-

Posts

3,170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

You may have already realized this, but the only points you have to cut are the 'tabs'. These keep the laser cut parts from falling out of the sheet during cutting. It's standard practice for laser cut parts. I've found they can usually be cut with a hobby knife, but going from both sides makes it easier.

-

Wipe On Poly Techniques

Gregory replied to Freebird's topic in Painting, finishing and weathering products and techniques

Wipe on Poly works best for me by brushing then wiping with soft cloth after a few minutes. I may make any number of coats till I get the finnish I want . FWIW, Wipe on Poly is just Poly varnish that has been thinned with mineral spirits. Maybe 75/25 varnish/thinner. I make my own, about 50/50. -

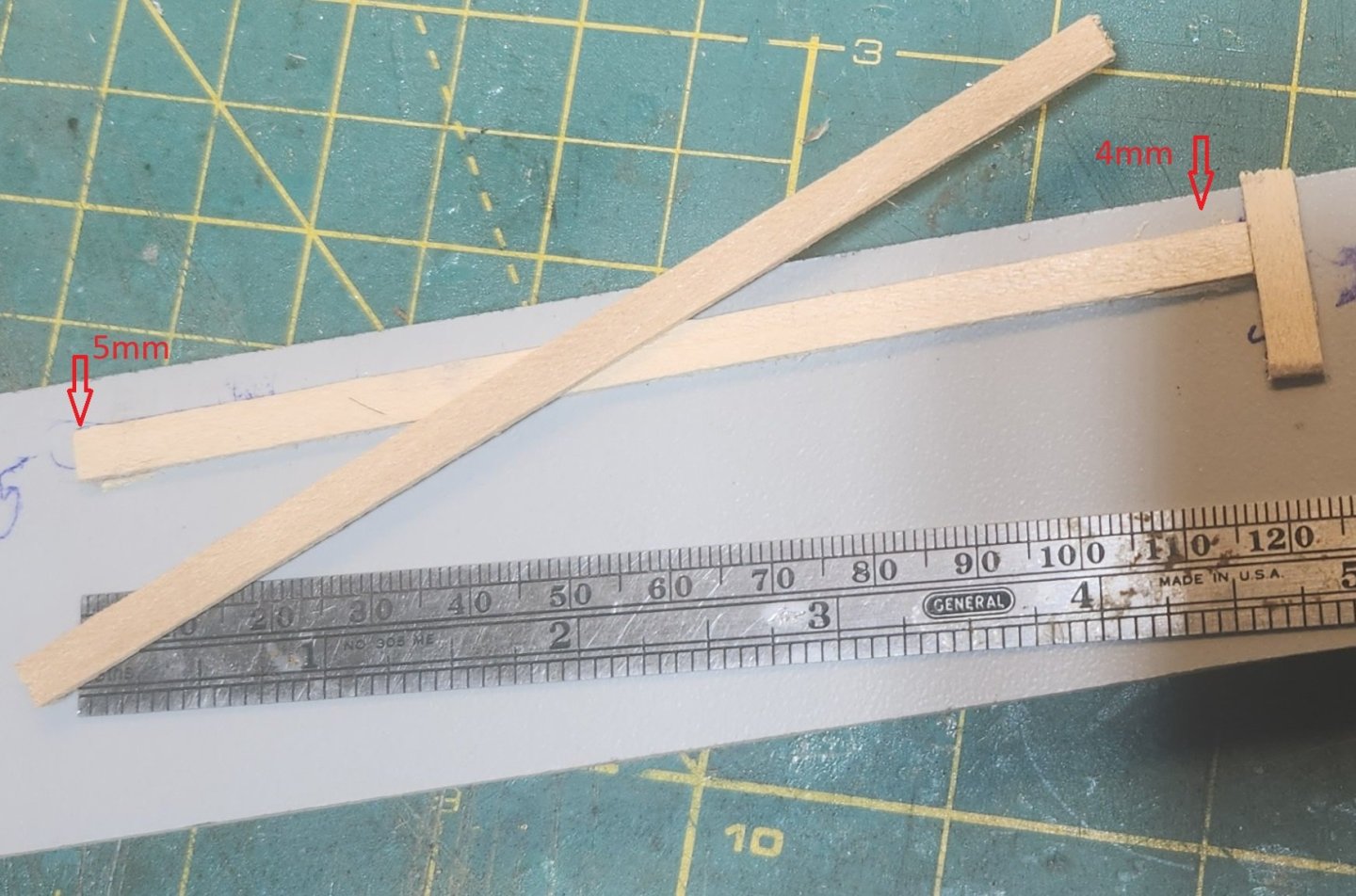

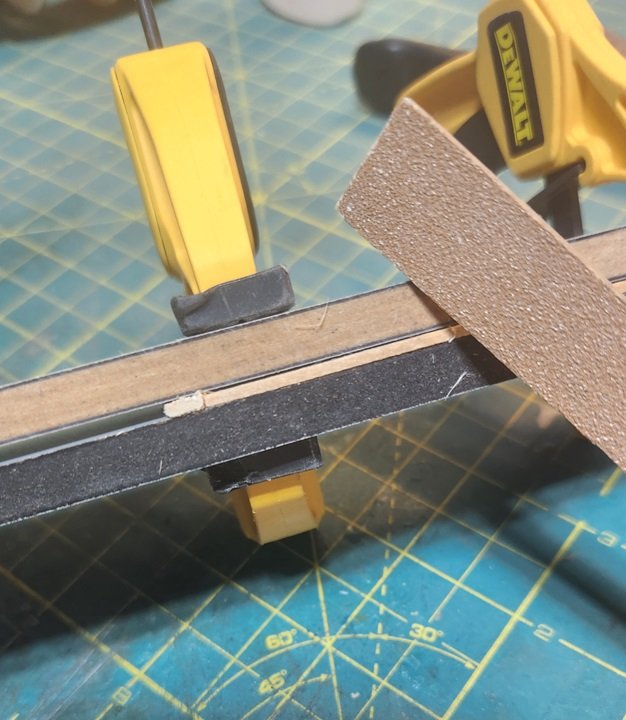

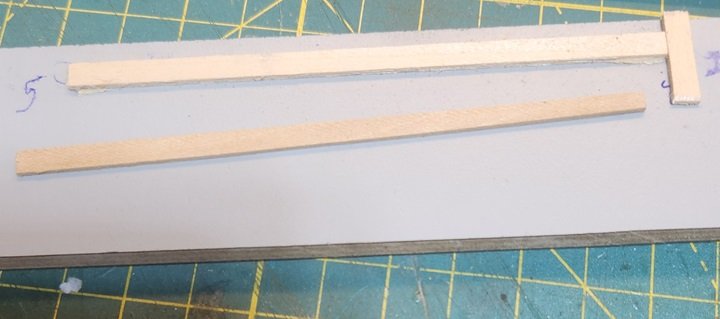

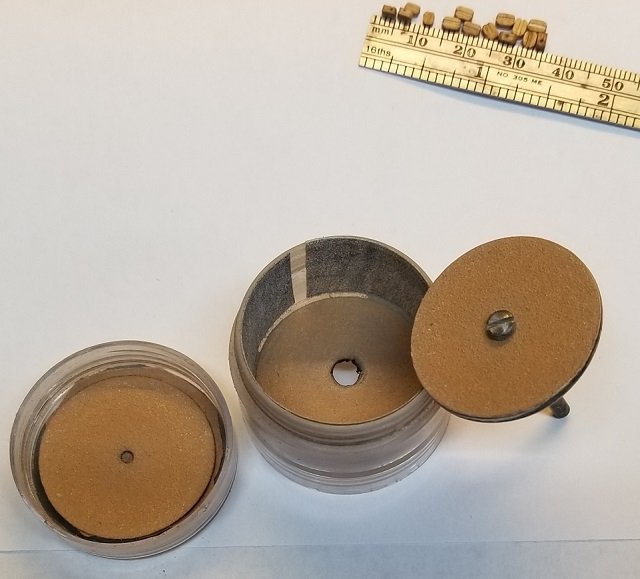

This is something I put together quickly to demonstrate, so it could be refined somewhat. I have this real hard melame/mdf stuff, but I'm thinking aluminum might be better. I glued ( just tacked at each end with CA, so it could be easily removed later ) a strip the same thickness and length as my target, to the MDF. The little vertical piece acts as a stopper. Note one end is 5mm from the edge of the MDF. The other end is 4mm. At this point you could probably just lay your strip to be tapered against the template above and trim with Xacto blade or scalpel and follow with a little sanding . I took another option and clamped the smaller piece of MDF onto the template and trimmed from there. The target still has a tendency to move around, so you have to make sure it stays flat against the jig. Make sure the business side of the two MDF pieces are flush. I also thought I might screw the jig together for a tighter fit. After the blade, I did a little sanding. 4mm On one end. 5 On the other. Let me know if I can explain any better.

-

We have a forum where members have discussed their CAD, 3D printing and similar endeavors. CAD and 3D Modelling/Drafting Plans with Software - Model Ship World™ There are a lot of resources out there for getting custom work done. Just Google " 3d printing services " and " photo etching services " . There are probably other online groups dedicated to those endeavors also. It may not be too late. Check out Fusion 360 .. It's free for hobbyist. This guy has some really great tutorials for beginners. Product Design Online If you use a 3rd party 3D printing service you can probably save a lot by having 3D drawings ready to go. For photo etching, 2D should be all you need.

-

Working with blackend brass.

Gregory replied to SiriusVoyager's topic in Metal Work, Soldering and Metal Fittings

What is your method for annealing the brass? If you are heating it with a torch, you might consider treating it with Birchwood Casey Plum Brown. It gives a nice dark finish that doesn't come off easily. -

Good point. This can be distracting on an otherwise excellent model when the knots scale to something about tennis ball size or bigger. Ratlines on Victory. Lees says ratlines are 1.75" circumference. About .5" diameter. This scales to .01" at 1:48. At 1:64 its close to .008" The smallest rope at Ropes of Scale is .009, so this would be a good match at 1:48. Syren has .008 and .012. At smaller scales you are looking at single strand thread to get a reasonable scale match. This is a good option. One might also consider just glueing the ratline to the shroud. A little blob of glue will look like a knot.

-

Help with tapering

Gregory replied to N1ckel's topic in Building, Framing, Planking and plating a ships hull and deck

I believe the 1/2 rule has a basis in actual practice. However, if you follow the procedures we have discussed, it probably will never be an issue. -

Help with tapering

Gregory replied to N1ckel's topic in Building, Framing, Planking and plating a ships hull and deck

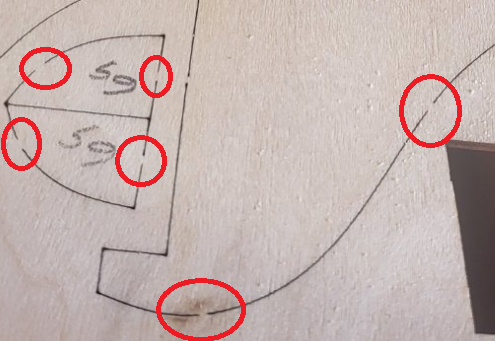

Good answers from Johnny and Dziadeczek. Just to clarify, here is a contemporary ' expansion drawing. This is Podargus (1808) This shows the actual shape of the planks laid out flat. This illustrates why Chuck's bending method results in the planks laying flat against the bulkheads -

Help with tapering

Gregory replied to N1ckel's topic in Building, Framing, Planking and plating a ships hull and deck

Measure the green line with a piece of string.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.