-

Posts

876 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rik Thistle

-

Thanks Mark. Even after only a few weeks away from my workshop I start to get withdrawl symptons. I think I just need to be making things... it's probably the Dopamine release from achieving milestones in a project, and having something to concentrate on. Maybe that's what model making is all about 🙂 Anyway, hope you have a comfy chair and a decent supply of beverages. See you again shortly, Richard

-

Seems Russia has around ten thousand rusty old tanks sitting in fields. But refubishing them to usable condition is much quicker than producing new tanks... https://www.popularmechanics.com/military/weapons/a44536878/rebuilding-russian-tanks/ " This upgrade process turns broken-down clunkers into modern fighting vehicles. It is far cheaper, quicker, and simpler than making new tanks from scratch. In theory, each plant is capable of producing roughly 20 modernized tanks per month, boosting Russia’s replacement capacity from 20 vehicles a month from UVZ to more like 120. " Richard

-

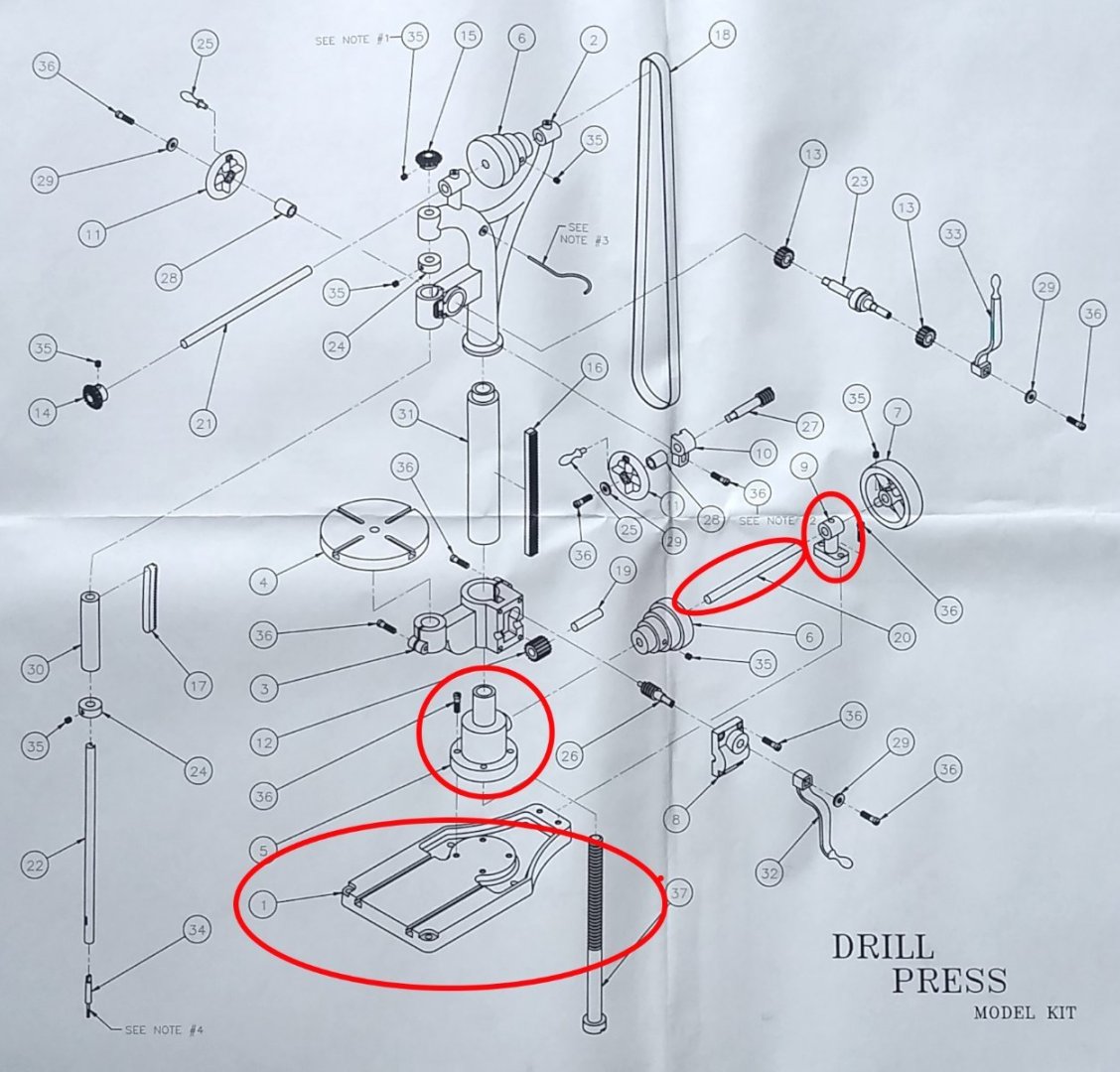

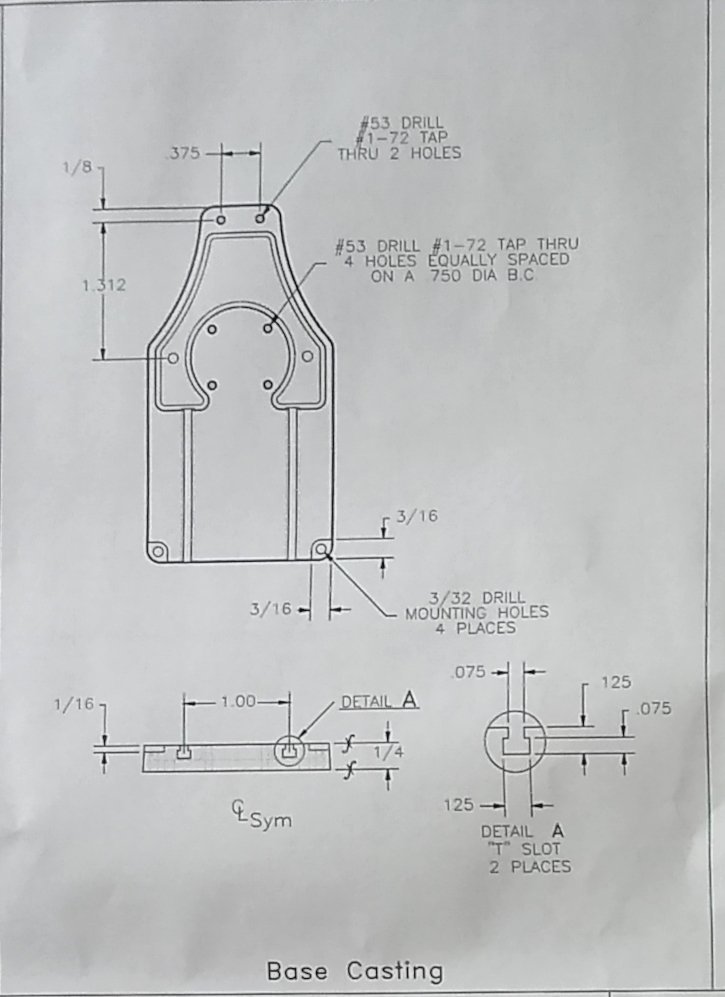

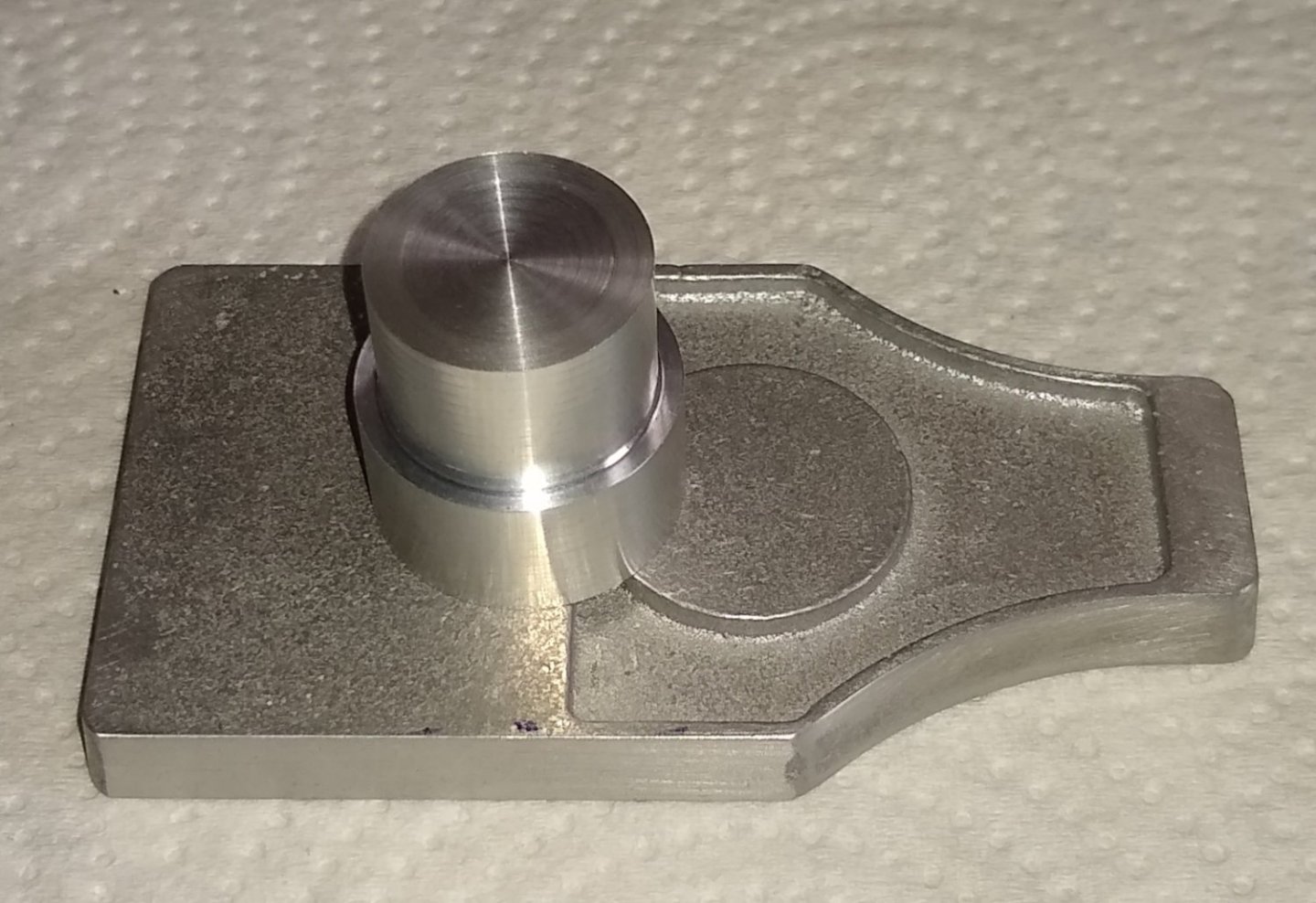

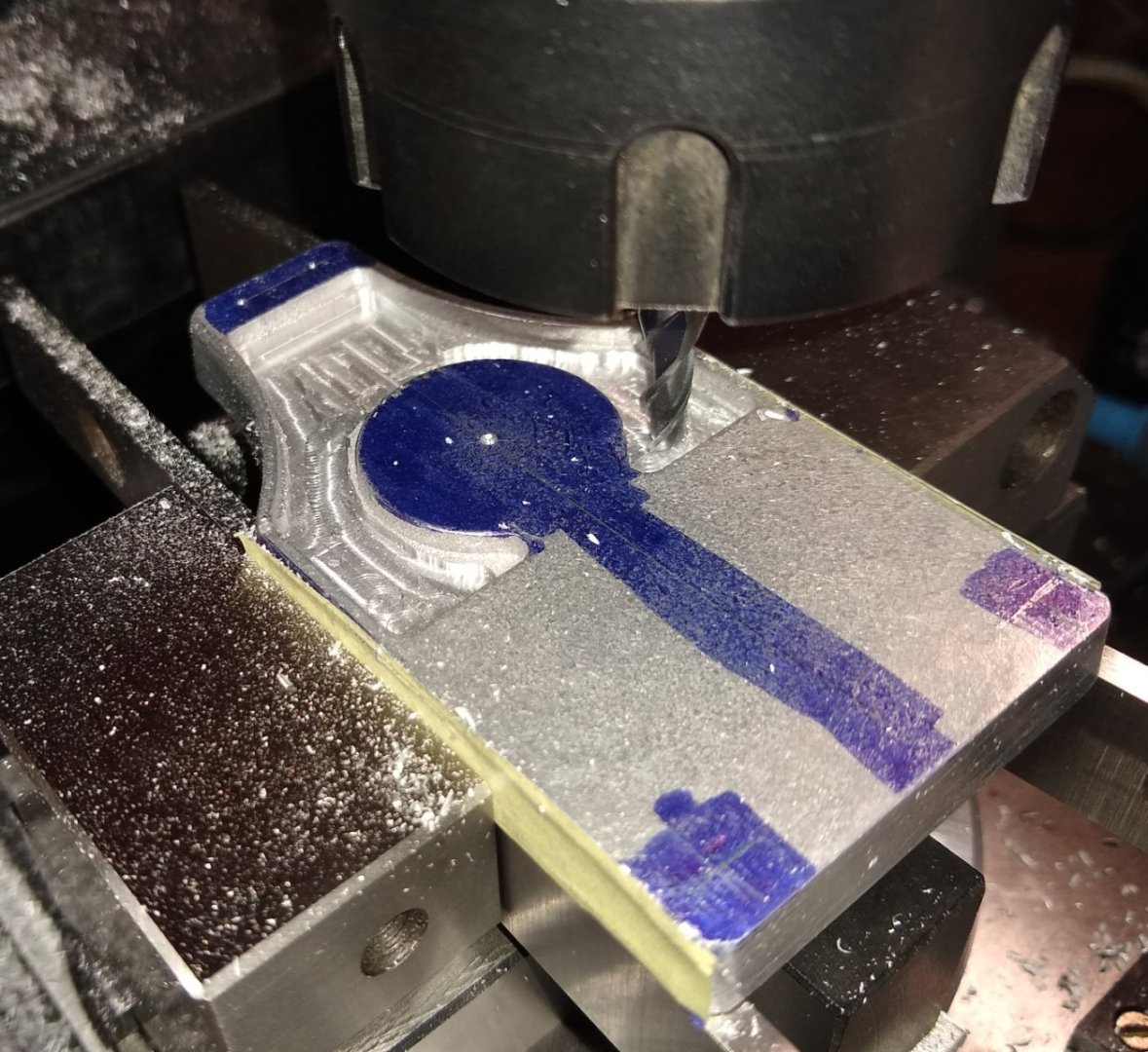

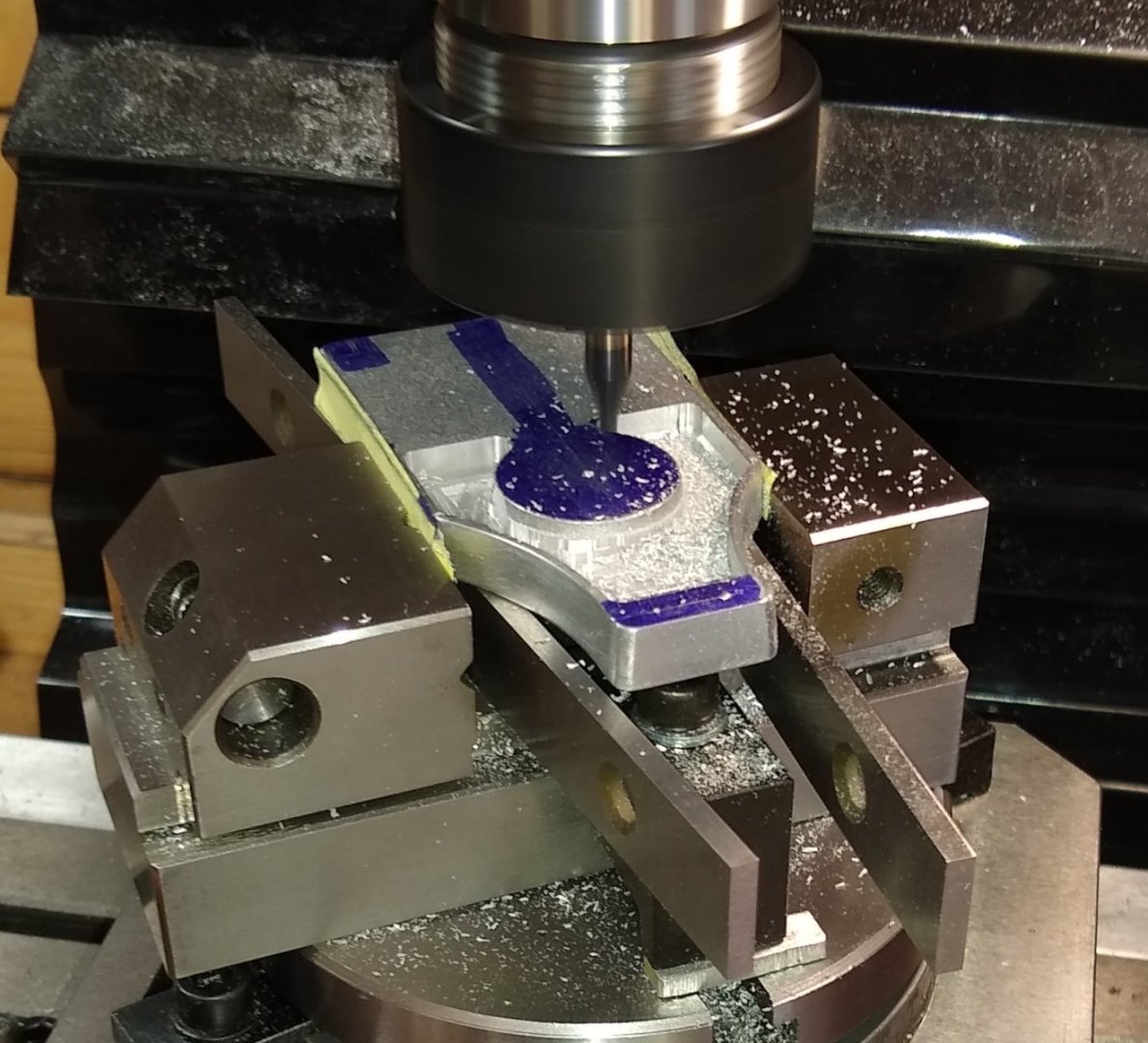

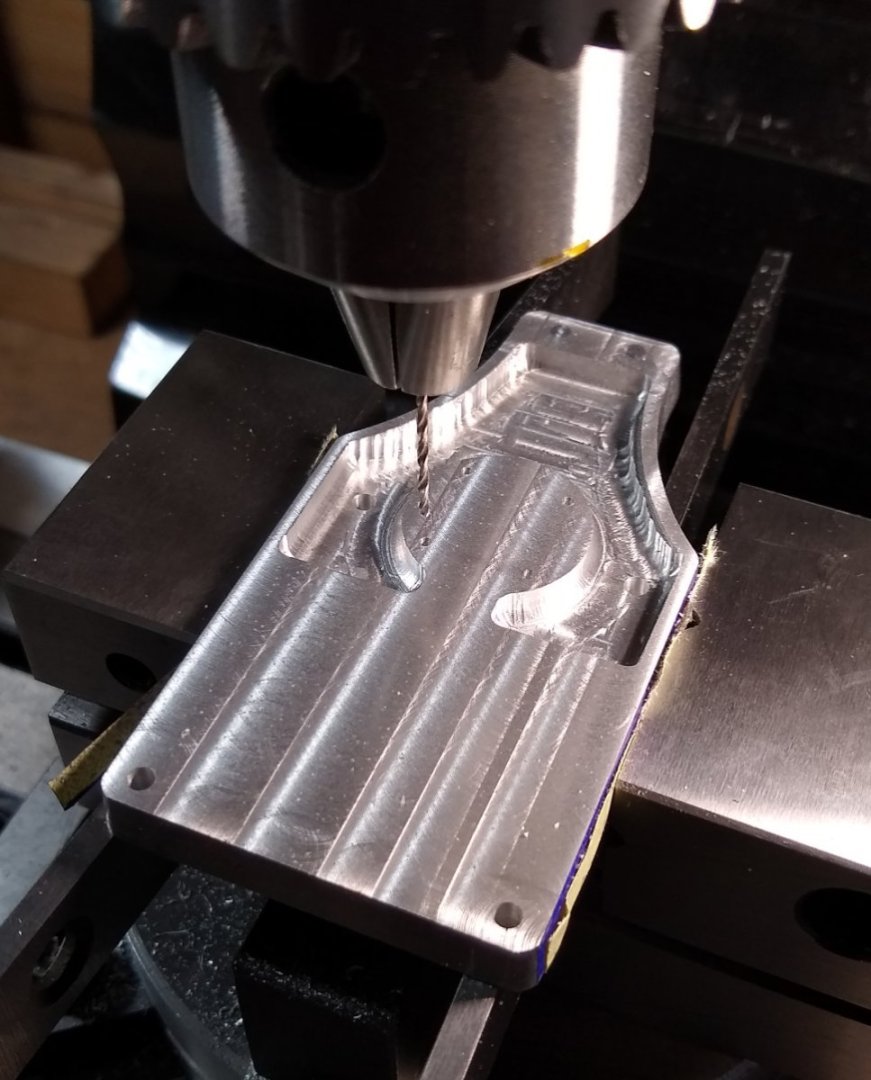

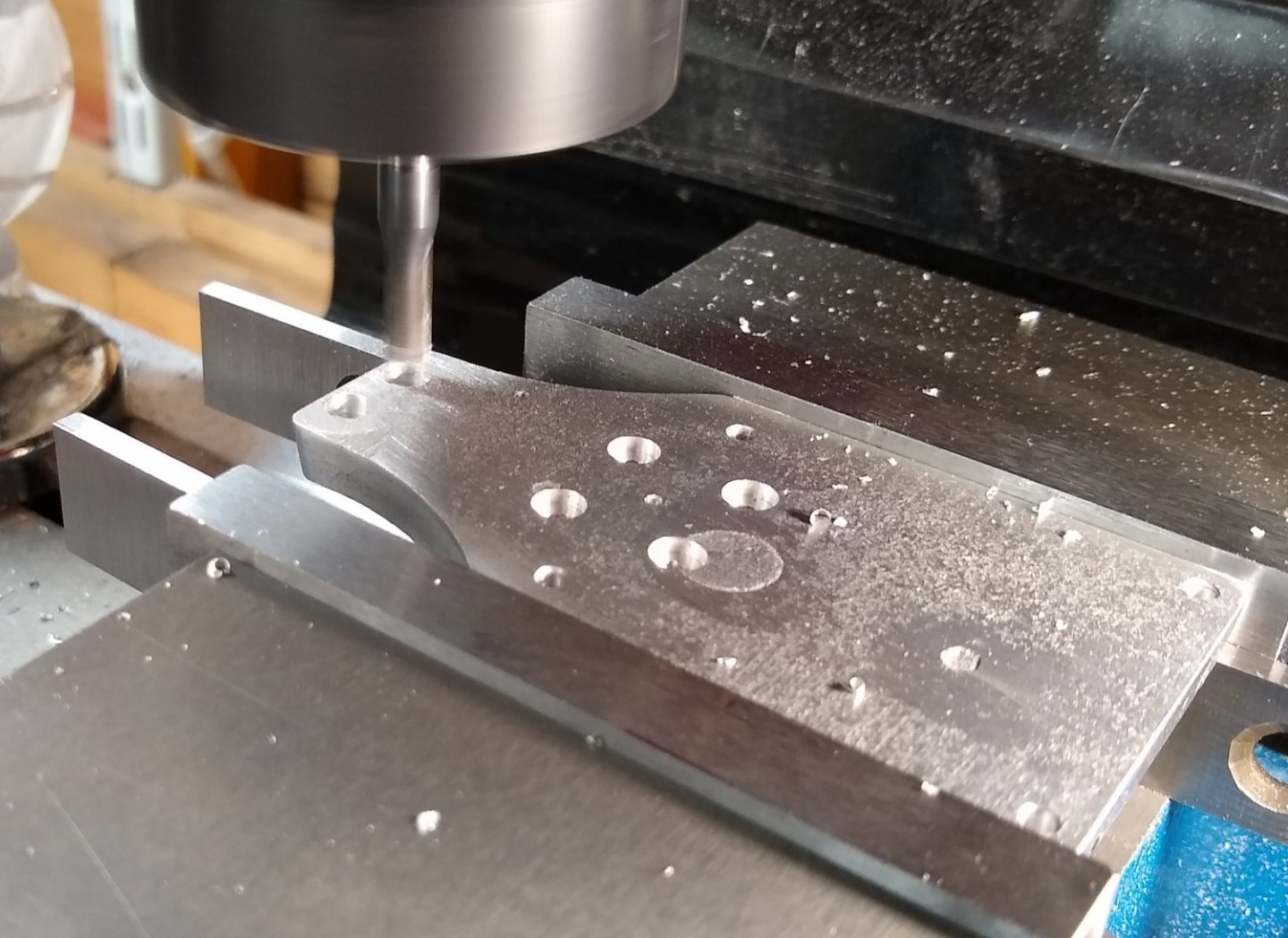

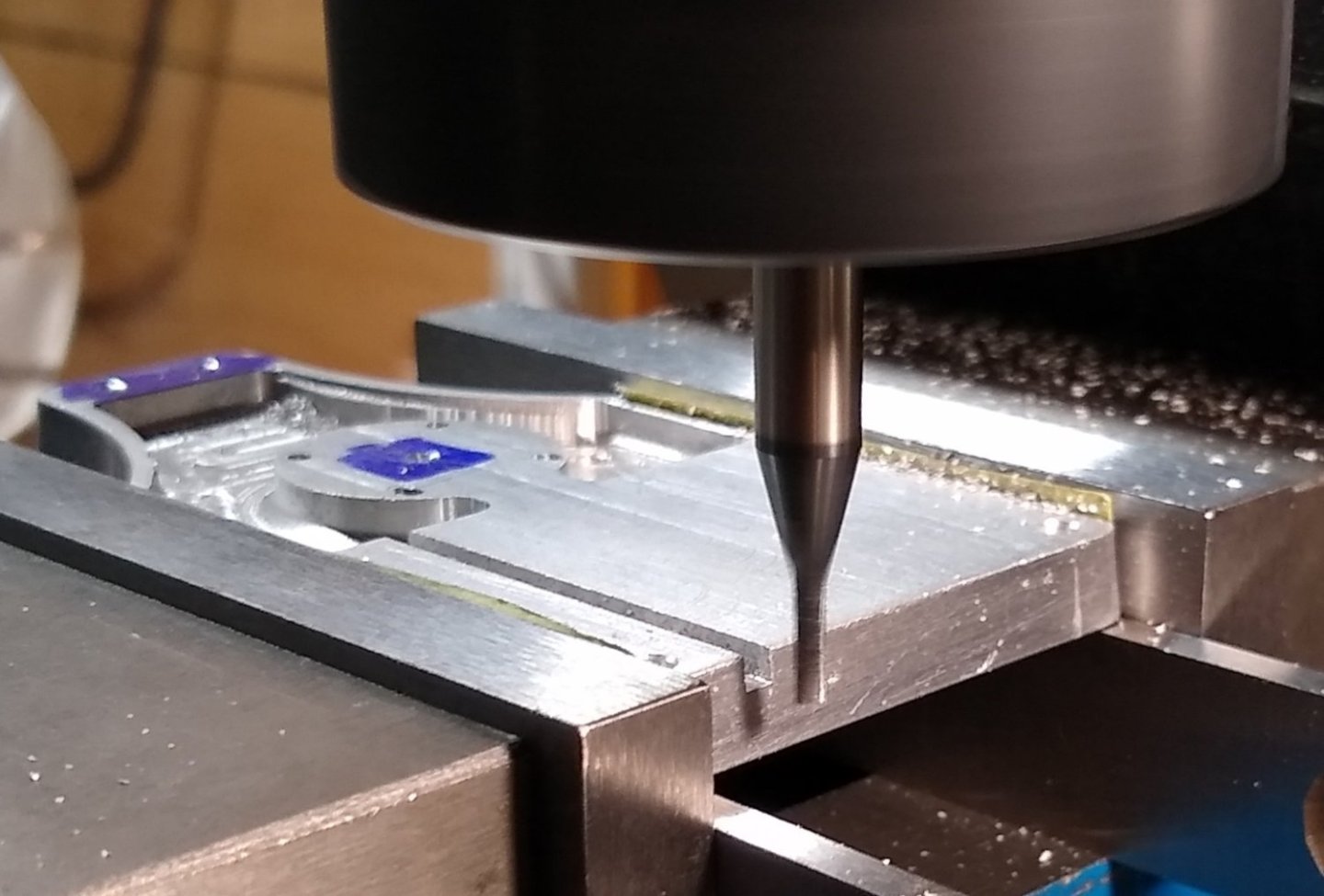

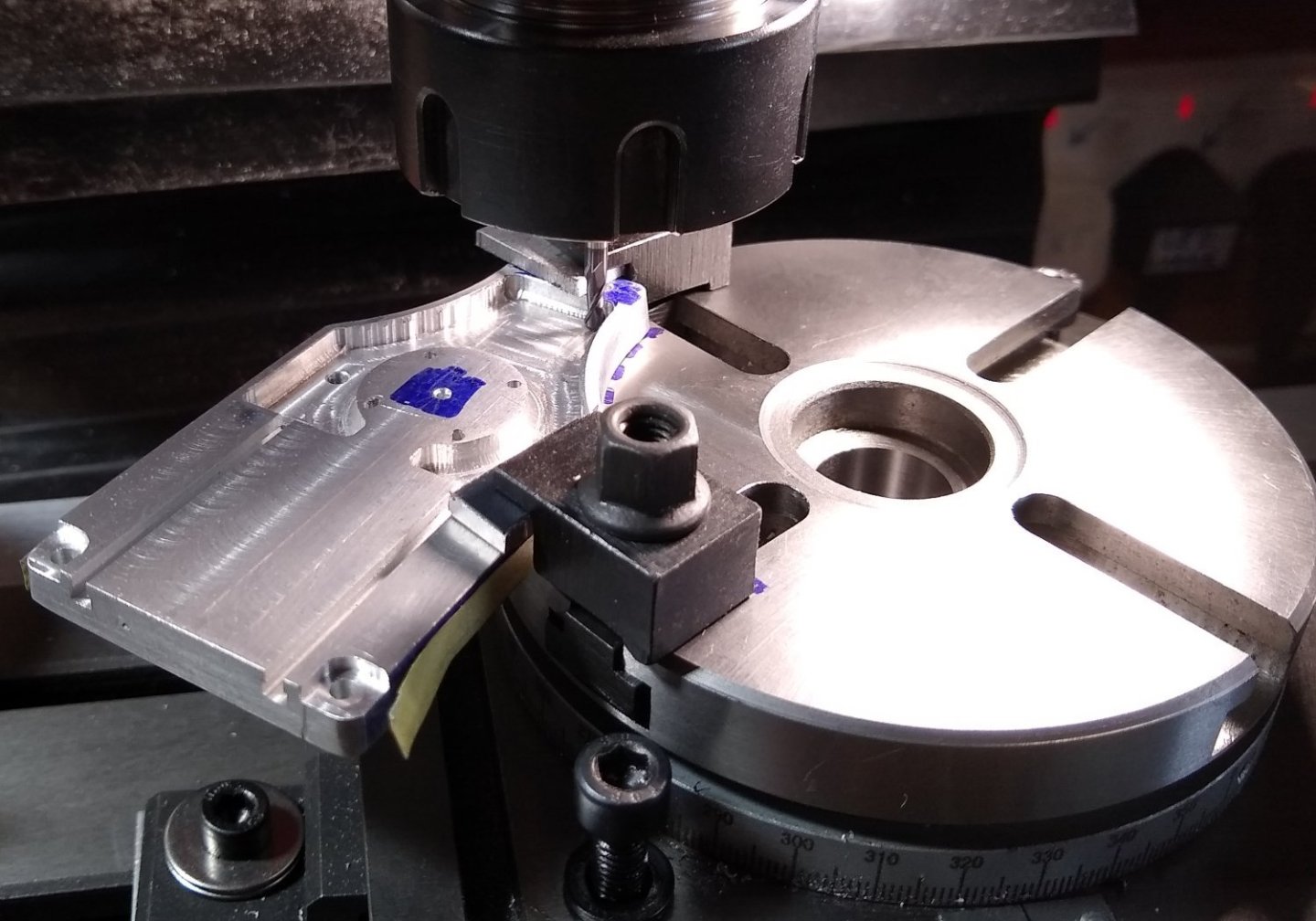

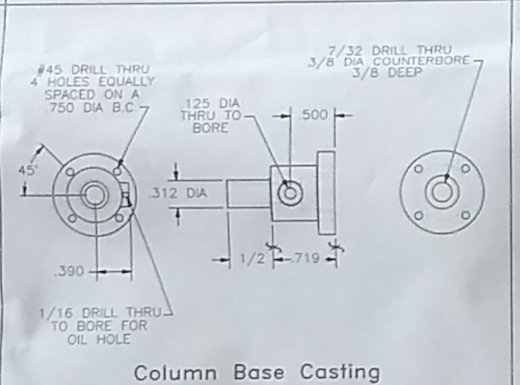

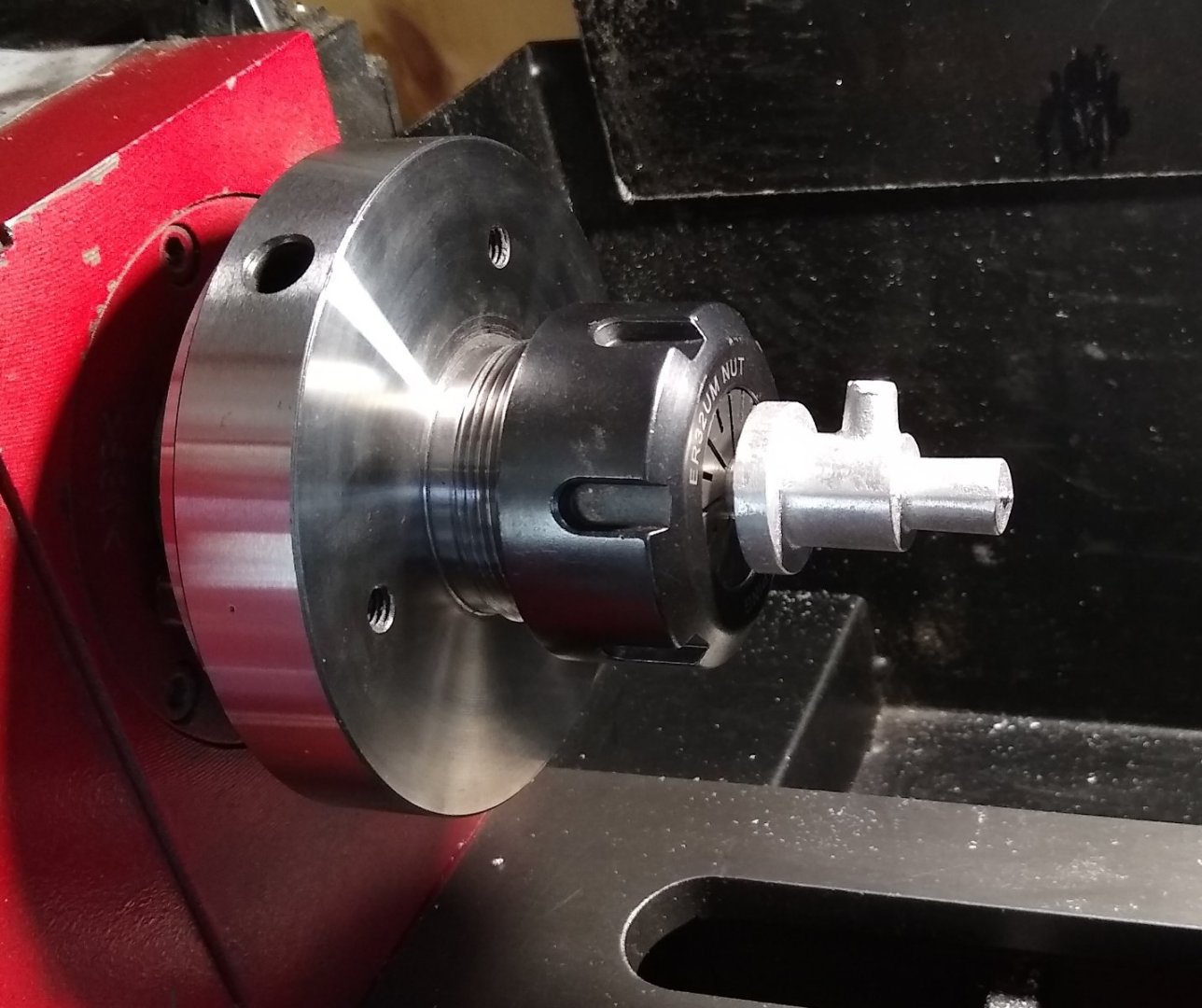

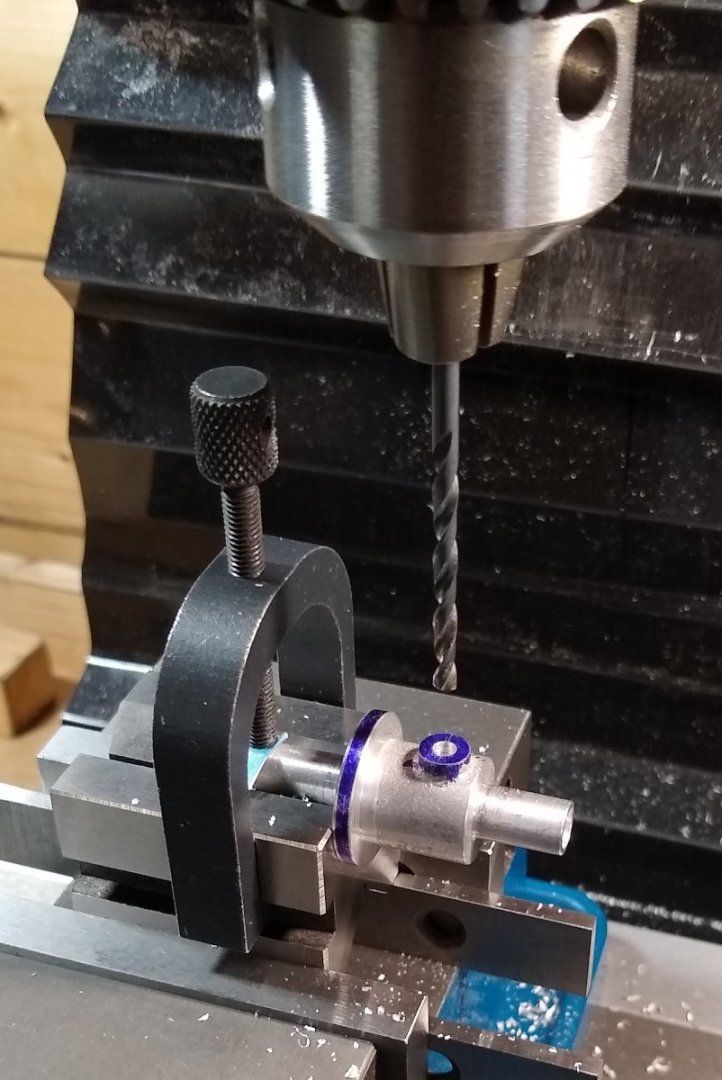

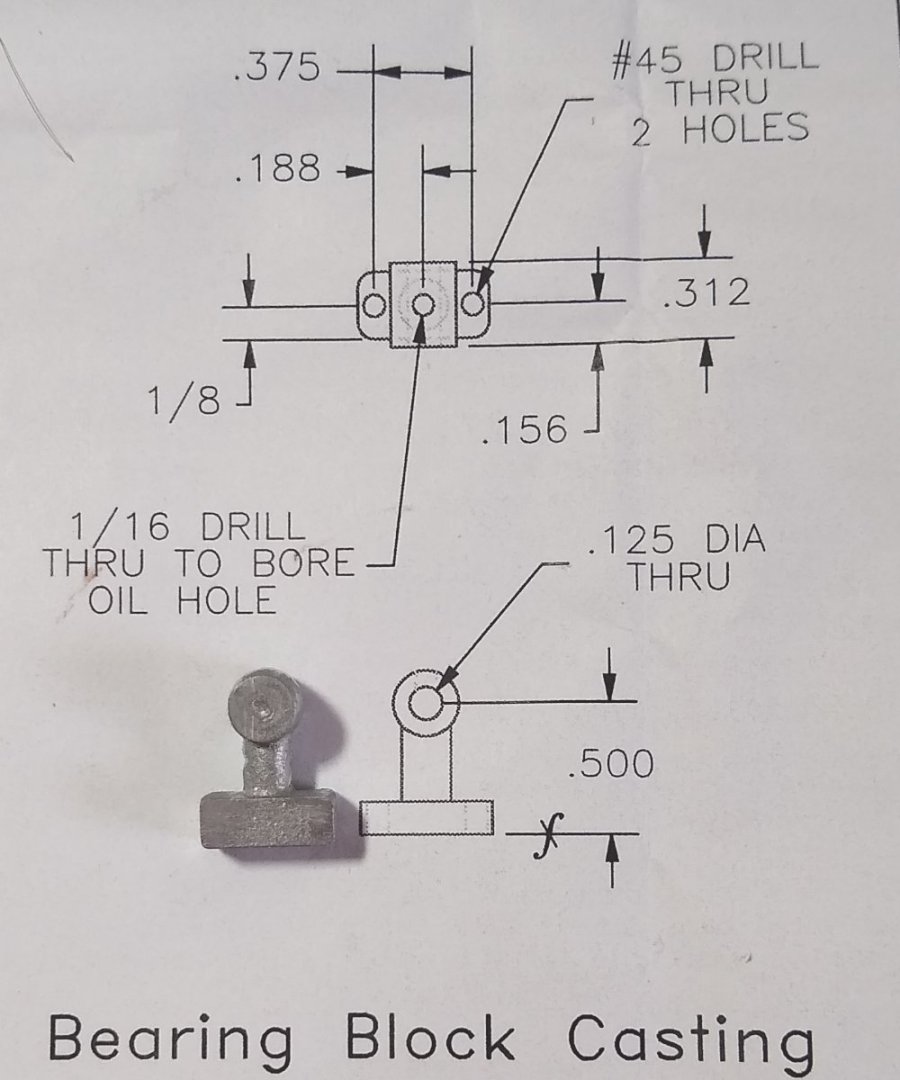

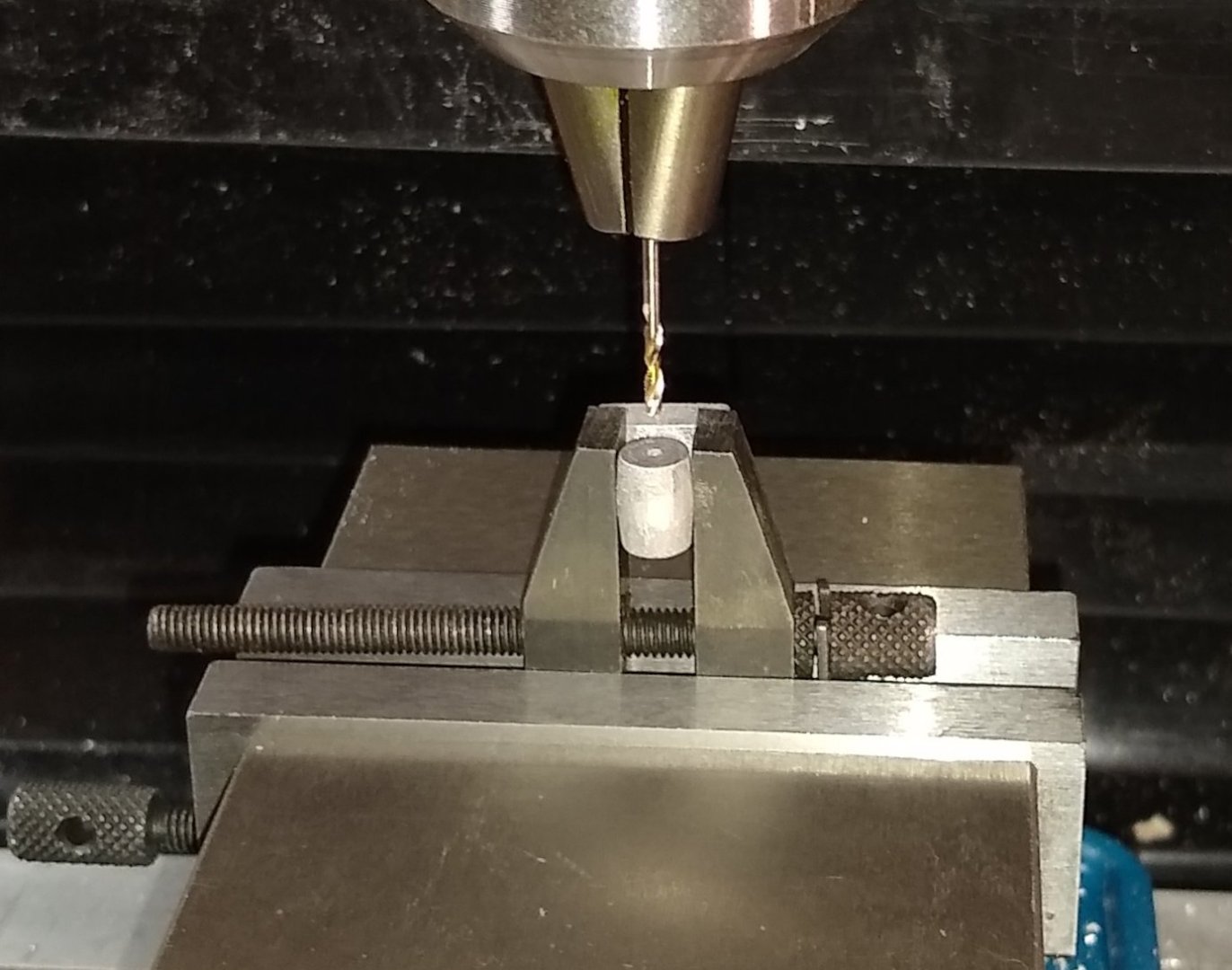

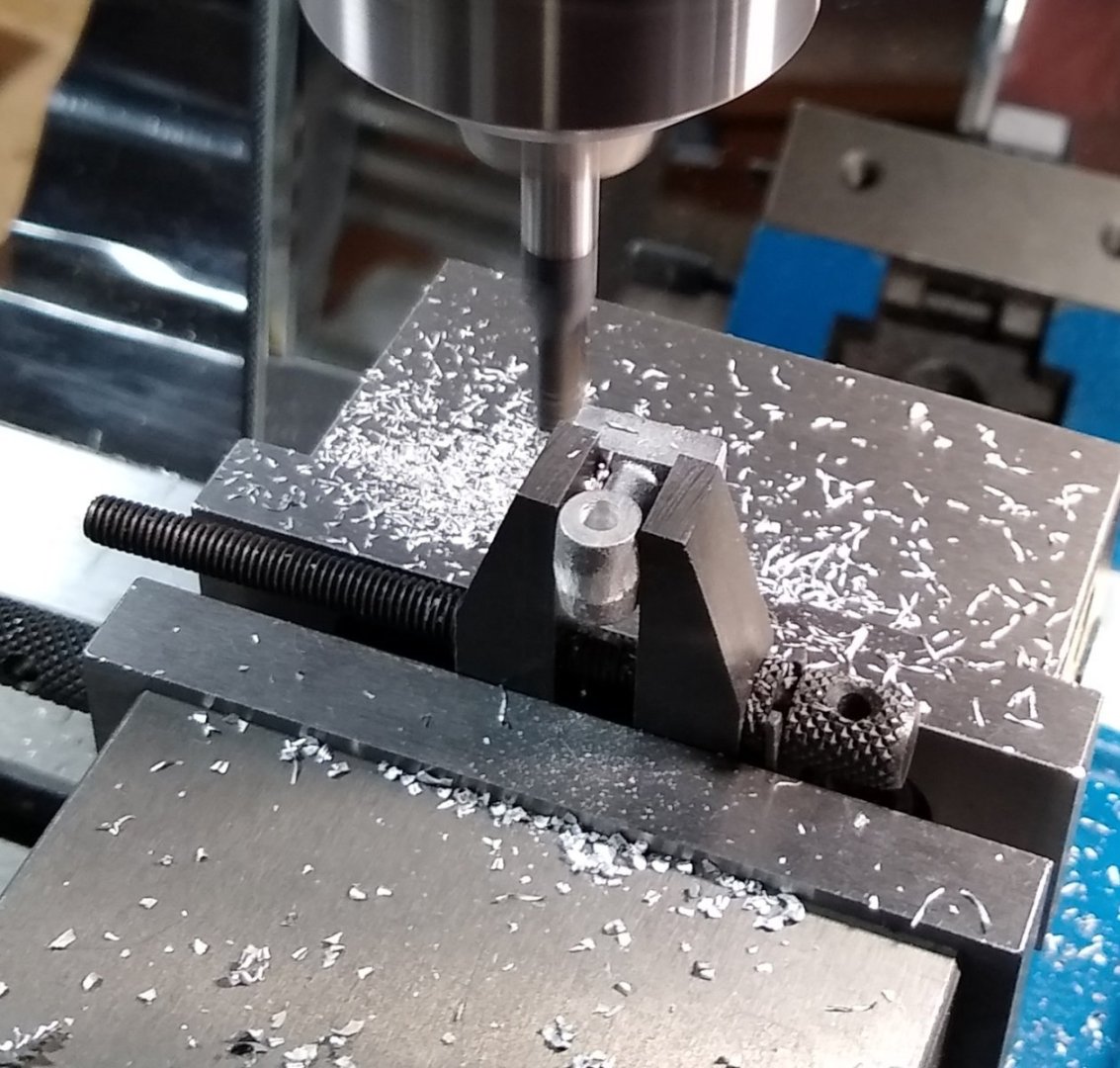

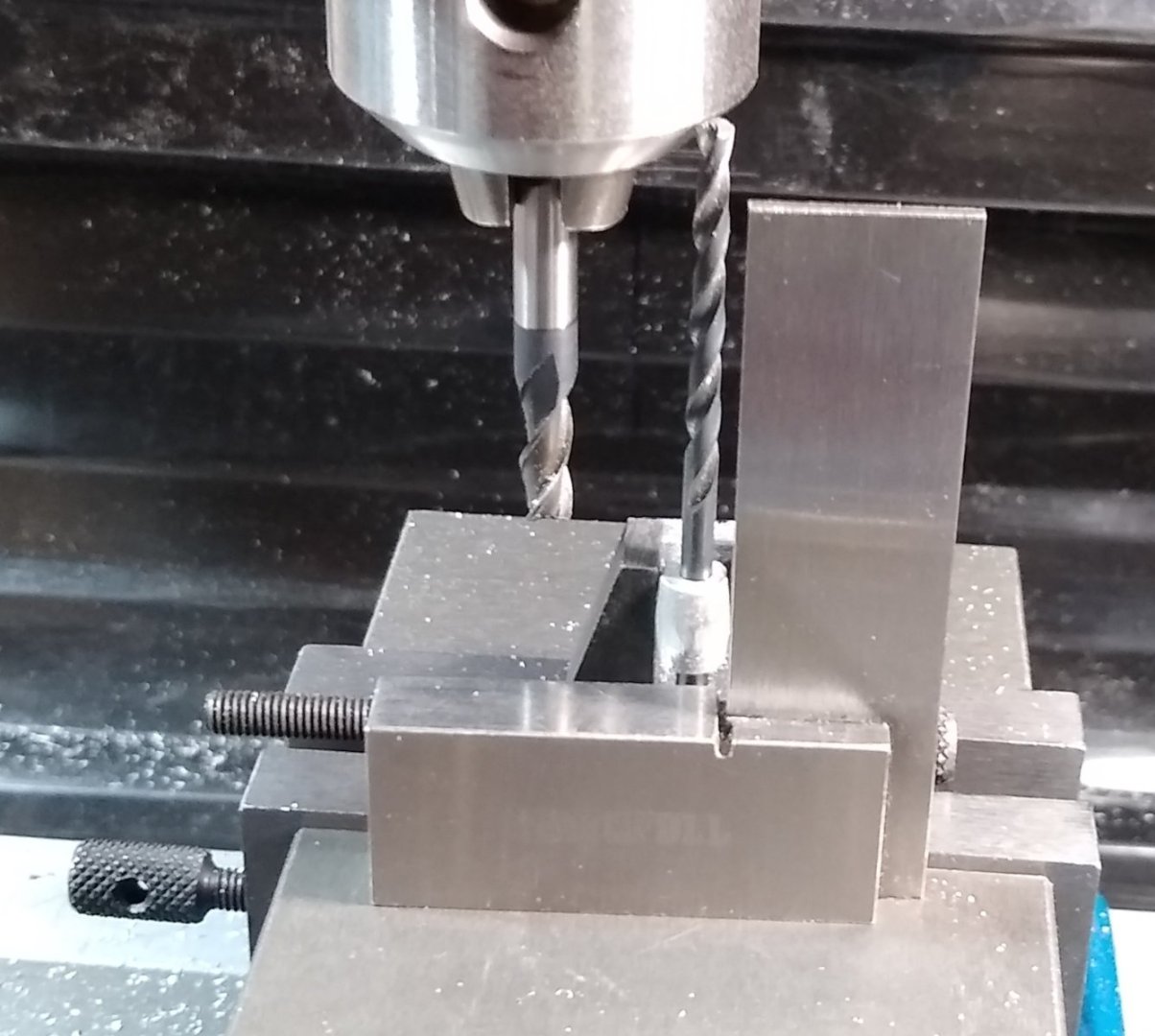

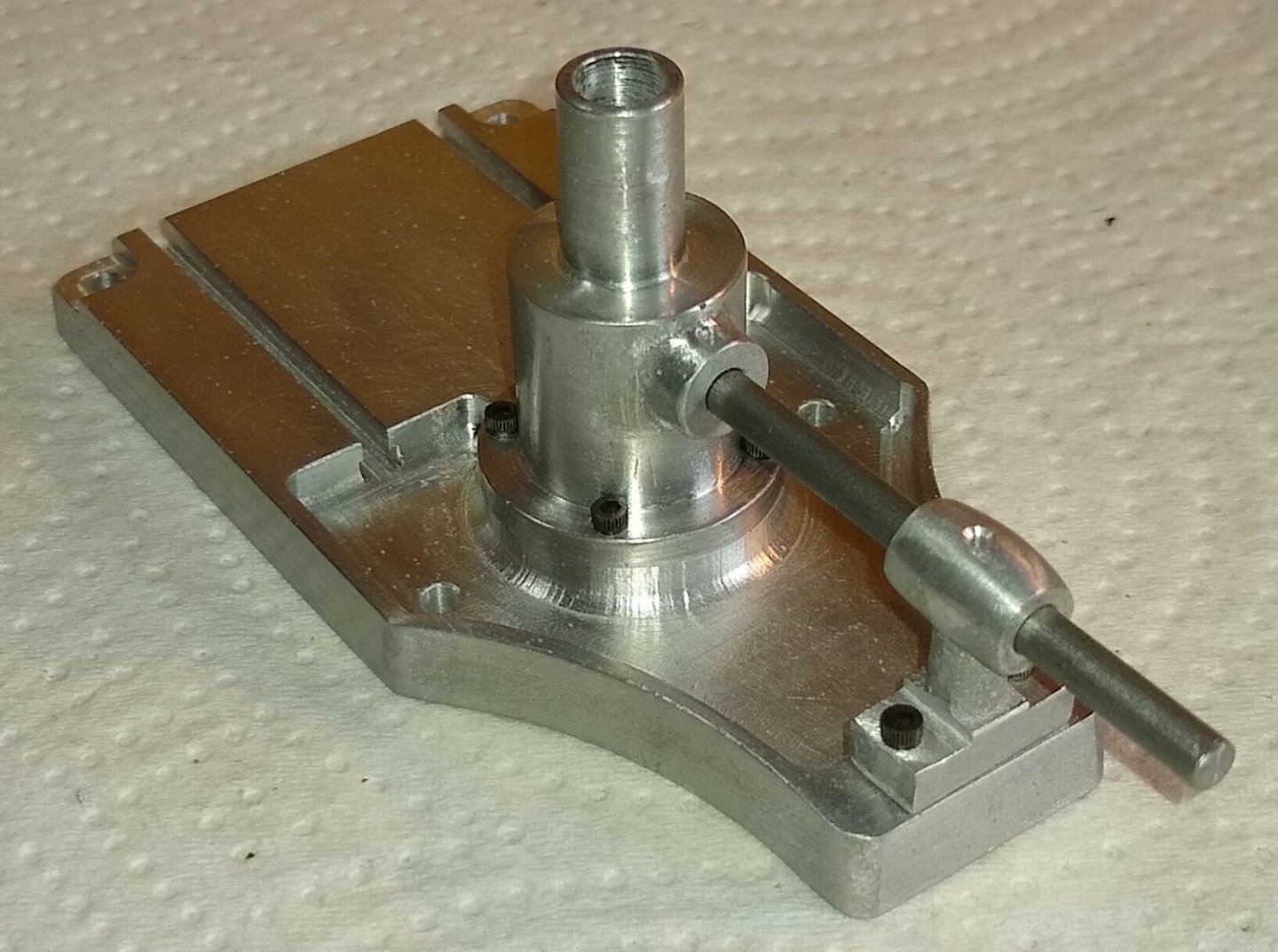

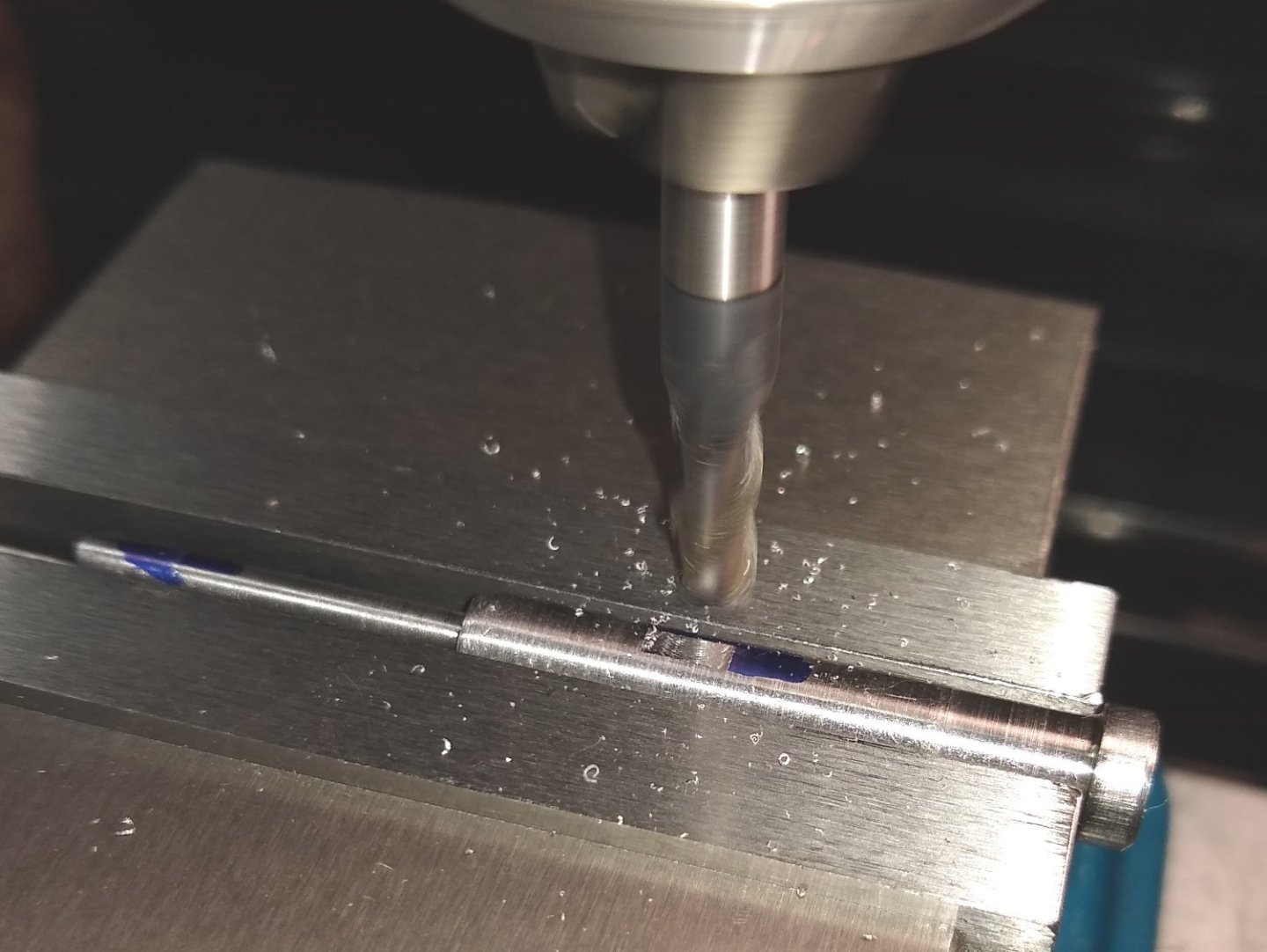

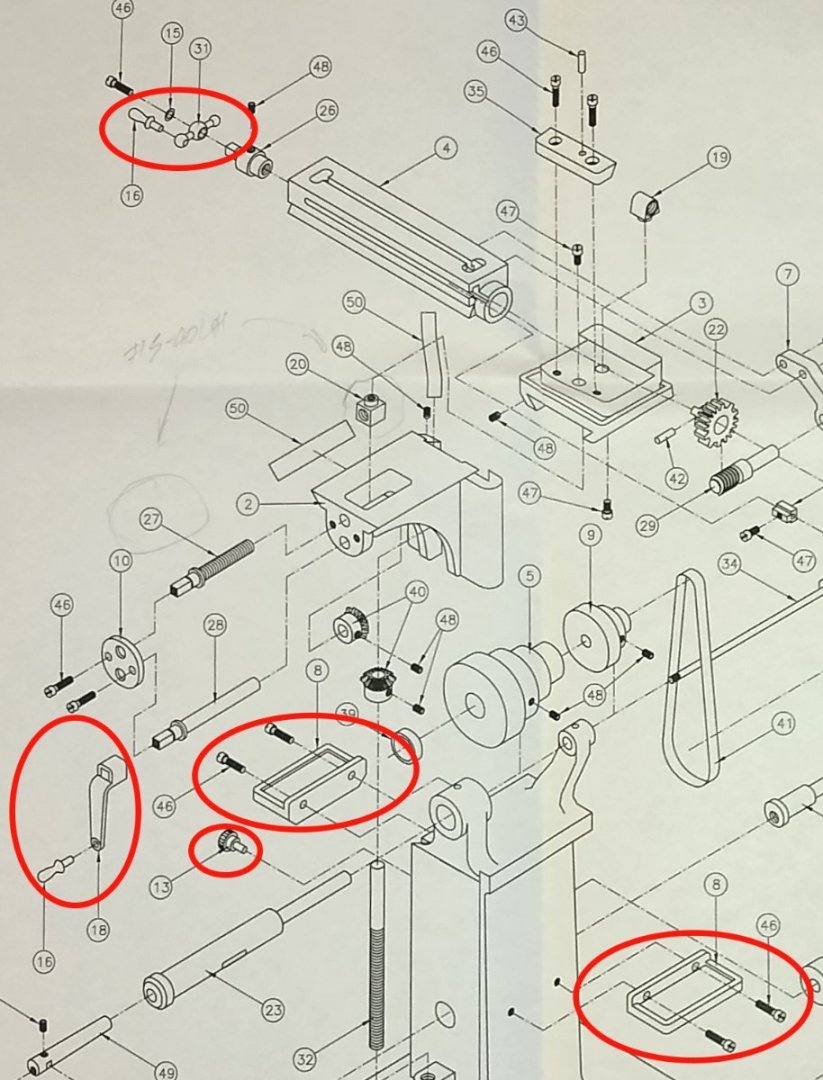

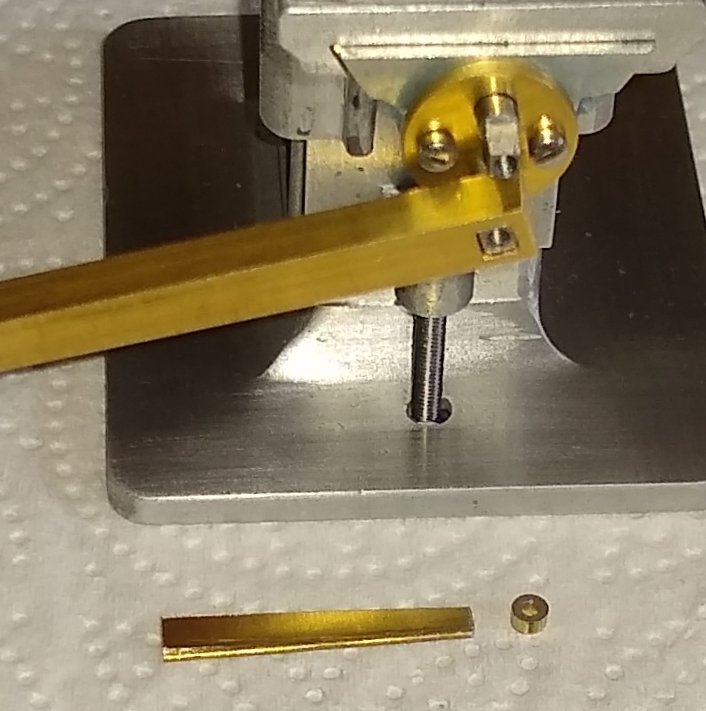

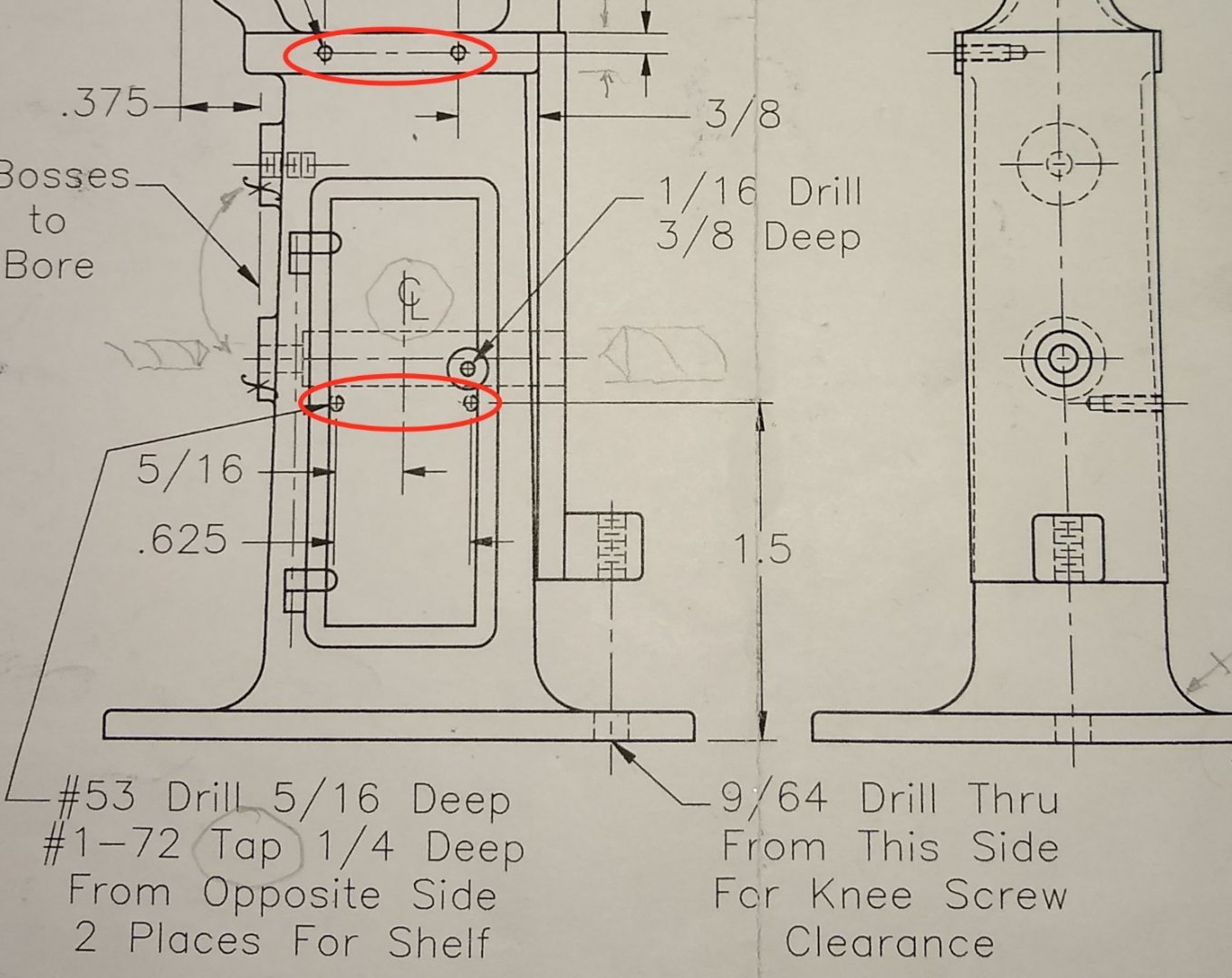

For my Autumn project I have gone with PM Research's Drill Press Kit .... https://pmmodelengines.com/drill-press-kit/ I sourced it in the UK via https://www.forest-classics.co.uk/pm-research/pm-machines/pm-research-drill-press in the Forest of Dean. Below is a PM Research image of the finished drill. It is based on a J.E. Snyder (Worcester, Massachusetts) upright drill press. The original item stood 98" (2.5m) tall and weighed 800 Lbs (364 Kg). More here ... http://vintagemachinery.org/mfgindex/imagedetail.aspx?id=3067 A quick look at the box contents....two drawing sheets and all the Aluminium castings, stock metals and fixings needed to finish the model. Below, all the parts. I decided to start from the bottom and work upwards, so for this Post - Pt 1- the Base, Pt 5 - the Column Base, Pt 9 - the Bearing Block and Pt 20- the Lower Pulley Shaft. I watched Part 1 of Joe Pie's excellent build of the drill ....https://www.youtube.com/watch?v=voeBhlRVBi0 That gave me a lot of starter tips. But have yet to watch the other episodes since I wanted initially to try to do my own thing....I suspect I will be back looking at Joe's videos before long though 😉 So, to the Base. Quite a lot of machining required including the use of a Rotary Table. Below, centring the 4" Rotary Table (RT) with the quill of the milling machine. Next I needed to mount the Base casting on the RT with the Base's circular pad coaxial with the quill. I measured the pad diameter - for a casting it was quite circular but a bit undersize compared to Part 5 which would sit on it . I turned an 'alignment jig' that matched the pad's diameter on one end, with the other end fitting in to a 20mm diameter collet. I then lined up the pad and the jig by eye and finger touch. Below, the Base now clamped in a toolmaker's vice and fitted to the RT. I also marked the centre of the pad with a sharp point since I felt that might come in useful later on. Everything fitted onto the 4" RT, but it was a little tight. Now reducing the thickness of the hollowed part of the casting to allow the T-Slots to emerge cleanly in to that space. IIRC, I used a 5mm 3 flute end mill. Now the fun stuff. I had skimmed the inside straight edges of the hollow with a 3mm round nose end mill...now it was the turn of the pad. It actually worked quite well, but by the time I was finished the pad's diameter was now quite a bit less than of Part 5 - the Column Base. I saw remedial work fast approaching over the horizon - see later. Below. Now to drill and tap the the four #1-72 holes in the pad. That didn't go well. The pad's diameter was already on the small side ie getting a bit tight for #1-72 screws, so I decided to use a #0-80 tap (- I already had suitable 0-80 screws at hand). The tapping did not go well. The Base casting is appx 0.300" thick, to later be reduced to 0.250" thick...the very small tap broke in the Aluminium casting before it was halfway through the first hole...I don't think it was excessive torque that did it, more likely a slight sideways force. The only way I could get the broken tap out was to grind an old small drill to the tap diameter and hammer it out (wearing safety glasses). That worked but left a large'ish hole. So I went to Plan B - drill clearance holes through the Base and Column for #1-72 screws and use half nuts under the base. Counter bores being made for the half-nuts. Now making the two T-Slots. Many shallow cuts of about 0.005" using a 2mm end mill were required but it all went OK. I then used a T-Slot cutter to finish off the slots - it only took one (very slow) pass for each slot. Now to clean up the curved inside faces of the Base using the 3mm round nose end mill. I used the two clamps that come supplied with the RT to hold the Base in place. A smooth 3mm rod in the collet was gently run along the outside of the curved face to align (by eye) the centre of that curve with the centre of the RT. That all worked fine. Note: on the left of the pic the two finished T-Slots are seen. Next, Pt 5 - the Column Base. The casting comes with a circular sprue on the RH end which facilitates chuck holding as seen in the 2nd pic below. Cleaning up the larger and smaller diameters. The largest diameter should match that of the Base's circular pad, but that pad was now reduced in diameter, so that meant the Column Base diameter also had to be reduced (from what the drawing stated) to match the pad. This had the knock-on effect of moving the PCD of the 4x fixing screws inwards. The protuberance is a bearing point for a shaft - the material around it was cleaned up using Needle files and Emery cloth. Drilling the 1/8" hole for the shaft, Pt 20. If the part was made of Mild Steel I'd probably have used a more sturdy clamping arrangement. Next, Pt 9 - the Bearing Block. The casting was a little askew, so I trod carefully when machining it trying to make it look as 'square' as possible. Using a 2mm Stub drill to start off the hole for the 1/8" drill. It had taken me a little while to figure out how to hold the Block but a Toolmaker's Clamp eventually came to the rescue. Whilst clamped, I took the opportunity to clean up the Block sides. I didn't go right up to the clamp when milling so that left a small ridge which was later removed with a Needle file. Turning the Block over to clean up the other side, using the 1/8" drill and a set square for alignment. Finally, a sub-assembly pic of the four parts. I'm using 3/8" long #1-72 Cap Heads (with half-nuts underneath) to hold everything in place. Slotted head screws come supplied with the kit, but I feel they don't really help the look of the model. The Cap Heads do stand out due to their 'blackness' but once I paint the drill parts black the Cap Heads will mostly disappear. [Edit Jan 2024 - I replaced the 6x Cap Heads with period correct Hex Head bolts and nuts]. Well, that's it for this first post. Overall, the Drill seems a nice project with some interesting challenges. Next post in a week or two depending on weather etc 🙂 Richard

-

Panard EBR 11 by RGL - FINISHED - Hobbyboss - 1/35

Rik Thistle replied to RGL's topic in Non-ship/categorised builds

Greg, Thanks for the tip. Sunday afternoon disappeared after reading your build and quite a few videos on Night Shift's channel...but worth it 😉 Richard -

Panard EBR 11 by RGL - FINISHED - Hobbyboss - 1/35

Rik Thistle replied to RGL's topic in Non-ship/categorised builds

Greg, That looks so real. Great stuff. One day I think I fancy trying my hand at weathering on models. Any books or websites you'd recommend for a beginner? Thanks, Richard -

Thanks RetiredGuy, I've got an f1.7 lens for my 4/3rds Panasonic camera which allows a shallow depth of field...it took a few tries to get the correct balance of sharpness of the Mill against putting the Lathe out of focus by the right amount. I also adjusted the distance between the Mill and Lathe to help with that effect. I too was happy with the end result 😉 Regards, Richard

-

Thanks Gary, I had noticed your dioramas a while back...amazing work and you have an amazing skill set. I'm off to read your latest, the Eastern rig dragger. As for my next project, well it's in the post....another workshop item, partly encouraged by a poster here 😉 After that, I think I need to branch out a bit....maybe in to an area Elon wouldn't be too enamoured with. Richard

-

Grant, Interesting insight into the Bob Smith glues, thanks. I see that BSI is based in California and has a distributor in the UK. Most of the SuperGlues I use are made by Loctite or Gorilla. Anyway, did a little reading on the history of SuperGlues ... https://tangibleday.com/the-history-of-super-glue-crazy-or-genius/ ... I didn't know that Eastman first discovered superglue, but I did know about the Vietnam link. Richard

- 57 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

Paul, That is very kind of you, thanks. It was an enjoyable build and probably just the right length of time for me. I'm now trying to decide what to do next. Stuart's Oil Field Pump is a possibility https://www.stuartmodels.com/product/oil-field-pump-unmachined/ along with some other ideas. However I feel I need something a bit different that will force me to learn new things whilst still being makeable on my mini-lathe and mini-mill. So, still thinking.... 😉 Richard

-

Thanks Wefalck. Yes, there is quite a lot of 'bling' on it 🙂 I think the model manufacturers do that deliberately to make the kit more attractive to potential buyers. It aslo makes the details stand out a bit more on a finished kit. For a display model it's OK, but for a 'real life' type model it would be unacceptable. Richard

-

I ran a Clausing 60" radial arm back in the toolroom days... Impressive machine... Those Clausing machines look like very serious pieces of kit. I did use a radial drill when I was undergoing training. I was always impressed how it could hold its accuracy even when the drill was out at the end of the arm. Not sure I could build a model from scratch though.....it would require a lot of research and design, whereas I tend to target 3-6 month projects, at least for now. But keep pushing...who knows 😉 Richard

-

Egilman, So, at 1/12th scale, it is right on the money. OK, got it. Thanks. a radial arm would be perfect Interesting. I've mostly been looking at Polly Models' range of Anthony Mount models.... https://www.pollymodelengineering.co.uk/sections/stationary-engines/anthony-mount-models/index.asp I'm limited to a 7" flywheel so quite a few of them are doable in my workshop. But I'm a long way from making my mind up....all suggestions considered 😉 Richard Edit: Yes, the Oil Field Pump has also caught my eye ... https://www.stuartmodels.com/product/oil-field-pump-unmachined/ ... it would be nice to see it running with my Stuart 10V, say.

-

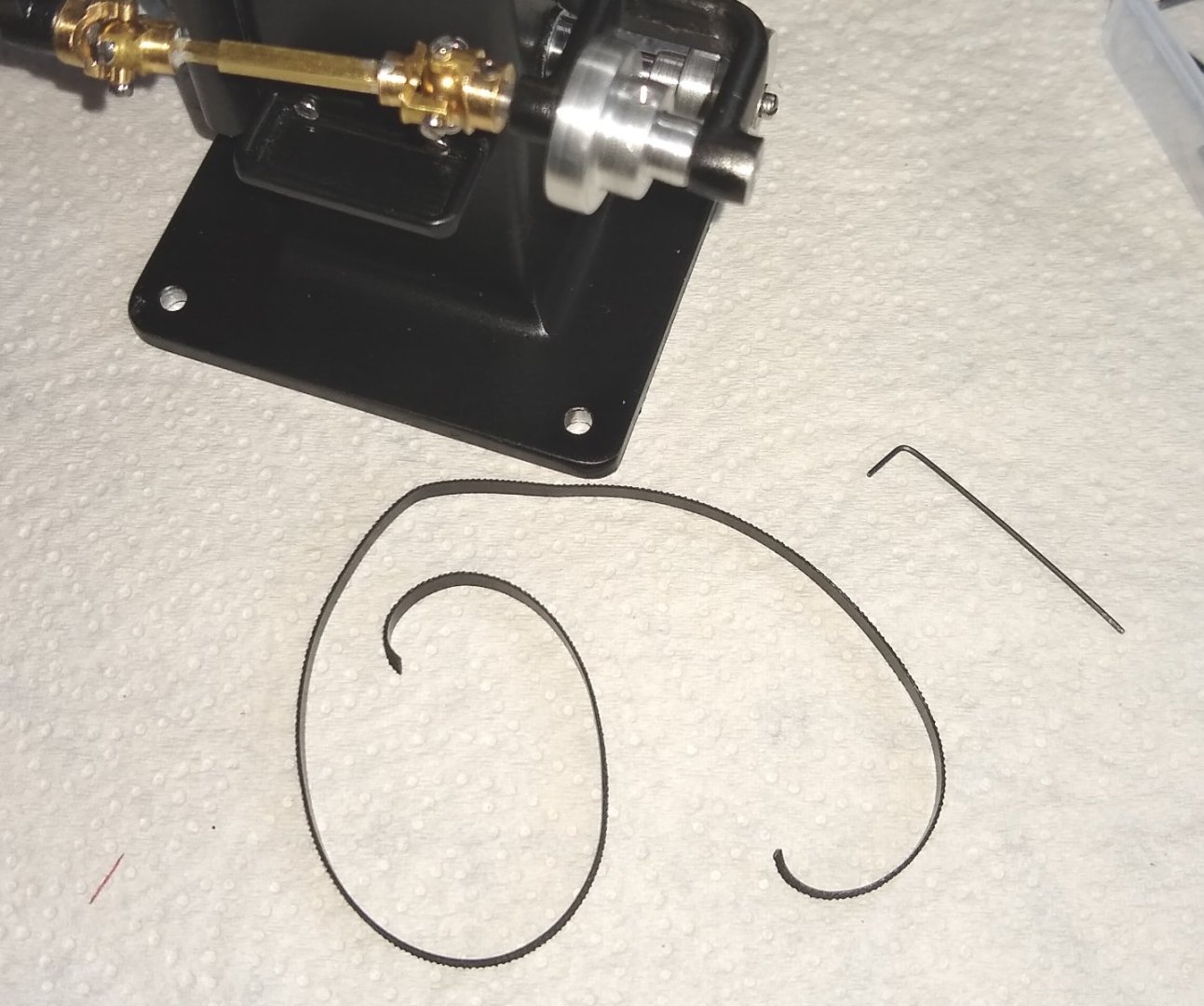

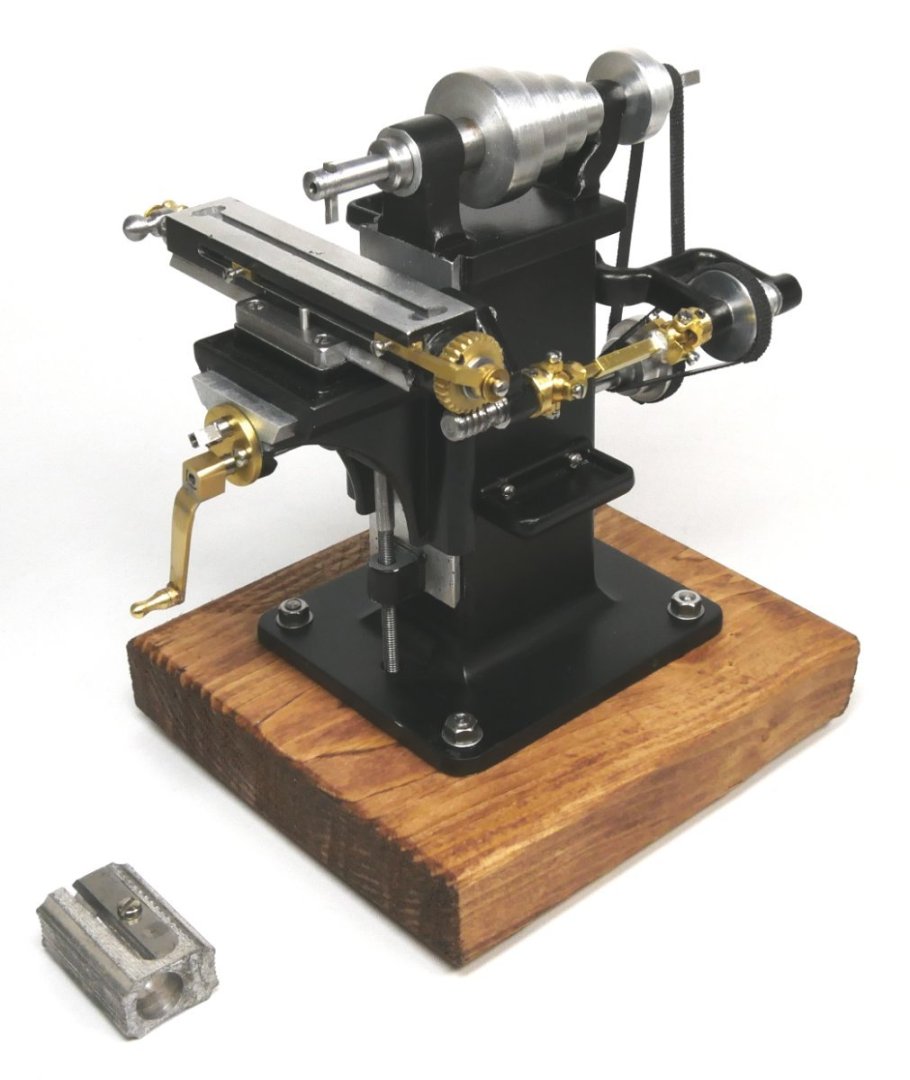

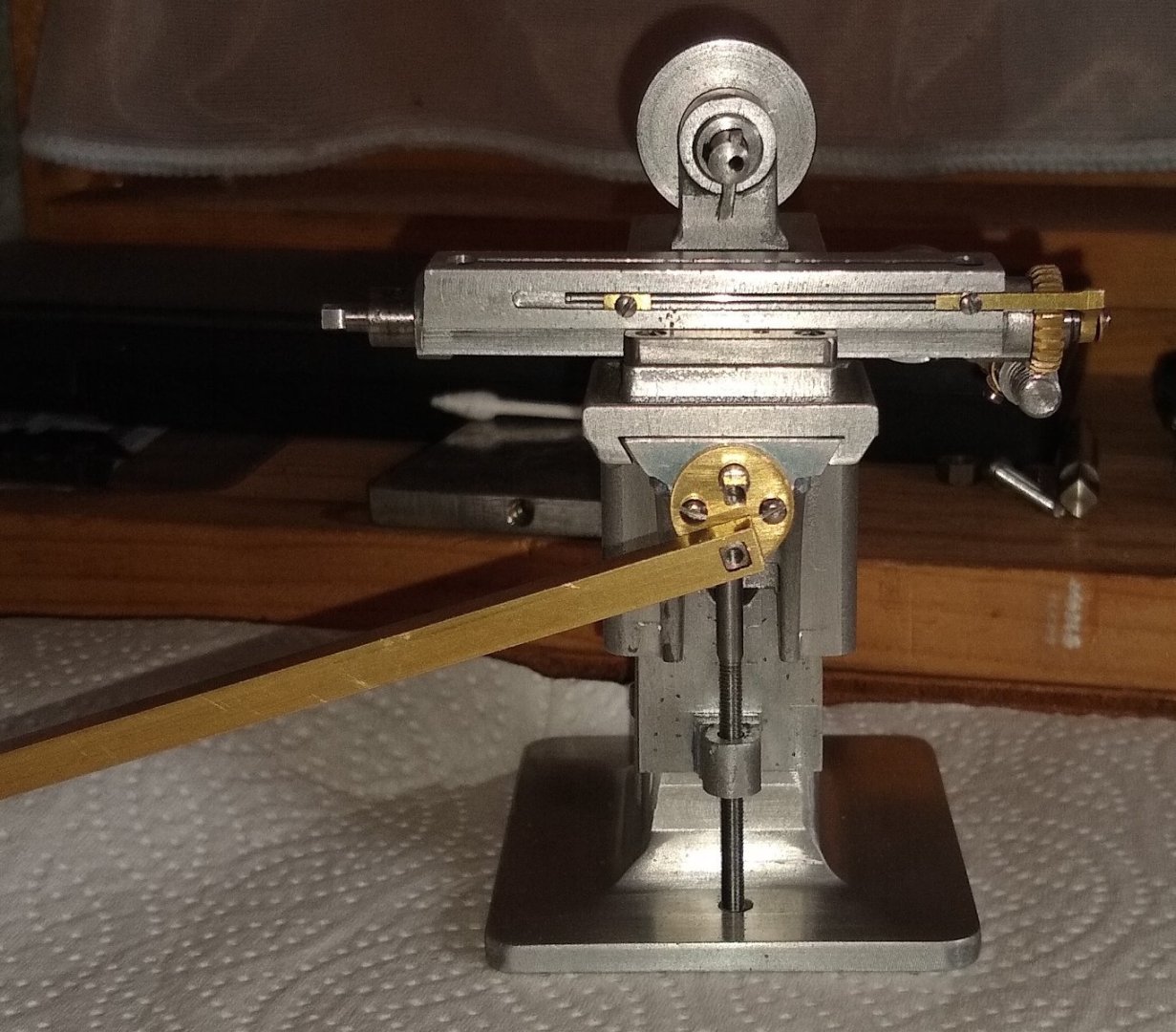

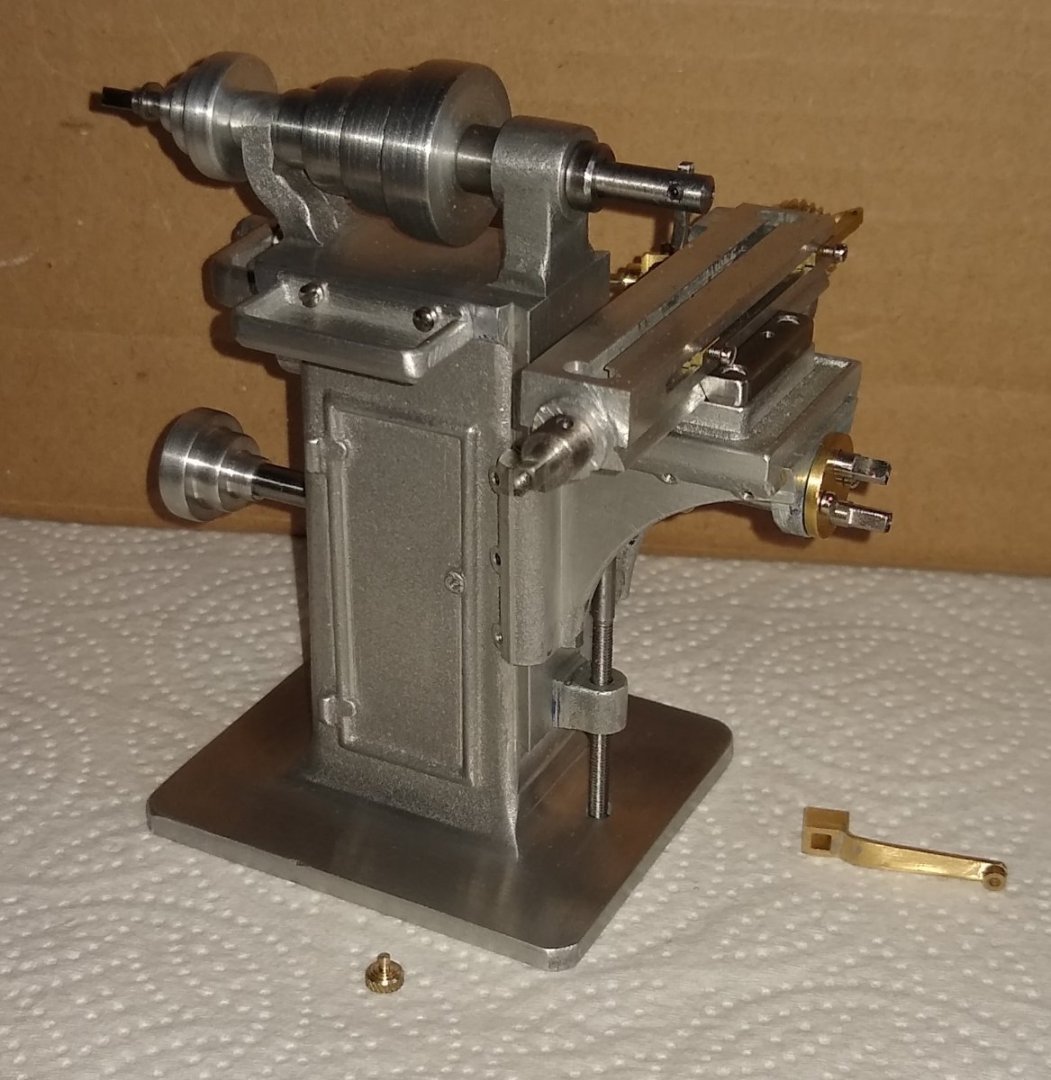

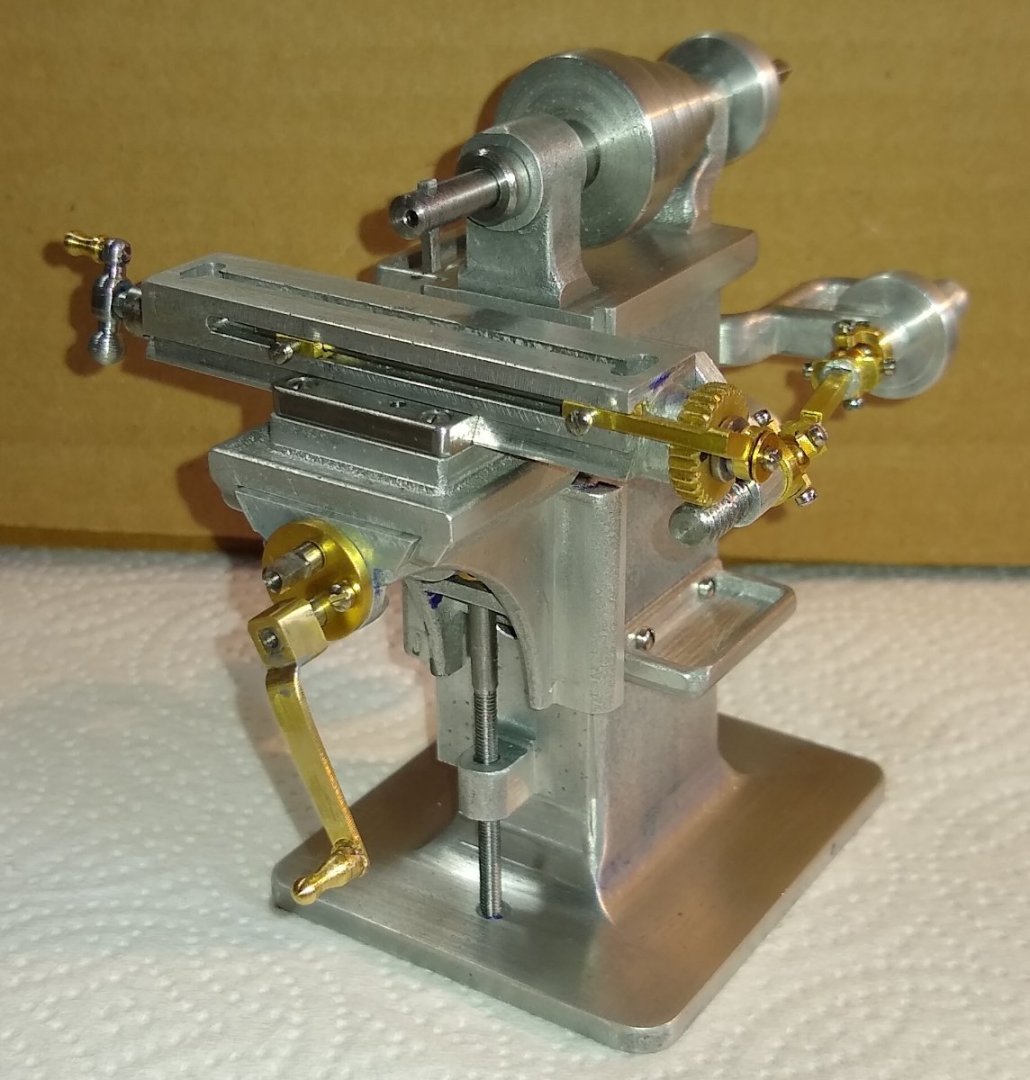

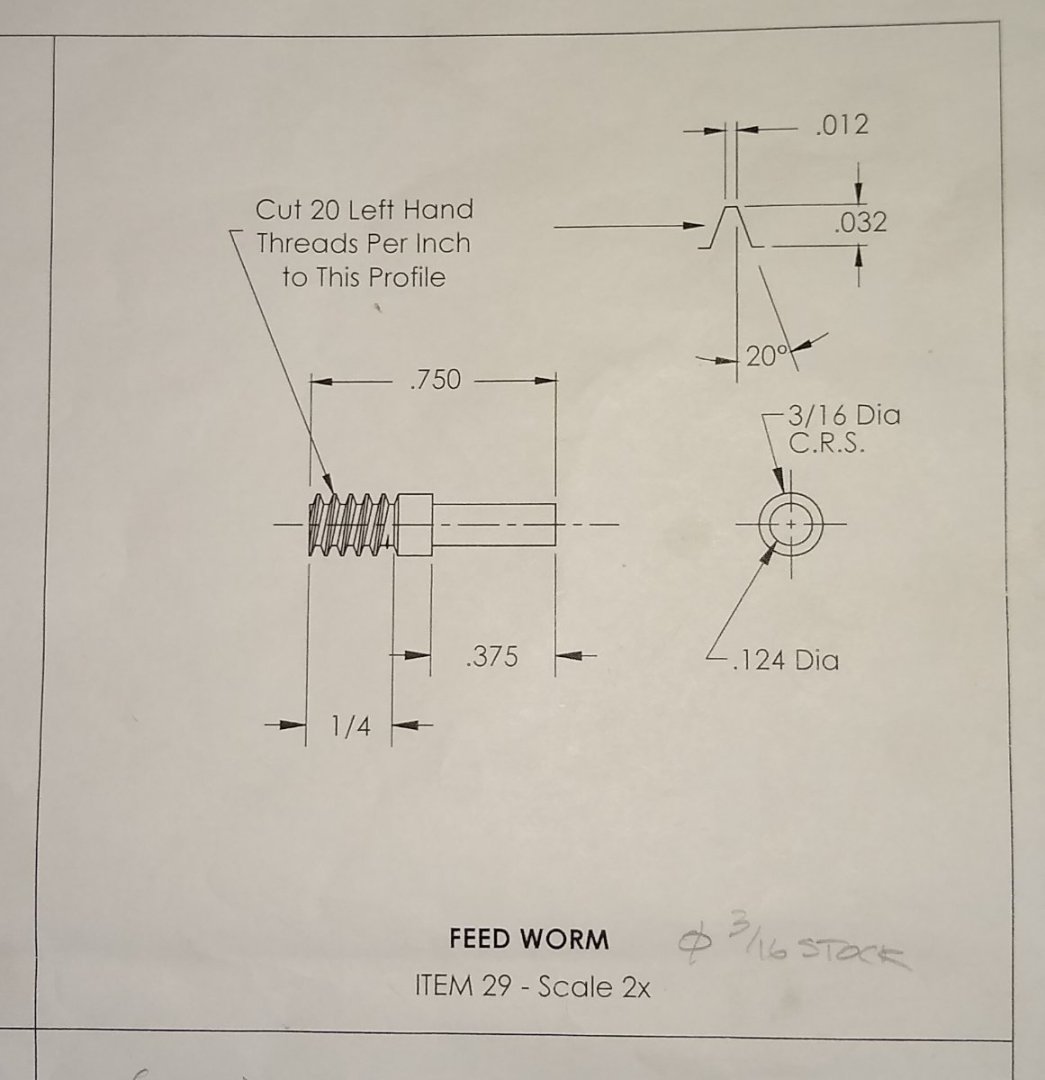

Hi all, The parts are back from the paint shop and assembled. Below. There was a good bit of masking areas off before spray painting. And after the masking was removed some touch up with a fine brush was required. Colour chosen was Black - this seems to be the dominant colour around the turn of the last century and matched the colour scheme of my Stuart Lathe. Also shown above are a couple of shafts that 1-72 UNC grub screws are meant to bite in to. I decided to add flats to all such areas. Below, flats are being added to Pt 23, the Spindle Shaft. Below. One of the last things to do was add the two Belts, Pts 41. The drawing calls for them to be cut to length, with a slight overlap, then the overlaps super-glued together. The best way I found to do this was away from the mill. I firstly coiled the complete length to introduce a curve to the belt, then cut to length and then I weighed down one end whilst a cocktail stick with a dab of super-glue was applied to that end. The other end was carefully introduced and held down with finger pressure, making sure I rolled my fingers to stop the belt becoming part of my hand. Finally, three pics of the finished Milling Machine. the wooden base is temporary till I find something a bit better- it did allow me to handle the mill more easily rather than getting fingerprints all over it. Below, for scale, one material removal device sitting next to another. And the last pic shows the Mill about to meet it's workshop colleague, the Stuart Model Lathe. All the moving parts of the mill function as they are meant to - the handle at the front moves the knee up and down, same handle also moves the saddle. The belt drives work, and move the bed left and right. I will have another go at screw cutting the Feed Worm, Pt 29, and add a post about how I got on. Final thoughts are: - An enjoyable project that I would recommend. The Aluminium parts meant the workshop was much cleaner than when machining the cast iron of the Stuart lathe. However, in some ways, the Stuart product seems a bit more 'real'. - The drawing set was fine and adequate for the task. However, some of the dimensioning was a bit strange eg more than one datum on parts when really only one should be used. - The scale is claimed to be 1:12 but I always felt the real mill would be approaching 6 feet tall - the model is 4" high. - I thought I had lost one of the 1-72 grubs screws (...there are no spares in the kit) but I had somehow managed to installed two grubscrews in the same pulley fastening hole .... I found that out late in the day....and it explained why I could never properly tighten that pulley 😉 - I probably should have paid more attention to accurately making the Bed, Pt 4. It is quite important to follow the drawing dimensions 100%. Thank you for all the Likes, Comments and very useful feedback I received. It really does help bring a Build to life and also helps motivate me and helps me learn. I'm not sure what my next project will be....I have a long list to consider and some workshop improvements that need doing first. All the best, and see you soon 🙂 Richard

-

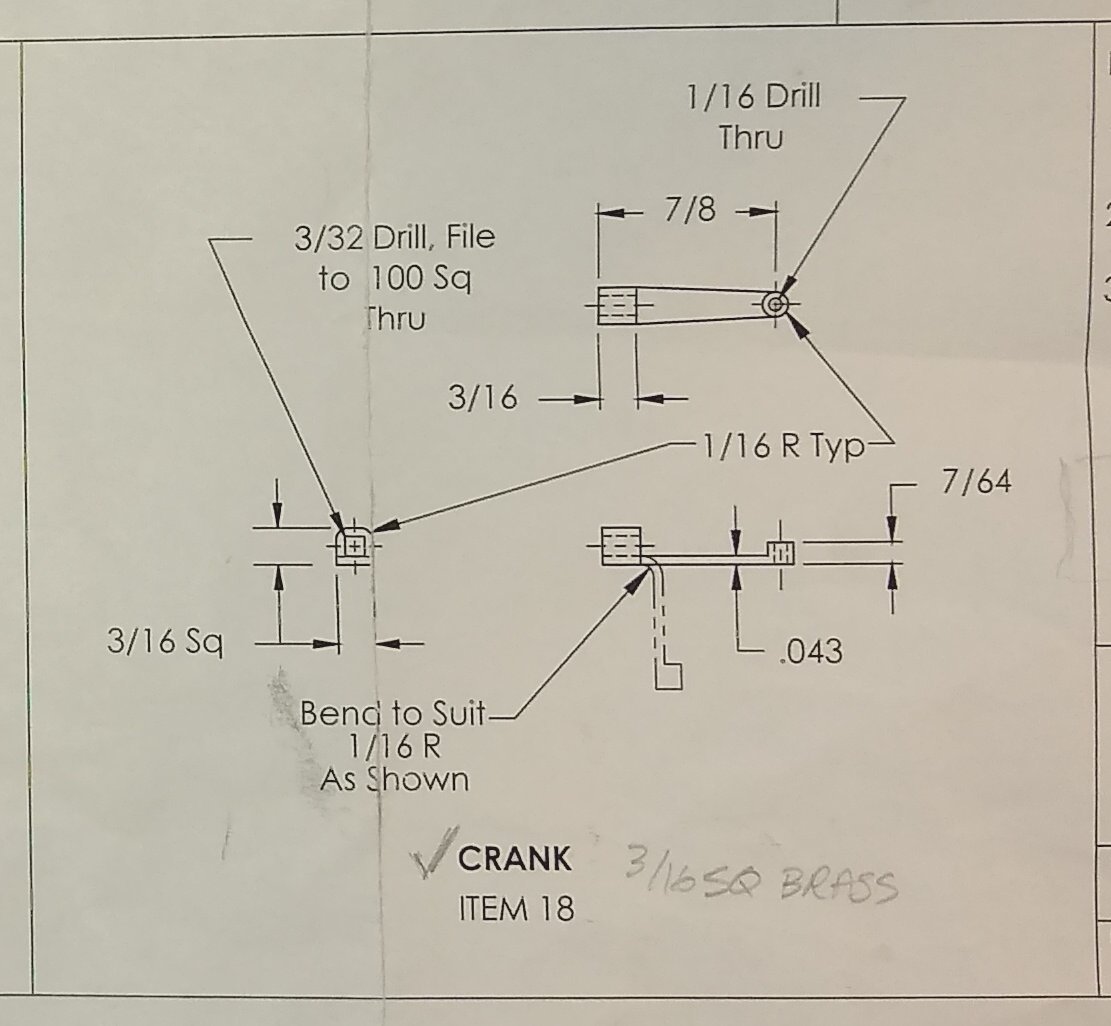

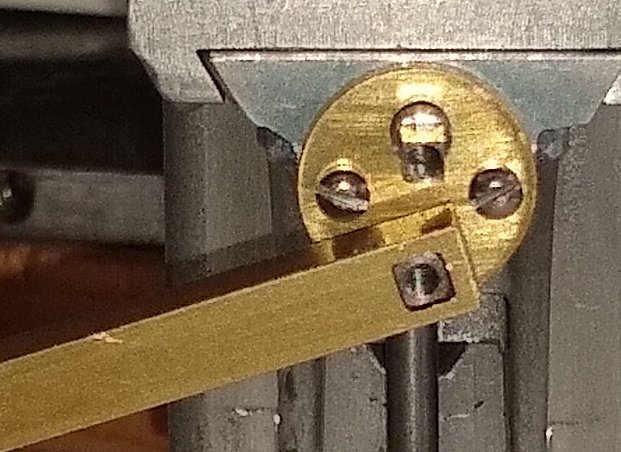

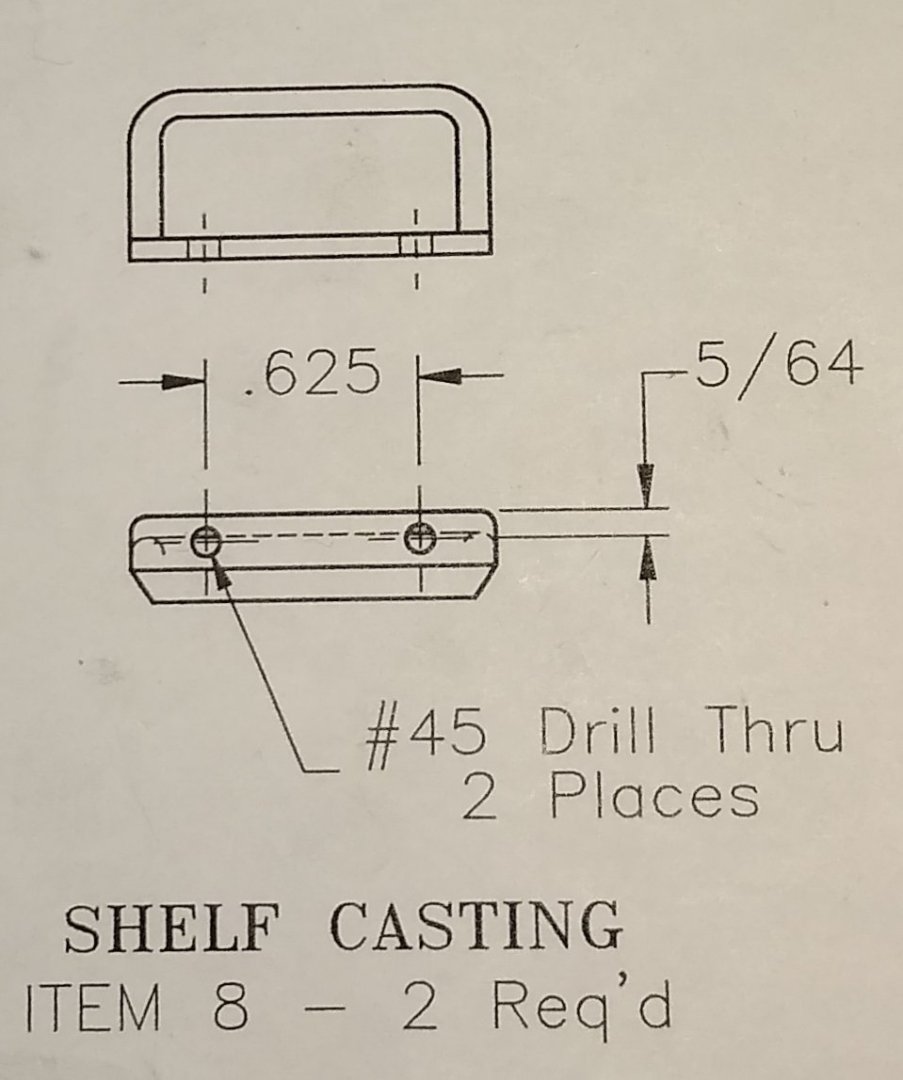

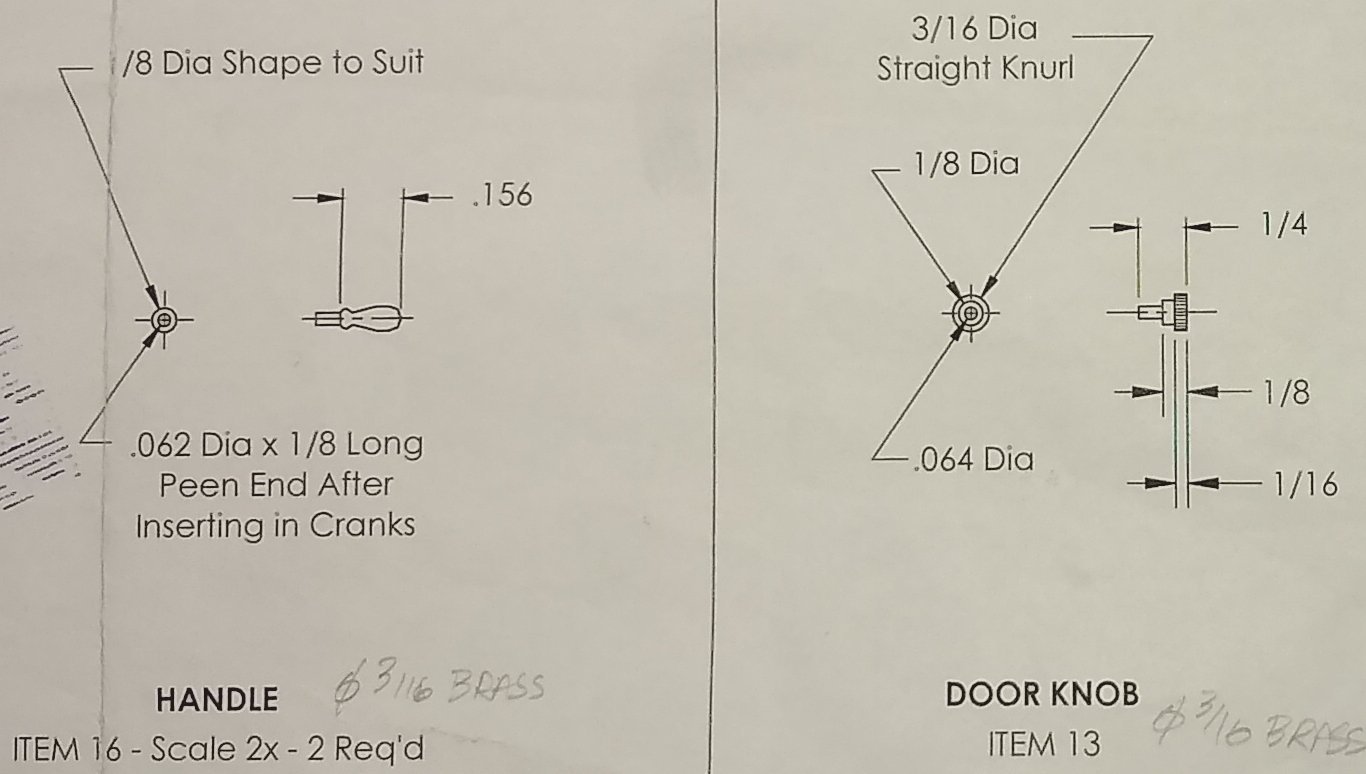

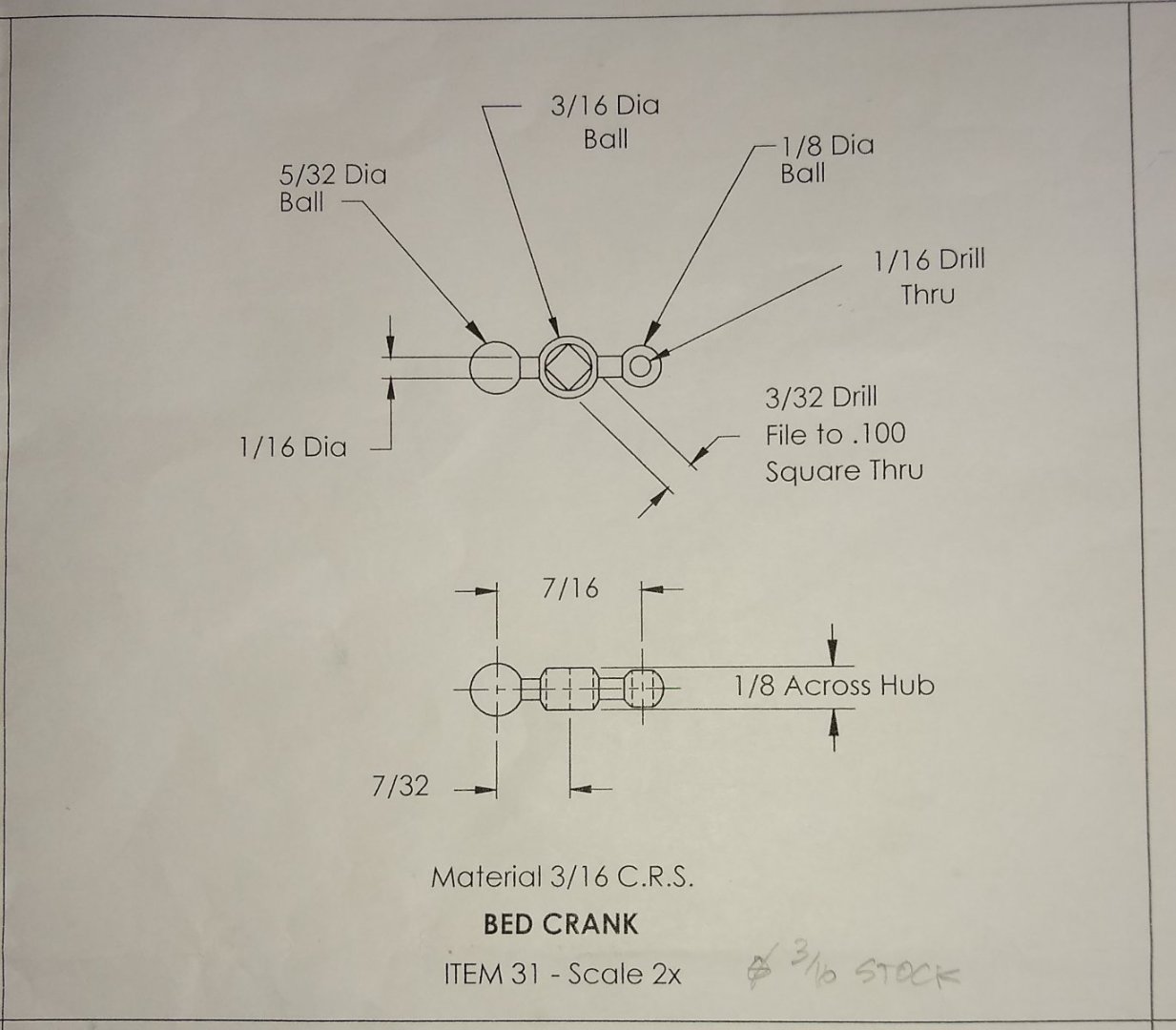

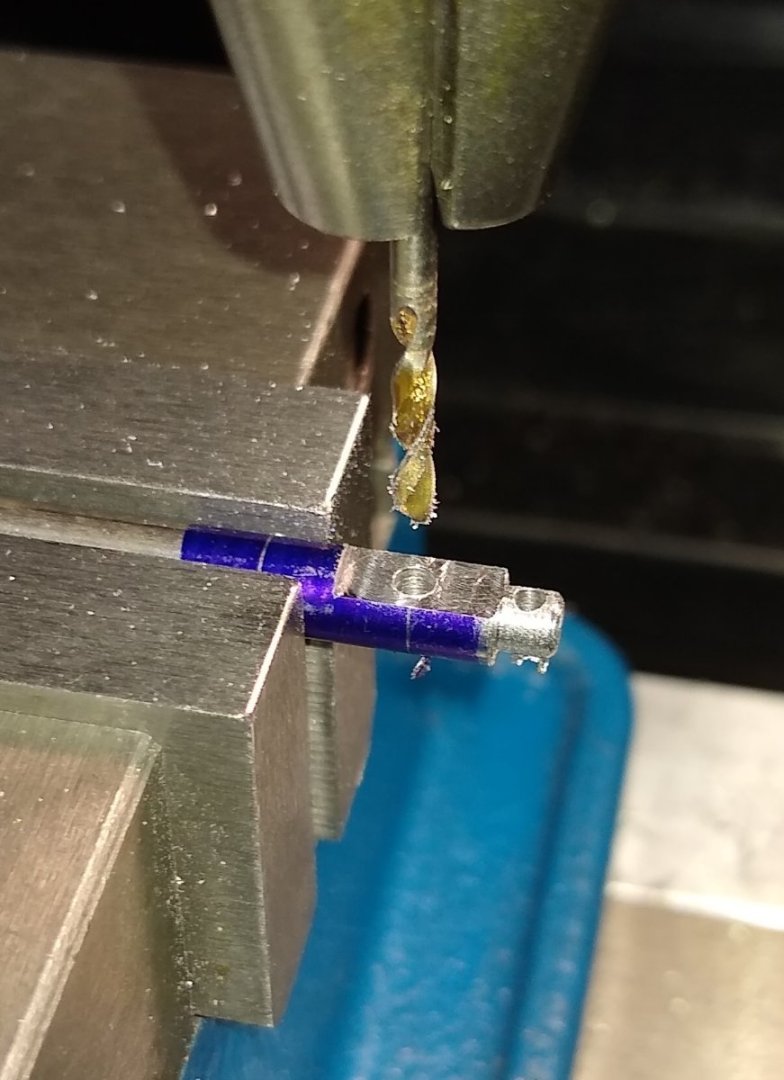

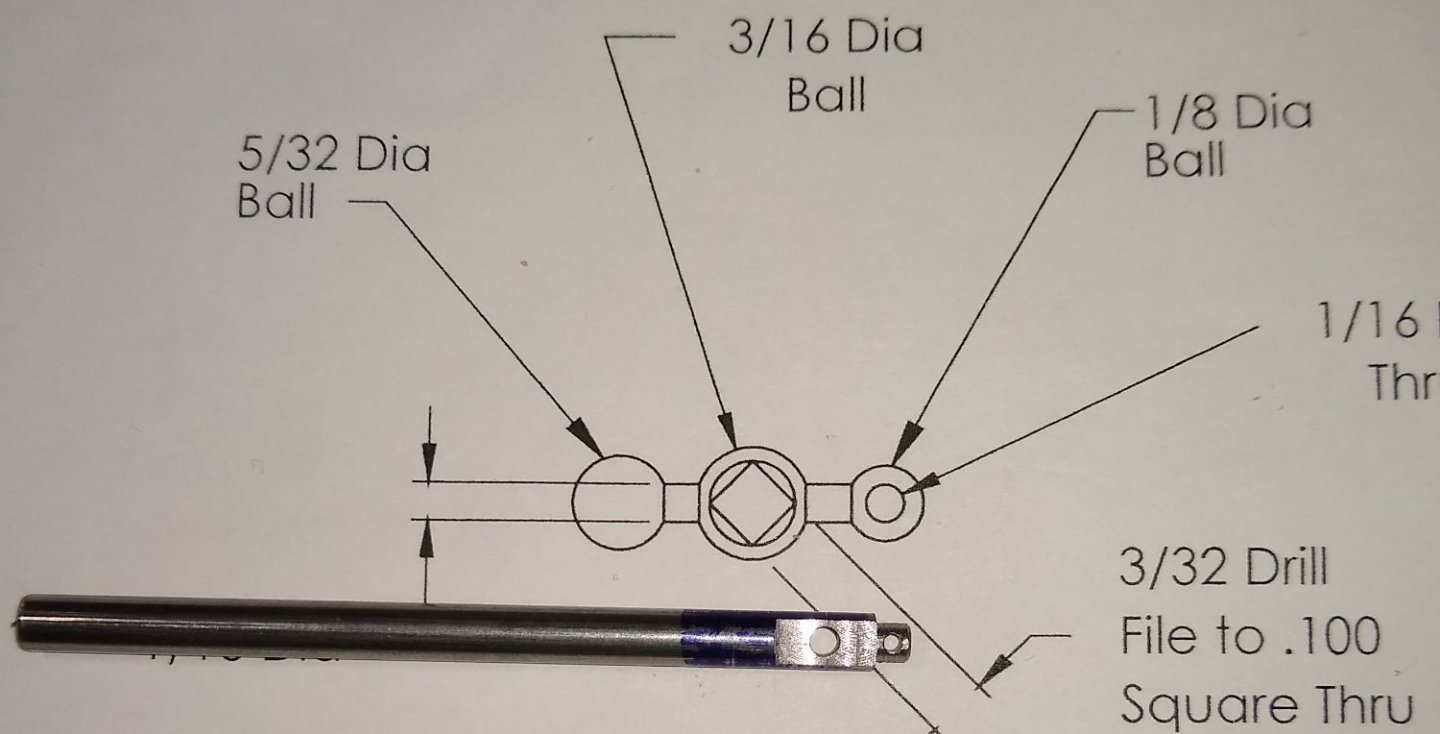

Hi all, I'm getting close to the finish line. This post covers the last remaining parts ie handles and shelves. Firstly, the Crank handle for moving the Knee up and down. The same handle also moves the Saddle in and out. The drawing calls for the Crank to be made out of one piece of 3/16" brass. I decided to fabricate it out of three parts. I wasn't convinced I could bend the brass as depicted. I had some 1mm thick brass sheet that I did a test bend on and that bent fine - that convinced me to fabricate the Crank. Below, the square hole was filed into the 3/16" brass stock. The end with the square hole was then cut off and cleaned up. Close up of the square hole. The arm and circular boss. After bending the arm of the Crank, it was soft soldered on to the square end using a hot air soldering station. Next was cleaning up and fitting the two tool shelves. As seen below, one shelf fits near the top of the mill and the other on the sloping side of the mill Stand. That latter shelf had it's mounting face slightly angled on my mill so that it would lie horizontal when fitted. Both the Crank and the Feed Shaft require handles, as does the 'door'. Below, the Door Knob and the Crank lying next to the mill. Lastly, the Bed Crank. Again, another square hole had to be filed...yup, I really need to get that broach made ;-). I had firstly turned the 1/8" dia end on the lathe. Then over to the mill to put the flats on the central section and drill the two holes. Now ready to move back to the lathe for profiling the ball shaped sections. Finally, a couple of pics of the fully assembled mill (less driving belts, Pts 41) The remaining work is to disassemble, fettle and clean, paint, make up the drive belts and reassemble. I'll post when that is done. I'll also have another go at making Pt 29, the Feed Worm and post progress. All for now, Richard

-

Bob, Jumping in on the bike tangent. I used to have a steel framed Trek 930 Singletrack .... it was the best mountain bike I ever had. Unfortunately, even after regular servicing the inside of the frame started to rust away so it was too dangerous to risk using it. I replaced it with a Marin Rock Springs - good but no 930. You are doing a very good milage per week. I need to start getting out on my bike more. Richard

- 57 replies

-

- live steam

- radio

-

(and 2 more)

Tagged with:

-

Egilman, Thanks. I think that ties in with what Wefalck has been advising. ...you set the top slide to 30 degrees... The procedure I have been missing is to introduce the tool to the workpiece at 30 deg (using the top slide) so that the tool's leading edge (on it's right side) does most of the cutting. I really can't remember if I was ever taught that back in the day...I may have but certainly don't recall it. I'm also wondering why the drawing asks for a chiselled end on the cutting tool. The mating teeth on the wheel are not flat bottomed...perhaps a rounded end on the tool would be less aggressive when cutting. As I mentioned previously, I have ordered some proper EN1A mild steel so will use that together with your's and Wefalck's advice when the time comes. Meanwhile I am getting on with making handles etc. I think I will tackle the Feed Worm issue once the project is finished, the decks are cleared and I have time to sit down and think it all out properly. I'll add an Edit if/when I am successful. Richard PS: I also just noticed that my Tailstock is about 0.25mm out in the horizontal plane - there is an adjustment for that on the tailstock, but it's a bit finicky to set-up correctly. I had adjusted it when I first got the lathe but over time it seems to have moved. Anyway, it would mean that my 2nd attempt, using the live centre for support, was probably causing the end of the workpiece to slightly wobble as it tried to straighten itself out.

-

Ron, "How to run a Lathe" by Southbend Lathe company. I've already built up a small library of general lathe and mill books, and specific ones such as 'Screwcutting in the lathe' - Martin Cleeve. I see that Amazon.uk does offer the book you mention and it's only £6. My concern is that most older books I feel are written around more rigid, higher tolerance UK/European/USA built equipments rather than small 'Chinese, built down to a price' lathes. But I'll have a think about it 😉 Richard Edit: Ron, I've now 'found' your book .... having a quick read-through now. And the lathe pictures therein remind me of a model lathe I built a few months ago!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.