-

Posts

892 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by GGibson

-

-

-

Great looking cleats, Mustafa! I assume you made them using your Proxxon mill? Excellent work, sir!

- mtbediz and Der Alte Rentner

-

1

1

-

1

1

-

58 minutes ago, mtbediz said:

You've been preparing extensively for Conny, Greg. I think we can expect a heavily modified kit build from you.

Well, yes, Mustafa... I have been preparing. I've gone through Jon's build-to-date and am now reading through yours from the start to where you are currently. Not sure about a "heavily modified kit", but if I can successfully build a "Jon/Mustafa" clone of the Constitution, I will declare it a win! You guys, along with Peter, usedtosail, xken, among others, have me inspired and excited to get started. All of you have created your own Constitution practicums. My appreciation for all of you is overwhelming! 🏆

- usedtosail and mtbediz

-

2

2

-

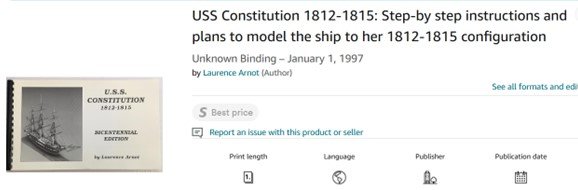

Sounds great, Jon. Also ordered this Laurence Arnot book but haven't received it yet. Just trying to prepare myself for the build. I have been re-reading all of your posts here to understand what you've done, and how well you've done it! May have a few questions in a month or so. Let's get past the holidays first...

Speaking of which, have a Happy Thanksgiving weekend with family!

-

-

On 11/21/2024 at 11:24 AM, palmerit said:

I've also seen folks make their own pins that have a piece of wood through them (that can act as a clamp on the plank above or below) and that these work especially well when doing a second planking. I'd love a "how to" for making those (e.g., what kind of pins, what kind of wood). I'm not especially handy.

What you may be referring to is a technique I saw Olha Batchvarov use in one of her YouTube videos re: the USS Confederacy. It's the #9 video in that series, if the link does not work here. Her process for making the clamps begins at the 3:50 mark of that video.

The biggest and most difficult ship model kit - #09 - USS CONFEDERACY - [WALES]

-

On 11/24/2024 at 4:57 PM, GGibson said:

...I placed my order with Woodland Scenics now, as well. I did, though, order the MG740 USA Gothic White dry transfers that Jon mentioned in his build log.

Apologize for taking up space on your build log, Peter, but just wanted to give a shoutout to the Woodland Scenics folks that we discussed on Sunday. Ordered my set of dry transfers on Sunday... and received them via UPS today (Tuesday). Great customer service!

-

I had sent the Proxxon folks a query about a possible accessory add-on for my MF70 milling machine and drill, and received a response back that indicated the accessory I was asking about might be a bit big for what I was wanting it for, but indicated they had a brand-new clamp that may interest me. Who isn't interested in brand-new stuff?!?

Eccentric clamping fixture ES 70 – PROXXON Inc

Wasn't completely familiar with the "eccentric clamping" term, but it appears to be a way to "quick clamp" things with the small turn of the lever/handle. A maximum of 1.5mm squeeze, if I am understanding the information correctly. This would be SO much easier than the step clamps that come with the Proxxon X-Y compound table, so I am all in on this accessory! 👍

-

1 hour ago, Der Alte Rentner said:

I just had an amazingly disappointing session at the shipyard. I spent the solid hour trying to get a single hinge on one of the stern gunport lids. Nothing I have tried works.

We've all had days like this... some of us more than a dozen days like this... I'm sure someone will suggest an A+ solution, Peter. And the rest of us will take notes for when it happens to us again. 👍

-

12 minutes ago, Jim M said:

@GGibson I am really surprised how this kit has so many challenges. Do you feel that is it poor quality or just bad design?

Difficult to answer specifically, Jim. Really don't think it's either. Pavel Nikitin is a quality builder and designer and has created some remarkable model ships. Not that I fully understand the "mass production" process of creating an inventory of model kits, but the issues seem to more be in how the parts are laser cut on the sheets, perhaps not setting the lengths perfectly in the CNC controls, etc. The builders over on the YouTube channel have commented about obvious omissions in parts that are shown in the instructions on particular laser-cut sheets but missing on the actual sheet in their kits. I have run across a couple of those instances, as well. So, I guess that comes down to quality control in the production process, rather than a quality/design issue?

But... we'll continue to work through it. The others have. With that said, though, I have already begun prepping for my Constitution build... 🤷♂️🤣

-

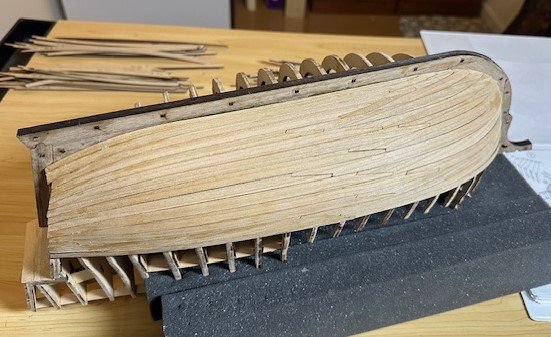

After completing the lower part of the port side hull, it was now the starboard side's turn. As you will recall, all of the Pavel Nikitin Santa Maria hull planks are pre-shaped and include nib scarfs where needed. Many of the strakes, though, did require some careful bending to shape them around the bulkheads. I've been doing this successfully on these planks by holding them under a stream of hot water for a bit, then pinning them against the bulkheads until dry, then glueing them in place, using Acco clips and mini-clamps.

Although Pavel has been adamant in other modelers' YouTube build logs that all of his planks fit perfectly, modelers have had issues with some planks not being long enough or the spacing being a bit off. I had that issue on the port side that I noted in my post #19 above, and had a similar issue on the starboard side (actually a bit worse). I also had an issue with what would, I guess, be Pavel's garboard strake #1 not meeting the keel fully, so I added a small 3/32" square strip to fit in the spot to take up that space. It will all be sanded and filled as I clean up the hull before finishing.

So, the lower half hull planking of both sides is now compete. I will now work on the hull planks at the wale and higher.

To those celebrating Thanksgiving this week, hope it is a wonderful time for you. Safe travels if enjoying away from home. As always, appreciate the reads, likes, comments and criticisms.

-

1 hour ago, Der Alte Rentner said:

I took a tip from the Bob Hunt method and obtained the dry transfer decals he suggested using.

It's a good thing that the dry transfer decals from Woodland Scenics we're still available online.

Transom looks really nice, Peter!

OK. Haven't even started my Constitution, so probably five years (or more) away from this step, but... based on your "still available online" comment, I thought I better knock that one off of the order list and I placed my order with Woodland Scenics now, as well. I did, though, order the MG740 USA Gothic White dry transfers that Jon mentioned in his build log.

Now if I can just remember 5 years (or more) from now where I put them! 🤷♀️🤣

Carry on, sir! Doing well!

- mtbediz and Der Alte Rentner

-

1

1

-

1

1

-

4 hours ago, GGibson said:

I actually do have a nice little palm-sized plane. Need to look to see if it has a brand name on it.

Yogeon Mini Black Hand Plane - Made in China - Purchased in 2021 on Amazon. Haven't used it in planking, but I have used it several times when shaping square dowels to a circle for masts. 👍

-

1 hour ago, Knocklouder said:

I always want to get me one of those Lee Valley mini plane but they are pricey.

49 minutes ago, Tonphil1960 said:Lee Valley has some great mini planes.

37 minutes ago, druxey said:Yes, pricey, but you get what you pay for. Looked after properly, one will last a lifetime and beyond.

Great... another "ooooh, I gotta have THAT new tool now, too" thread. Thanks, guys! I'm such an easy target.... 🤷♀️🤣

I actually do have a nice little palm-sized plane. Need to look to see if it has a brand name on it. But keeping that Lee Valley website open "just in case"...

-

After you draw a line on the wood plank where the taper should run to, if it's a decent amount that you can trim an excess off carefully with an X-Acto blade, go for it. But for more precise tapering, I use and would recommend a sanding block and sandpaper. Maybe start with 180/220 grit paper. Good luck!

- Ryland Craze, Tim Moore, mtaylor and 1 other

-

4

4

-

I have two fully-height-and-brightness-adjustable LED lamps on either end of my shipyard workspace that provide me with awesome light.

The AmazLit Desk Lamp - AmazLit Desk Lamp, Desk Light with Clamp, Stepless Dimming & Adjustable Color Temperature Modern Eye-Caring Architect Lamp with Memory & Timing Function for Study, Work, Home, Office, 15W - Amazon.com

and the Neatfi LED Desk Lamp - Neatfi XL 2,200 Lumens Adjustable LED Desk Lamp & Task Lamp - Bright, Dimmable Lighting for Office, Crafts, Nails & Hobbies with Clamp (Non-CCT, White) - Amazon.com

I have had the combo light-and-magnifier type lamps previously and found that they did not hold position well and never really used the magnifier... I use my helping hands alligator clips with magnifier for that type of work.

-

Looks great, Peter! Well done!

- mtbediz and Der Alte Rentner

-

1

1

-

1

1

-

After working on two of the Model Expo Shipwright Series boats, I built the Ballahoo and then the Bluenose.

The Bluenose was a fun ship for me to build and I learned a lot more about the build process (especially rigging) working on her. Highly recommend. Best wishes on whatever you choose!

- GrandpaPhil and mtaylor

-

2

2

-

Hello Haiko! I will begin following your Constitution build with great interest, as I have this same Constitution kit up on my shelf, waiting for my completion of the Santa Maria build I am currently working on.

I have been following the builds of @Der Alte Rentner, @JSGerson, and @mtbediz, among others, as Peter, Jon and Mustafa are all doing fantastic and I am learning so much watching each of their Constitution builds and the challenges each of them face (and conquer) in the process.

Not entirely sure how far out I am in beginning my Constitution build but will definitely add your build to my list of projects to watch. Hope all goes well and look forward to watching! Thanks for allowing me to tag along!

-

21 hours ago, usedtosail said:

I set up a simple test rig and tried some different ways to add rope coils. Here is the test rig.

I do like your single arm helping hand and its base, Tom! I've got the 4-arm model with the yellow base, but the single arm style would also have some practicality! Especially if it were a longer arm.

- mtaylor and Keith Black

-

2

2

-

On 1/6/2023 at 1:19 PM, VTHokiEE said:

I wanted to start a topic dedicated to a software tool that I wrote to automate the downloading of MSW threads into a merged PDF.

Just used this tool to download a couple LARGE (40+/- internet pages) MSW threads I was interested in saving. Worked great! Thank you, sir!

- Knocklouder, Ryland Craze, Nirvana and 1 other

-

4

4

-

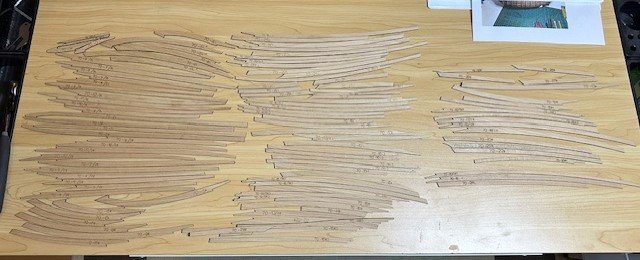

Began doing the stern and hull planking on this Santa Maria. I will remind viewers that this Pavel Nikitin Santa Maria kit comes with pre-shaped hull planks that are removed from the sheets provided. Here's what we begin with in order to plank the hull...

I am beginning with the port side and the instructions have us placing the double-planked wale strips just below the deck line (in what they call position #14) on first and moving down to plank #1 at the keel. After the first couple planks, I realized that we should probably first place the planks on the stern section, as the hull planks will need to fit against the cedar stern planks. The stern planking went fairly smoothly until I discovered a problem with the diagonal planking that others working on this Pavel Nikitin kit and documenting on YouTube were having... all of the pre-cut diagonal planks on the transom were not long enough. To cure this, I added 3/32" square wood strips both vertically and horizontally to fill the gaps. There were still some of the planks that were still too short and those spaces will need to be filled with some wood filler during the sanding phase.

The port side hull planking went fairly well. I did have to hold many of the planks under a stream of hot water to make the wood pliable enough to shape perfectly against the bulkheads. But the process worked quite well. There were a couple of the planks (#3 & #4 close to the keel) that were not quite long enough to meet the transom planking, but that will also be dealt with using some wood filler when we get to the sanding phase. Otherwise, edges of the planking at the stern will be sanded even with the transom.

So, the port side lower planking is complete. I'll work on the lower starboard side next, then will work on the upper planking (Planks #15 and higher) on both sides. I will then sand and fill everything where needed.

I haven't honestly become a big fan of this Pavel Nikitin kit. Definitely different with all of the pre-fabricated CNC pieces than what I have worked on previously and what I'll be doing in the future. But... I keep looking at what the finished product has a chance of looking like and continue moving forward. So, moving forward is what we shall do...

Appreciate, as always, the follows, reads, likes, comments and criticisms.

- Vivian Galad, JpR62, mtbediz and 3 others

-

6

6

-

On 11/11/2024 at 5:14 PM, popeye2sea said:

There were, more than likely, belaying pins or a fife rail for all of those lines. Those bitts are primarily for the anchor cable. There may have been belaying pins set in between the uprights of the bitts.

Regards,

Henry

I like the idea of some hooks or belaying pins on the bitts. Would be interesting if we could find some pictures showing how the rope is hung or set. Great question, Tom!

-

1 hour ago, Der Alte Rentner said:

I feel even better now, after 2 hours of tweaking those moldings.

48 minutes ago, JSGerson said:Well worth the effort!

Looks really nice, Peter! Definitely worthy of the time. 👍🏆

USS Constitution by JSGerson - Model Shipways Kit No. MS2040

in - Kit build logs for subjects built from 1751 - 1800

Posted

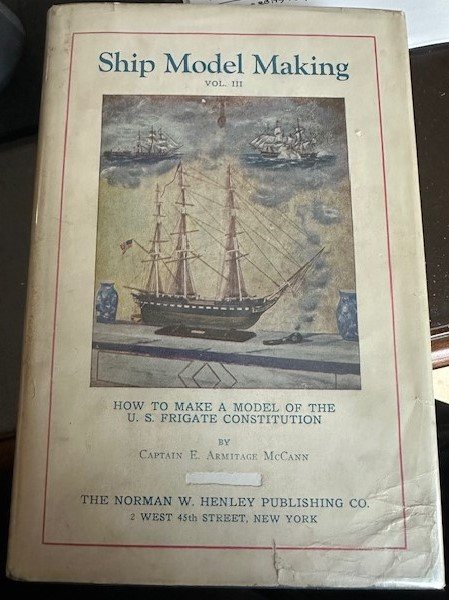

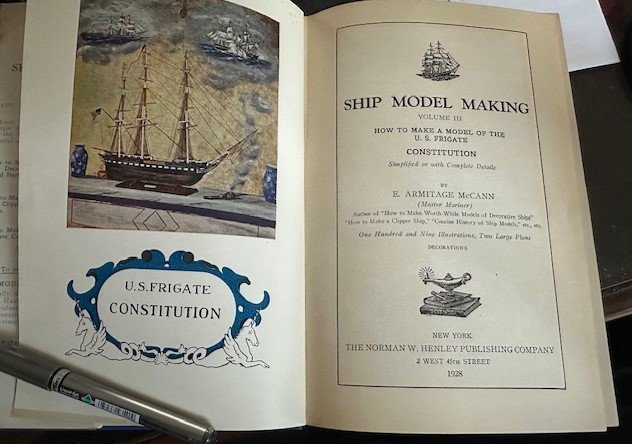

Hi Jon, hope you have had an enjoyable extended Thanksgiving weekend. To save you some time looking on your library shelf, I did see in re-reading your build log in more detail that, in your discussion regarding rudder iron chains, you reference Captain E. Armitage McCann's book, so... not surprisingly... you have the book! I'm looking forward to using it as one of many references!