in has a fascinating name – only in England.🤪

- 395 replies

-

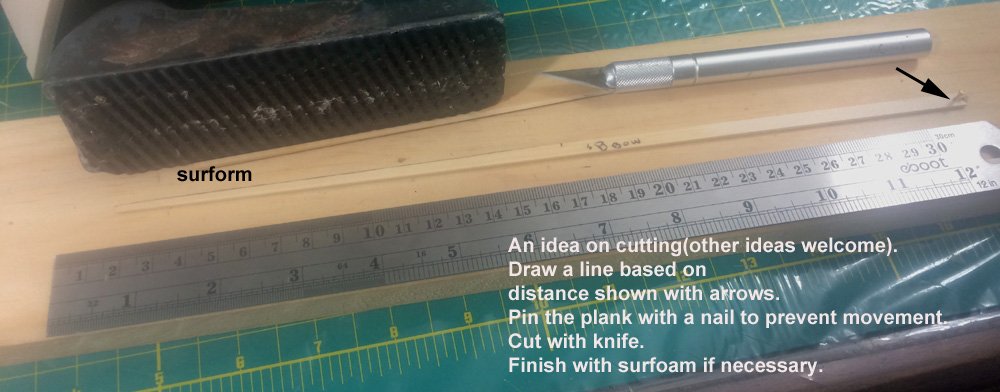

I have done some labeling and put them in wrong place. Luckily I did not do it with different sizes yet. Only you will know.

- 395 replies

-

Not sure you will get this Keith but thought I would leave a comment here to see. I had planned on spending some time here. I was observing how you decided on a spot on the bow where you would terminate the walnut pieces. I was thinking of making pieces that would terminate in different locations along the hull. Was that your decision or was it the way the Terror was built? I liked your approach with wood glue. But don't the pins make bit of a dent? How did you fix those if you had to? Did you apply the glue to the planks or to the hull?

-

I am going with quarter inch copper tape. I am going to make a jig for riveting the tape. Thanks for mentioning the installation of the strips.. It will give me some practice doing the walnut. Bending on the bottom of the ship is much more difficult and it will make for a better job up top after I finish the copper. I am going to New Jersey for two weeks. I was thinking of beginning the Santa Maria down there and just leave it. Since I am almost finished with smoothing the hull so I may take it with me.

-

This is Emmet Well Christopher I think your ship looks pretty good. The beech certainly looks like an interesting approach. Where are you getting your woods? Trying to copy the real thing is worthwhile and I like your creative approach. I am in the process of trying to think of a way to do the ship under the waterline.

- 395 replies

-

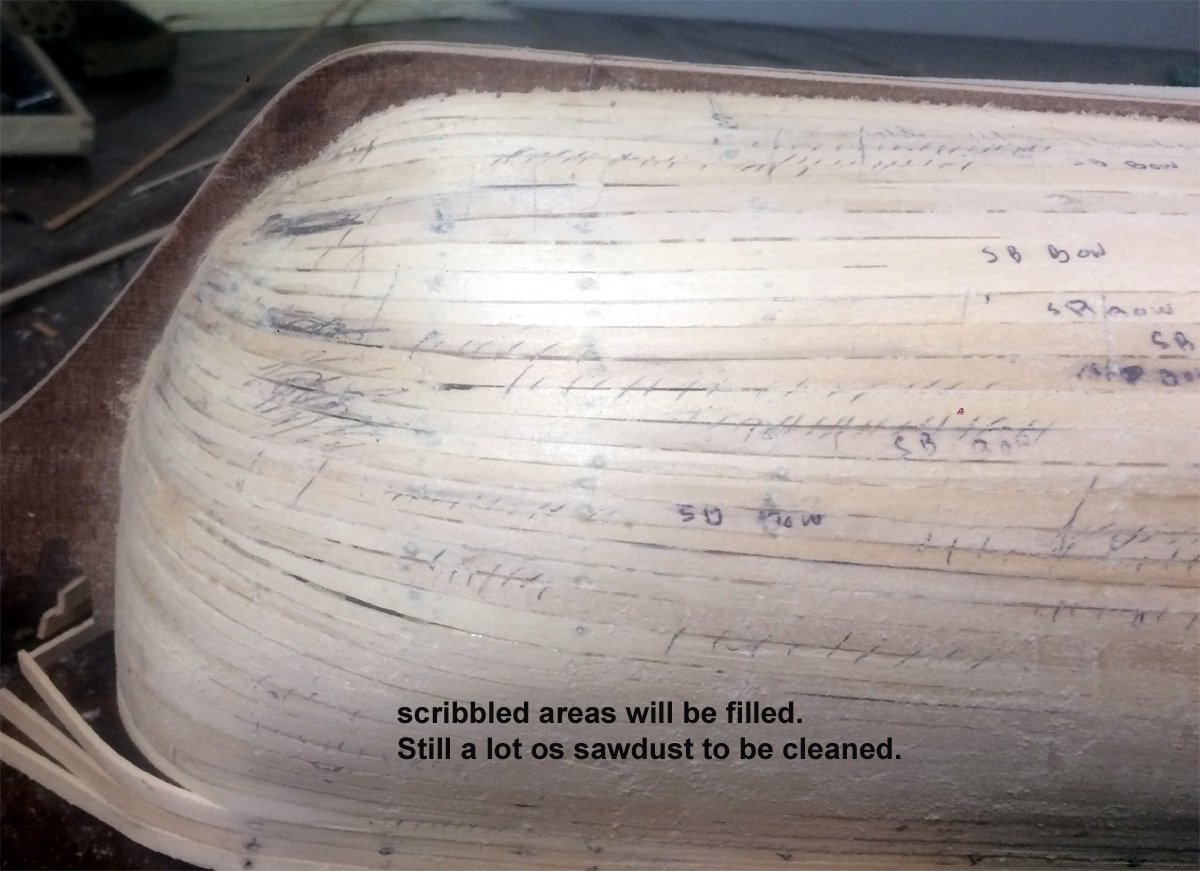

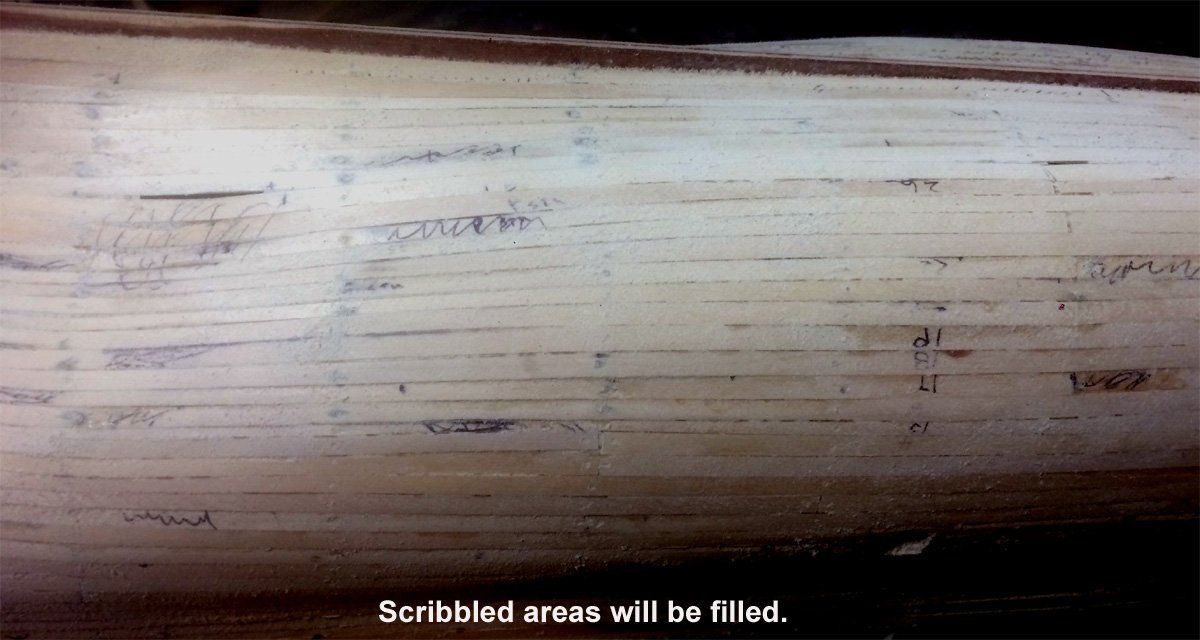

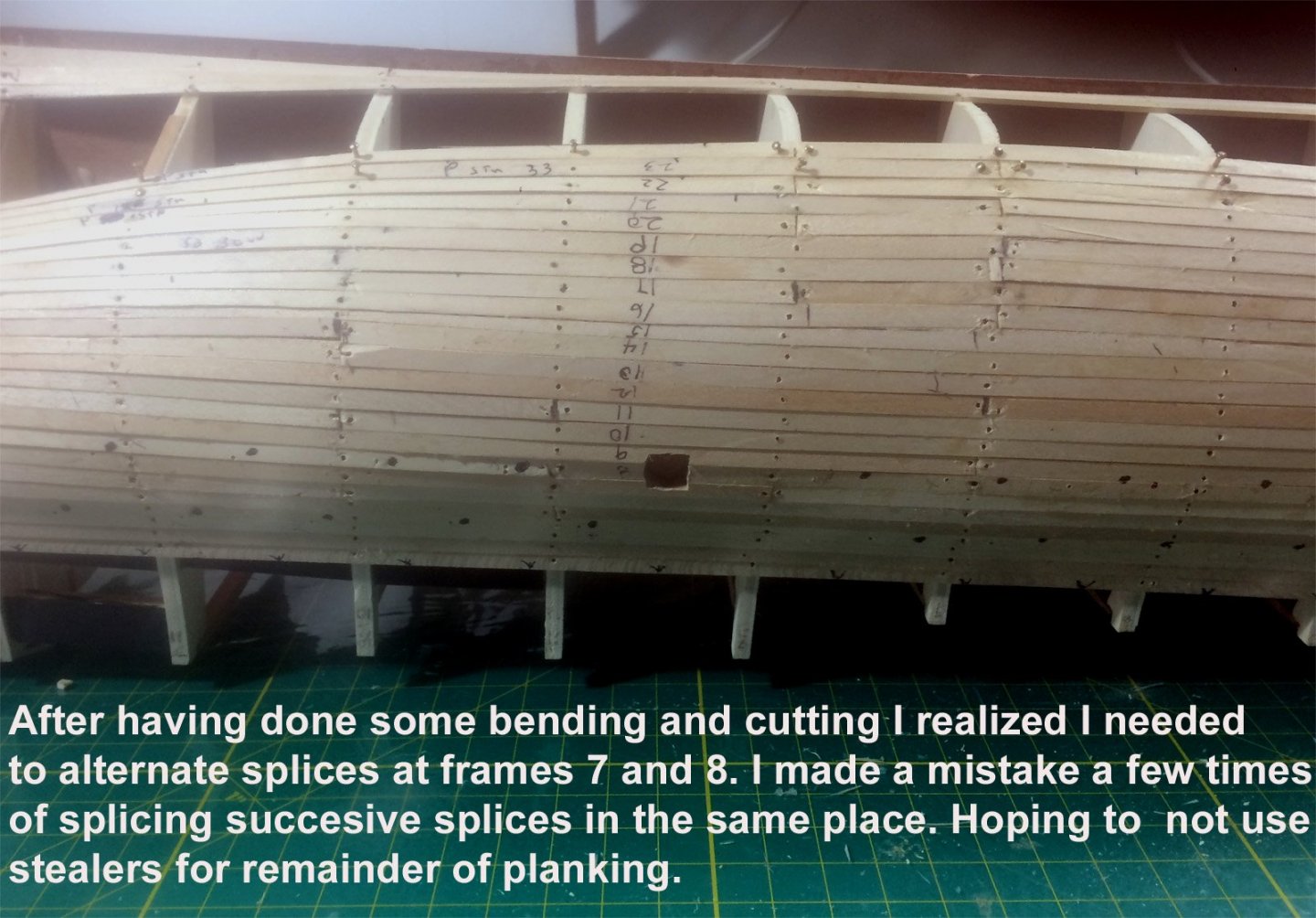

Let me say I appreciate all comments and they are food for thought as well as direct help. I am almost finished with planking. I am trying to make up my mind about coppering. I feel like I will go with 1/2 in. copper tape or similar. I would like it to be thicher than .05 mm. any ideas here would be helped. As i explained before it is not practical to simulate the real thin as the pieces would be much too small. 48" x14" divided by 98 is too tiny. Here is a look at the status of all sides.

-

You might try steaming Rob. I have seen where builders use a steam iron but I have not done it myself. Then again soaking for a long time might work. Perhaps repetitions of soaking,heat bending,soaking,heat bending.

- 395 replies

-

I am anxious to see what the finished product looks like. As I have mentioned in my log my 98:1 scale makes it difficult to be do the copper to scale. I am still up in the air about how to do this. I like authenticity as much as possible.

- 395 replies

-

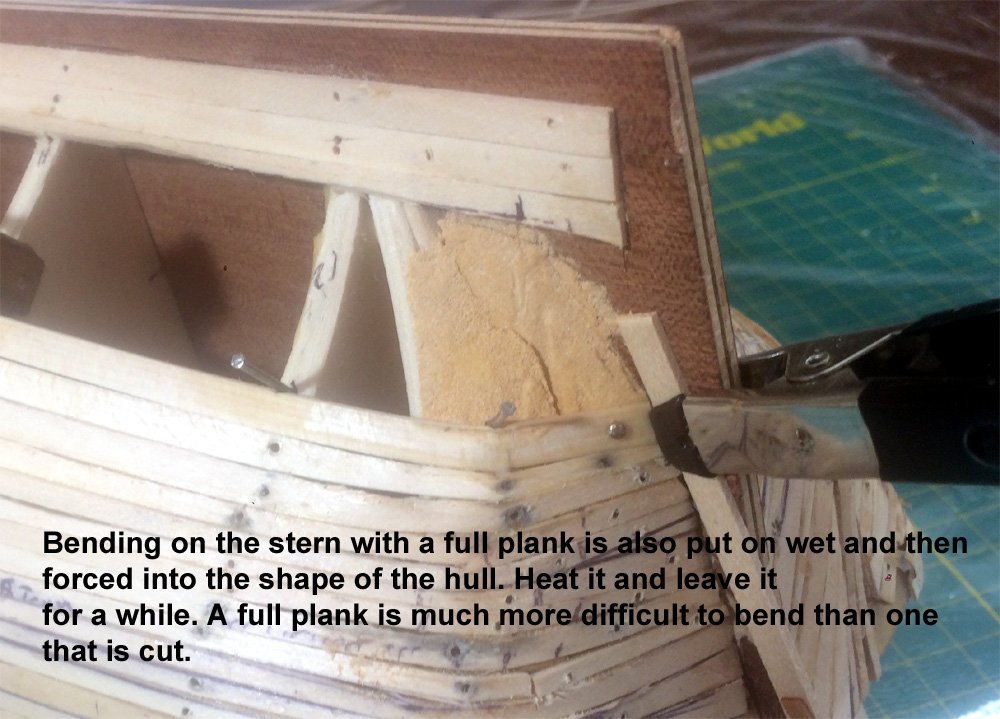

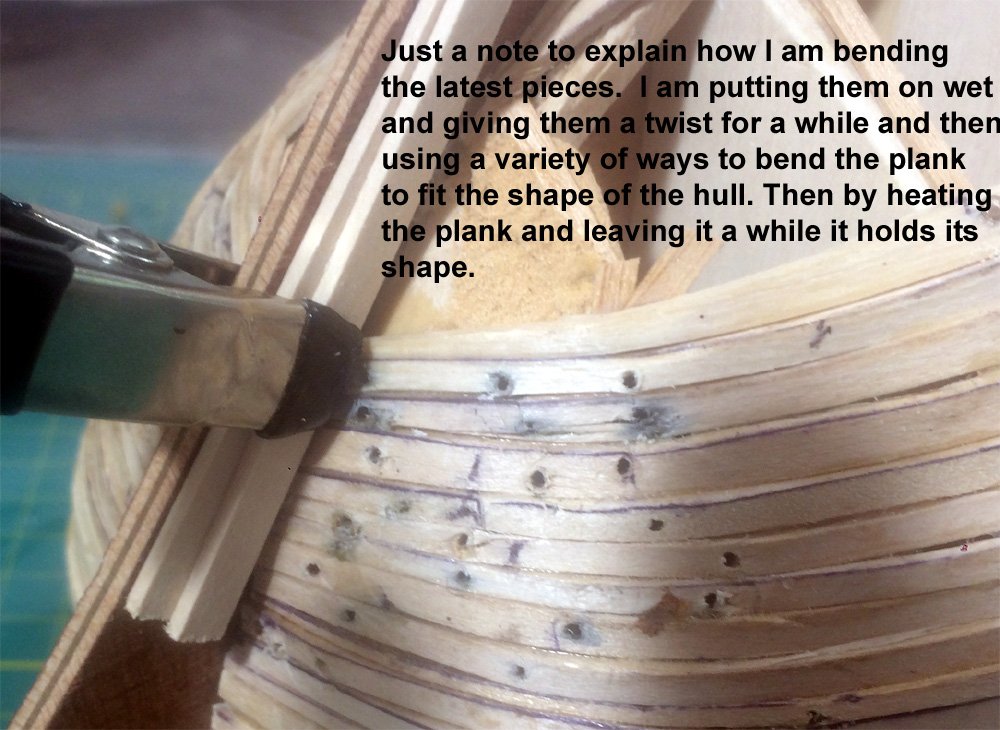

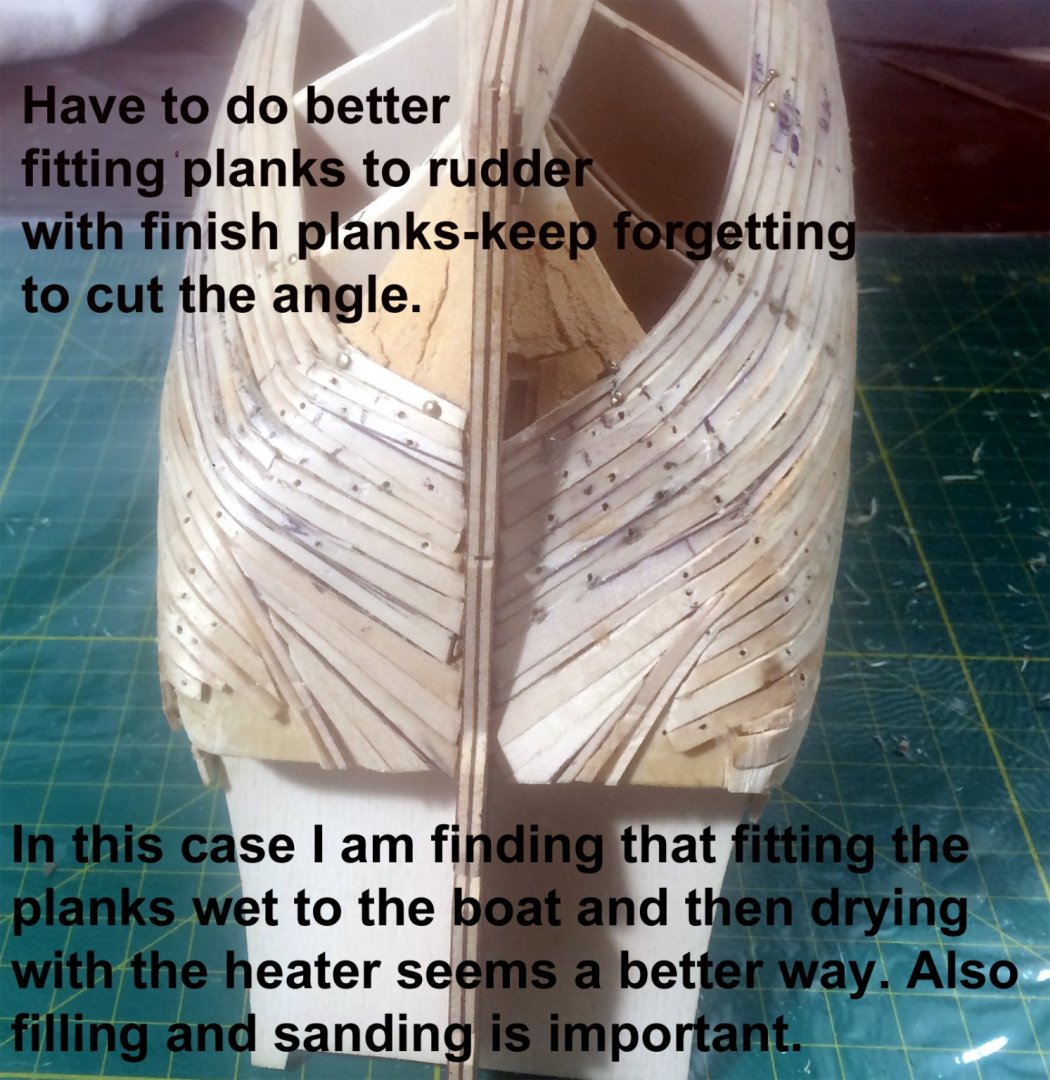

Thanks Rob, I guess I arrived at a similar approach. The area I am currently working on is hairy. The stern of the Corel model sweeps inward and then goes into a sharp bend. I did make one of those pvc tubes. I go in and out of water depending on how long it takes me to mark and cut them. In other areas of the hull the bends were not so dramatic and I could dry them with the heater when fitting to the hull. I then could remove them and dry them more and then glue. In this area of the hull I am leaving them stay overnight or a few hours. Thanks for giving me your ideas. I put my ideas in the log because I feel like it is an obligation to let others know how I fumble around.

-

Thanks Rob I have been considering scale and since my build is 98:1 the pieces should approximate 48” x14” tiles on Victory. That equates to about 0.5”x .14” or 12.5 mm x 3.6 mm. Not to get crazy but this is small. Just thinking. Again thanks for the details in words and pictures.

- 395 replies

-

I am deliberating about the copper below the water line. any ideas about how to establish the water line out there-no instructions. I am looking at different kinds of copper. I have used copper tape for stained glass but wondering if there is not something better. I guess I will just smooth the area and only use 2nd planking above the water line. Happy 4th to everyone -sorry Brits. It turned out good for all sides anyway.

-

Great detail! I am still trying to understand the green wood idea. How will it be finished?

- 395 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.