-

Posts

1,954 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glen McGuire

-

Nice recovery, Roel. You had me really worried as I was reading thru your post. Those self-inflicted wounds are the worst (spoken from experience and many scars).

- 70 replies

-

- Scheldt River

- Dredger

-

(and 2 more)

Tagged with:

-

I feel like caveman with stone knives and bearskin tools when I seen you doing stuff like this! Very cool!

- 235 replies

-

Fabulous work, Bob! She is a beauty and a fine addition to your growing fleet. Tell Goober sorry, but he's a little late. I had a job opening for a ratline expert but don't need one anymore. I guess he will have to settle for a title!

- 207 replies

-

- vanguard models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

Sorry to hear about the arm, Keith. I figure broken arms are similar to broken bowsprits, so with all of @Knocklouder's recent experience, he could probably help fix your arm if needed!

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Nice test run. Fingers crossed for the real thing.

- 70 replies

-

- Scheldt River

- Dredger

-

(and 2 more)

Tagged with:

-

I'm with you, Bryan! You would not believe how much time I spend trying to figure out what the instructions are telling me to do!

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

The crow's feet look great! Well done, Bob.

- 207 replies

-

- vanguard models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

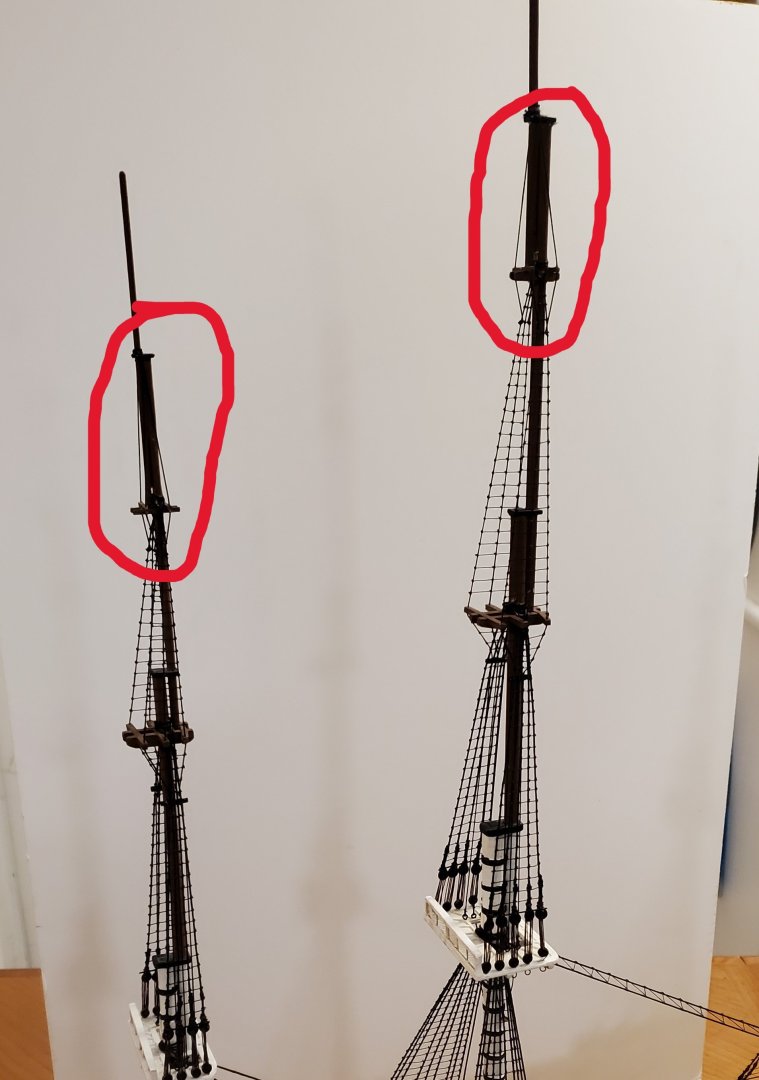

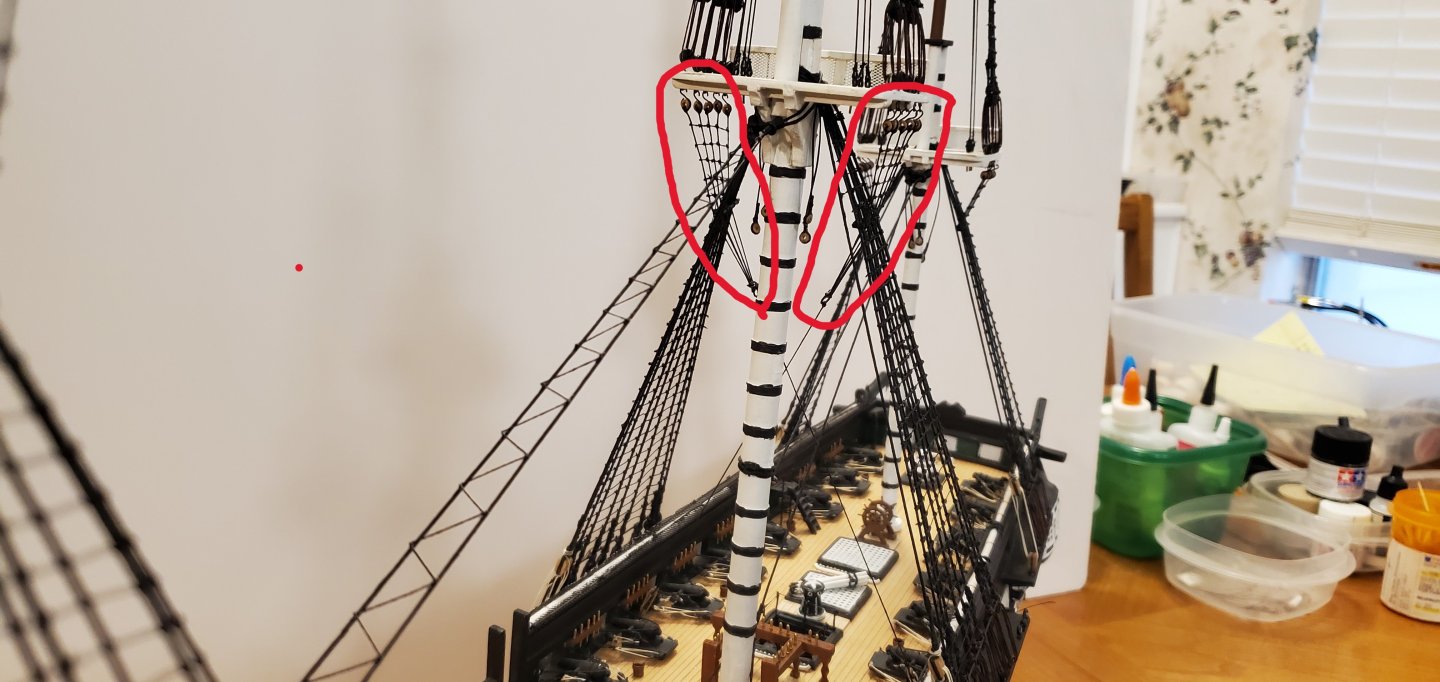

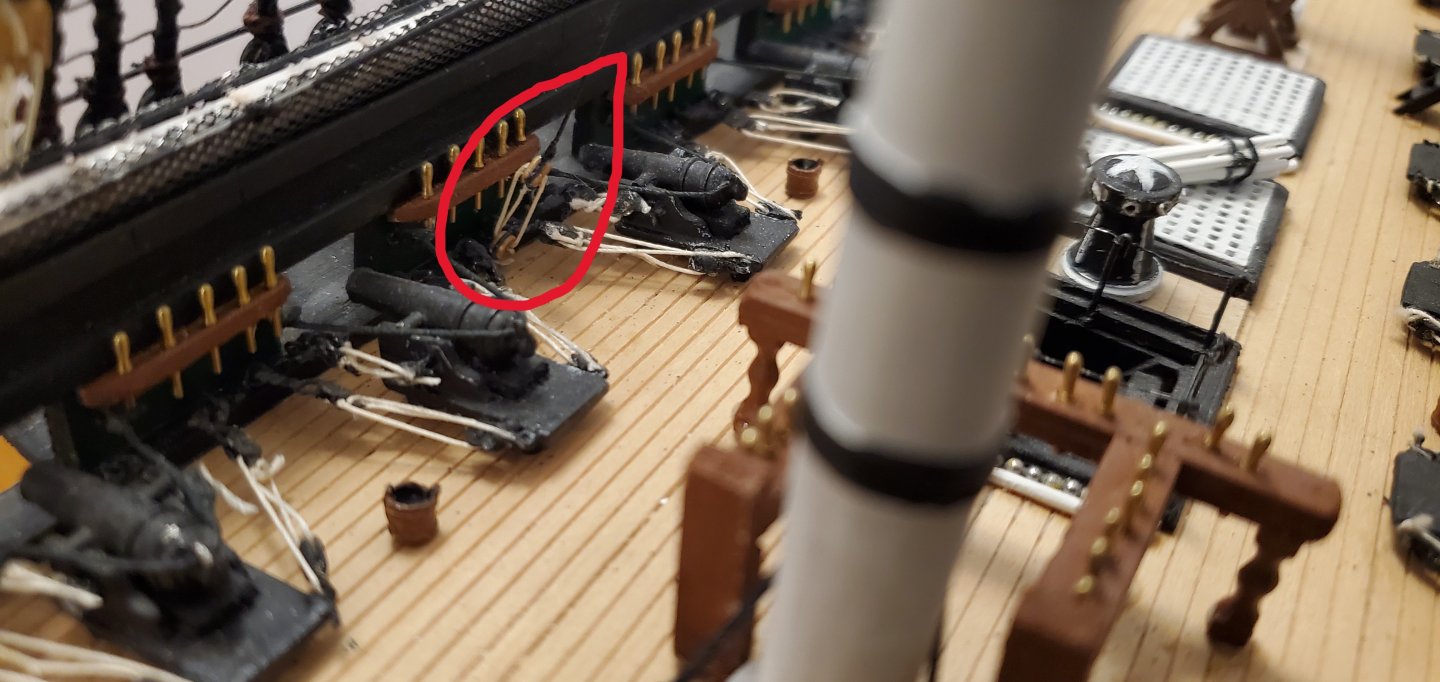

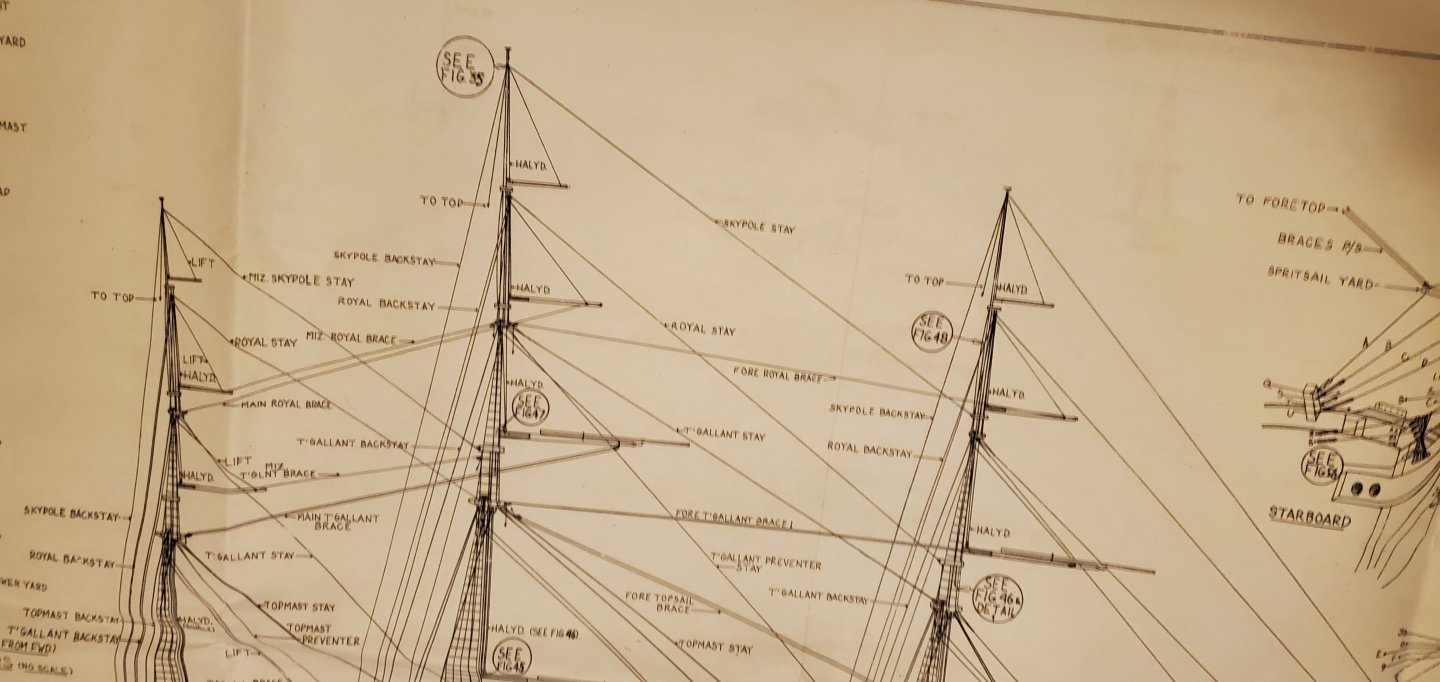

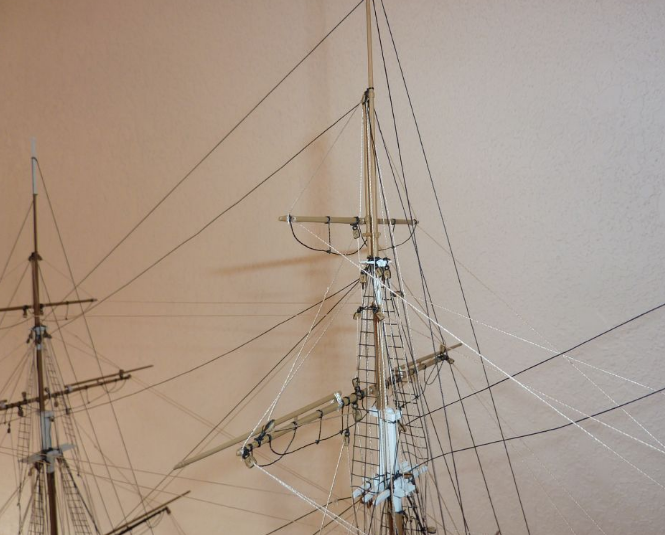

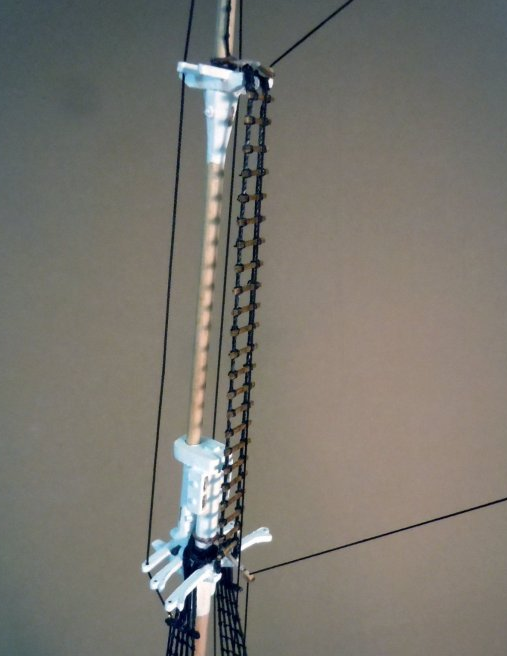

Thank you @Robert in Austin and @Ian_Grant for the comments! I have finally completed what I consider a major milestone on this project - all shrouds and ratlines are finished! That's roughly 3000 knots behind me. WOOHOO!!! For the top gallant shrouds, the ends run through holes in the crosstrees. For tying them off, the instructions gave an option of lashing them to futtock staves in the topmast shrouds or running them down and tying off to eyebolts inside the lower topmast deadeyes. I chose the latter, which I've seen in several build logs and liked how it looked. So the first step was to make futtock staves with eyelets for the ends of the shrouds to run through on their to the mast top. Here's the main top gallant shrouds running through the crosstrees, tied off to the mast top. Next, I added the royal shrouds. To my great relief, they did not require ratlines! With the upper stuff out of the way, it was time to circle back to the futtock and bentinck shrouds. The futtock shrouds have hooks on the ends that hang from the eyebolts underneath the mast tops (mast top eyebolts are visible in the pic above). The hooks are stropped to bullseyes. The futtock shroud is tied to the bullseye, lashed to the futtock stave and tied off to the Bentinck shroud ring. Here's the hook/bullseye assembly along with the Bentinck shroud rings. Here's the futtock shrouds highlighted in the first pic below. The Bentinck shrouds run from the ring at the end of the futtock shrouds, cross each other to opposite sides of the ship, and tie off with lanyards to eyebolts on the deck as shown in the second pic. And here she is with her full complement of shrouds. Although I do need to get a larger piece of poster board as a backdrop. That one works fine for my SIBs but is way too small for the Constitution! I seem to recall an old honky tonk song by Mac Davis called, "I Thought Happiness was Ratlines in my Rearview Mirror." I'll be humming that tune for a while. Next up is the 30 or so stays, plus those little ladders mentioned in an earlier post. But first, I'll be off for a couple of weeks to take several of my SIBs up to the USS Constitution Museum in Boston for their annual ship model show. Inside the museum, there's a LARGE model of the Constitution that's gotta be 5 or 6 feet tall. I'll be taking a ton of pictures of it to help me get through the rest of this Constitution project.

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

OK, now I get it. I like the look of the sand base even better. Ties in well with the theme of the project.

- 70 replies

-

- Scheldt River

- Dredger

-

(and 2 more)

Tagged with:

-

I wholeheartedly agree with what everyone said above. Exceptional craftsmanship in every detail. So well done. Congratulations on a fine build!

- 201 replies

-

- Oyster Sharpie

- first scratch build

-

(and 1 more)

Tagged with:

-

I like the curves and the stairstep on the base. Very elegant.

- 70 replies

-

- Scheldt River

- Dredger

-

(and 2 more)

Tagged with:

-

Thank you to everyone for the kinds words and likes and everything else. As I've said before, I consider these projects a team effort and y'all are the best team anyone could ever imagine.

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

I was fumbling around for a couple of days trying to figure out how to finish this thing up. I liked the weathered deck planks, but I wanted more than just the bottle sitting on a cradle on top of the planks. The Final Jeopardy music kept playing and nothing was coming to mind. The next day, I was walking through an old shed out at my ranch and noticed a discarded, rusty chain and some scraps of a rusted gutter lying in the corner. Hmmmmm. I wasn't exactly sure what I could do with them, if anything, but they were interesting enough to take home and ponder further. I got them home, started playing around, and finally stumbled upon a way to use them to enhance the presentation. After sealing the chain with spray poly, I coiled it around the bottle's cradles to where it hid the cradles and made it look like the bottle was resting on the chain. OK. I liked that. Now, the only thing left was the nameplate. I was sizing up various small pieces of wood to glue a nameplate to when another light bulb went off. Why not use a piece of the thin, rusted gutter to glue the nameplate to? So I found a piece that had rough edges and was about the size I needed. I bent the bottom edge of it backwards so it could act as a base. Then I printed out my paper nameplate and Mod Podged it to the rusty piece of gutter. Before I post the final pictures, I want to extend a sincere THANK YOU to everyone that took part in this project. I would have never made it to the finish line without your comments, critiques, suggestions, encouragement, and humor. What an amazing group of people we have here at MSW and I’m fortunate to be a part of the community. Whether you popped in and out or suffered through every post of this build log, I owe you a debt of gratitude: @BANYAN, @Keith Black, @Knocklouder, @Ian_Grant, @Javelin, @Canute, @GrandpaPhil, @FriedClams, @gjdale, @Paul Le Wol,@mtaylor, @Bryan Woods, @tmj, @Landlubber Mike, @BLACK VIKING, @JacquesCousteau, @Old Collingwood, @Dan Poirier, @Kauz, @CiscoH, @herask, @ccoyle, @John Fox III, @Baker, @Snug Harbor Johnny, @PvG Aussie, @Desertanimal, @Thukydides, @gsdpic, @firdajan, @vossiewulf, @DanielD, @Pfälzer, @Ainars. Oh, and special thanks to Plumber Paul, PFC Gnomer Pile, and Goober for their support (even though Mr. Goob had his doubts about me). One more. Extra special thanks to my friend Eric. He is an extraordinary artist/carver/creative genius, etc and is the one that came up with the idea of building the whirlpool in layers outside the bottle and then inserting them piece by piece. That was the key to pulling this whole thing off. Here's how all that came out.

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

That dog house (and the pup) is awesome, Bryan!!

- 55 replies

-

- Le Martegaou

- billing boats

-

(and 1 more)

Tagged with:

-

That little pump is soooo well done (as well as everything else)!!

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Agree, Keith. I still like that piece of wood so don't be surprised if it shows in some future project. We just never know what might come in handy, do we, Paul! Thanks, Grant. I learned from a pro!

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

I finally emerged from my ratline stupor on the Constitution and got to work on the base for this project. However, I decided to change directions on the base. Originally, I was going to set the bottle in the middle of that swirled piece of wood shown in an early post. But looking at it now, I think the piece of wood is too large. It swallows up the bottle and overwhelms the ships. So I decided on a base that’s smaller in stature and ties more directly to the pirate/ghost ship theme. So now the idea is to make a base that looks like a section of an old, weathered, pirate/ghost ship deck and have the bottle rest atop it. I started with finished oak strips that are ½” tall by 2” wide and 24” long. I only had 4 in hand that were long enough so I pieced 2 shorter ones together for the middle plank (the seam between the ends will be hidden under the bottle). Next, instead of clean ends on each plank, I decided to make rough, broken edges to add to the old, weathered look. Here, I found another use for my heavy pieces of railroad track. I used 2 pieces of track to securely hold the oak plank down on a cinder block. Then I took a hand sledge hammer and gave the extruding end a hard WHACK. It broke off pretty rough but I figured I could clean it up a bit and soften the sharp splinters. Here's all the planks whacked down to their proper length which is about 16”. Now for the ageing and weathering. I’ve learned 2 things about ageing and weathering wood. The first was from @gjdale and his Foss Landing diorama when he taught me that ageing and weathering is not just about the color, it’s also about the texture. To give my planks the proper texture, I used an angle grinder with a stiff-wire scraping attachment and cut deep, random grooves into the surface. I also used it on the splintered board ends to soften them. Here’s all the raw planks after the angle grinder treatment. The second thing I’ve learned about ageing/weathering wood has to do with the color. There’s a lot of old barn wood at my ranch that’s been out in the elements for decades. Studying the old barn wood, there are layers of colors that provide its aged look. So that’s what I tried to do with these planks. I had it in my mind that an old pirate/ghost would be on the dark side, with shades of brown, and gray showing through. So I started with a layer of English Chestnut stain. Then I hit the deeper grooves with a much darker Early American stain. When that base coloring dried, I made several mixes of Tamiyo white and Tamiyo gray and thinned each pool with a bunch of acrylic thinner to make several fairly transparent washes. Finally, I took a fan brush and very lightly applied the different washes across the surface of the planks. In the pic below, the first 2 planks have the wash applied and you can see how the wash really adds to the layering of colors compared to the planks above them. The last pic shows all the planks with stain and wash. The picture makes it look a little more shiny that it really looks with your eyeballs. Here's all the planks with the washes applied. The final task for the base was to add oakum between the planks. For oakum, I used strands of hemp which I colored black before pushing them into the grooves. And here's the completed base with cradles for the bottle added. Not quite home yet, but the finish line is right around the corner!

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Beautiful craftsmanship. Every line is so clean and tight. Well done, Paul.

- 201 replies

-

- Oyster Sharpie

- first scratch build

-

(and 1 more)

Tagged with:

-

Nice recovery. She looks great!! And I'm sure the first mate's laughter was the supportive and encouraging type of laughter!

- 207 replies

-

- vanguard models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

I find that interesting too, Ian. Some of the build logs I've been using for reference do not have ratlines on the topgallant shrouds. However, the BlueJacket rigging plan clearly shows ratlines on the topgallant shrouds. I've also gone thru a bunch of Constitution pics in the MSW Gallery and most of those also have the 3rd level of ratlines, like this one from @AndyMech. So as much as I'd like to have all the ratlines in my rear view mirror, I've still got a few to do. You make another interesting point about the topgallant shrouds being too narrow for use as a ladder. The plans also show a "Jacob's Ladder" that runs from the cross trees of the topmast to the cross trees of the topgallant mast and is perpendicular to the longitudinal line of the ship rather than parallel like the ratlines. So not only do I get to do more ratlines, I also get to build a few ladders!

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.