-

Posts

1,215 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin-the-lubber

-

You've already gone way beyond my knowledge but google tells me 1/3 to 1/2 would be fine. This thing won't be turning heavy loads, probably about 1 kilo or thereabouts.

- 219 replies

-

That's really not bad at all for FDM printing, is it. I'd also chop off the funnels and do them separately - you can probably do that in the slicer. Ian, can I pick your brains a little about motors, as you seem to know a sight more than me about these. I'm making various simple machines for other arty projects and one of these is a roller machine, that is quite similar to a rock tumbler. I could just buy a rock tumbler but I like solving puzzles and making stuff, besides which I can make everything apart from the motor. I've used a small, cheap, 220V synchronous 5 rpm motor for proof of concept, it does the job but gets very hot after 30 mins continuous use. I need something that can run for hours, maybe even days. It also reverses direction at will, there must be some kind of internal counter that determines that this time it'll be clockwise, next time anti. Ideally I'd have control over that and even more ideally, I'd be able to control the speed via electronics rather than gears. Any suggestions, pointers?

- 219 replies

-

Phil, did you change your mind about closing this log? As a follower, I received an email overnight like so (below) but it doesn't show up in the log? GrandpaPhil has posted a comment on a topic, HMS Victory by GrandpaPhil - Mantua - Scale 1:98 - Kit-Bash - Aborted Posted in HMS Victory by GrandpaPhil - Mantua - Scale 1:98 - Kit-Bash - Aborted I am closing out this build log. I learned a lot from working on this model, but I have no real desire to continue it. I have ... Go to this Post

-

I think our views are fairly similar Phil. It's just another material and like all the others it has pro's and con's. I use whatever seems most suitable for the job at hand, be that wood, metal, resin, paper, card and the clear poly-something-or-other found on cake boxes which is great for window glass 😁. At least that's what I tell my wife when asking her to buy yet more chocolate eclairs. (Don't tell her but I actually use transparent resin coated with high gloss lacquer). Have you tried ABS-like resins? I prefer to stiffen them up a bit by mixing with a bit of tough or rigid resin but it does make parts pretty tolerant of being bent etc. I print window bars at 0.25mm - 0.3mm without issue but below that would be pushing the boat out a bit too far, in most cases. Anyway, that is a gorgeous little boat and an impressive bit of model-making to do it this small.

- 54 replies

-

- 18 ft cutter

- ships boat

-

(and 1 more)

Tagged with:

-

You’ve made a lovely job of this Phil, especially at this scale. Ply at 0.8mm is seriously thin stuff! It won’t surprise anyone that I have a different view about 3D development and printing. It opens up a new model making avenue in much the same way as injection moulding and die casting made model building accessible to gazillions of school kids. But each to their own of course. I’d just add that resin printing has come a long way. Parts can be much more robust than you might think and I have no end of objects sat unpainted and in full sun without the slightest signs of deterioration. I suspect the things I make will long outlast me!

- 54 replies

-

- 18 ft cutter

- ships boat

-

(and 1 more)

Tagged with:

-

Have you thought of making it from card, possibly stiffening this up with diluted wood glue to reduce feathering? Just thinking that it’s much easier to cut card with a scalpel than plastic. (It doesn’t really help but this would probably come out well as a resin print). ps. Not just any old card - I mean the good quality, smooth surface stuff from an art supplies shop.

-

I stuck with it all the way until I just couldn't do what I wanted any more. Every so often I have reason to go back into my TinkerCAD account, usually to retrieve something I made for gardening or DIY, and I'm surprised at just how much you can do with it.

- 219 replies

-

Are you still using TinkerCAD? In F360 (and, I imagine most of CAD packages) you’d quickly loft this. It looks like you’ve already become very adept at 3D Ian. The scraps photo made me smile. I bet we all have a big box like that somewhere in the workshop!

- 219 replies

-

This is an amazing build Michael, I will need to read the whole log as at first I thought this was a scratch build, wood POF at something like 1:78! Your Victory is beautiful too, and as for the Vasa - gosh, you really do rise to the challenge, don't you!

- 287 replies

-

- Sovereign of the Seas

- Airfix

-

(and 1 more)

Tagged with:

-

It still looks great from here. As others have said, maybe inspiration will come with the passage of a bit of time, but in any case maybe you could look at it as a 99% success, which really isn't bad score, is it. There are some exquisite models on this site but I think this kit is on another level in terms of complexity and detail.

-

3D printing material question

Kevin-the-lubber replied to CPDDET's topic in CAD and 3D Modelling/Drafting Plans with Software

Yes, this resin can be machined, but do be careful, resin has a relatively low breaking threshold. If I was you I would ask them to give me some scrap pieces if possible, to practice on, or else get an extra print done. That said, you might be surprised at just how thin parts can be printed. I regularly print objects with walls that are only 0.2mm thick, including tubes. However the risk of print failure is higher on these parts, which increases costs, so commercial printers may be reluctant to take that risk. -

3D printing material question

Kevin-the-lubber replied to CPDDET's topic in CAD and 3D Modelling/Drafting Plans with Software

Go for the elegoo abs-like grey. This will have a bit of flex whereas the elegoo standard will be more rigid and prone to breaking. Grey is a very good colour for seeing the detail quality. -

3D printing material question

Kevin-the-lubber replied to CPDDET's topic in CAD and 3D Modelling/Drafting Plans with Software

Dave, list the options or the company and I'll have a look. For best detail you'll want it printed in resin and, generally speaking, for non-functional model parts you are not going to need anything exotic and their default option will probably suffice. -

I don't think I'd say it's 'out-of-range' but it depends on what you prefer and how much work it would be to try to lighten it.

- 219 replies

-

For what it’s worth, as a ex-mountaineer and caver I would often coil rope around an arm and lay it down on the ground, where it would look just like Marc’s coils. I agree that some very stiff rope, especially when new, can want to do it’s own thing but even hemp or bark/grass rope softens fairly quickly. (On the climbing and caving side, most of us would have paid more for a rope that did behave rather than continually kinking. We used to have to regularly drag 50 metres of rope along the ground to get the kinks out and stop it twisting during coiling).

- 2,667 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

CNC for model making

Kevin-the-lubber replied to Jefta's topic in CAD and 3D Modelling/Drafting Plans with Software

While I haven't noticed any F360 workshops on here, there is a huge amount of free tuition on youtube and back in the day, my go-to was Kevin Kennedy. I can't help you with vectric or carveco but for what it's worth, I would start with free software and take it from there before spending $300+ on something I might not like. -

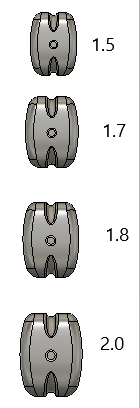

I thought I'd give 1.5mm a go again, as I'll probably want to try using these myself shortly. It's worth saying that a 1.5mm block is close to half the size of a 2mm, in terms of surface area, i.e. it's not just a tad smaller, it is a LOT smaller! As expected I had to ream out the through hole and still couldn't get 0.1mm thread through, so I used some 34g beading wire (0.2mm) as a proof-of-concept proxy. I fear thread of the same diameter might look a bit too large for the block and the thinnest possible might be the way to go. My takeaway conclusion is that 1.5 is bordering on insanely small, but still doable so long as you have a bottomless well of determination 🙂and I know, by putting it next to a victory 12lb-er, that it just looks more 'right' than the 2mm. Maybe the solution (for me at least) is a compromise, 1.7mm or 1.8mm.

- 2,667 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

1.5mm blocks… that is incredibly small, isn’t it, but if anyone can manage those it’ll be you Marc. It’s probably do-able using a resin printer but the real challenge is the through-hole, chances are that this will close up and need opening out by hand on each block. Plus the walls will almost certainly be wafer thin and fragile, although that’s less of an issue. What size thread is being used for the ropes? For that matter, is the block design for the SR significantly different to later ships like the Victory?

- 2,667 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Looks good! That EzeTissue is tough stuff, I’ve used it while experimenting and it doesn’t tear easily. My issue has been that I can’t get it to stretch or deform. When I’ve made a half-furled sail (albeit a not good enough example) using well dampened tissue, and spread the tissue flat again when I give up, it’s exactly the shape it was when I cut it out. I haven’t tried using dope, does it make the fabric pliable?

- 114 replies

-

- Cutty Sark

- plastic

-

(and 4 more)

Tagged with:

-

Yup, macro is an evil something, isn't it. The worst of it is that getting back into model-making led me to buy a new camera and 2 macro lenses, which shows up every last, tiny blemish. Vaseline all over the lens is the way to go 😄. I can't wait to see the engine in the bay, this one super-realistic model kit!

-

Commiserations. I realise this is a little superficial, but I’m not sure I’d really want to work for an organisation that doesn’t have the courtesy to call each of the final four personally. It’s never a nice task but it’s an important one. I had a comparable experience 20 odd years ago and, on reflection, realised I hadn’t liked them nor they me. I figured that might have been because we had different values. So maybe you’ve had a lucky escape. Anyway, I wasn’t even aware of the Scott Polar Research Institute in Cambridge. That’s now added to the must visit list! There is also a beautiful botanical garden near Cambridge, Anglesey Abbey, so I can kill two birds with one stone.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.