-

Posts

405 -

Joined

-

Last visited

About Veszett Roka

- Birthday May 23

Profile Information

-

Gender

Male

-

Location

Budapest, Hungary

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Veszett Roka reacted to a post in a topic:

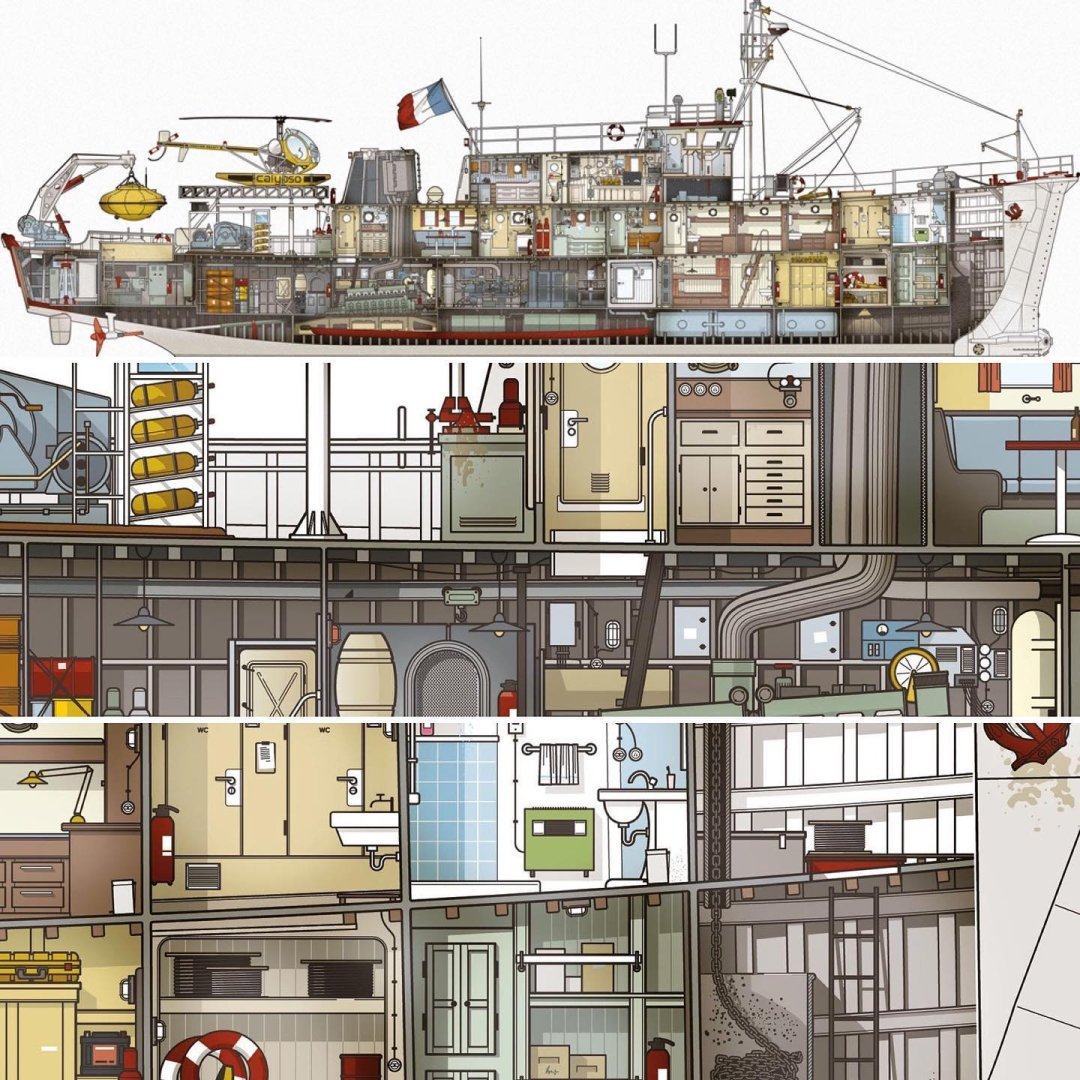

Calypso by mandolinut - Billing Boats - 1:45

Veszett Roka reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

-

robert952 reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

robert952 reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

-

Veszett Roka reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Veszett Roka reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

I think the wood toothpicks are too thick. I would go with copper rods instead, if you glue them with superglue it will be fine - don't need to solder them together. The early shark cages were much more sleek: https://www.gettyimages.com/detail/news-photo/commander-jacques-yves-cousteau-famous-underwater-explorer-news-photo/514957924

-

Veszett Roka reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Veszett Roka reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Canute reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Canute reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

Canute reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Canute reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

Mirabell61 reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Mirabell61 reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

Jack12477 reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Jack12477 reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

Be careful with Revell enamels Nils, they need very excessive stirring before application. I used artistic terpentine as thinner with fine results.

- 313 replies

-

- lightship

- Feuerschiff Elbe 1

-

(and 1 more)

Tagged with:

-

Mirabell61 reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Mirabell61 reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

Jack12477 reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Jack12477 reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

Paul Le Wol reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

Paul Le Wol reacted to a post in a topic:

ELBE 1 1948 by Mirabell61 - scale 1:87 - Lightship

-

Good to see you on board again Nils. Happy building!

- 313 replies

-

- lightship

- Feuerschiff Elbe 1

-

(and 1 more)

Tagged with:

-

king derelict reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

king derelict reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

-

king derelict reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

king derelict reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

-

Veszett Roka reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

Veszett Roka reacted to a post in a topic:

Mary Rose by Baker - scale 1/50 - "Your Noblest Shippe"

-

Veszett Roka reacted to a post in a topic:

HMS Victory by dafi - Heller - PLASTIC - To Victory and beyond ...

Veszett Roka reacted to a post in a topic:

HMS Victory by dafi - Heller - PLASTIC - To Victory and beyond ...

-

Hey Bob, you've earned another follower for you. I'm pulling my seat with great interest,

- 22 replies

-

Welcome on MSW Brant! Be careful, this hobby will evolve to addiction i admit.

-

Veszett Roka reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

Veszett Roka reacted to a post in a topic:

Calypso by mandolinut - Billing Boats - 1:45

-

Veszett Roka reacted to a post in a topic:

NORDKAP 476 by _SalD_ - FINISHED - Billing Boats - 1:50 - RADIO

Veszett Roka reacted to a post in a topic:

NORDKAP 476 by _SalD_ - FINISHED - Billing Boats - 1:50 - RADIO

-

Veszett Roka reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

Veszett Roka reacted to a post in a topic:

Ranger type yacht by Mark Pearse - 1:12 - SMALL

-

Veszett Roka reacted to a post in a topic:

NORDKAP 476 by _SalD_ - FINISHED - Billing Boats - 1:50 - RADIO

Veszett Roka reacted to a post in a topic:

NORDKAP 476 by _SalD_ - FINISHED - Billing Boats - 1:50 - RADIO

-

I don't know their size in scale, so all my comment is purely theoretical. I would use some kid's felt tip pen as a jig, especially their cup like this: or this, these are smaller and their general form is better match the aerial: The O-rings could be made by wire.

-

This is an interesting knot. Hard to imagine how they knot it, which end is starting and which one is the finish line. I guess you have to lift up the three round and put the end under them?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.