-

Posts

1,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DocBlake

-

Great job on the planking, Don! It looks like you're using Weldbond and CA to glue the planks. I use the same technique and it works well.

- 653 replies

-

- trabakul

- marisstella

-

(and 1 more)

Tagged with:

-

Hi, Dave! Thanks for your kind comments out my AVS. Very much appreciated. The answer to your question is yes, the plans for the Patrick Henry can be used for a scratchbuild. If you check my log you'll see that I rebuilt many parts for technical reasons as well as personal preference using the plans. Everything is pretty well designed and turned out well. Realize, however, that not including any of the strip wood used for planking, etc. that there are over 700 parts to the kit!. Not easy, but doable. Bob Hunt is a bit of a fanatic (rightly so) regarding copyright issues, so I wouldn't sell you my copy of the plans. I am sure Bob will provide them to you, and probably at nominal cost. You'll likely have to enlarge them to full size at FedEx or some such. The cost would be around $40. Hope this helps!

- 306 replies

-

- armed virginia sloop

- Patrick Henry

-

(and 2 more)

Tagged with:

-

Hi Elijah! Great progress. I've also got the gunboat Philadelphia in my queue.

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

I'm not sure how I missed this log, but I just pulled up a chair, Charlie. Most interesting. I may have to learn CAD to run with the crowd you've recently joined!

- 362 replies

-

- active

- revenue cutter

-

(and 1 more)

Tagged with:

-

Yep, Don! The difference is that with the Hahn jig, the hull is constructed upside down, and the long extensions of the tops of the frames are cut to free the hull from the jig after fairing. With the Patrick henry, the hull is constructed right side up (as a real ship would be) and there is no cutting to free the hull. Each frames is held in place by a tight stretched rubber band. Both jigs get pitched after one use.

-

Thanks for looking in, Don! The frames are glued to the jig as well as the keel. The practicum suggests 5 minute epoxy as the glue of choice. The reason is to give the hull a rock-hard solidness it needs to survive the sanding when fairing the outside. The inside will be partially smoothed before glue up so there will be less stress in sanding once the model is freed from the jig and inboard fairing begins.

-

Lots going on in our life, so slow progress on my projects. I'm just finishing the last of the frames, and completed the Hahn-style jig last night. The frames have not been faired or sanded in any way. Just to test the fit, I set the whole frames in the jig. i was surprised that the tops of the frames fit snugly and accurately into the notches on the jig with no trimming or adjusting! Very well designed. Once I finish the last frames I'll need to check them against the plans and trim/shim so they match exactly. If that part isn't done right, fitting the keel on the frames will be impossible.

-

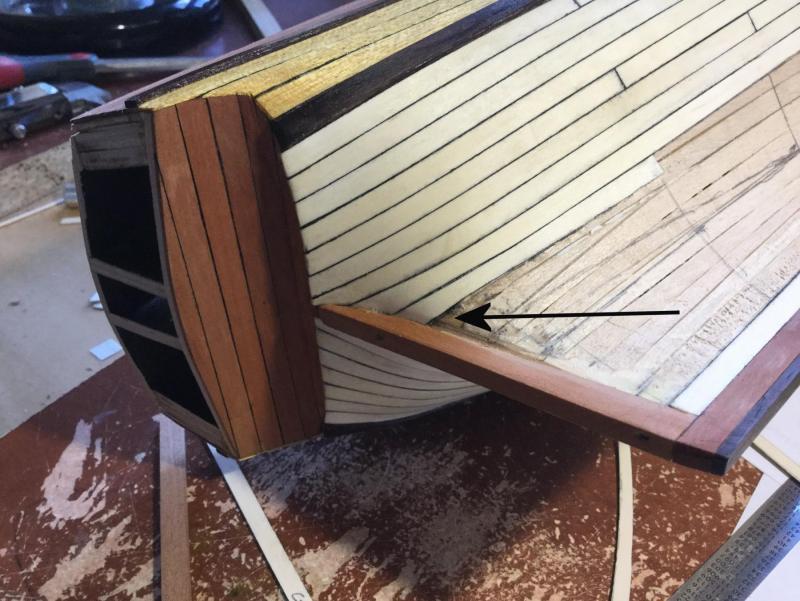

You're making great progress, Joe. It doesn't matter too much whether you cover the side planking with the transom planking or butt up against them. The final planking and placement of the fashion piece will sort that all out! It's easiest to plank over the ends of the side planking...that's why I did it that way!

-

Slow going on the planking. The hull dimensions are weird. Rather than be significantly wider at he stern, I'll actually have to taper some planks after adding a stealer to start an upward run of the planks. There is also a little "tail" that points upward at the sternpost. I custom cut some planks to eliminate it. So at the stern I have to add a stealer, and then taper planks to make up for it so the planking matches the sheer of the wales. UGH! Not my favorite part.

-

I agree with Brian. For the sprit hole I started with a very undersized drill bit and "worked my way up" to near final size, using a series of progressively larger bits. This limits tear out around the hole. Leave the hole smaller than needed and adjust the final fit with a rat tail file.

- 194 replies

-

- armed virginia sloop

- model shipways

-

(and 1 more)

Tagged with:

-

Outstanding work, Jonathan! Great job on the netting. When I built my battle station I couldn't find tulle in the right scale for the hammock netting, so I made my own! My log shows the process.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Looking great, Elijah! Like David I'm interested in you you next build. Any thoughts?

- 701 replies

-

- phantom

- model shipways

-

(and 1 more)

Tagged with:

-

You'll be surprised! The plank will hold it's shape nicely tomorrow after it's dried. There is really no reason you can't soak all the planking to coax it into place. People will say that it will shrink and small gaps will appear between the strakes...and they might, But so what? This is the first layer of planking, and gaps at the seams can be filled with wood filler. the only purpose of the first layer of planking is to provide a smooth, stable base for the second layer. It is good practice, though!

-

Joe: That plank is the most important plank in the entire process. You have to get it right, because it defines the sheer profile of the wales (and the subsequent planking). With your remarking it looks like you nailed it. Great job! If you want to see how this plank can be installed incorrectly, read my log over at the Lauck Street forum and see how I screwed it up!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.