-

Posts

1,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DocBlake

-

Hi Tony!

As you may know, I'm starting the Triton cross section in 1/24 scale: a scale that introduces a lot of problems in terms of scaling. For example, the layout lines for the parts and the profile views etc. are about 1/32" thick, leading to a lot of potential error especially in terms of room and space layout of the frames on the keel. What I'm hoping for is that you can help me out with some pointers in building the jig to construct the model. How do I size the upper portion, with the cutouts for the frames, given that the frames are curved? How do I account for the slight curvature of the frames moving aft in the plan view? How do I keep consistent space bewtween fromes, given the thickness of the layout lines?

I'm almost thinking of not using the 2 tiered jig you and others have employed. Instead I'd set the first frame on the keel, use a standard precut spacer for the space between it and the second frame, then set the second frame. Using the standard spacer again, I'd set the third frame and so on. I would need to make a right angle jig to keep the frames square to the keel and their tops level, but I could avoid the upper tier of the jig. What do you think? Any advice or tips? Thanks so much for any help you can lend!

PS: Thanks for your superb build log and model. I really enjoyed it.

-

I don't know why you can't access me through PM, unless the box is full or something. I'll have to figure it out.

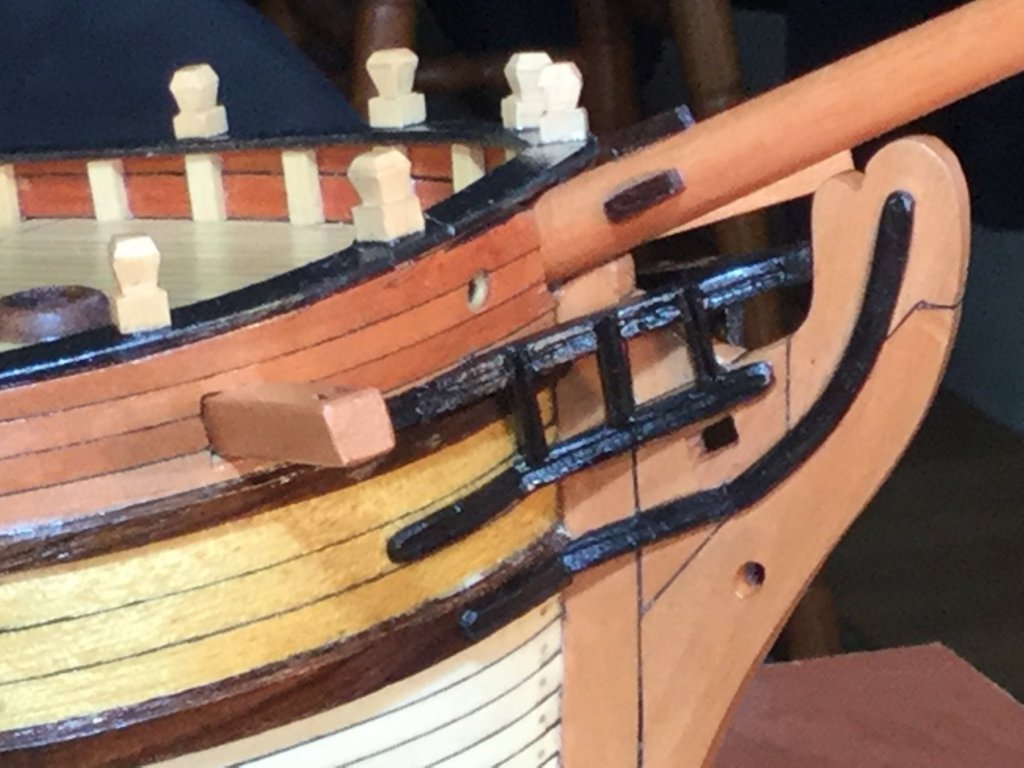

Building the jig was easy, I just set the height for the widest part of the cross-section -- i.e. the widest frame at it's widest height. I then measured the widths of all the frames at that height and printed the plan with all the frame markings. I put this on a sheet of plywood and cut out the part that would hold the frame. I then aligned that very carefully with the frame layout on the base, as you should see from my log, and drilled holes for the bolts through both pieces whilst still aligned. I then set the height for the cutout by placing the holding nuts at the right height.

For consistent spacing, as you might seen from my log, my cutout was such that it had indents for each frame, so the indents acted as spacers. In terms of measurement, it's a question of consistency as to where you take the measurements from. In general I think the safest is to use the outside of the line, but that varies with the situation. Sometimes I use the middle -- e.g. between planks.

The other method you propose of having a movable jig with set squares is possibly the more common method, and is one that is also used when making longer models of the full ship. It looks good to me, but for my particular purpose with the cross-section, I thought the jig method would be simplest.

I'm always happy to help, so don't worry about pestering me!

Tony -

-

-