-

Posts

1,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DocBlake

-

Beautiful job, Tony. Really inspiring!

- 132 replies

-

- triton cross-section

- cross-section

-

(and 1 more)

Tagged with:

-

Thanks, Pete! The frames are rough, glued up after the parts were cut on the scroll saw. No sanding yet! I need to make a building jig next. As I mentioned earlier, the top timbers do not form a rectangle in plan view but rather taper on slightly both for and aft. Any tricks as to how to lay that out? Second question: Should the futtocks be fastened with treenails or historically more accurate simulated bolts?

-

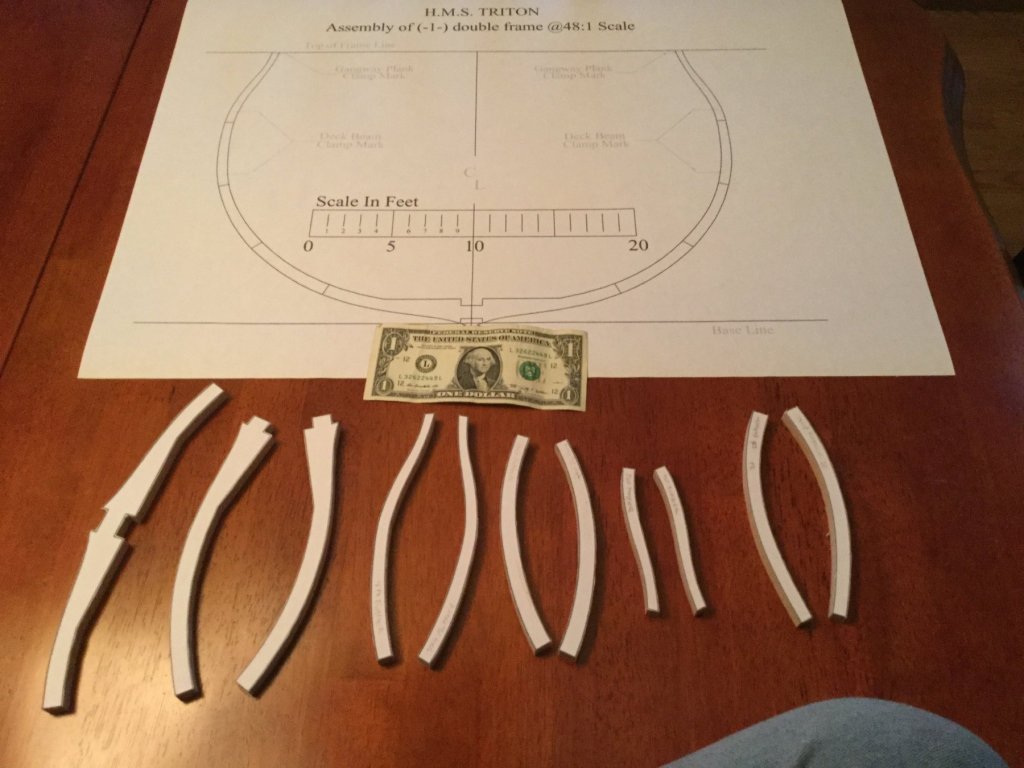

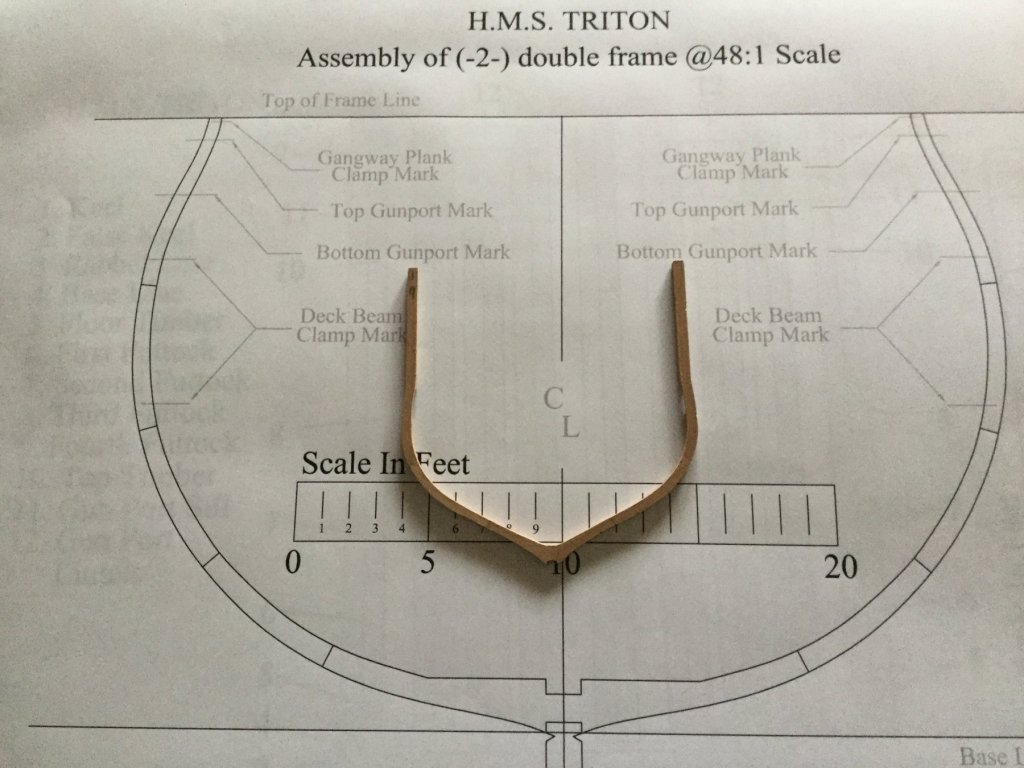

I finished gluing up the last of the 9 frames. I used Weldbond so I'll give the most recently completed frames a couple of days to dry before rough handling. The frames will require minimal trimming and shimming in a few spots to conform to the plans. Once that's done, I'll rough sand the frames to match the plans and start to glue and dowel then to the keel. It took one week to enlarge the plans, glue up the individual futtock on to the billets, cut them out and glue them together. I used double sided tape to hold the appropriate futtocks to the plans and glued the second layer to the first. taped down layer. I put a piece of plywood weighted with big food cans to weight down the plywood until they dried. The beer is to celebrate! It's a Hofbrau Maibock.

-

I've glued up 5 of the 9 frames and I'm noticing some "tolerance creep". When I enlarge the frame parts to 200%, the lines outlining the parts get some real thickness to them: 1/32" - 3/64"). This is especially a problem where the frames butt each other. They need to be accurate or the frame doesn't match the plans, and things like gun port lintels and sills are thrown off. I've already noticed some slight inconsistencies as I glue up the frames. They are not matching 100% and on both sides of the frame. The errors are small...in the range of 1/32", but they are there. Hopefully I can figure out a fix when the time comes. Very thin shims will likely be the answer for any frame component too short at the top timbers, with trimming if they are slightly long. This problem is a function of the large scale of the model (1/24). Has anyone else encountered this problem?

-

Great tutorial, Don! And continuing great work on the model. BTW: Before the switch in software, MSW "content I follow" always listed the latest comment on a topic first, with the other comments on other topics chronologically in order. You were always able to keep up with the latest developments. With the current setup, that's not the case. Despite the post above mine (Mike's) posted 14 hours ago, this build log and it's latest post remain on page 5 of my "content I follow" menu. Can that be fixed? Anyone know?

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Tony, I think the Triton area has been re-opened to new builders once again. Access to the build files is available after producing a keel, false keel and keelsonas it had been..

- 132 replies

-

- triton cross-section

- cross-section

-

(and 1 more)

Tagged with:

-

I love the companion way (well, everything really!). The model's stand is also outstanding. Great work, Don.

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

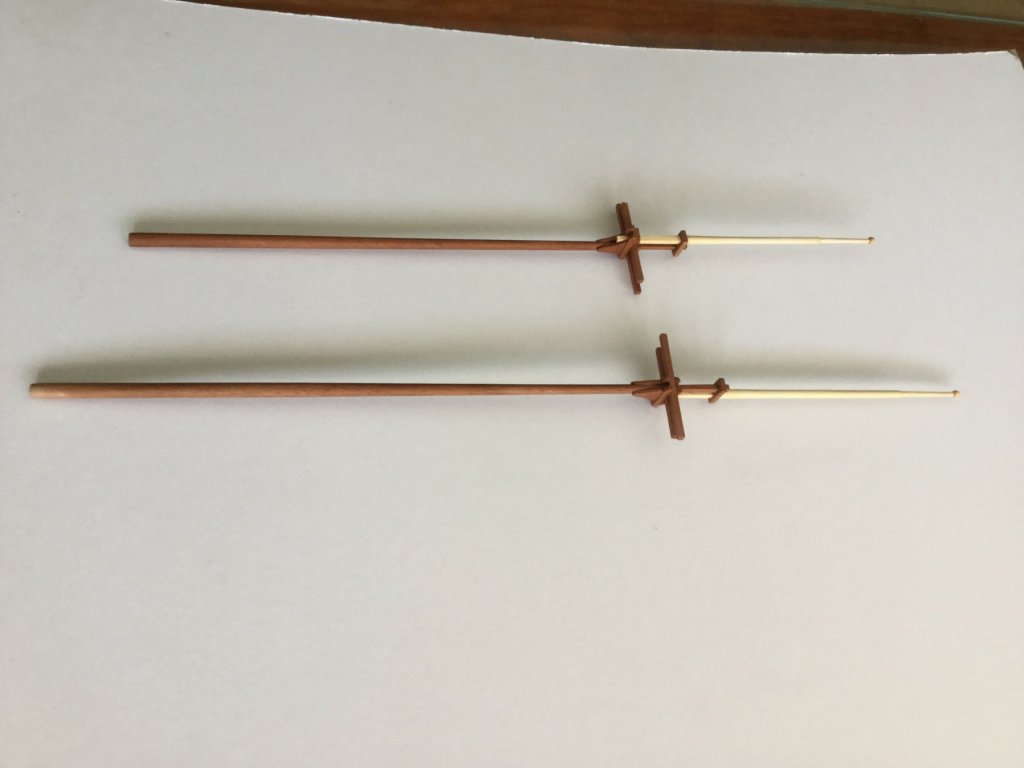

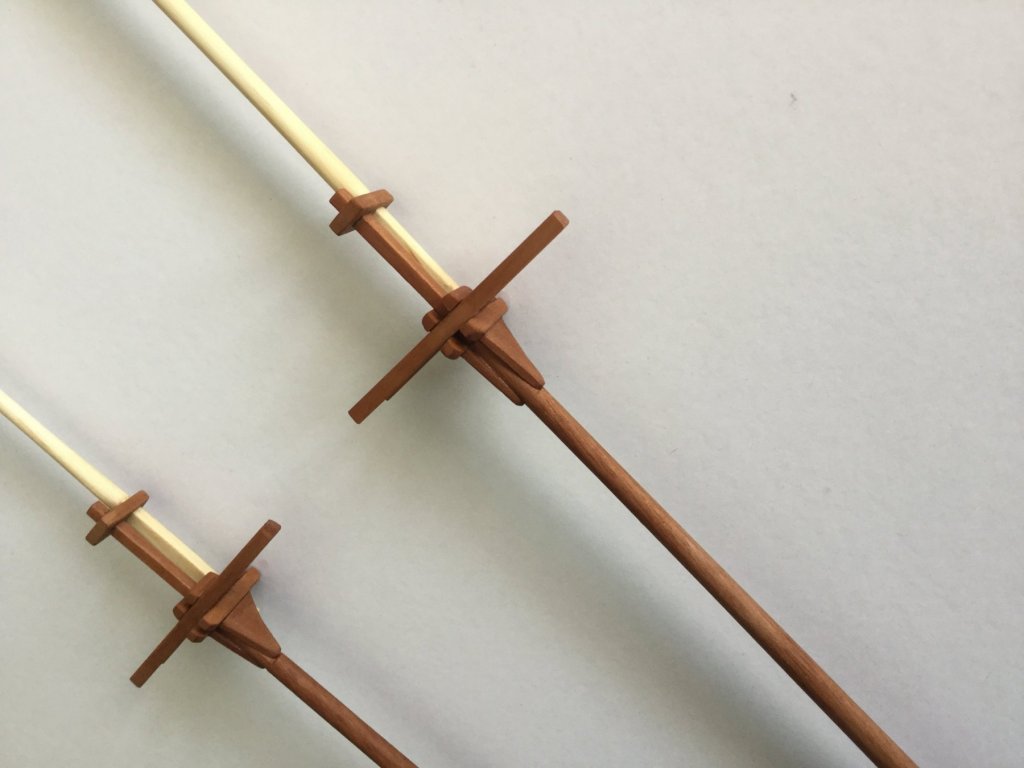

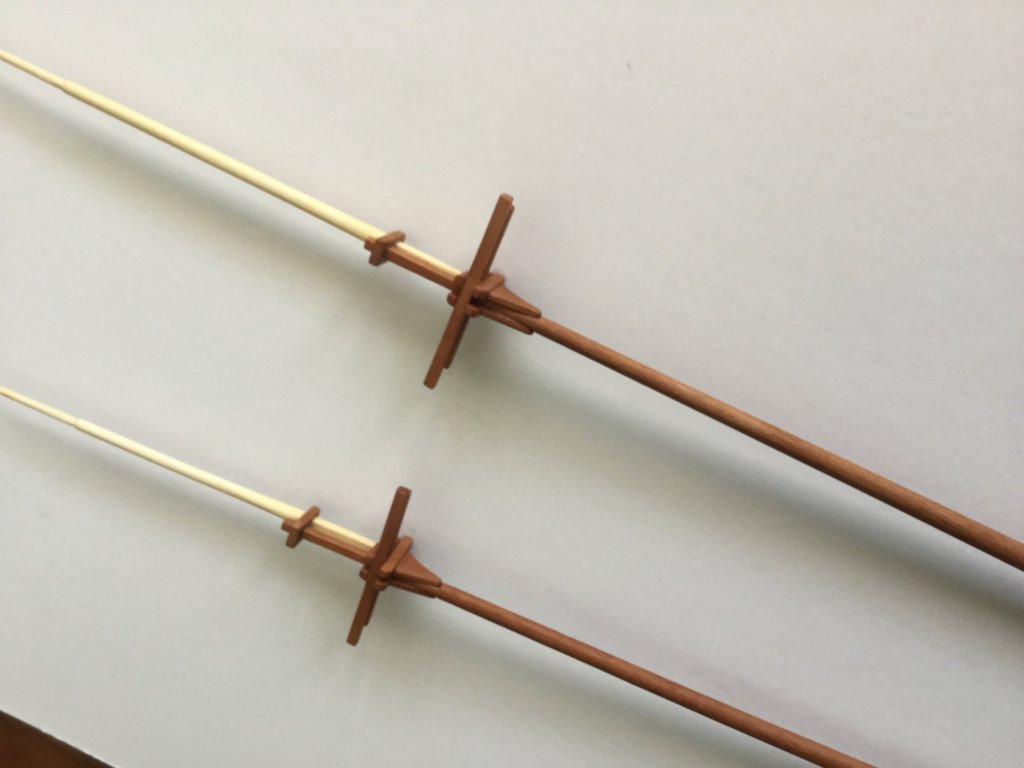

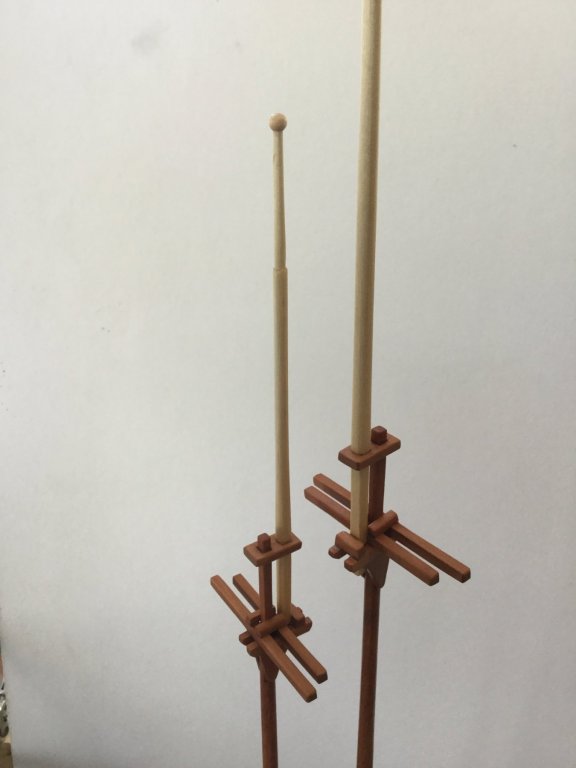

I'm finishing up the masts. The plans call for boom rests on both the main mast as well as the fore mast. This is similar to what was found on "Hannah", "Chaleur" and "Gaspee". "Sultana" and "Halifax" had boom rests on the main mast only, the sails on the fore masts being loose-footed. As you can see from the pictures, Chaluer's fore mast boom rest was quite a way up the mast compared to Independence. The rest is only 3' 8" above the deck on Independence, while the main is 6' above the deck. By contrast, Hannah's fore mast boom rest is 5'6" above deck , according to Hahn's plan. So while it would be okay to have booms on both the main and the fore masts, the boom rest on the fore mast should be raised significantly higher. I'm leaning toward no boom rest on the foremast, with a loose-footed fore sail. What do you all think? Chaleur Hannah

-

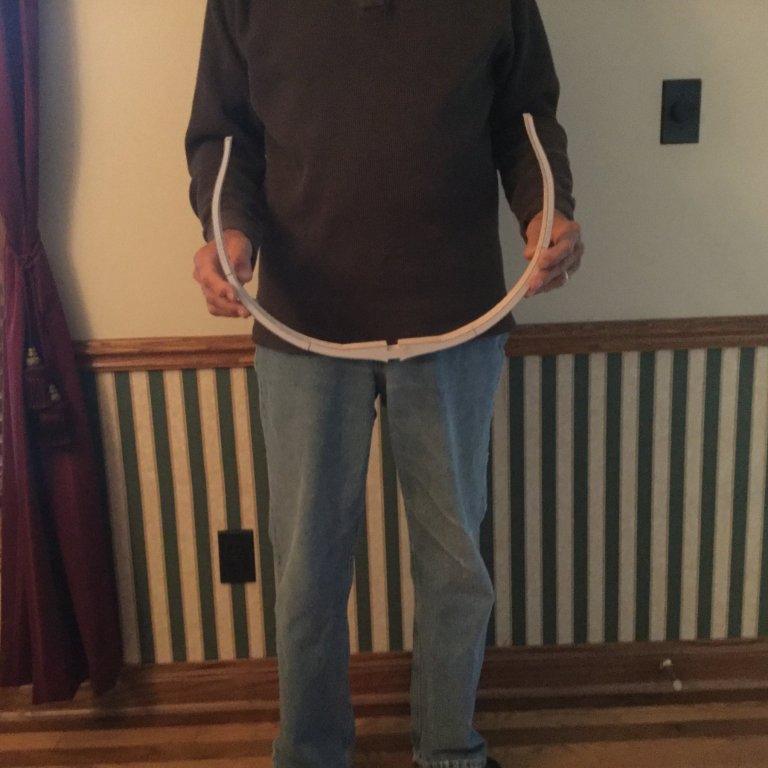

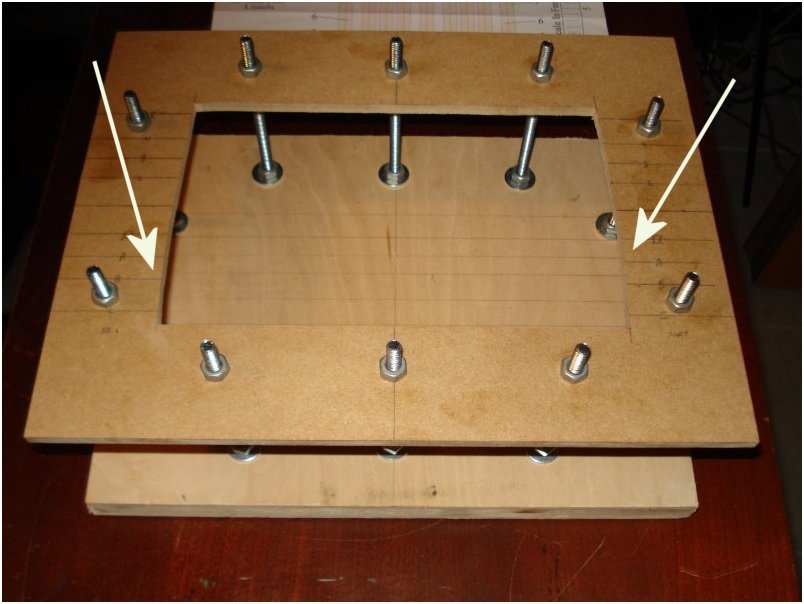

I'm restarting this build. Mike Shanks and I have been planning on doing a joint projet: POF "Hannah" in 1/24 scale...the whole ship. Not sure about rigging yet. I think the Triton cross section will be good practice for that build. I cut out and surfaced the blanks of hard maple I'll use for the frames. The maple is 3/8" thick, giving a final double frame thickness of 3/4". The footprint of the cross section at this scale is huge: 9-7/8" X 14-1/2"! The photo shows the plans for frame 2 compared to a midship's frame of "Fair American" at 1/48 scale. I'm also planning a building jig. The jig in the photo is one of the popular "2 level" jigs used for the cross section, but it takes into account that the plan view profile of the model is not a rectangle. The bulwarks curve slightly. The profile of the sides of the jig (marked by the arrows are clearly curved. Does anyone have a good way to lay out this curve accurately? There is no plan view of the framing in the plans.

-

Started back on this project. I'm currently sanding the inboard surfaces of the frames before gluing them to the keel. There isn't much room to sand inside the model once the frames are glued in place. I own a oscillating spindle sander, but I found the revolving speed was sanding too aggressively. I have a rheostat, but it didn't work on the spindle sander. Fortunately, my full size drill press has an induction motor which allowed the rheostat to control the speed of the revolution. I slowed it down and got a speed where I could control how much stock I was removing more easily. No pictures here...kind of boring work.

-

Beautiful job, Ken! That is a great looking model.

- 481 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

I tend to agree, Don. The ship is "stylized" anyway. Bulwarks are redheart, not vivid red pain, and the planking below the wales is all holly, and it doesn't follow the waterline. The detail at the doublings is some of the most interesting on the ship and I think it tends to get lost with the black dye.

-

Thanks, guys! Ken: The sailor is 44mm tall, which is 5'6" in scale height...typical height for a man in the mid to late 18th century. Clare hess chose to stain his masts black between the doublings. I think it looks good and I've added a photo of the result. But I also like the look of pear and maple, without any black stain, as my masts appear now. I've not yet cut the topmasts to length nor made the fids. what do you all think? Black stain or natural wood?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.