-

Posts

1,974 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Glen McGuire

-

Fabulous work, JC! She looks amazing. This was really a fun and interesting build to follow. It took a lot of creativity on your part to find the right materials and methods to complete such a unique model. Well done, sir!!!

- 286 replies

-

But now the ships. Yes, Roel, thank you for bringing me back to reality from my euphoric stupor! But now the ships...

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Now that is an idea!!! At least you didn't see a penguin in there! There's another whirlpool in a different room of the house I thought you were going to mention but glad you did not! 😃

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Thanks for adding that step of the building process. Fascinating work, Keith!

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

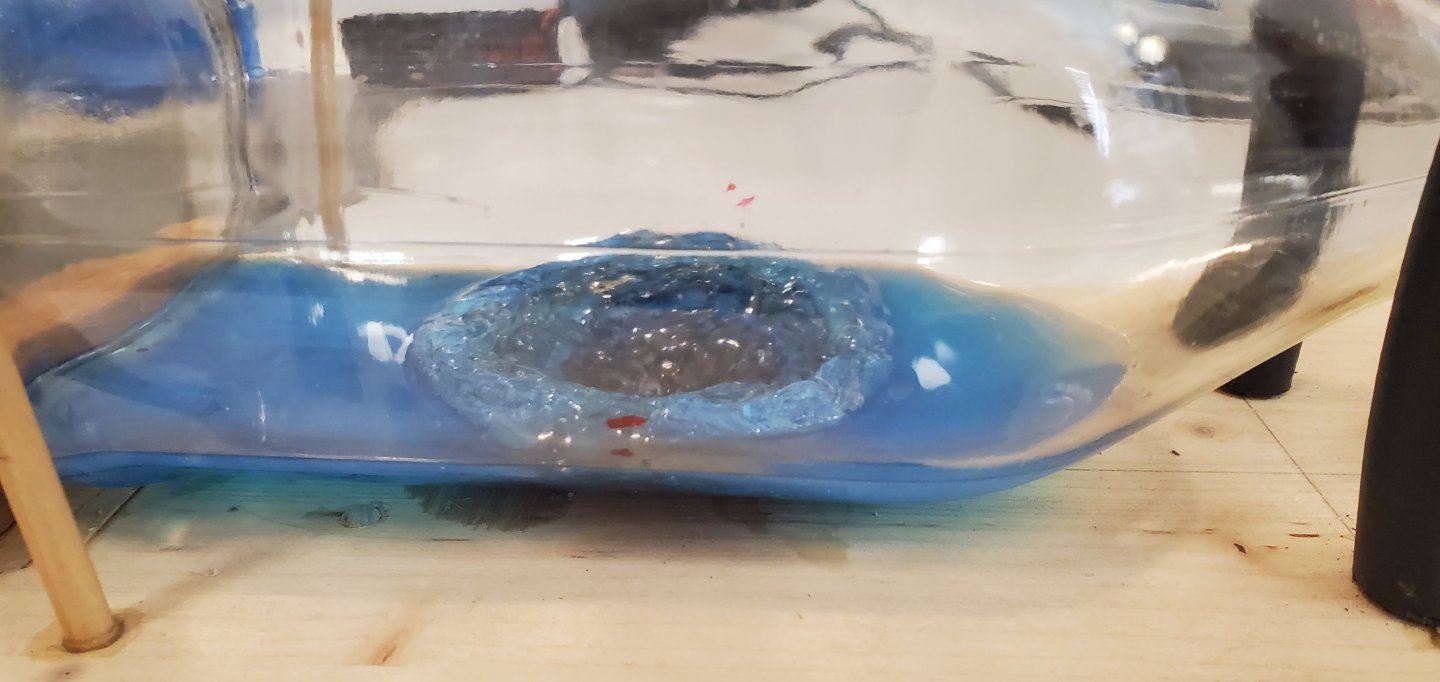

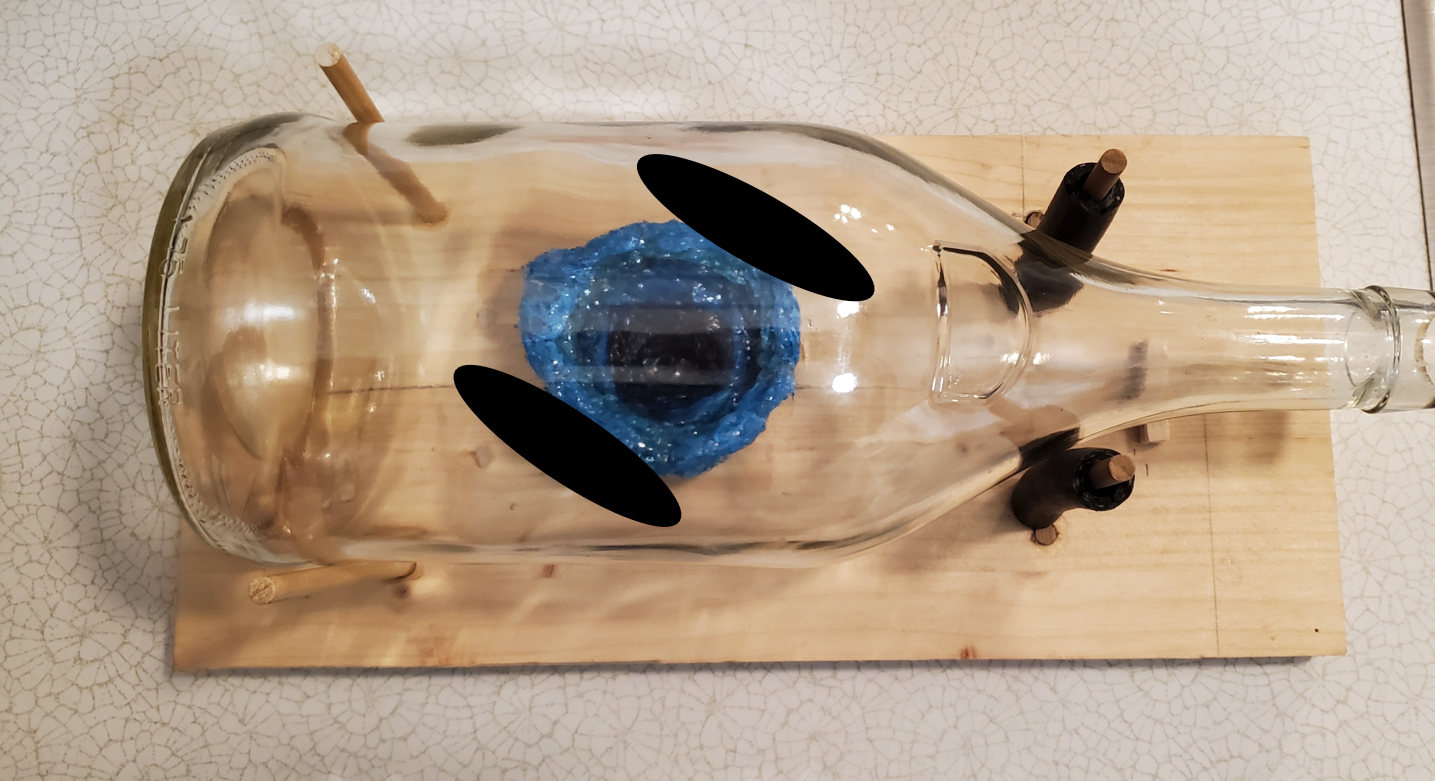

Seems like it doesn't it! I've got 850+ knots left on the lower ratlines of the Constitution waiting for me when I finish this thing here. And then the uppers after that! WOOHOO!!! Time to hit the bottle again and try to finish up the water effects. To build up the ocean water to the edge of the whirlpool in the front and back of the bottle, I needed to add about 1/8" - 3/16" of "water". That's a little too thick for acrylic gel medium (or at least the stuff I have) because it gets opaque if applied too thick. So I used Woodland Scenics Water Waves product. Getting the product in place inside the bottle was a tedious process and took several hours. I had to put it in one small dab at a time on the end of my long clothes hanger prong. You can see in the pic below that I swirled just a touch of matching blue color into the product. After I got the Woodland Scenics Water Waves into the bottle at the desired level, I used the tip of a small, hard brush to agitate the surface into ripples and waves. And here's where things got annoying. The water waves product is a thick gel that is supposed to hold its shape after you sculpt it (hence the name). However, When I checked on it an hour later, all my waves were gone. The product had self-settled into a nice smooth, glossy surface. That is NOT what it is supposed to do. So I recreated all my little waves and positioned a fan pointing into the bottle hoping to dry the product before it wilted again. An hour later, waves gone. GRRRRRRR. So I pretty much spent the entire day and evening recreating the waves every couple of hours until the product FINALLY stiffened enough to somewhat hold the wave shapes. I contacted Woodland Scenics and complained. They said I must have gotten a bad batch and are going to send me a new bottle to try. Too late for this project, but happy to try it again on the next one. I let it sit overnight to dry out completely, then added the white caps to bring the whirlpool and surrounding ocean to life. This was done with Tamiyo whit paint and a brush that has maybe 3 bristles left on it. Here's the completed whirlpool along with the picture I was attempting to recreate for comparison. I think I'm in shock. I keep looking at it in disbelief. It's not a perfect match to the picture, but I think I actually pulled it off and made a halfway decent looking whirlpool inside the bottle! I was not going to give up on it, but I have to be honest and admit that there were more than a few times over the past couple of weeks that I thought it was an effort in futility. That southern breeze you feel in Canada, @Knocklouder, is my huge sigh of relief!

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

No worries, Keith. I just enjoy seeing how the sausage is made, especially on something as unusual as your engine.

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

Great job on the engine, Keith! A very nice replica of the picture. What are all the individual parts made from?

- 732 replies

-

- Lula

- sternwheeler

-

(and 1 more)

Tagged with:

-

I actually like the look of your initial fold of the fore end. To me, it hangs in an unruly but natural way. But if you are trying for a look that is more tidy and ship-shape, then refolding is a good idea. Beauty is in the eye of the modeler!

- 286 replies

-

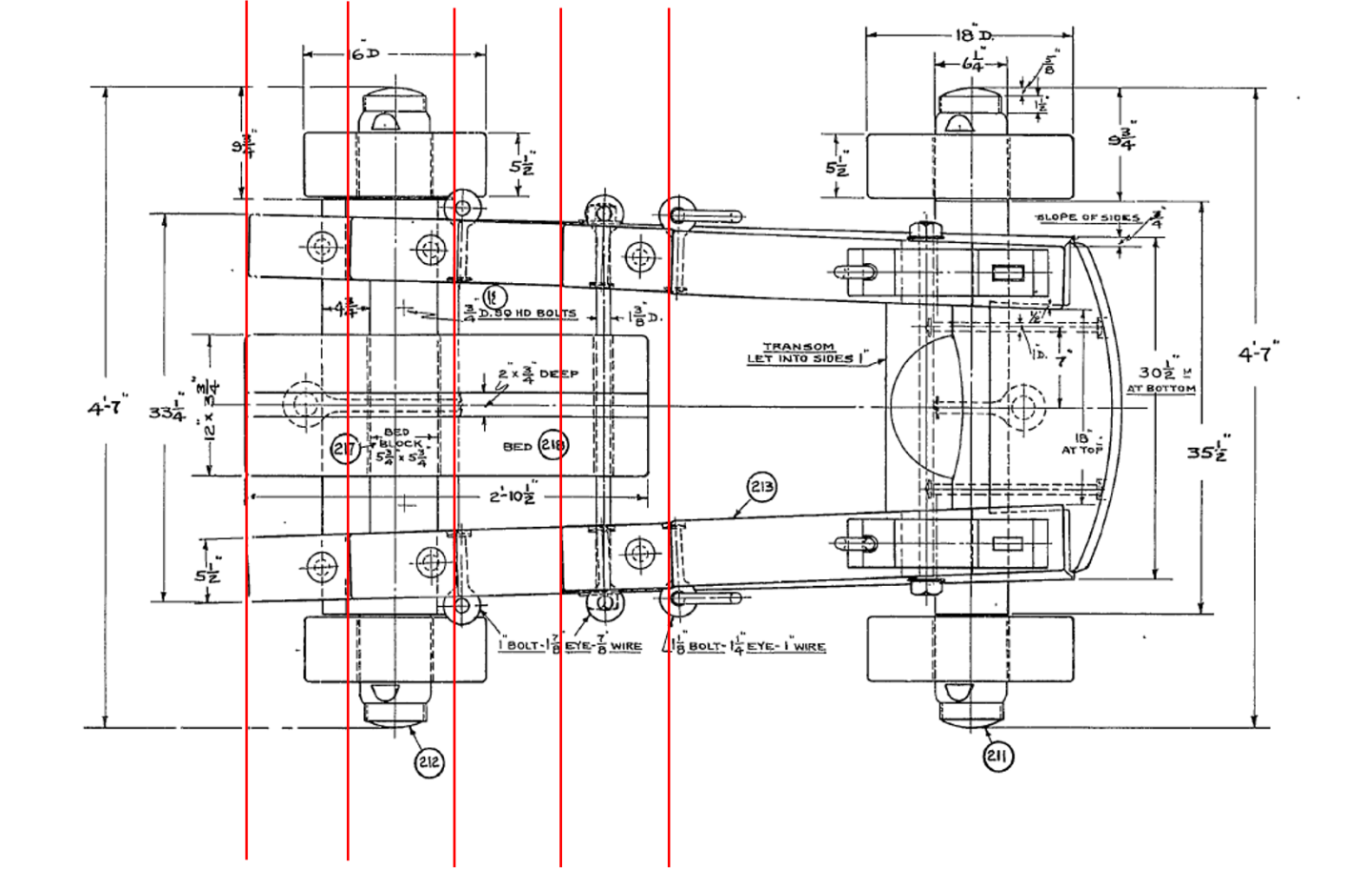

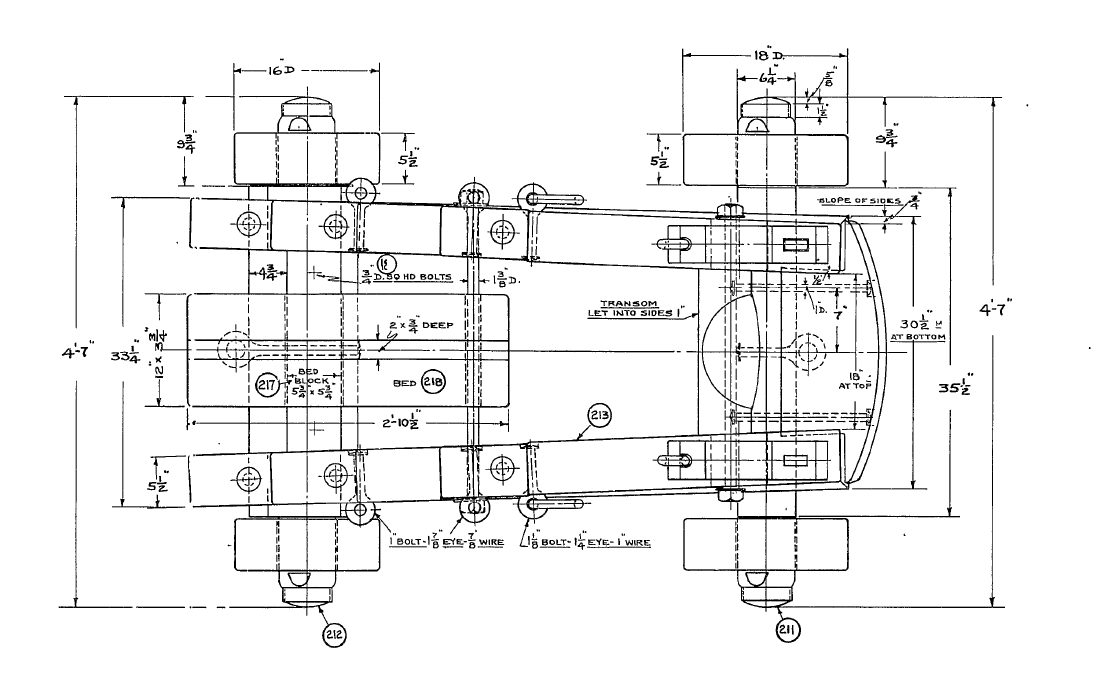

Well Alan, you made me go back and take a closer look! I drew some vertical lines on the plan and the steps for both brackets do appear to be off the centerline, but just barely. However, they do not appear to be exactly perpendicular to the brackets either. So I think Thukydides is right and further investigation is required to get a definitive answer.

-

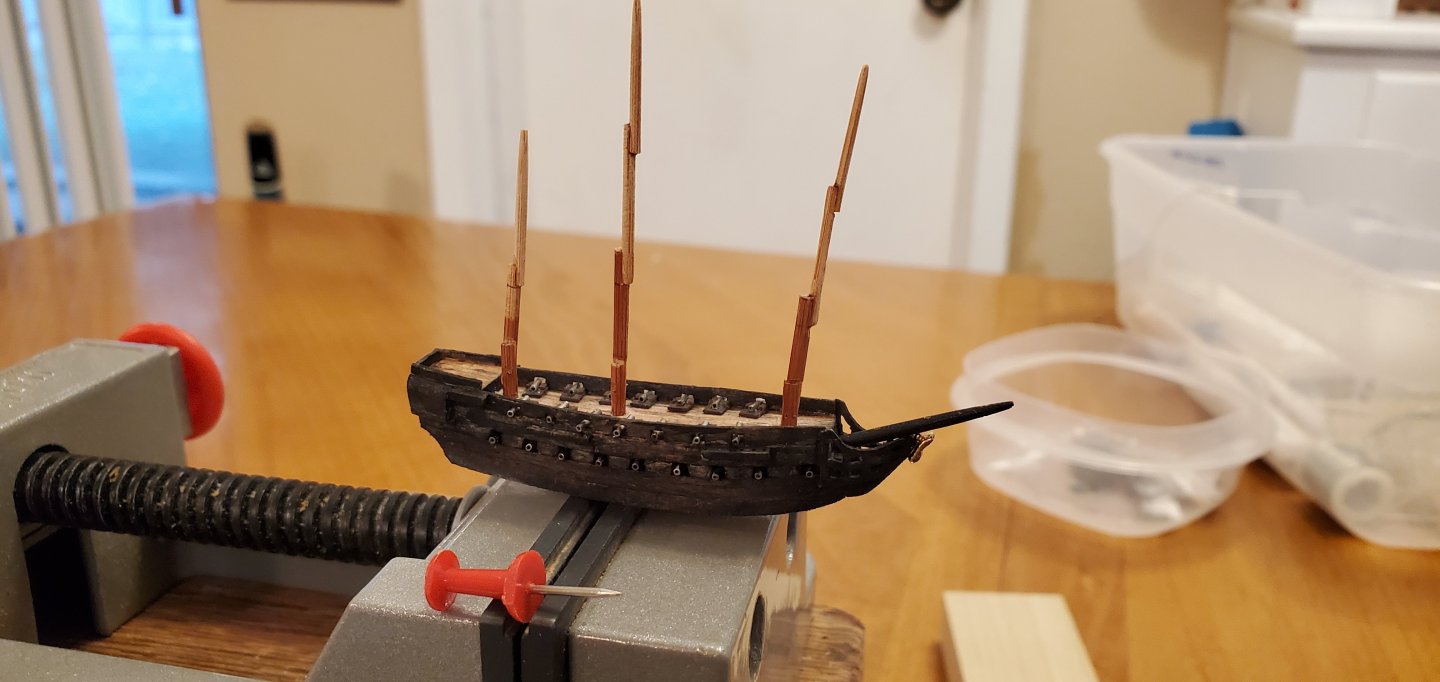

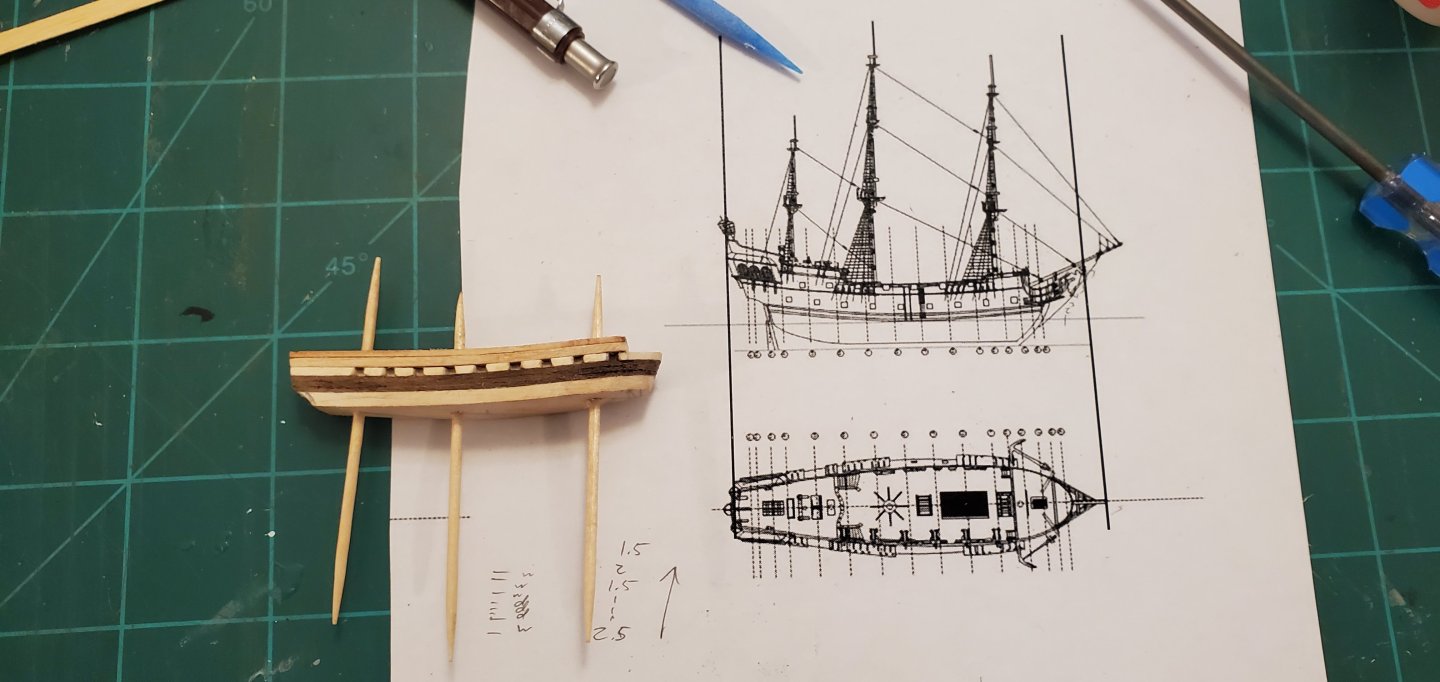

Amen to that, Gary. And such a thrill to find something in that junk box that is just what you need. Entering the home stretch on the Pearl. First the bamboo masts built and in place. Next, added the mast tops and black paint. Then added the stays (which serve as the pull threads), shrouds and backstays. Next, the ratlines. So much easier on this ship than the much larger Constitution! I cut fly tying thread into 1/4" to 3/8" pieces, drag them thru fabric glue, and lay them across the shrouds. After the fabric glue dries, I snip off the ends with cuticle trimmers. There's a few ends in the pic below that I went back and trimmed a bit closer to the shrouds. I managed to snip all the edges without cutting any of the shrouds. I've done that before and it's a real pain to try and remedy. I did get careless and cut 2 of the stays/pull threads but they were an easy replacement. Finally, I added the yards. Other than some minor details, the only thing left to add to the Pearl is the sails. The epoxy resin inside the bottle is dry now, so before I do the sails, I am going to finish up the water effects inside the bottle. I'm anxious to get going on that.

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

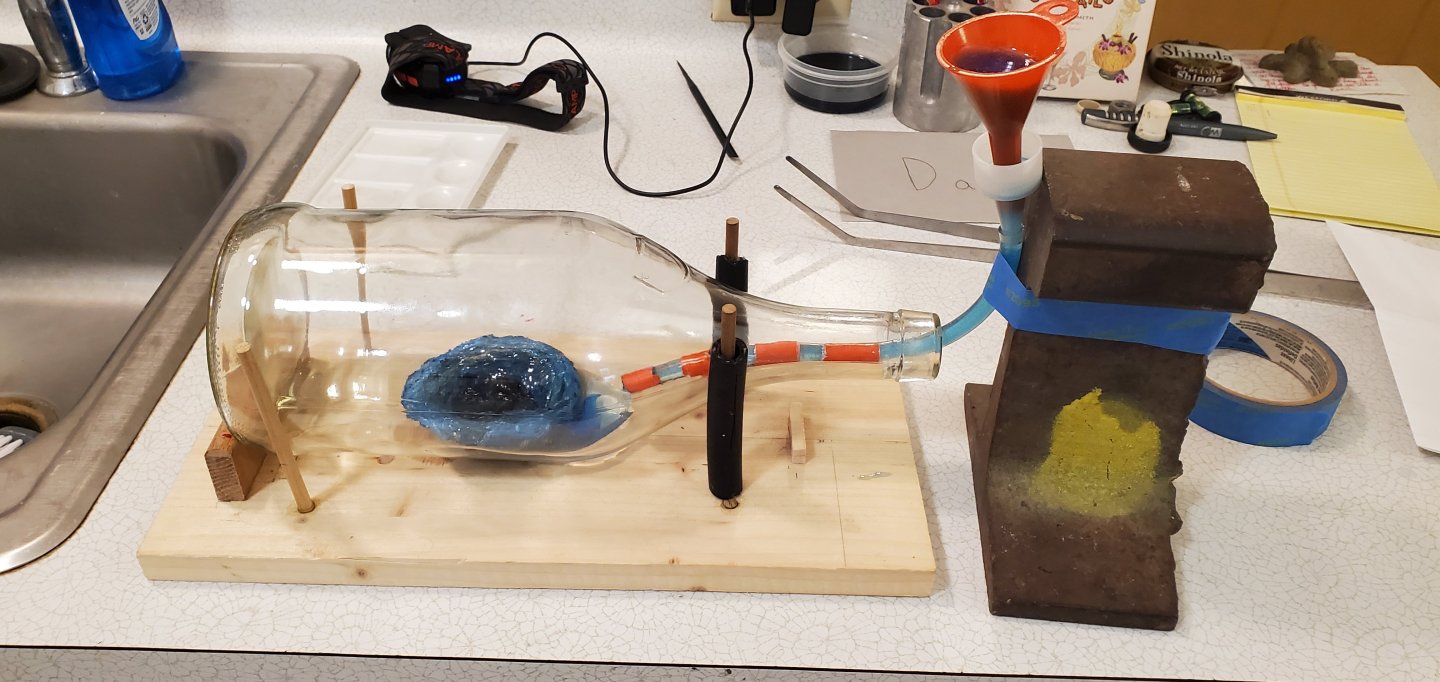

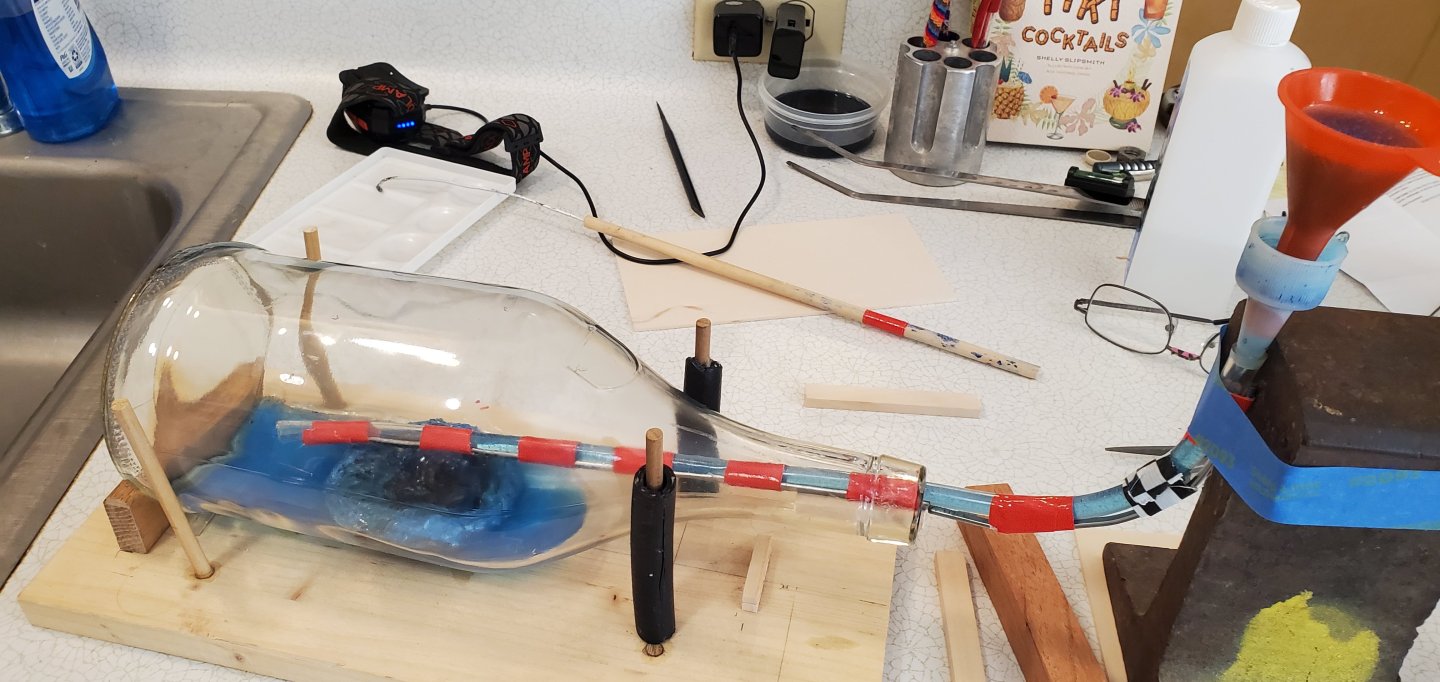

The whirlpool failed a couple more leak tests. Ugh. I started getting real impatient because it was taking a couple of days each after each test for the water inside to dry out, and that was with a fan blowing air inside the bottle constantly. So decided to try what I think @Javelin and @Knocklouder were suggesting, which was to basically coat the inside of the whirlpool with caulk rather than plugging leaks on the outside. After I did this, I decided no more leak tests. I was just gonna let er rip and see what happened. So I mixed some epoxy resin and used resin dye trying to color match it with the outer ring of the whirlpool. I think I got pretty close. Then I set up my funnel/surgical tube fixture and started easing the epoxy resin into the bottle in front of the whirlpool. Hobby Lobby did not have my normal brand of epoxy resin in stock so I tried a different one. This one (Clear Cast Epoxy Resin) mixed easily and took the dye well, but it had a much higher viscosity than my usual brand so it was super slow flowing thru tube. I had to put on my higher magnification glasses and look at the tiny air bubbles to make sure it was actually flowing. Things stared out pretty well. But then I hit a problem. I thought I could just pour the resin into the area in front of the whirlpool and have it work its way thru the side and into the back area as it self-leveled. I soon found out that was not going to work because the sides of my whirlpool were hitting the sides of the bottle with only tiny gaps for the resin to flow thru. The resin was thick to begin with, and it was taking so long for it to flow into the bottle that by the time it reached the gaps on the sides of the whirlpool hardly any would flow thru to the back. And the resin was rising in the front to the point where I figured I'd better stop before it overflowed into the whirlpool itself. So I stopped the flow and pulled the tube out. But not before I knocked the funnel over while it still had resin in it and spilled a bunch all over the counter top and floor. Bob mentioned in his Duchess post that we say DANG here in Texas. I can promise him that I said a whole lot more than DANG when that happened. Nevertheless, I got things cleaned up and set up another fixture with a longer tube to reach the back. This worked out pretty well. The only problem came as the resin neared the top of the whirlpool's edge. I ended up having to stop pouring resin with the level about 1/8" below the top edge of the whirlpool because I was limited with the angle I could set the tube at to keep the resin flowing. It took about 5 hours total to get as much resin as I could on both sides of the whirlpool. I will build the resin up from there to level with the whirlpool's edge with acrylic gel or Woodland Scenics water effects and give it some texture. All in all, I'm pretty pleased with the result and very relieved that I got past that major hurdle. In between leak tests, I did get some additional work done on the Pearl. I painted and installed the beakhead railings. Then I spent some time trying to come up with something for the figurehead. I'd never put one on any of my SIB ships before but the Pearl has such a prominent one that I wanted to try something. No way I could carve anything that small, but going thru my box of junk I found a gold clasp that had a shape close to the curve of my Pearl's knee. So I cut it off, did a bit of filing and attached it. Up close, it just looks like junk, but at a distance, it does have the rough shape of the Pearl's figurehead. And with SIB's, often times it's about giving the impression rather than the reality.

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Do you have fabric glue available? I use Aleene's Fabric Fusion to glue on the bolt ropes for some of my small SIB sails. It has a good bond but dries flexible so it can survive me wadding up the sails tightly when I insert the ship into the bottle.

- 286 replies

-

I reckon nobody will ever notice that upside down deadeye but you. Your Duchess is coming along quite nicely. Tip of the hat to PFCGP and Goober for keeping you in the shipyard while the snow piles up outside!

- 207 replies

-

- vanguard models

- Duchess of Kingston

-

(and 1 more)

Tagged with:

-

That is a possibility. I think it would present another challenge with cutting the lines as Pat mentioned, but at least I would not be reaching around the length of the ship to do it.

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

It does make sense, Pat and is an interesting idea. I agree with you that the hardest part would be cutting the pull thread off the bowsprit. The bottle I'm using has a very long neck and with the ship pointed towards the back would be a really long reach. Plus, it would be at a difficult angle. Cutting the threads inside the bottle is always one of the most nerve wracking things for me as I'm always afraid my razor will slip and cut other lines which would be disastrous. You may have just convinced me that I will have to raise the masts and cut the lines with the bowsprits close to the bottle's neck and then push the ships into position afterwards.

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

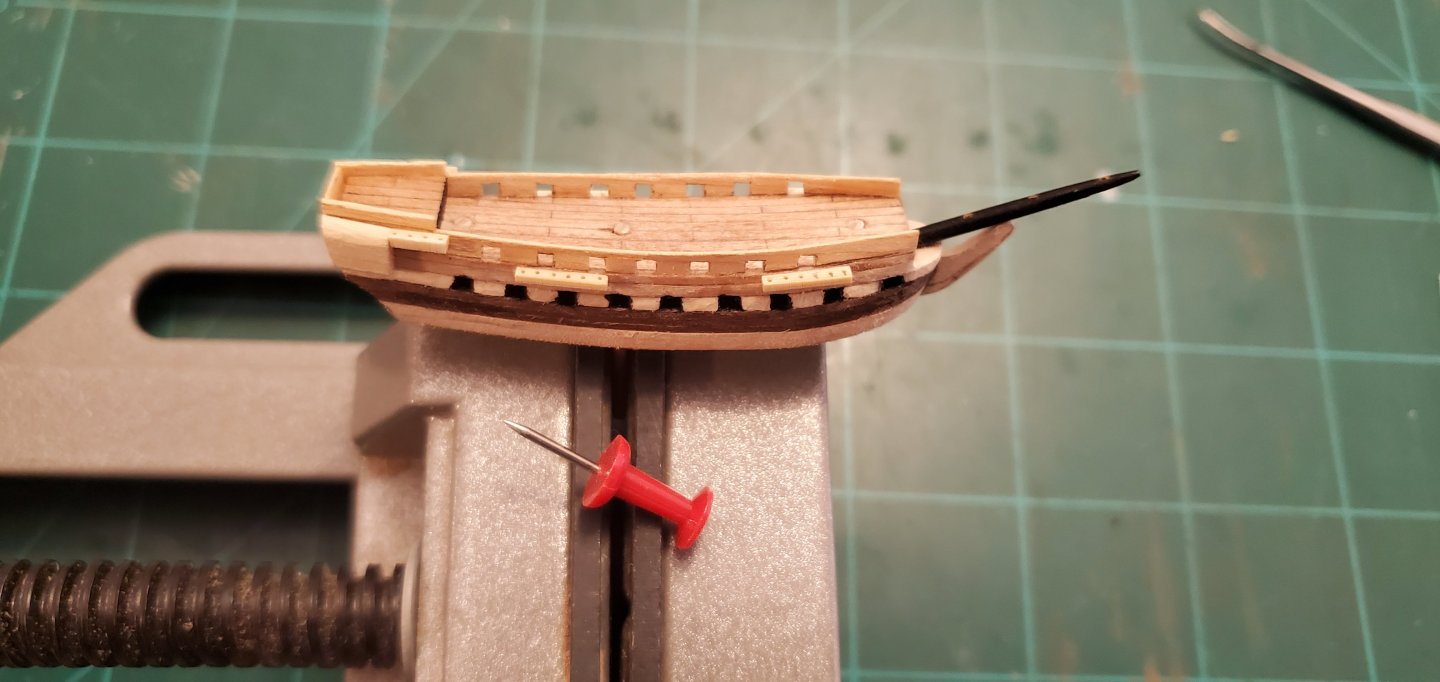

Still patching whirlpool leaks, but in between, work continues on the Black Pearl. First up were the 14 cannons for the spar deck. The barrels are 20 gauge vet needles. The carriages are made from .5mm planking strips. Next was carving the beakhead rails that extend from each side of the bow to the top of the keel. I have a hard time carving sharp angles that are so small. I use a scalpel with a fine pointed blade but it's still to big for some of the tight spaces. Next, I carved and added the knee, channels, poop deck, and quarter galleries. Finally, I gave it a paint job. Following @Old Collingwood tip, I wanted the to have something that resembled the storyline from the movie where the Pearl was set on fire and sent down to the bottom of the sea with Captain Jack Sparrow aboard. Sparrow sold his soul to Davy Jones and was allowed to raise the ship and continue his command. So the ship needed a dark look of charred wood. At the same time, I wanted to make sure there was enough color contrast between the Pearl and the dark gray Dutchman. So I made a black wash with liberal amounts of thinner (Tamiya black and acrylic thinner medium) and brushed it lightly over the hull making sure that a hint of the underlying wood color showed through. I left the deck a lighter color with some random streaks of ash color.

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Proof that I have not given that subject the proper amount of thought yet. I did not really pay attention that they were sailing in opposite directions until you brought it up! So I will probably need to raise the masts first then position the ships, at least for the one sailing away from the bottle's neck. Hmmmm. Much to consider. But not just yet! That's funny about finding your piece of railroad track. At least you were smart enough not to throw it away!!

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Thanks, Roel. The way the whirlpool turned out is that there are horizontal fissures or crevasses between each layer on the outside. So that would probably make brushing anything on the outside futile. So I decided to put blobs of the clear caulk onto my prong and push it into the fissure where the big hole was, which was between the first 2 layers. I could not find any other obvious holes but I went and did the same thing for every spot that looked even a bit thin or weak. Bob had the same idea about brushing glue or something on the surface. The inside of the whirlpool is more of a uniform surface than the outside so the brushing technique might work there. I may give that a try. As far as the ships, I plan to orient them at an angle similar to the screenshot picture from the movie that I put in a previous post. That way, when viewing from the side, you will have a good look at both the ships. Here's the idea: The challenge will be how to raise the masts once each ship is inside the bottle. Do I glue the ship in place and then try and raise the masts at something near a 45 degree angle? Or do I try to raise the masts without the ships locked down (difficult) and then move them to their final position? I haven't thought that one through yet. I gotta get past a few more hurdles before I'm ready to focus on that. I don't think I've seen your piece of railroad track in any of your build logs yet! Hopefully soon!!

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

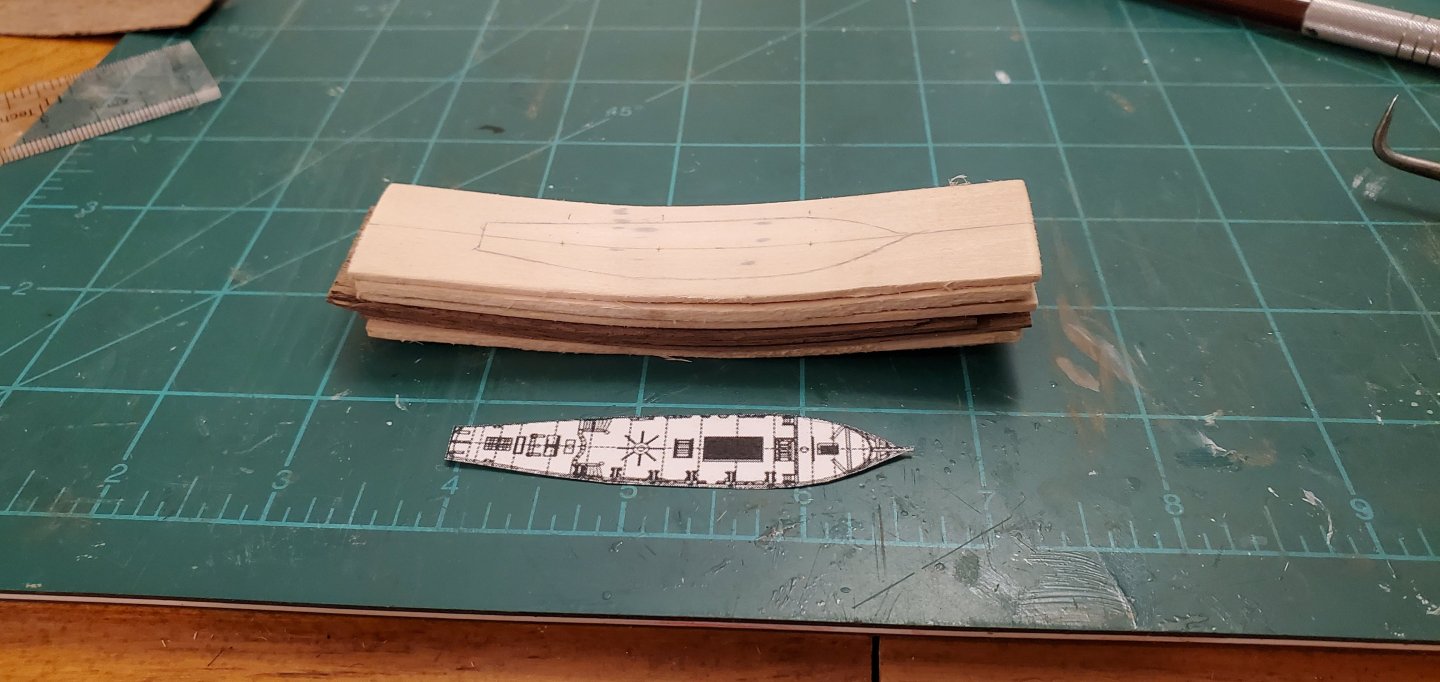

Thanks, Ken. No way I'm giving up on this one. It's gonna work one way or another! In the meantime, I began work on the Black Pearl. I'm building it similar to the Flying Dutchman with a layered hull, using my favorite technique for plank bending. @Keith Black - I know on your Lula build you said creating the upward sweep of the deck was a challenge. I highly recommend pieces of railroad track for the task! 😃

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

-

Breaking news - the leak test failed spectacularly. My whirlpool had more holes in it than the S.S. Minnow after its 3-hour tour. I just patched up everything I could see and more. I'll give the caulk a day to set and give her another try.

- 185 replies

-

- Flying Dutchman

- Black pearl

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.