mcb

-

Posts

142 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by mcb

-

-

Congratulations Keith, well done again.

- Keith Black and Canute

-

1

1

-

1

1

-

Hello Again,

Thanks for the comments, Keith Black, Jim Lad and Canute. Thanks all for the likes.

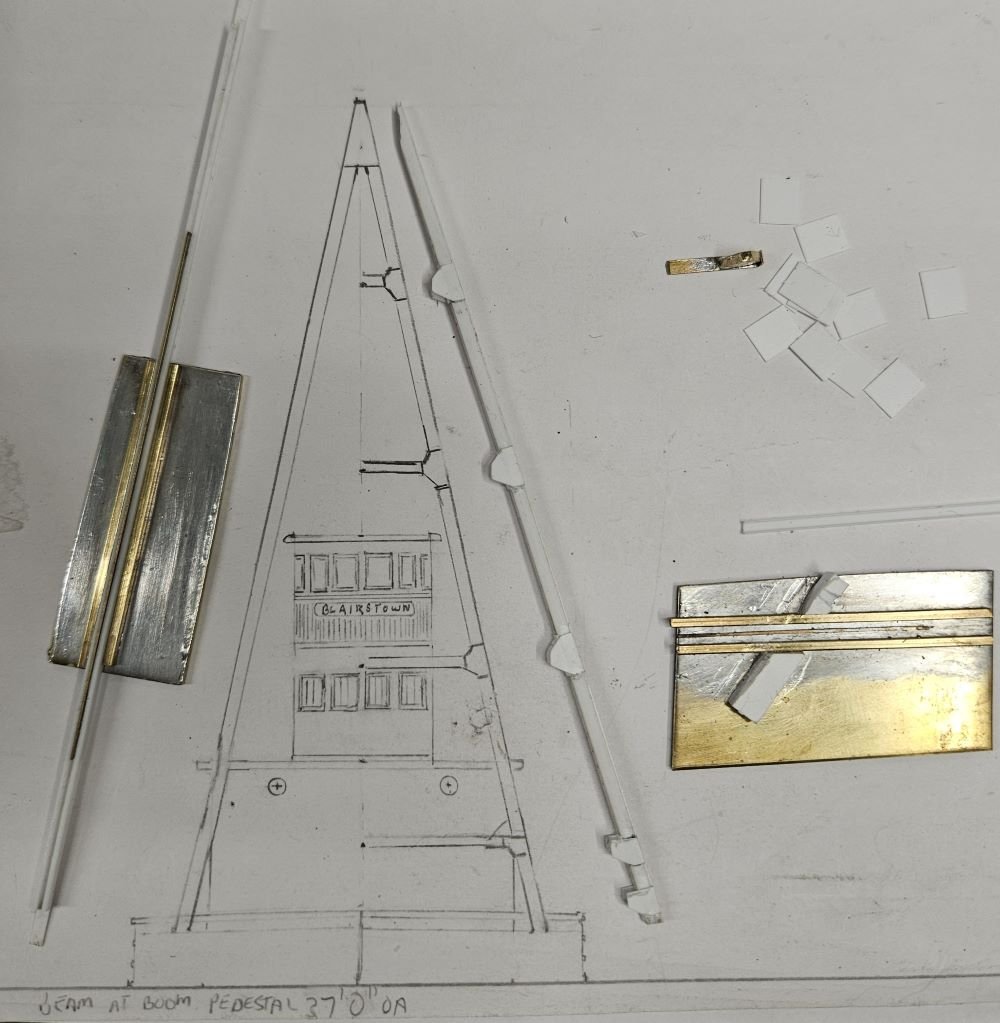

A small update: I have been working on the boat crane of which I can only see the top 1/3 in the pics that I have, so I must 'imagineer' the lower parts.

It is made of a tapered brass rod with roller, hand crank winch, etc. soldered to it.

First picture is under construction, second is with rigging temporarily attached. Last pic is 'Blairstown' as it is now with all the superstructure and dust sitting roughly in place. Nothing is permanently attached except the boom pedestal.

Next, I will have to make a list of all the remaining items to be made and/or attached.

Soon I will remove the windows on the pilot house and winch house and make better scale replacements.

Last difficult task (I think) will be the railings and stairs which I believe should consume the summer months.

Thanks for looking,

mcb

-

Hello Keith,

Lula is almost finished now I suppose, looking good with all the details and a crew to liven things up.

Thanks for posting about the 'Hard Coal Navy', very interesting, I never heard of that before.

Now I'm off to scrape the broom off my grain elevator.😀

Thanks for posting,

mcb

-

Looking good with all the details, I especially like the bell.

Take care,

mcb

- Keith Black, Canute and Glen McGuire

-

2

2

-

1

1

-

Hello again,

Its time for another update. Thanks wefalck, Keith Black, Jim Lad, Canute and FriedClams for the comments and thanks to everyone for the likes.

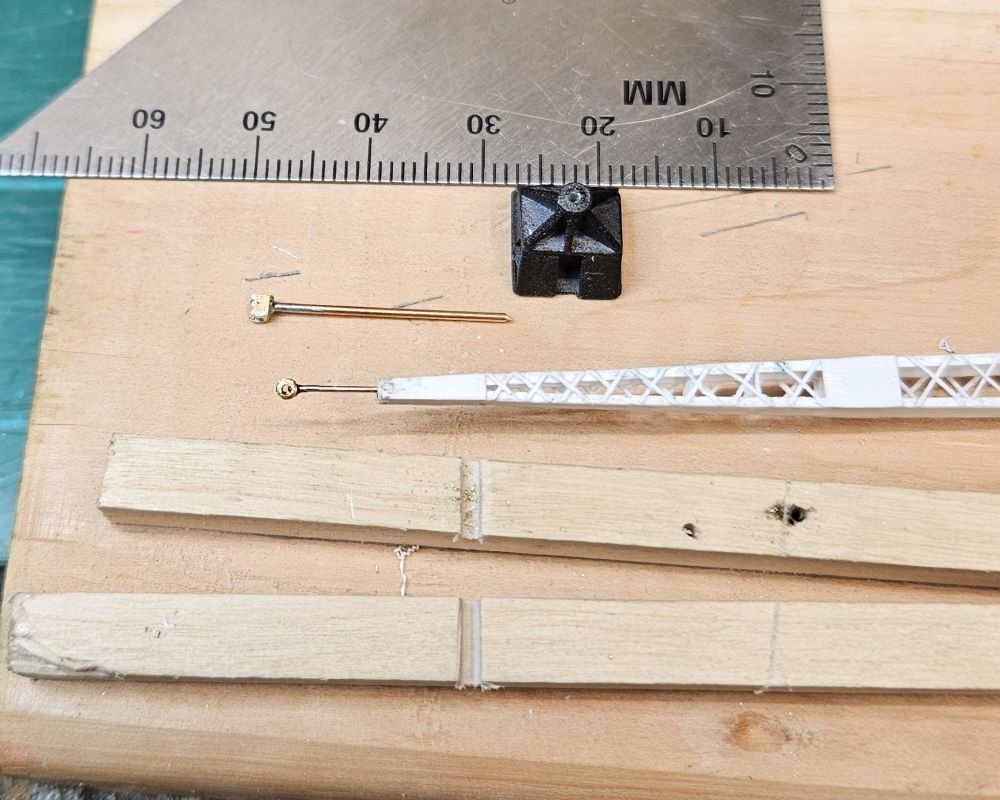

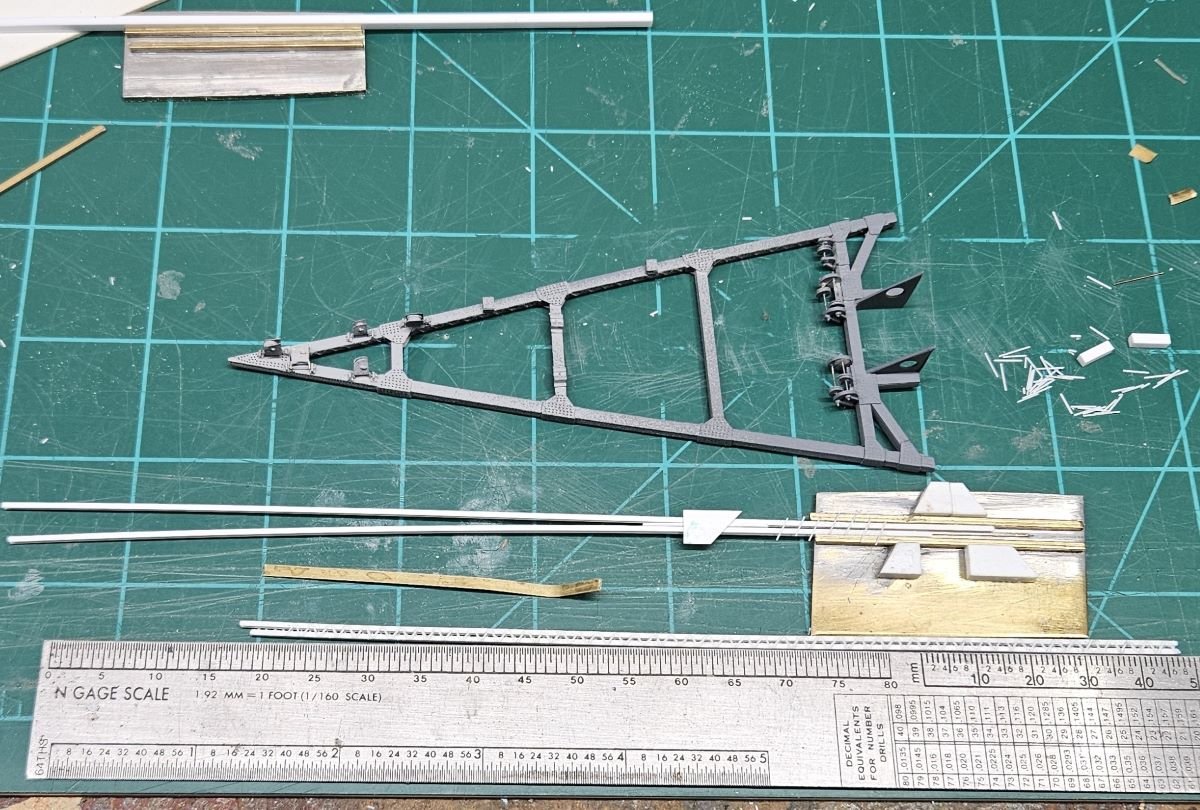

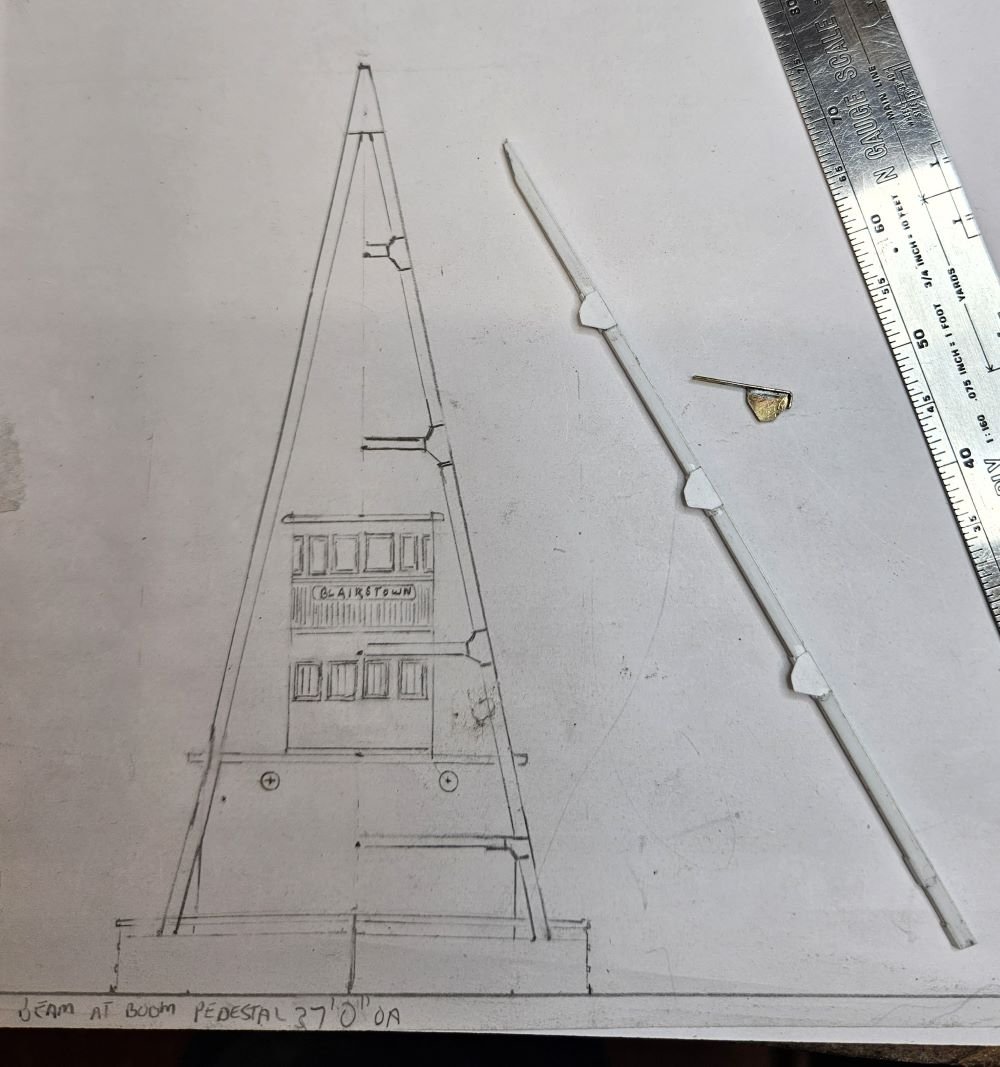

I am working on the boom now, it progresses much more quickly than the derrick as it is made of far fewer pieces.

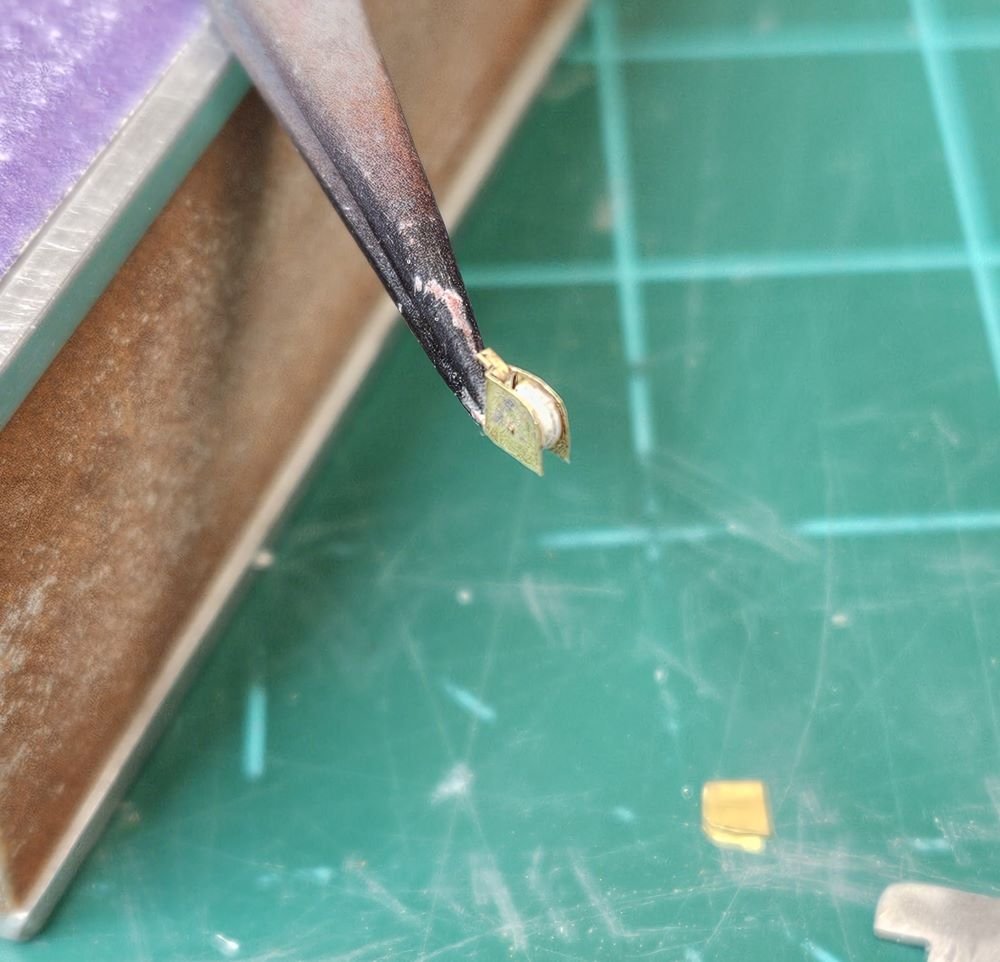

I made a brass pivoting hinge for the base of the boom which sits on the pedestal built previously.

Last pic is the boom temporarily in place on the boat.

After a little clean-up, I will start rivets next.

Thanks for looking,

mcb

- Keith Black, Canute and FriedClams

-

2

2

-

1

1

-

Hello Wefalck,

I have been following your progress on this build for a while, and I find as usual, that your work is excellent and very informative.

I suppose that this Bakelite is the same as circuit board material or similar, as opposed to the old 'plastic' of the '30s and '40s?

Do you need to use anything special to bond it?

I think I will order a sheet or two to have on hand so that I can expand my toolset beyond the usual styrene

Thanks for posting,

mcb

- Keith Black and FriedClams

-

2

2

-

-

Hello Keith,

Lula is looking fine, almost finished now. Ready for the crew.

The letters are quite a good match to the original. Well worth adding them.

Hoping you make out alright with your troubles.

mcb

- Keith Black and Canute

-

1

1

-

1

1

-

Hello all,

Thanks for the comment, Jim Lad. Thanks everyone for the likes.

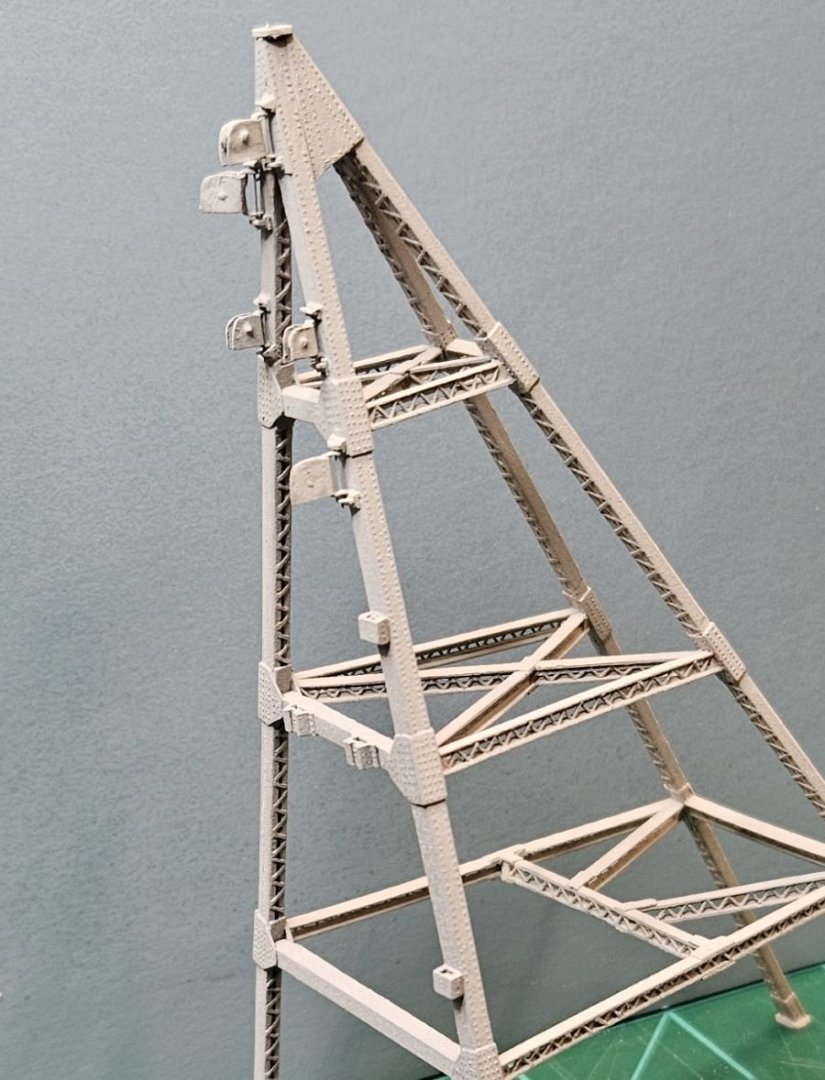

I have finished the derrick tower and will probably put the red paint on it today. It comprises a lot of pieces. I am happy that it actually fits around the rest of the superstructure.

Starting on the boom now.

Thanks for looking,

mcb

-

Looks good to me.

I think too small beats too big for this work.

mcb

-

- Canute, Keith Black, FriedClams and 2 others

-

3

3

-

2

2

-

-

-

Beautiful hull there Keith.

Thanks for posting,

mcb

- FriedClams, KeithAug and Keith Black

-

3

3

-

Hello All,

Thank You to Keith Black, Canute, Fried Clams and Wintergreen for your comments and thanks to all for the likes.

Here is a brief report as this build moves slowly along.

The rear derrick legs are built up and resting temporarily in the fixture. I will now have to build the three sets of cross braces between the front and rear legs. All these legs and cross braces are of different sizes and constructions. I hope that it will be apparent in the final product.

Before long I should check clearance on the actual model, so I don't have any nasty surprises.

Last night I brushed the front leg assembly knocking it over gently onto the cutting mat. One of the guide sheaves went flying to the floor, I was an hour finding it. At least I don't have to make another.

Thanks for Looking in,

mcb

-

Hello All,

Thanks for the comments, Wintergreen, Keith Black, Jim Lad and Canute. Thanks everyone for the likes.

I just want to put up a pic of where things are now on the forward derrick leg.

I mounted the pivoting guide sheaves (3 larger and 2 smaller) high up on the derrick. I am not sure of the proper name for these, please correct me if I am wrong.

I also put rivets on the gusset plates, I think they will look alright after paint, and I will be using more on the remaining parts of the derrick and boom.

After viewing the latest pictures, I see more touch up, clean-up and corrections are needed.

Thanks for looking,

mcb

- wefalck, Canute, Keith Black and 4 others

-

7

7

-

Merry Christmas and Happy New Year to you and your family Keith.

mcb

- Canute, Keith Black and mtaylor

-

2

2

-

1

1

-

Hello everyone,

Thanks for the comments Keith Black, Jim Lad and KeithAug. Thanks all for the likes.

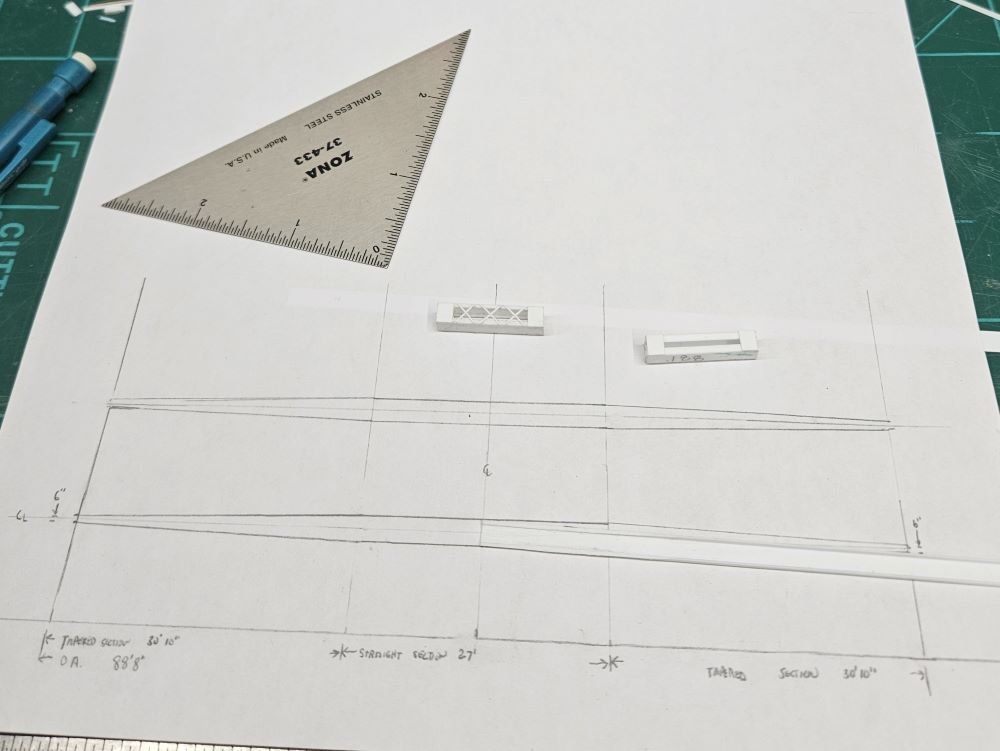

Just a small update here as progress continues on the forward derrick leg. First pic should show the fixtures for assembling the components for the 2 beams of the forward legs. with cross braces and gusset plates.

next photos should show the assembled leg assembly with guide sheaves/rollers at the bottom and smaller guides further up on the derrick.

Last pic is where I am currently. Preparing one of the 3 larger pivoting guide sheaves for the top of the derrick. There are also 2 smaller ones that must be installed just below.

After this I will prime and fix blemishes, then I will probably put rivets on the gusset plates as they are quite visible in the picture that I am using for a model.

Thanks for looking,

mcb

- yvesvidal, vossiewulf, Canute and 3 others

-

6

6

-

Hi Keith,

That looks good. Your pastels seem like the old chalks that I use, easy to adjust (until you clear coat it).

This project is really moving along.

Thanks for posting it,

mcb

- mtaylor, Keith Black and Canute

-

2

2

-

1

1

-

Congratulations, well done. I especially like the muted colors. Looking forward to the stern wheeler.

mcb

- FriedClams, Canute, Keith Black and 1 other

-

3

3

-

1

1

-

Hello All,

Thanks for the comments Jim Lad, Wefalck, Keith Black, KeithAug, and Canute.

Its been quite a while. I have been busy with the usual home maintenance and have actually started to build the modules that these harbor models will occupy.

I had to set aside the 'BLAIRSTOWN' for a bit as well. As I mentioned above I was not happy with the windows I installed on the pilot house and winch house. This is because they were far too thick, especially on the winch house. I think they will have to go. I have a few ideas about what to try next for them. We'll see.

As far as the color of the windows Canute's reply is exactly right. I am building this model as it was in ~ 1964 when it was operated by Petterson Lighterage. Black hull and deck, red superstructure, white windows (with black trim which I probably won't be able to do) and pale blue! derrick top, stack top and mast top. I am using the cover photo of Transfer #30, as Canute says above, for 90%+ of my info for this build. I really should see if I can get permission to post that pic so that everyone can see what I am doing.

I agree the white is too vibrant in my photos above I will have to tone it down on the next try. It is slightly more muted in person.

Meanwhile as I stew over the windows I have started on the derrick. I took measurements from the above-mentioned pic and began on (crude) drawings.

Started with the front derrick leg, building it up from styrene strips and shapes.

Thanks for looking,

mcb

-

-

-

Congratulations for completing this outstanding model.

I must thank you for introducing new methods, materials and knowledge to consider in my own future efforts.

She looks good in the water with figures and flag.

Thanks for posting,

mcb

- FriedClams, mbp521, Keith Black and 1 other

-

4

4

Sternwheeler From the Susquehanna River's Hard Coal Navy by Keith Black - 1:120 Scale

in - Build logs for subjects built 1901 - Present Day

Posted

Hi Keith,

As wefalck said you sure didn't waste any time getting to this one.

I really like the choice of these interesting, slightly dilapidated subjects. In the first 2 photos it looks like there may be some sag in the stern😮.

The pic in post 29 looks like you will get a lot of useful information from it though the boat appears newer and not so beat-up.

I agree that its: Pennsylvania Water and Power,

If its not too late you may be able to contact The Hagley Museum in Wilmington DE, as it seems they have some of the company archives and photos.

Perhaps you could get some more info (photos) that way.

Thanks for posting this,

mcb